Unstable stratum variable-diameter casing pipe hole-protecting drilling process

A variable and stable technology, applied in directional drilling, drill bits, drilling equipment, etc., can solve problems such as hole collapse, economic loss, hole collapse, diameter shrinkage, etc., achieve good hole formation, strong stability, and avoid sticking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

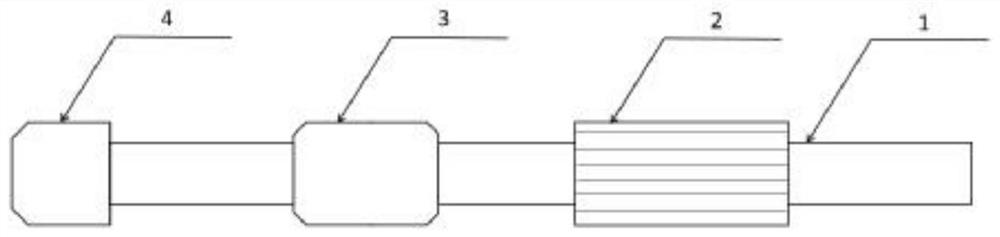

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure, the drilling process of the variable-diameter casing protection hole in the unstable formation in this embodiment includes the following steps:

[0018] S1. Select the drilling point, set up the drilling equipment, first install the drilling tower, assemble the drilling rig bracket, stand the drilling rig on the bracket, install the air compressor, mud pump, mixer, generator, drilling tools, etc.;

[0019] S2. Open-hole drilling. When drilling into unstable formations, hole collapse, diameter shrinkage, and drill sticking occur, replace the drill bit, and use variable-diameter drilling tool assemblies to continue drilling operations and cooperate with variable-diameter sleeves. Pipe 2 protects the hole. While drilling, the mud pump pumps the flushing fluid to flush the rock and soil generated during drilling to form mud and discharge it;

[0020] S3. The variable-diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com