Dry sandy gravel stratum cast-in-place pile construction method

A construction method and technology of sand and pebbles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as reducing pile side friction, affecting pile end bearing capacity, and reducing concrete workability, so as to improve pile foundation The effect of bearing capacity, improving construction quality and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

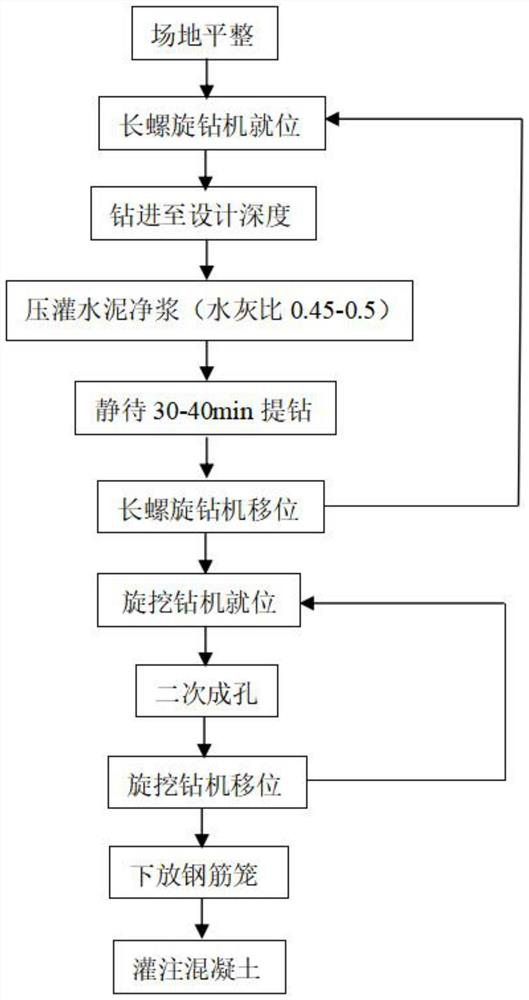

[0022] The present embodiment provides a specific embodiment of the construction method of a dry sand and pebble stratum cast-in-place pile, such as figure 1 shown, including the following steps:

[0023] site level;

[0024] Use a long auger drill to pre-form holes and press-fill cement slurry;

[0025] A rotary drilling rig is used to form holes for the second time, and the steel cage is lowered and concrete is poured.

[0026] Further, a long auger drilling machine is used to preform holes, which need to be drilled to the design depth.

[0027] Further, the water-cement ratio of the cement paste is 0.45-0.5.

[0028] Further, after pressing the cement paste, wait for 30-40 minutes, so that the cement paste can be effectively combined with the dry sand and pebbles of the hole wall to form a protective wall.

[0029] Further, after waiting for 30-40 minutes, the long auger drill is lifted and reset.

[0030] Further, the depth of the secondary hole forming is the design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com