Patents

Literature

38results about How to "Solve the problem of collapsed holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

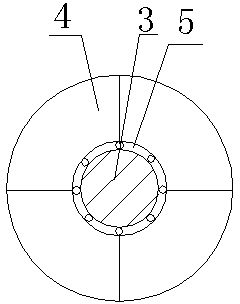

Drilling-fixing integrated device and method for yolk coal terrane

InactiveCN102199991AHigh porositySolve the problem of collapsed holesDrill bitsDrilling rodsRound tableEngineering

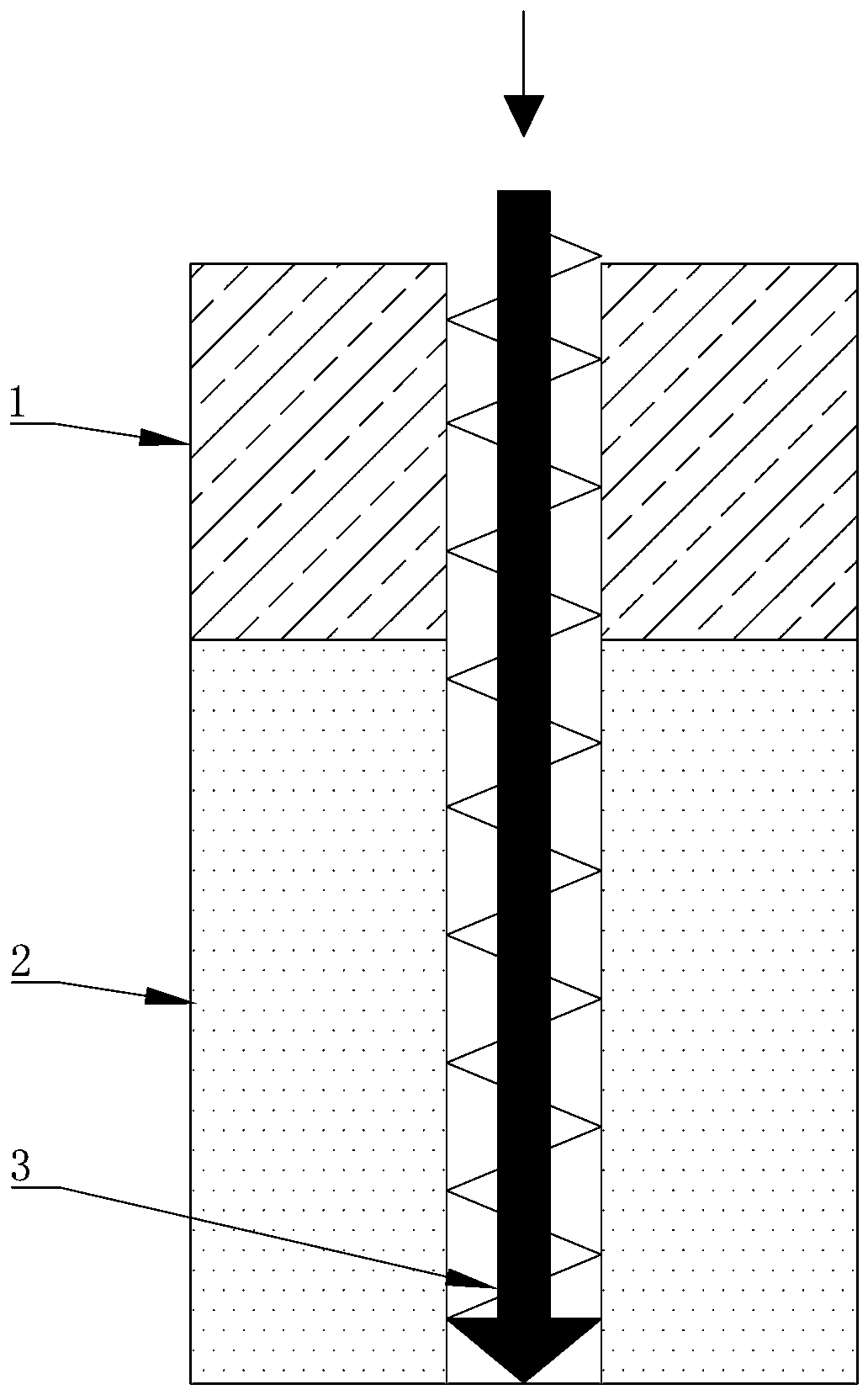

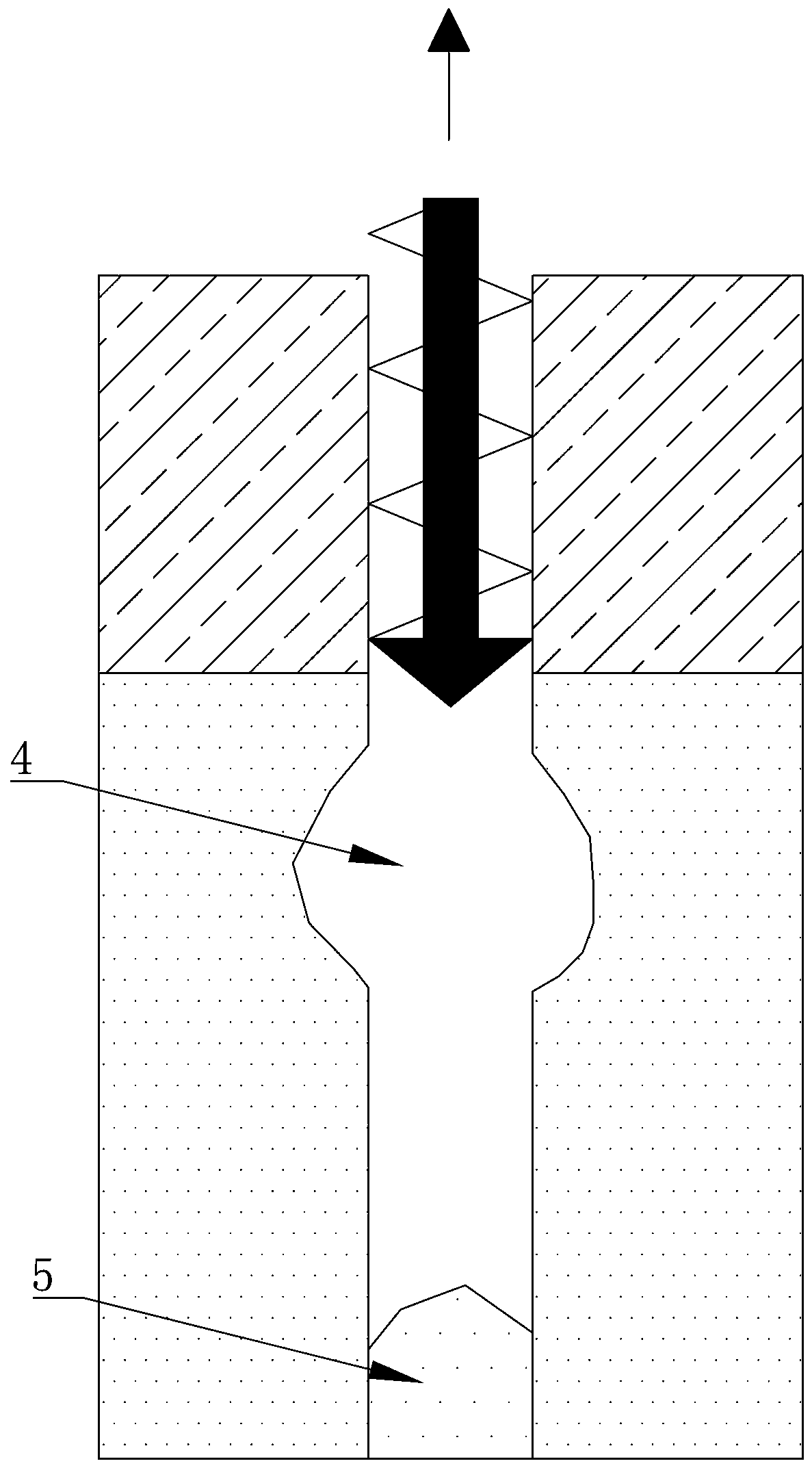

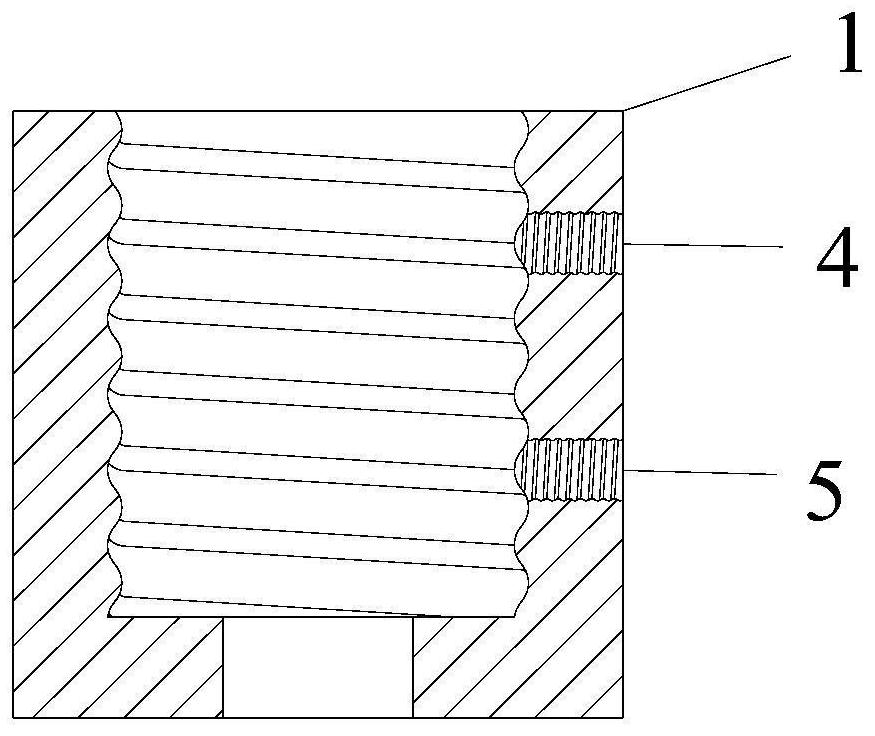

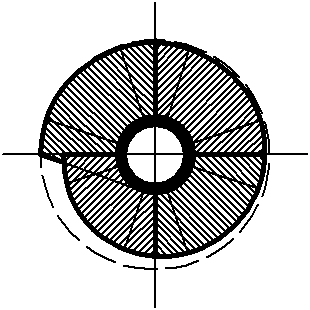

The invention discloses a drilling-fixing integrated device for a yolk coal terrane. The drilling-fixing integrated device for the yolk coal terrane comprises a drilling rod, wherein the drilling rod is in transmission connection with an outer power mechanism; the device also comprises an extruding helicoid with a round-table-shaped outline, one end with a bigger diameter of the extruding helicoid is a back end and is fixedly connected to the front end of the drilling rod, one end with a smaller diameter of the extruding helicoid is a front end and is provided with a drill bit and the diameter of the drill bit is the same as the diameter of the front end of the extruding helicoid. The diameter of the front end of the extruding helicoid is small and the diameter of the back end of the sameis big, so that the coal on the periphery of the drilled hole can be extruded in the drilling process, the problem of collapse because the coal layer is very soft is solved, the hole-forming rate of the drilled hole is improved and the developing cost is reduced; and therefore, the device provided by the invention provides important guarantees to follow-up gas extraction and coal layer gas development. The invention also provides a hole drilling method using the drilling-fixing integrated device for the yolk coal terrane; the hole drilling method can realize hole drilling, extrusion and hole expansion, diameter expansion and support of the drilled hole in the process of primarily drilling, thereby extremely improving the hole-forming rate of the drilled hole of the yolk coal terrane.

Owner:HENAN POLYTECHNIC UNIV

Method for removing pile foundation intruding in shield tunnel range and controlling parameters

PendingCN110735432ASolve the problem of displacementLow costUnderground chambersTunnel liningRebarEarth surface

The invention provides a method for removing a pile foundation intruding in a shield tunnel range and controlling parameters. The construction method comprises the following specific steps that firstly, an inclinometer is embedded into a central lead hole of the pile intruding in the range, plain concrete positioning piles are constructed around the pile intruding in the range, after the positioning piles are constructed to have the height reaching 1 / 3-1 / 2 of the height of the pile intruding in the range, backfilling is conducted, and jet grouting piles are constructed on the areas of the upper portions of the positioning piles; secondly, ground installation of a protection sleeve on the top of the pile intruding in the range is conducted, and then the pile intruding in the range can be removed by using a pile jetting method. After a pile body is removed, an impact hole is backfilled with concrete to form a displacement pile, and when shield excavation is conducted to pass through theplain concrete pile, targeted regulation of the specific excavation parameters is conducted; according to the ground surface settlement monitoring situation, WSS is adopted to track grouting, fillingof an underground sunken soil mass is conducted in time, and it is ensured that the ground is stable. The method has the advantages of being good in construction effect and convenient to implement, the pile foundation intruding in the tunnel range is effectively helped to be removed by jetting, and the risk that in the shield construction process, a cutter disc is wound and tightened by steel barsis avoided.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

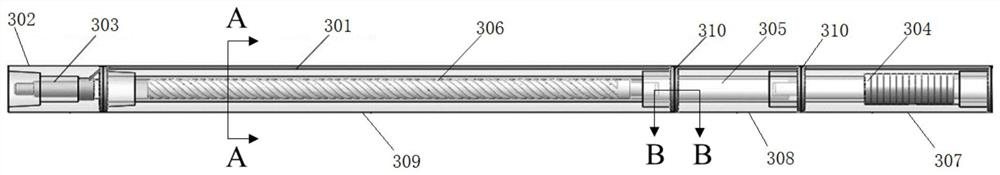

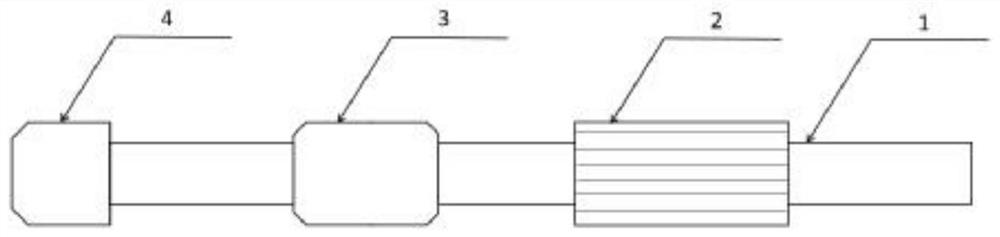

Broken soft thin coal seam gas extraction directional long drilling construction drilling tool assembly and method

The invention discloses a broken soft thin coal seam gas extraction directional long drill hole construction drilling tool assembly and method. The broken soft thin coal seam gas extraction directional long drill hole construction drilling tool assembly comprises a directional drill bit, a front measuring short section, a non-magnetic wire passing screw drill tool, a rear measuring short section and a central cable passing drill rod which are connected in sequence. The front measuring short section is used for measuring a drill hole inclination angle, a tool face angle and stratum natural gamma radioactive intensity at a near-bit position; the non-magnetic wire-passing screw drilling tool is used for providing rock crushing power for the directional drill bit and transmitting measurement data of the front measurement short section to the rear measurement short section through the non-magnetic wire-passing screw drilling tool side wall communication assembly; the rear measurement short section is used for receiving measurement data of the front measurement short section and measuring a drilling azimuth angle; and the central through cable drill rod is used for uploading hole bottom measurement data. According to the technical scheme, the hole forming depth and the hole forming rate of the broken soft thin coal seam gas extraction drill hole can be effectively improved, the gas treatment period is shortened, and the gas treatment cost is reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

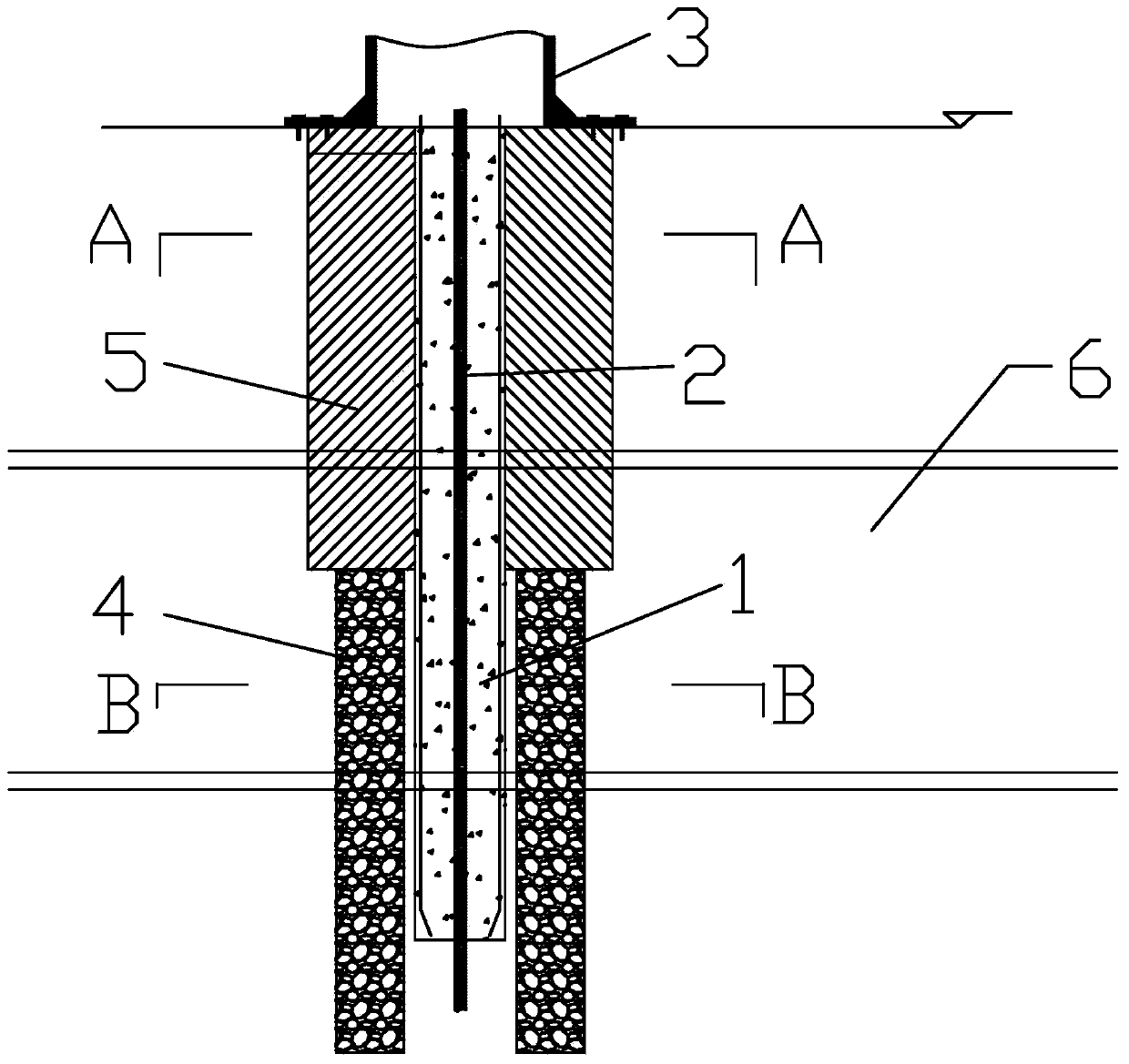

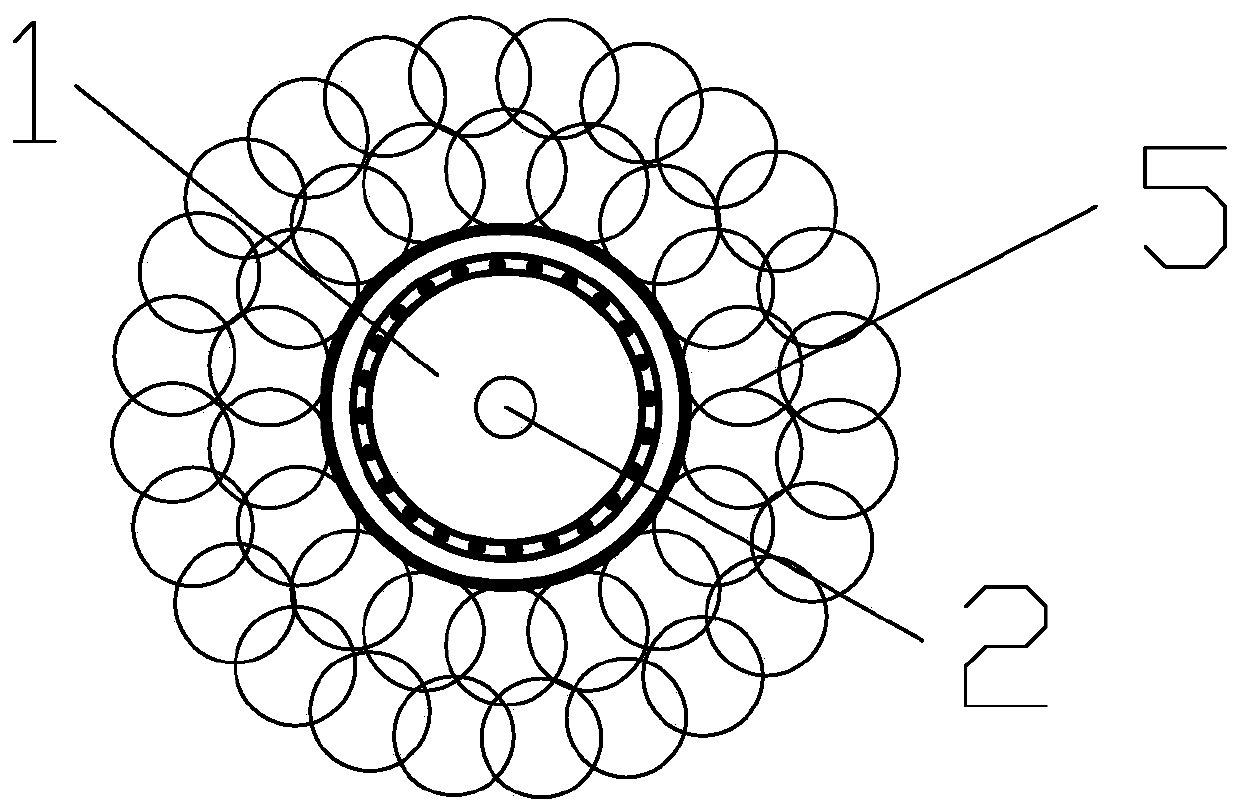

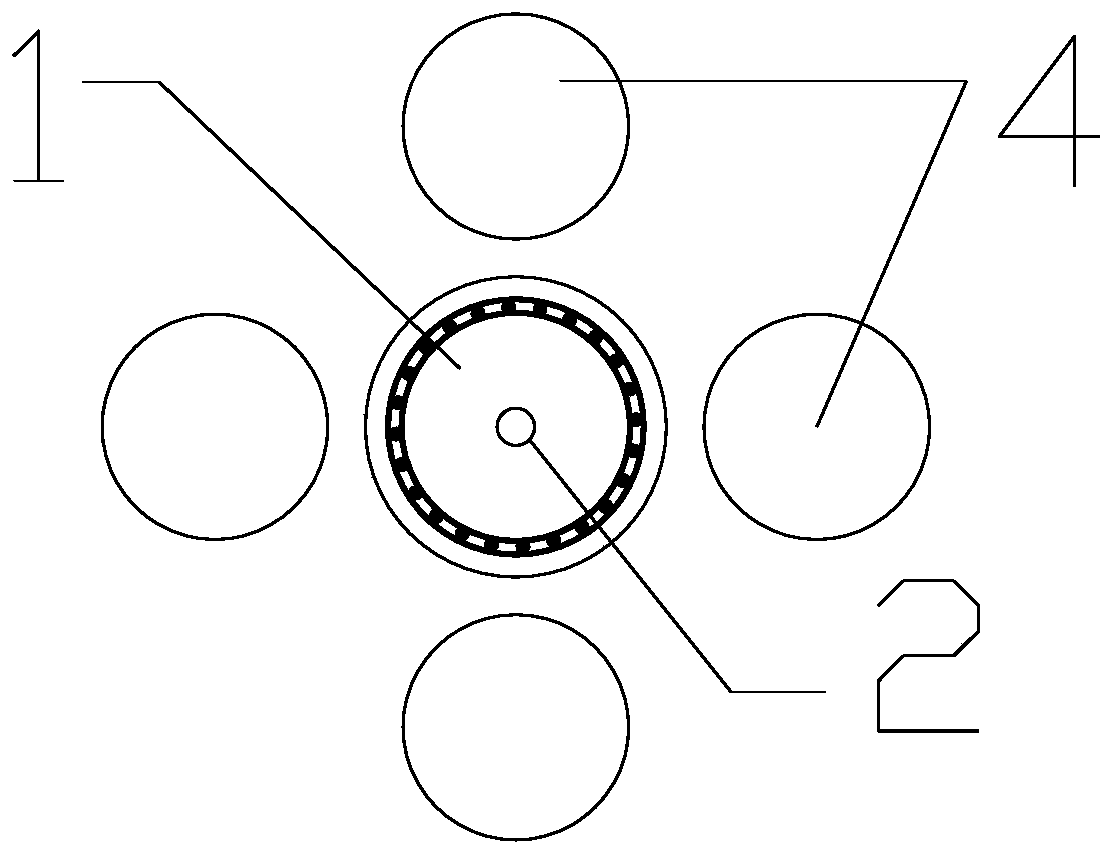

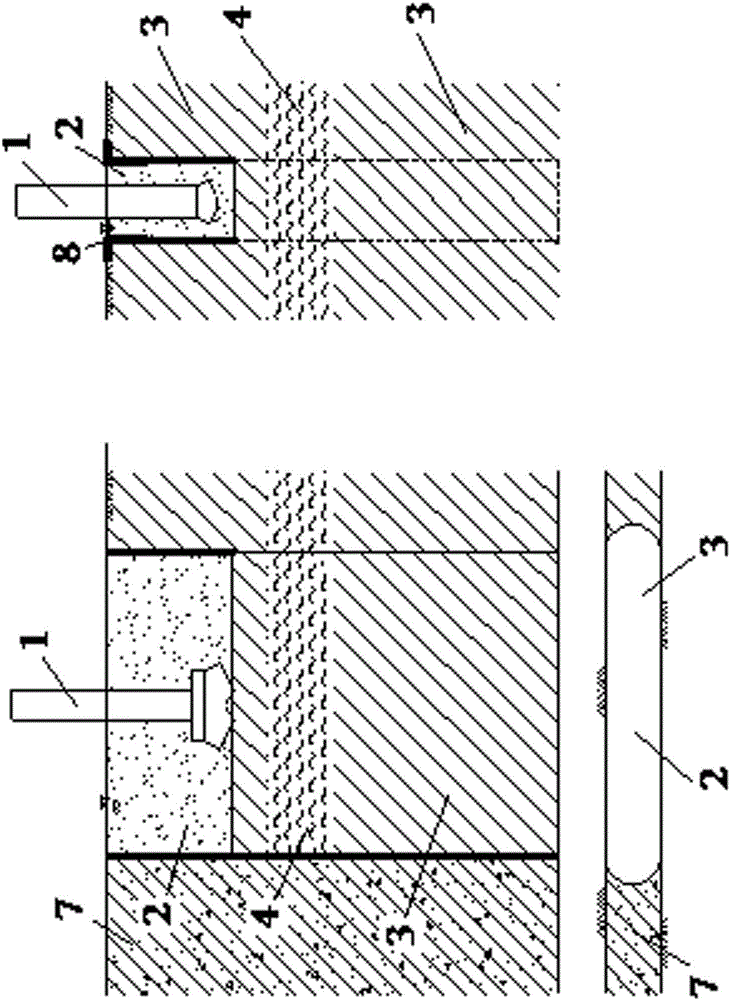

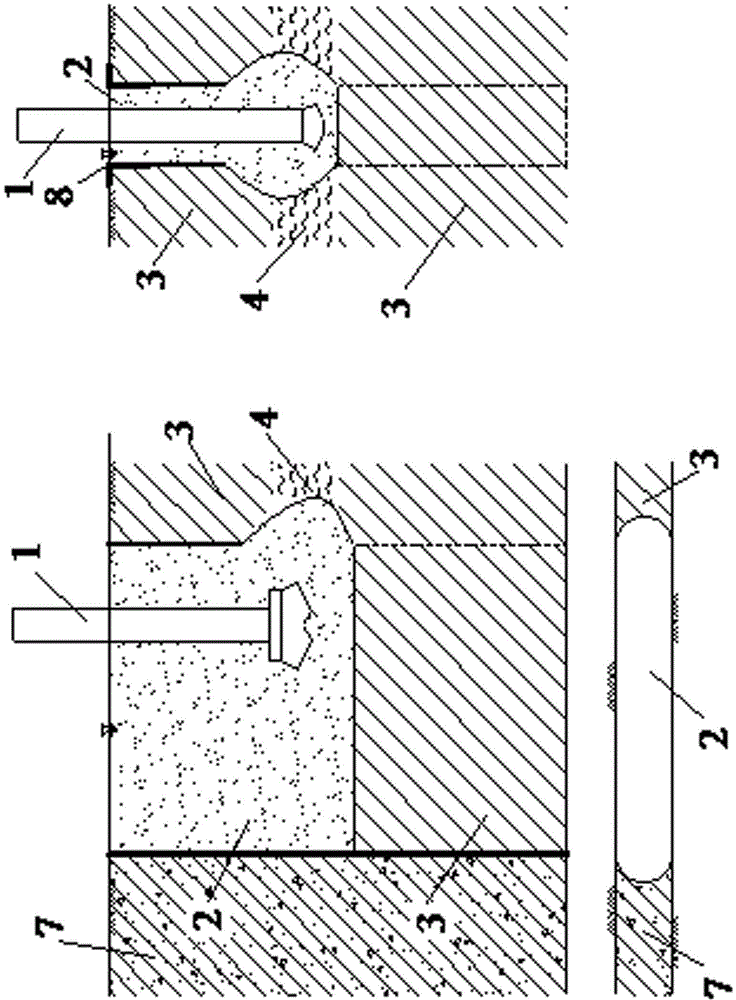

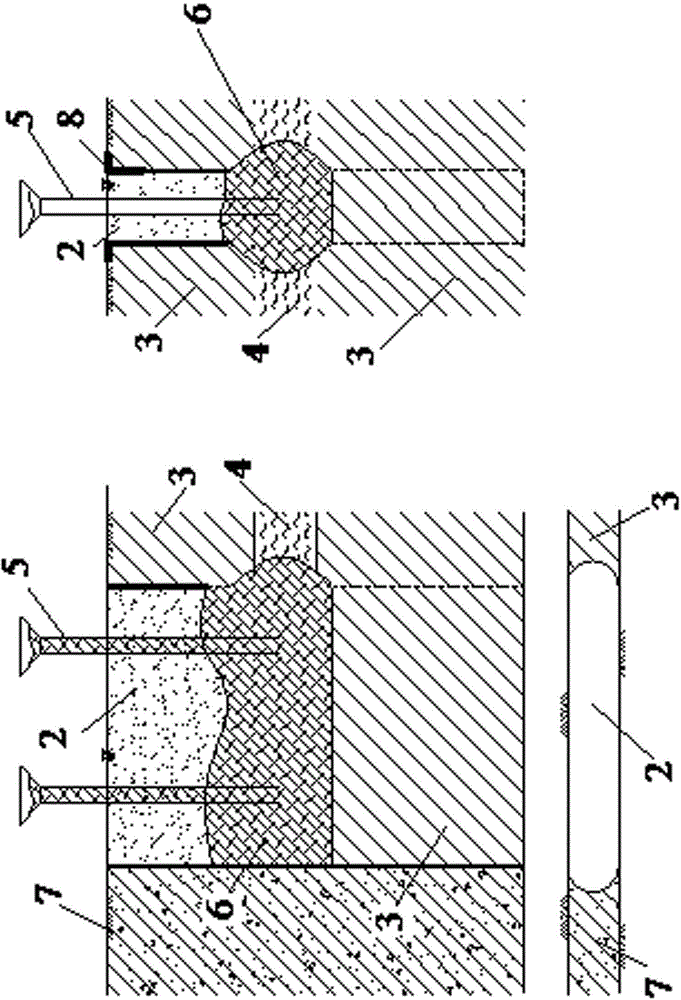

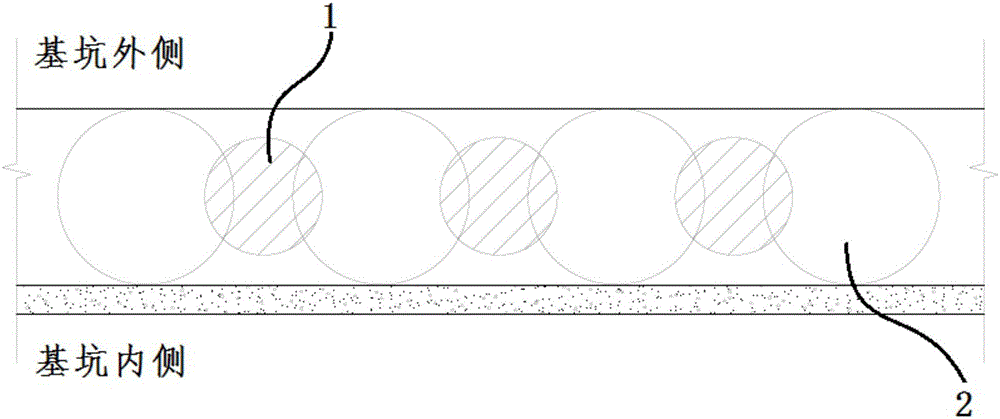

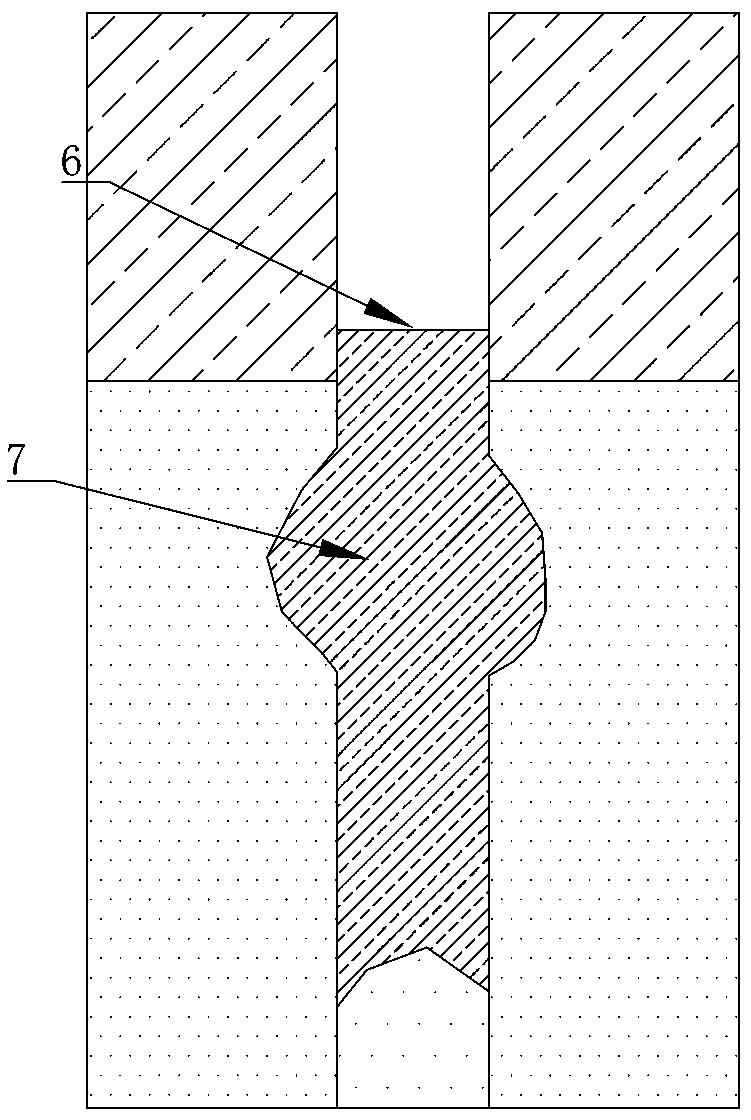

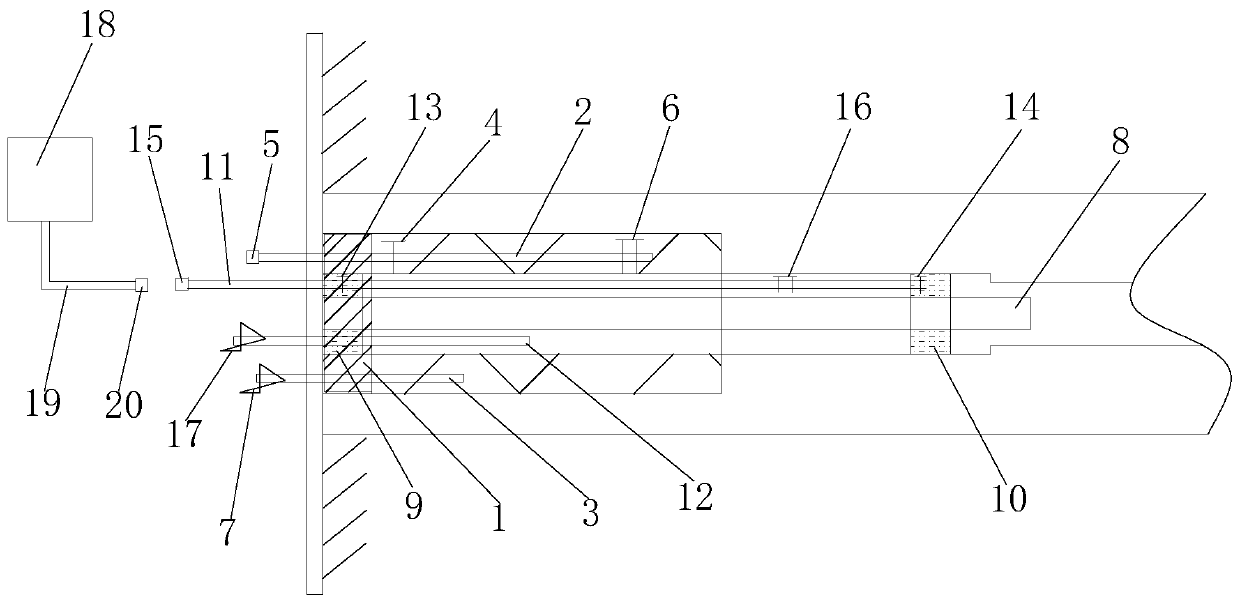

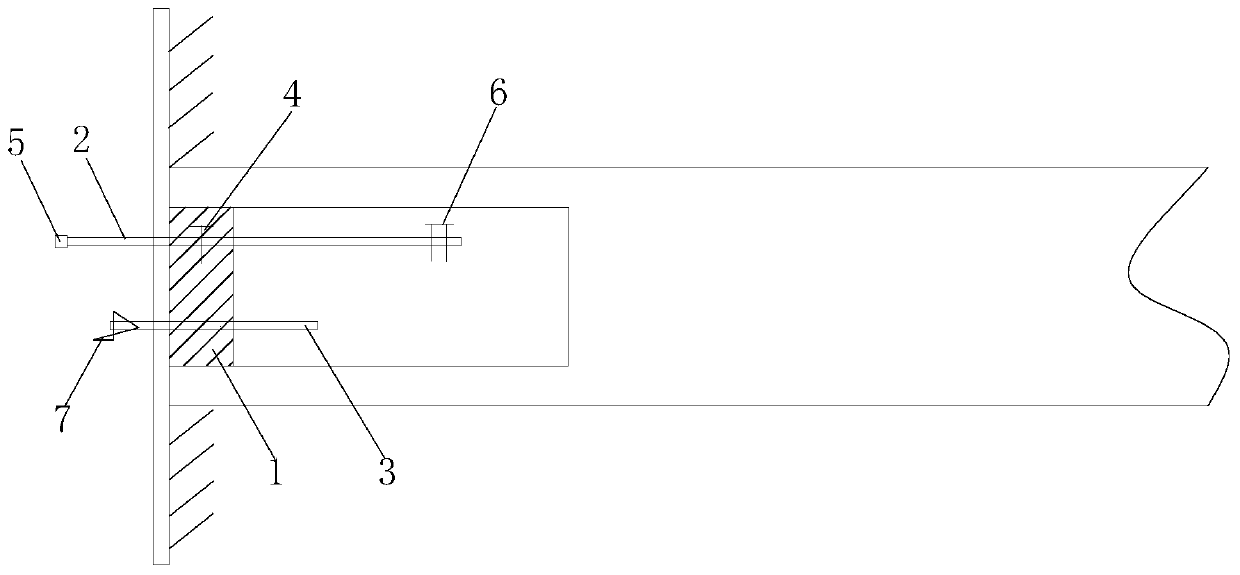

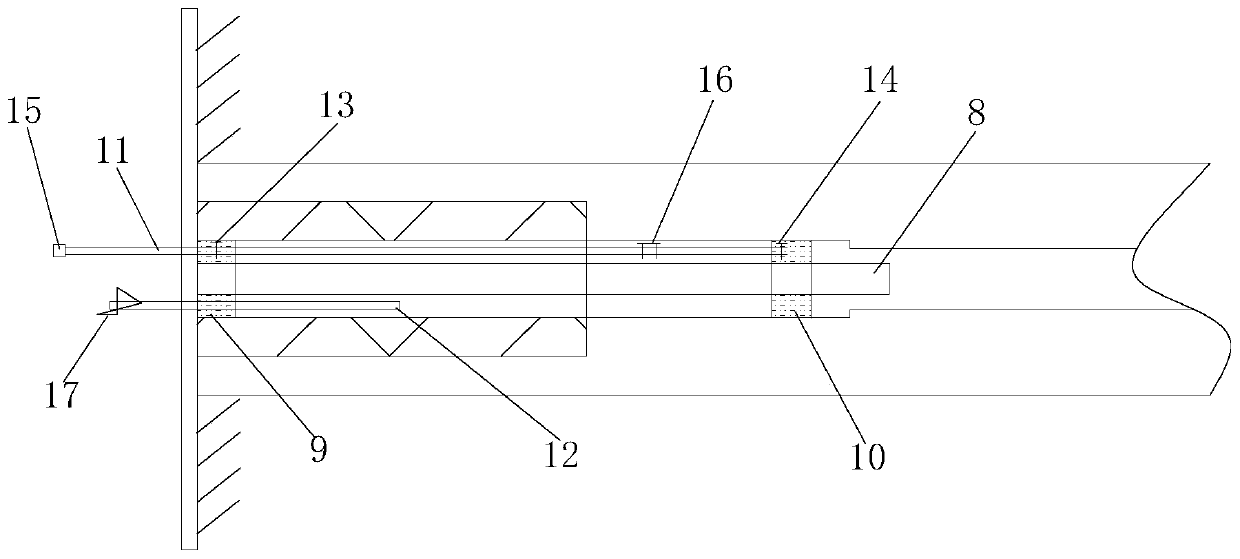

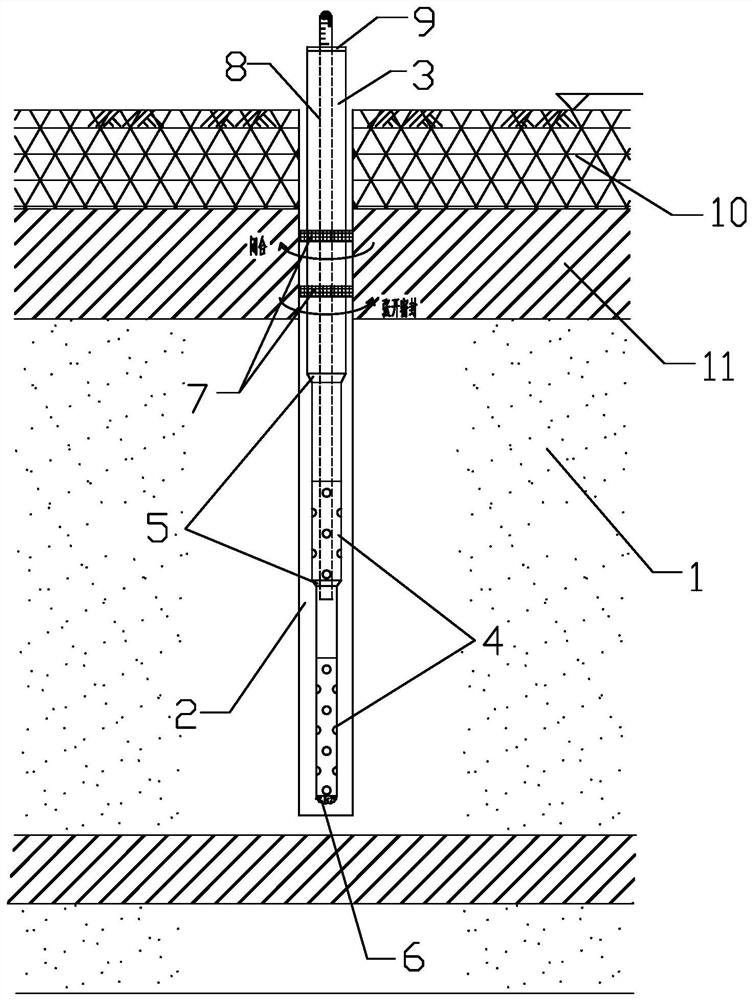

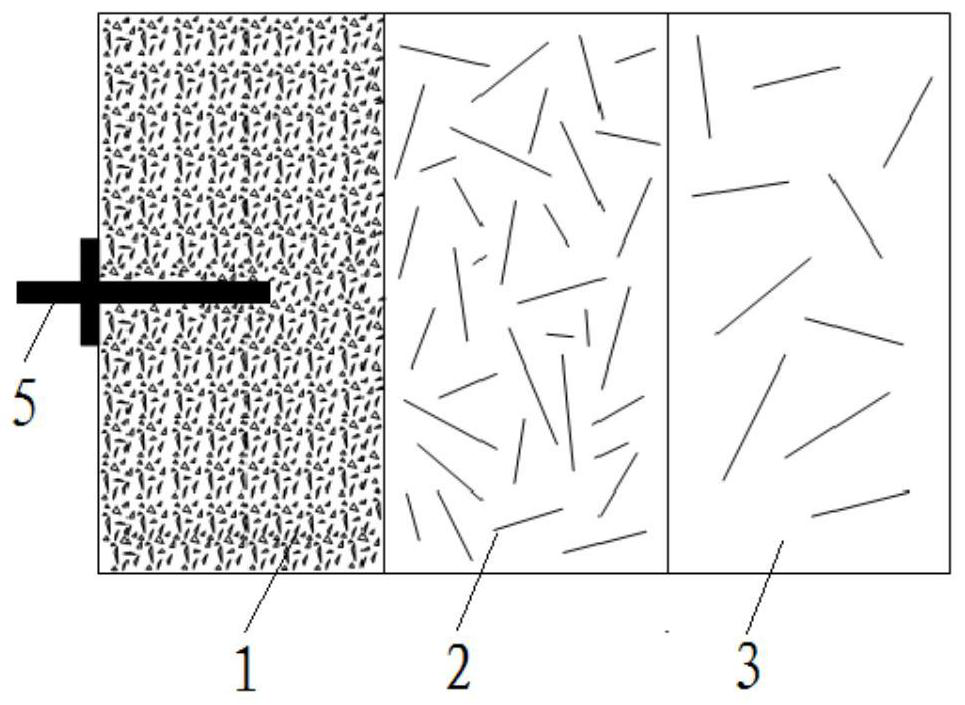

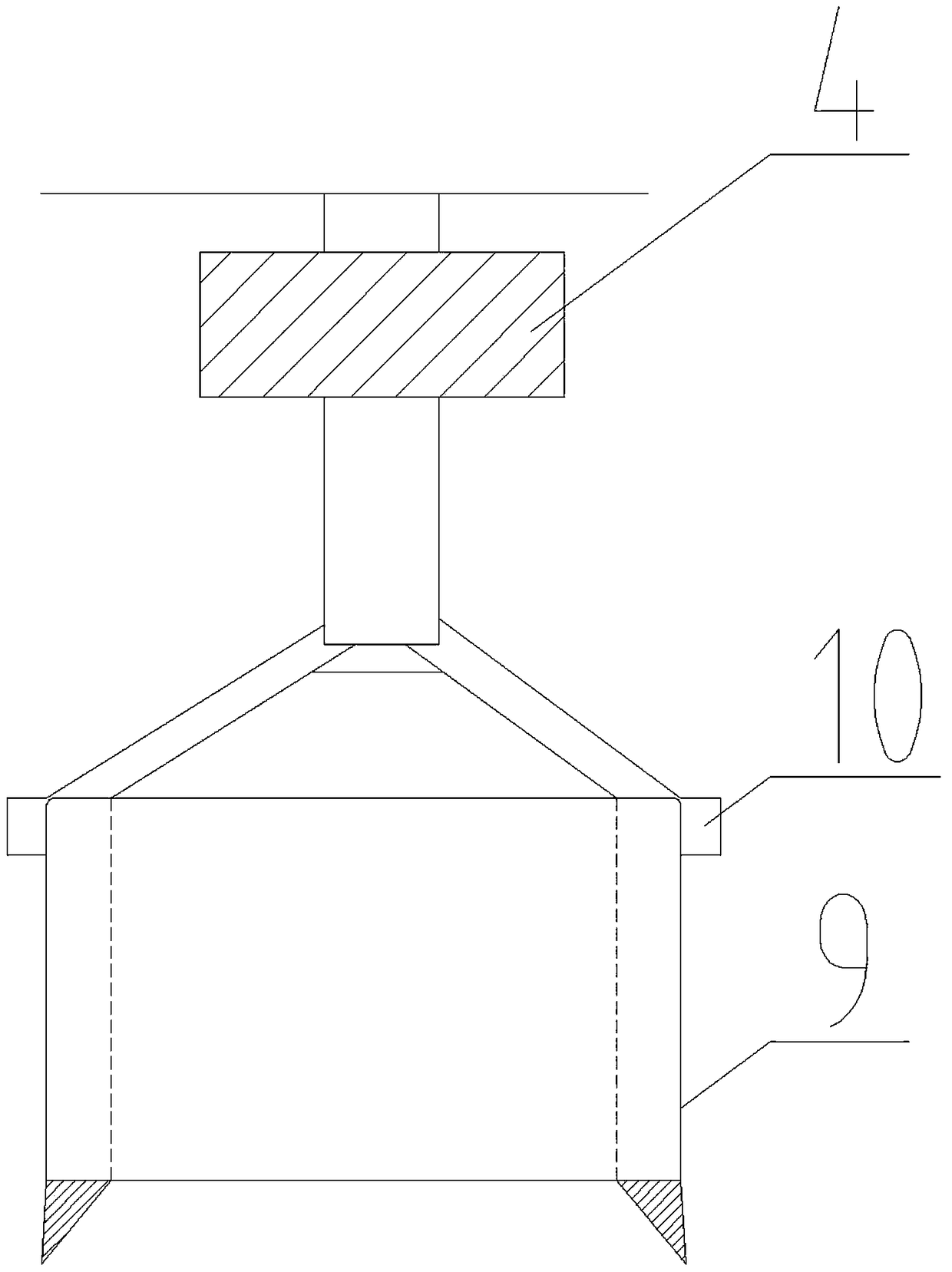

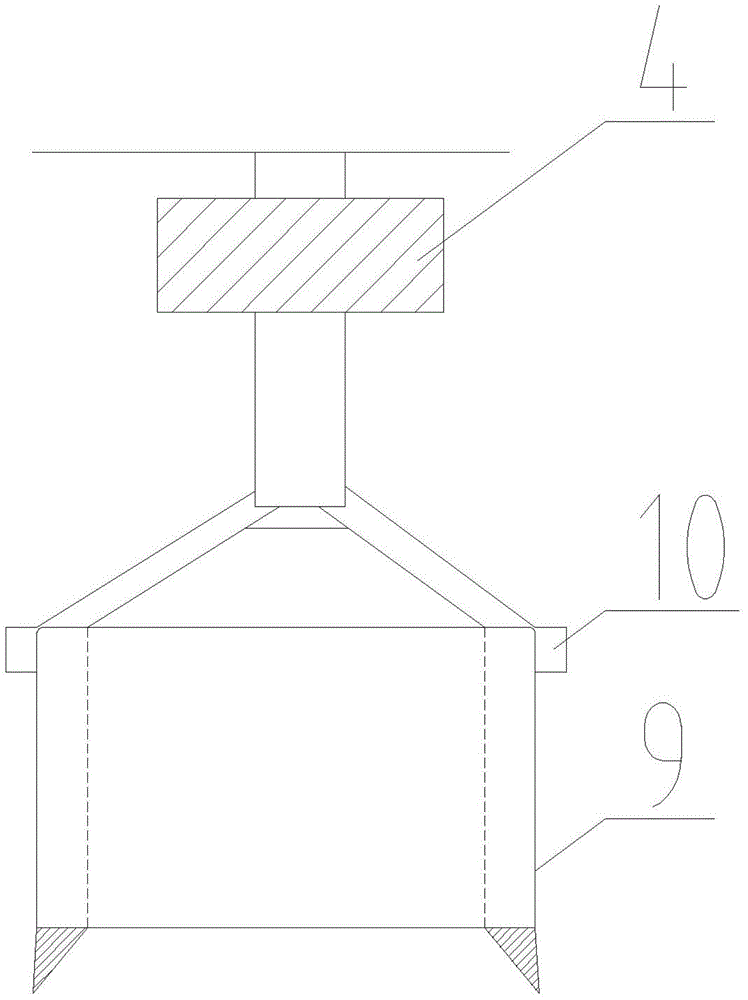

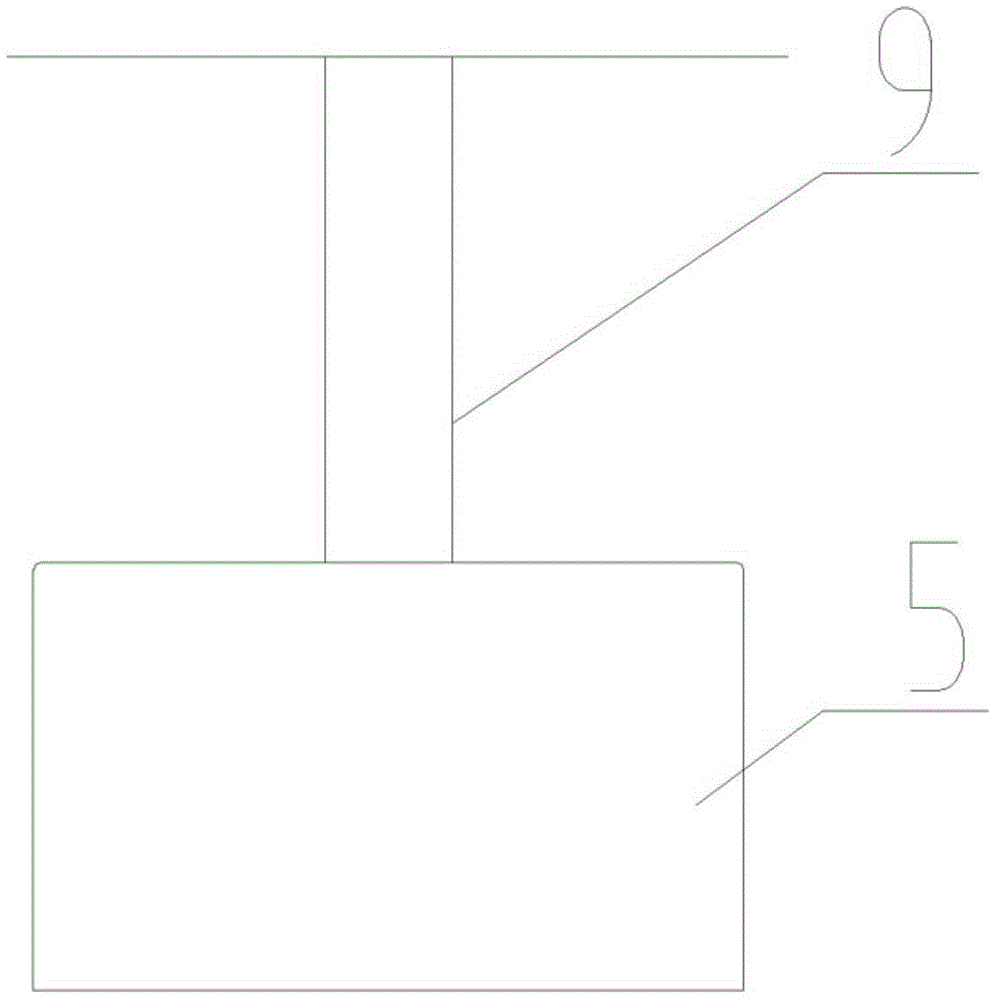

Hole collapse preventive trenching construction method of underground diaphragm wall

InactiveCN104947689AAvoid collapsing holesSolve the problem of collapsed holesExcavationsSlurry wallSoil cement

The invention belongs to the field of building foundation pit engineering and discloses a hole collapse preventive trenching construction method of an underground diaphragm wall. A construction is composed of a grab bucket (1) of a trenching machine, retaining wall slurry (2), a soil layer (3), a soft soil layer (4), a conduit (5), cemented soil (6), an underground diaphragm wall (7) constructed, and guide walls (8). The underground diaphragm wall easily suffers hole collapse during trenching construction; to solve the problem, a trench of the underground diaphragm wall can be filled with the cemented soil reaching 1 to 2 m above the trench hole collapse part, and soft retaining walls form after settling and compacting; after the cemented soil has stable quality and has certain strength, trenching construction continues, and the soft retaining walls made up of the cemented soil function in retaining jointly with the slurry so as to prevent hole collapse. The environment with the soft soil layer is improved through the cemented soil, the soft retaining walls are formed and finish retaining jointly with the slurry, the problem that lateral supporting force of the slurry is poor is effectively solved, the soft soil layer of high flow plasticity is protected from hole collapse, smoothness of trenching is ensured, and trenching quality is improved.

Owner:THE THIRD CONSTR CO LTD OF YNJG

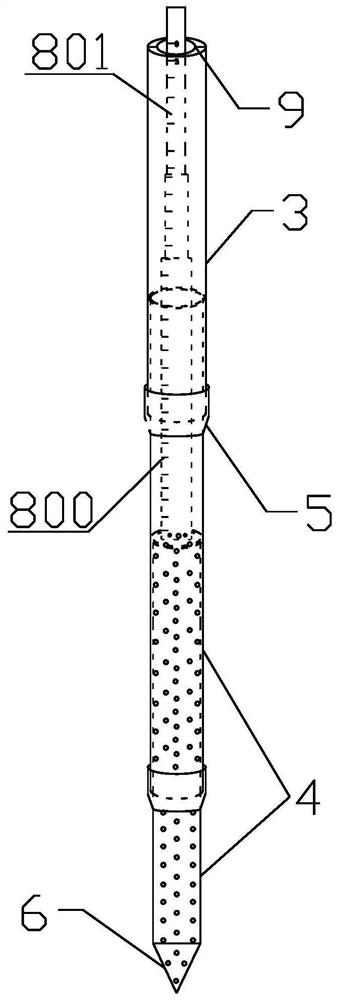

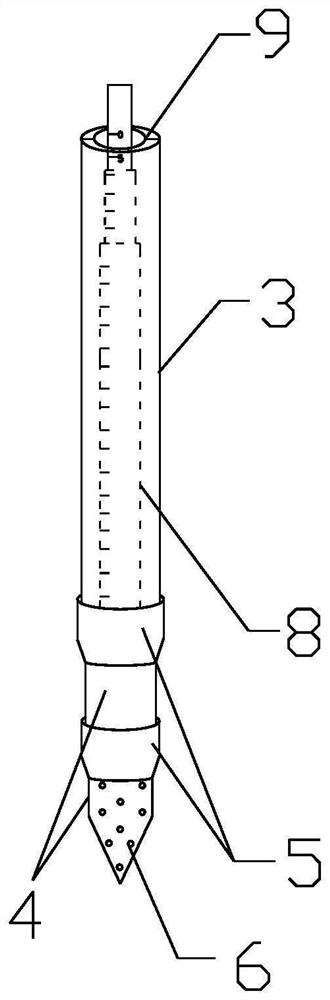

Offshore wind power batter pile rock-socketed construction hole collapse treatment device, using method and treatment method

PendingCN112726580AEasy to operateFast constructionDrilling rodsWind motor supports/mountsEconomic benefitsOffshore wind power

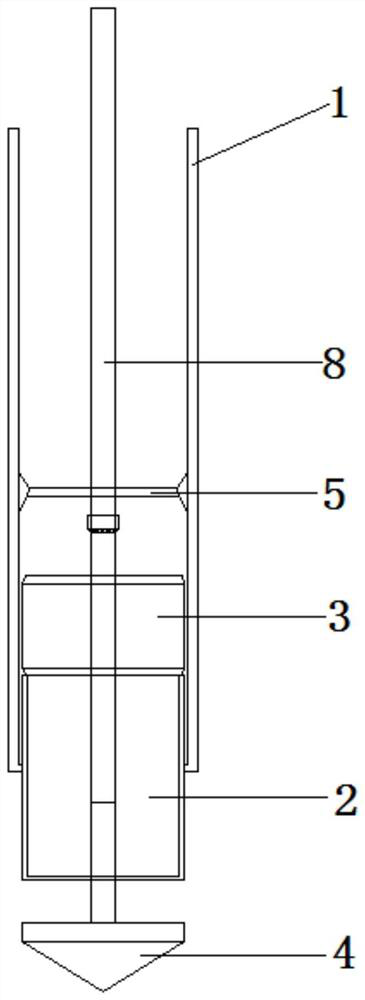

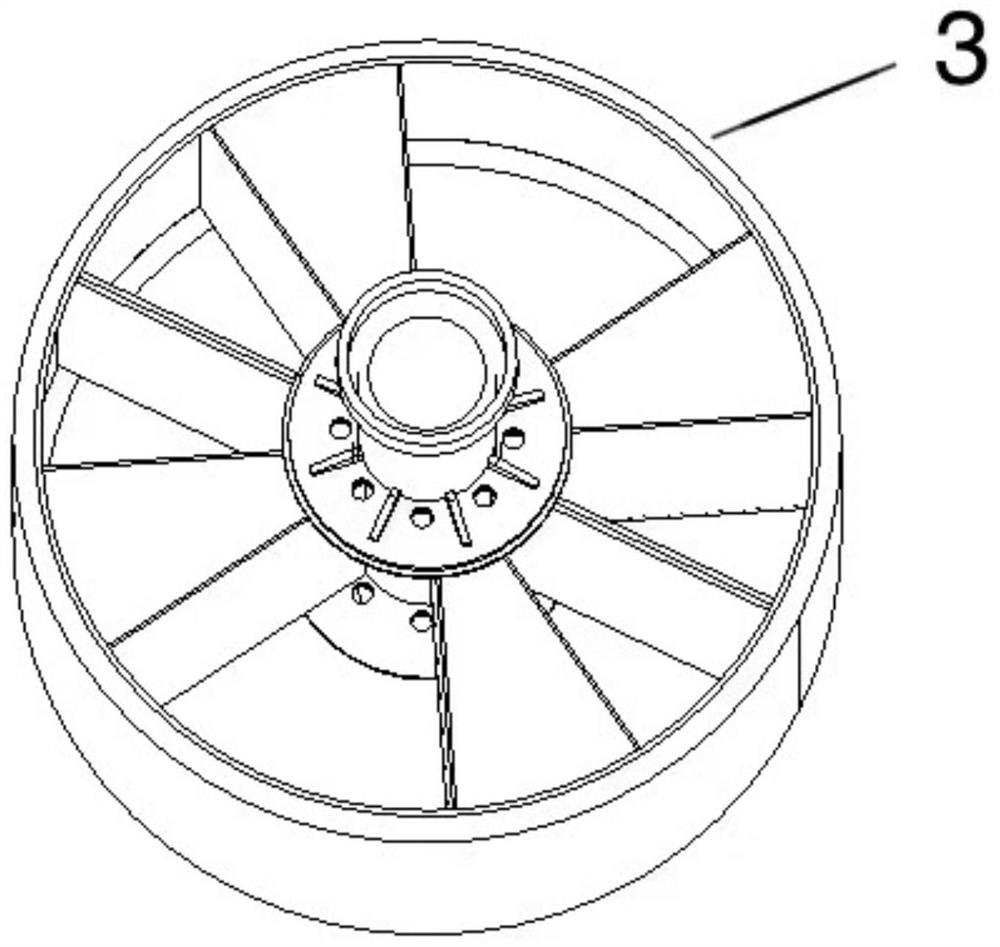

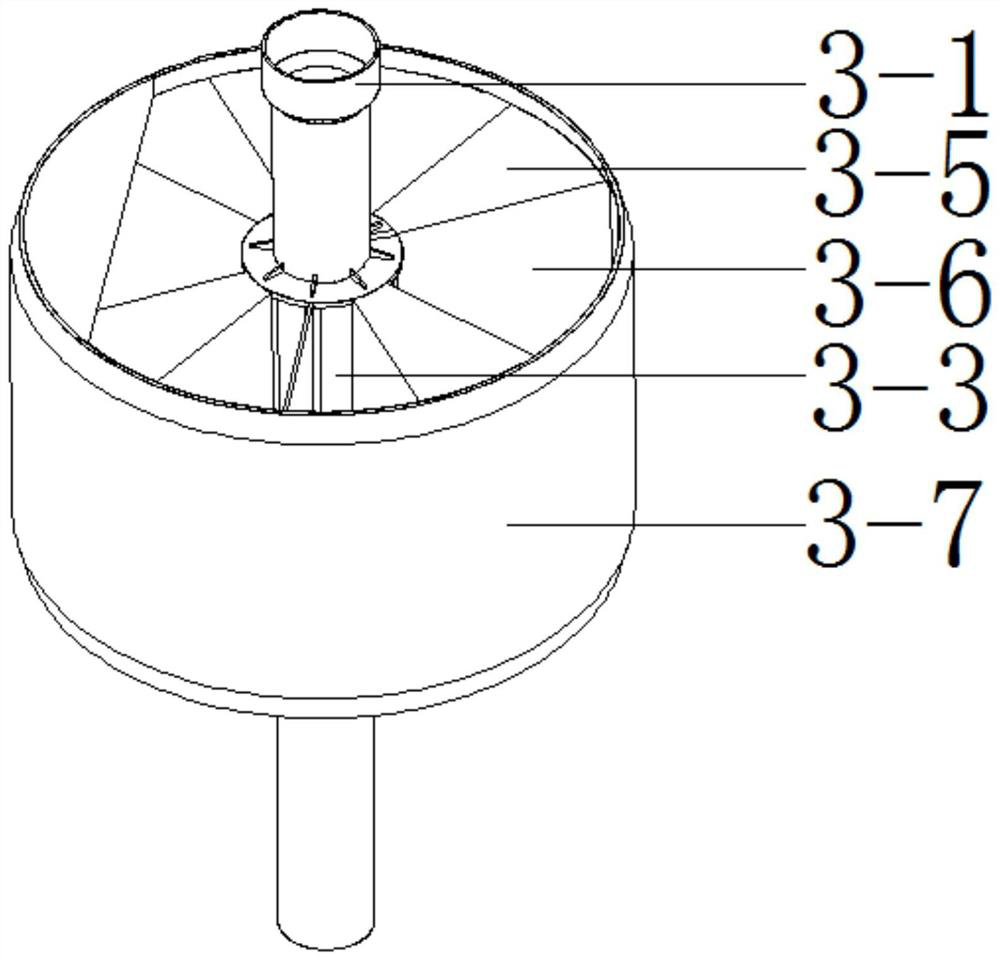

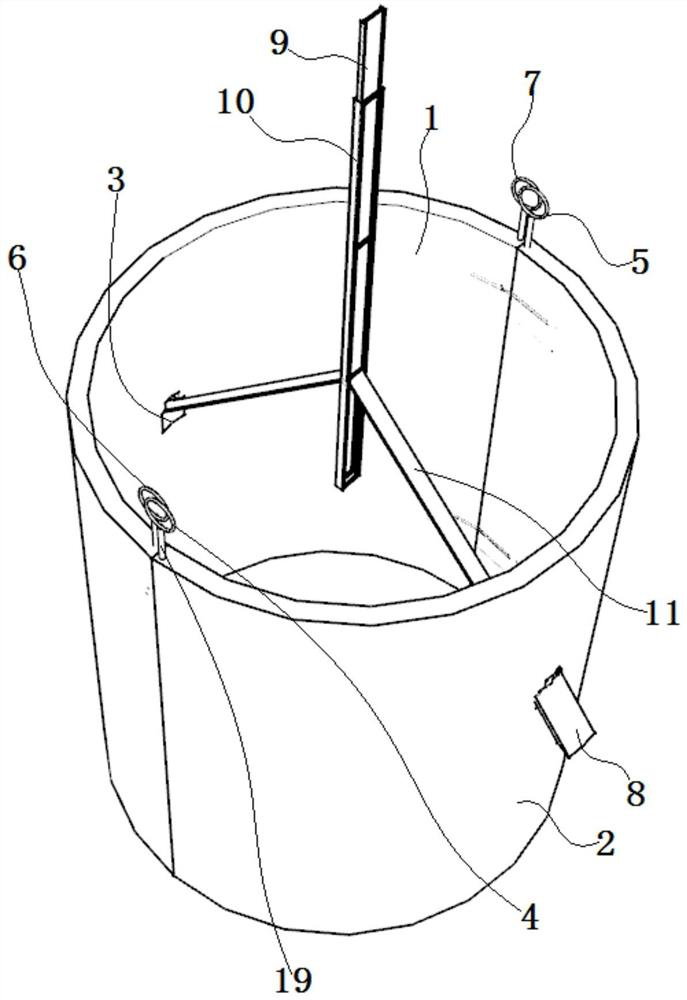

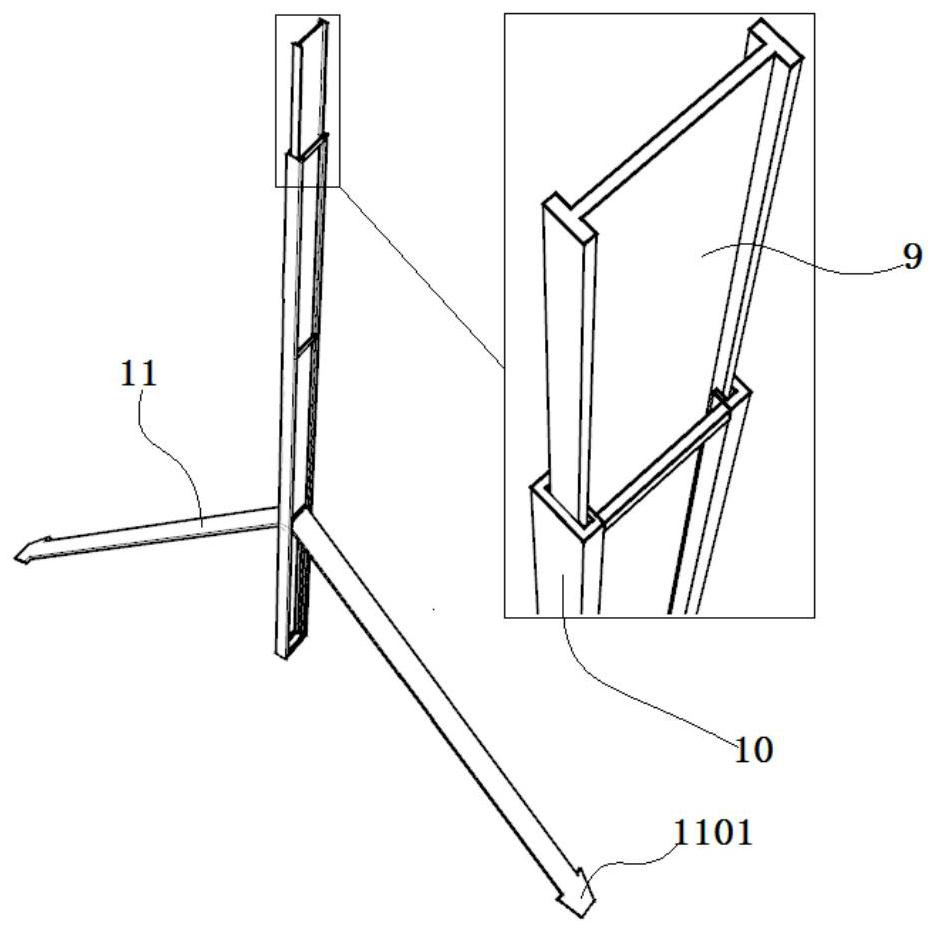

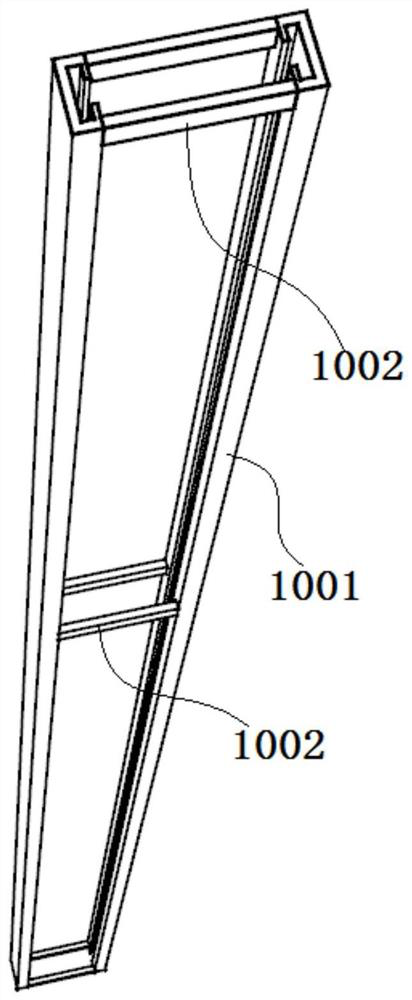

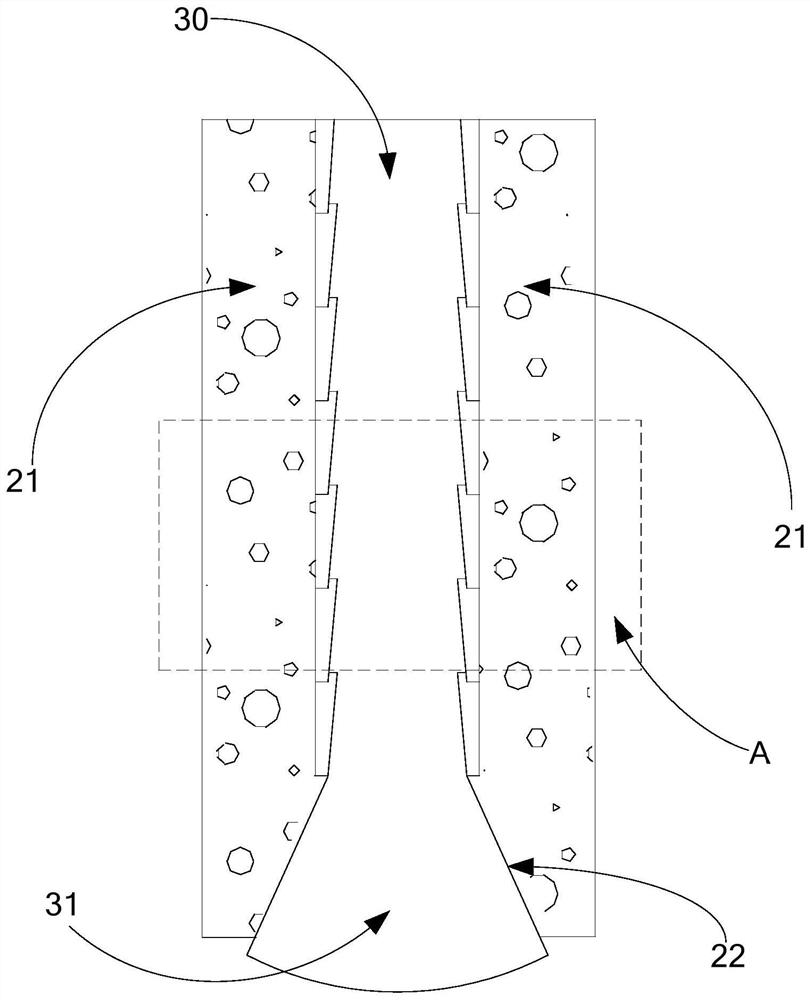

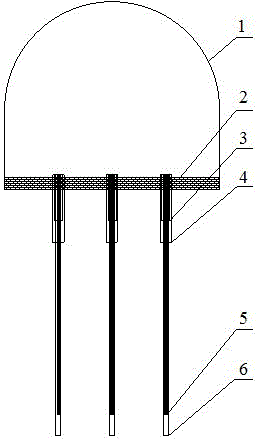

The invention discloses an offshore wind power batter pile rock-socketed construction hole collapse treatment device, a using method and a treatment method. The device comprises a steel pipe pile (1), an inner pile casing (2), an inner pile casing follower (3) and a centralizer (5). The steel pipe pile (1) is in the shape of a cylinder with two open ends; the inner pile casing (2) is installed at the bottom of the steel pipe pile (1); the centralizer (5) and the inner pile casing follower (3) are arranged in the steel pipe pile (1); a drill rod (8) penetrates and extends into the centralizer (5) and the inner pile casing follower (3); and a drill bit (4) is installed at the end of the drill rod (8). According to the offshore wind power batter pile rock-socketed construction hole collapse treatment device, the using method and the treatment method, the inner pile casing follow-up leaking stoppage mode is adopted, so that the problem of inclined pile hole collapse is solved, and the difficulties of complex seabed rock stratum and large construction difficulty in a limited space are overcome. The device has the advantages of convenient and fast construction, good economic benefit, guarantee of offshore operation safety and the like.

Owner:CCCC FIRST HARBOR ENG

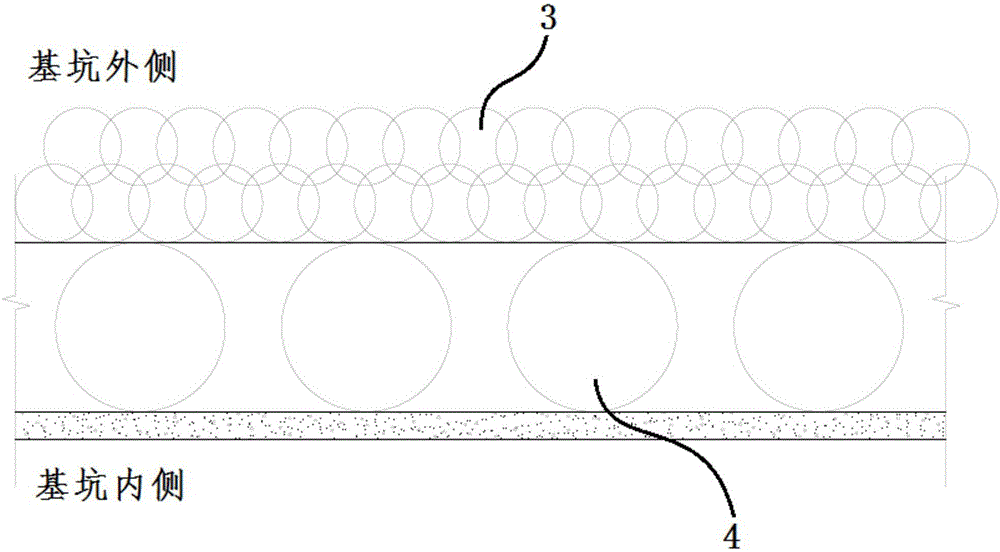

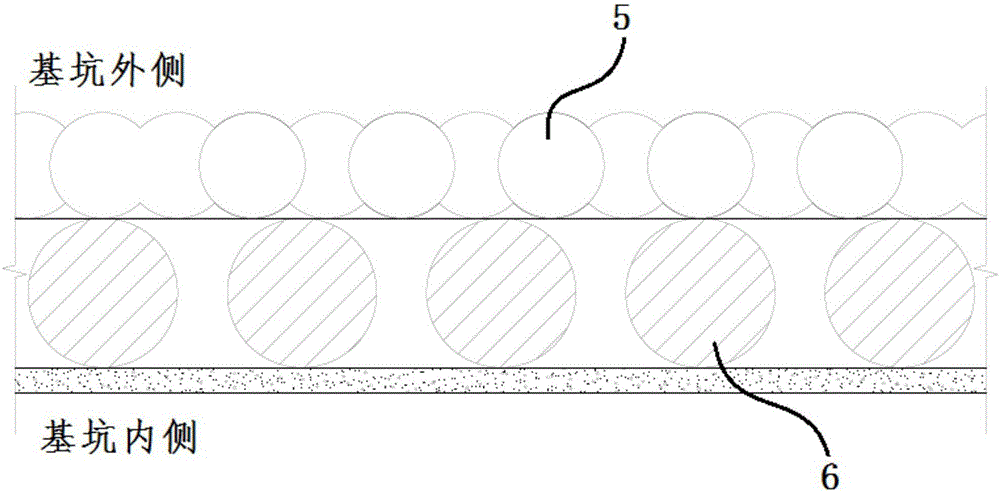

Foundation pit bracing water stopping structure with support pile and three-axis stirring pile arranged in cased drilling manner

Provided is a foundation pit bracing water stopping structure with a support pile and a three-axis stirring pile arranged in a cased drilling manner. The support pile is constructed on the outer side of a foundation pit; the stirring pile is constructed in a support pile area in a three-axis stirring manner; and the support pile directly cuts a pile body on the three-axis stirring pile for construction, and the whole bracing water stopping structure is formed. The three-axis stirring pile is large in power, and can perform stirring in strong-weathered rock and the above stratum. Compared with a conventional small diameter cement stirring pile, the beneficial effects of being small in number of lap joints, good in water stopping effect, high in construction efficiency, high in stratum adaptability and the like are achieved; and compared with a jet grouting pile, the beneficial effects that the water stopping effect is good, and price is low are achieved. According to the foundation pit bracing water stopping structure with the support pile and the three-axis stirring pile arranged in the cased drilling manner, the support pile and the three-axis stirring pile are combined together, construction is performed in the manner that the support pile and the three-axis stirring pile arranged in the cased drilling manner, the stratum condition can be improved, the problem of hole collapse of the support pile is effectively solved, a water stopping effect better than that of the conventional stirring pile and the jet grouting pile can also be achieved, meanwhile the occupied space of a supporting structure is saved, and the water stopping capacity of an existing pile-in-row bracing water stopping structure is enhanced.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

Construction method of sandy ground hole-forming anti-floating anchor of steel pipe and PVC pipe compound bushing

InactiveCN108589724AEasy to operateSimple constructionProtective foundationBulkheads/pilesSoil horizonCorrosion

The invention discloses a construction method of a sandy ground hole-forming anti-floating anchor of a steel pipe and PVC pipe compound bushing. The method comprises the following steps: (I) positioning and numbering anchor holes; (II) taking a conventional hole drill in position and drilling a steel sleeve; (III) blowing and cleaning holes at a high pressure and lifting a drill; (IV) putting a PVC bushing down and pulling out the steel bushing; (V) grouting; and (VI) putting the anti-floating anchor down. The process method solves the hole collapsing problem by drilling the steel bushing to form holes and blowing and cleaning the holes, so that the anti-floating anchor is smoothly hole-formed. According to the process method, a protective wall is formed by means of the PVC bushing, so that the hole collapsing problem in the grouting construction process is solved, and meanwhile, the anti-floating anchor plays a role of corrosion resistance. The process method is simple to operate andsimple to construct, and can form holes within a relatively short time and construct the anti-floating anchor. The process method can solve the problem of an anchoring force of the anti-floating anchor in a soil layer effectively; and holes are formed by means of a conventional hole drill through the process method, and the steel bushing is repeatedly used, so that the extra cost is prevented frombeing increased.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

Non-excavation in-situ replacement filling spiral drilling method of unconsolidated stratum

ActiveCN108049804AImprove stabilitySafe and efficient advancementDrill bitsDrilling machines and methodsSoil scienceSlag

The invention discloses a non-excavation in-situ replacement filling spiral drilling method of an unconsolidated stratum. According to the method, an annular space formed at the collapse part of the unconsolidated stratum is utilized to achieve replacement of targeted rock and soil, the most rock and soil are replaced at the most unconsolidated part of the stratum, then a drill bit is tripped in and rotates positively and negatively for pressing and compacting, most clay is extruded in and compacted at the most unconsolidated stratum section, and a formed wall protecting layer is thicker. According to the non-excavation in-situ replacement filling spiral drilling method of the unconsolidated stratum, in the process of pressing, extruding and expanding of the drill bit, a backfill clay layer is extruded tightly and compacted, and meanwhile, an undisturbed soil layer around a drilled hole is extruded tightly and compacted, so that the whole stability of the drilled hole after being processed in this way is improved greatly, and safe, efficient and stable propelling of subsequent processes is ensured effectively. Clayey soil in a put-in hole can use the clay drilled out by other drilled holes or materials are taken at the nearest position. According to the non-excavation in-situ replacement filling spiral drilling method of the unconsolidated stratum, the extra cost is not additionally increased in the process of solving collapse holes, based on the use of original equipment, even clay backfill can also be drilling slag of the other drilled holes, and the cost is saved.

Owner:河北省地矿局国土资源勘查中心

Waste concrete pipeline penetration drilling pile construction process

InactiveCN109024596APrevent channelingHigh degree of mechanizationBulkheads/pilesSoil horizonEngineering

The invention discloses a waste concrete pipeline penetration drilling pile construction process. According to the construction process, the extended steel casing protection is adopted, a percussion drill and a rotary drilling rig are cooperatively used for processing an underground waste concrete pipeline with larger burial depth, and the drilling pile construction obstacles are removed, so thatthe construction process has the effects that (1) the extended steel casing protection is adopted, so that the problem of hole collapse of a surface miscellaneous filling soil layer and a disturbed soil layer during the construction process can be solved; (2) the percussion drill is used for impacting and processing the waste concrete pipeline with larger burial depth, so that the problem that a narrow field has no excavation condition or the excavation processing safety risk is high due to the complicated surrounding environment is solved; and (3) from the economy point of view, by adopting the extended steel casing protection and cooperatively using the percussion drill and the rotary drilling rig for processing the underground waste concrete pipeline with larger burial depth, compared with an excavation method, the processing period can be saved by 50 percent to 60 percent, and the cost can be saved by 20 percent to 30 percent, so that the economical efficiency is good. According tothe process, the manpower and the labor time are reduced, the forceful guarantee is provided for fitting to the project progress, and the utility tool is simple in structure and easy to implement.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

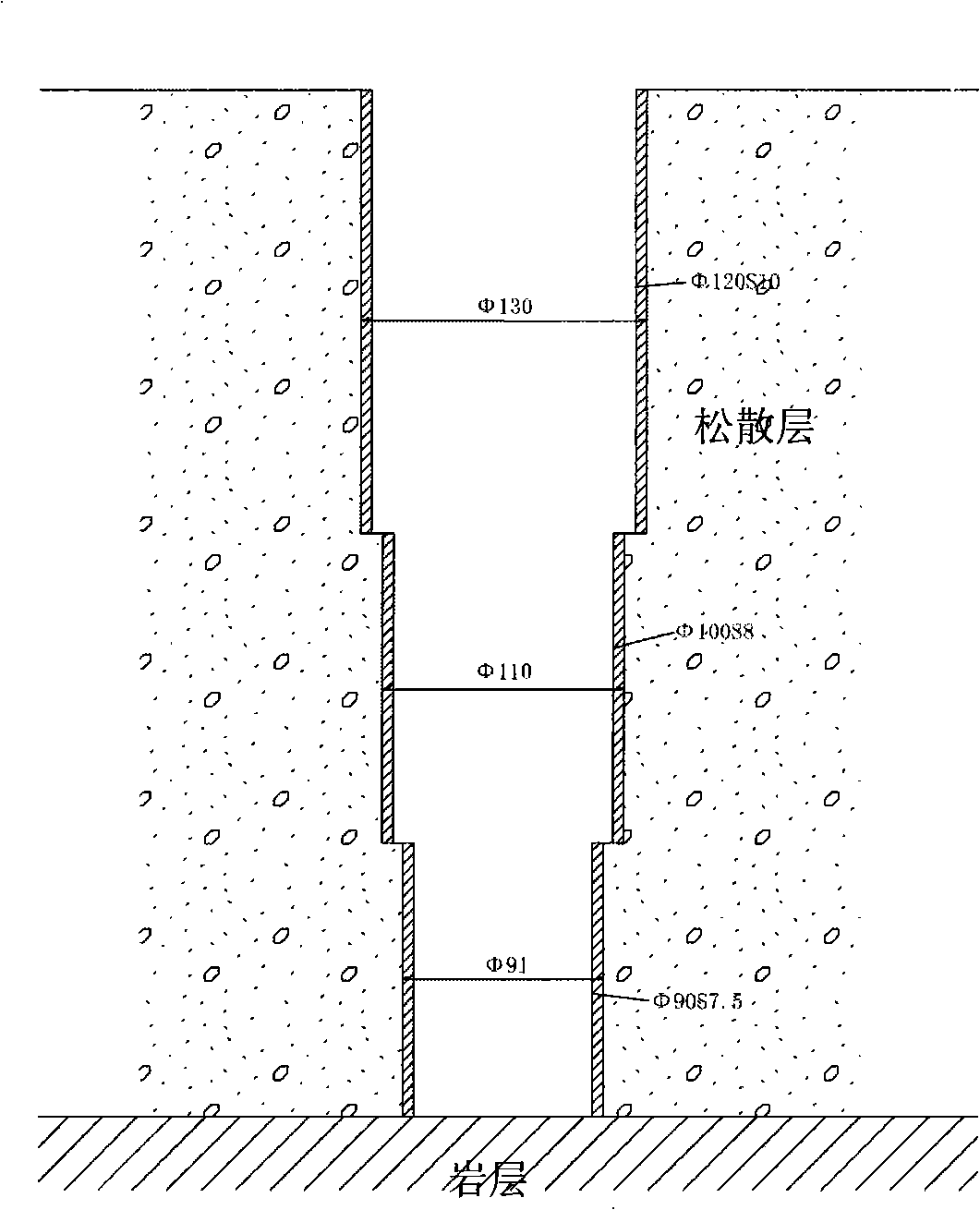

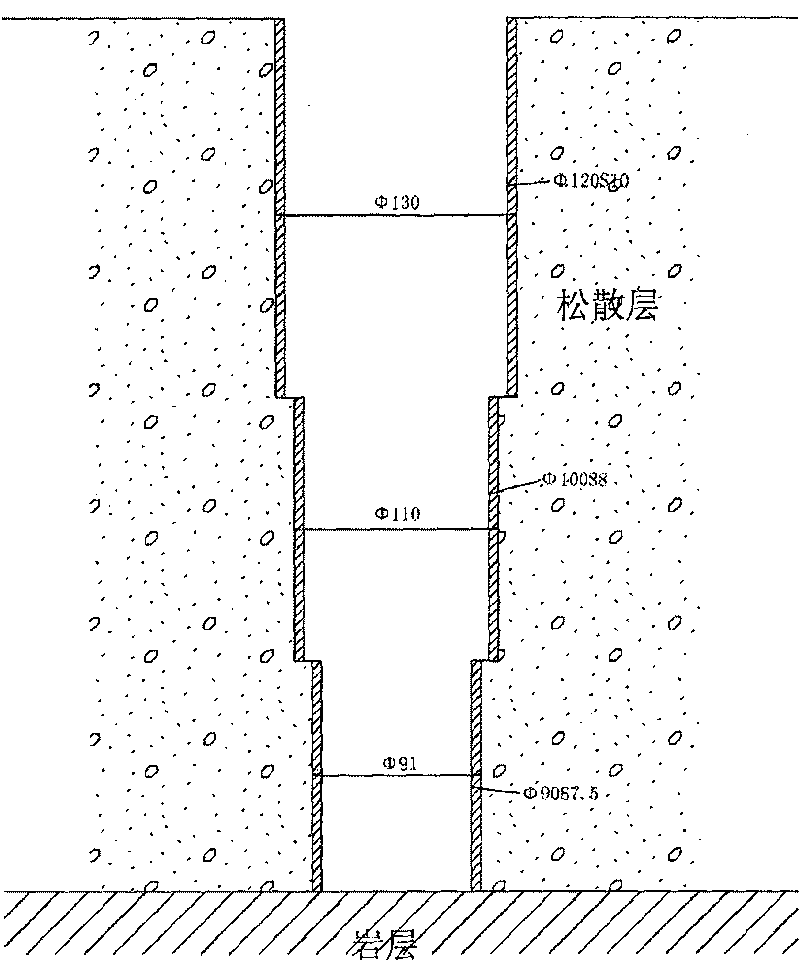

Unstable stratum variable-diameter casing pipe hole-protecting drilling process

ActiveCN111677448ASolve the problem of collapsed holesSolve problems such as shrinkageDrill bitsDirectional drillingPipeMechanical engineering

The invention discloses an unstable stratum variable-diameter casing pipe hole-protecting drilling process. The unstable stratum variable-diameter casing pipe hole-protecting drilling process can realize hole-protecting directional drilling in an unstable stratum, and solves the problems of hole collapse, hole shrinkage and the like in unstable stratum drilling, under the hole protection effect ofa variable-diameter casing pipe, the situations of hole collapse, hole shrinkage and the like in an unstable stratum hole section during subsequent drilling are avoided, drill jamming and drill falling accidents are avoided, smoothness of a directional drilling channel is guaranteed due to the hole protection effect of the variable-diameter casing pipe 2 in the unstable stratum hole section, therequirements of a mine for gas control, water damage prevention and the like are met, and the method is good in effect in the construction process, high in stability, high in unstable stratum hole protection drilling efficiency and good in hole forming performance.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

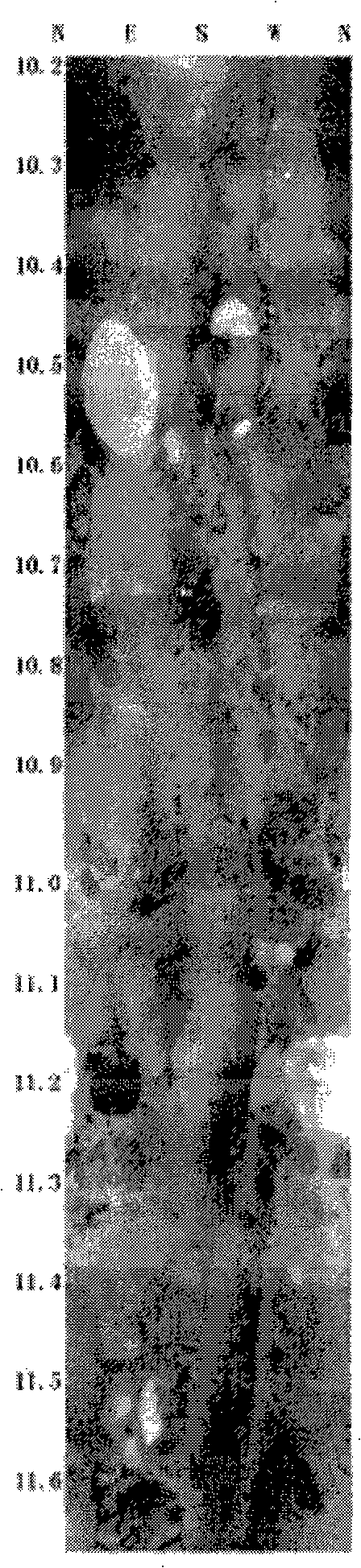

Profound unconsolidated formation visualized detection method

ActiveCN101285781ASolve the problem of collapsed holesOptical prospectingMaterial analysis by optical meansSteel tubeEngineering

The invention relates to a visual detection method for a deep loose bed. The method comprises the following steps: A. drilling is performed on the loose bed by adoption of the general drilling and wall retaining method, namely one section of steel pipe retaining wall is followed when one section is drilled; the steel pipe retaining wall is followed to the bottom of a hole, and then a wall retaining machine is run to the inside of the hole by the up-down means or the down-up means; an outer steel pipe is lifted out on a hole section for pickup; B. the hole section with the wall retaining machine is cleaned; C. after cleaning, pickup is performed on the hole section in which the wall retaining machine is positioned. The method successfully manufactures a high transparent PMMA pipe into the wall retaining machine and uses the general drilling technique to drill the deep loose bed, and then obtains the geological materials of the loose bed, thereby effectively solving the problem of hole collapse of the deep loose bed during the drilling process; moreover, the material compositions and the structural characteristics of the loose bed can be known really and intuitively through the pickup, and the method is a great breakthrough of the drilling technique for the deep loose bed.

Owner:长江三峡勘测研究院有限公司(武汉)

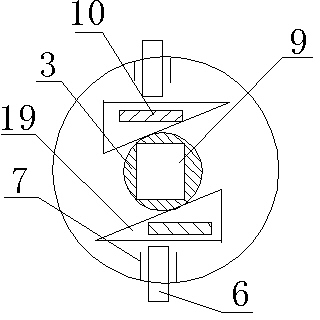

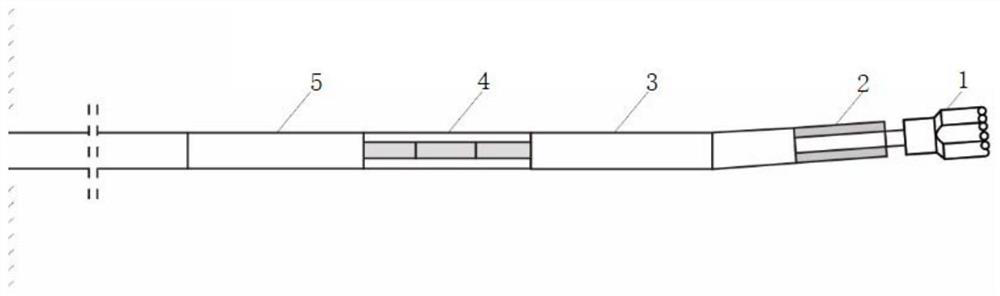

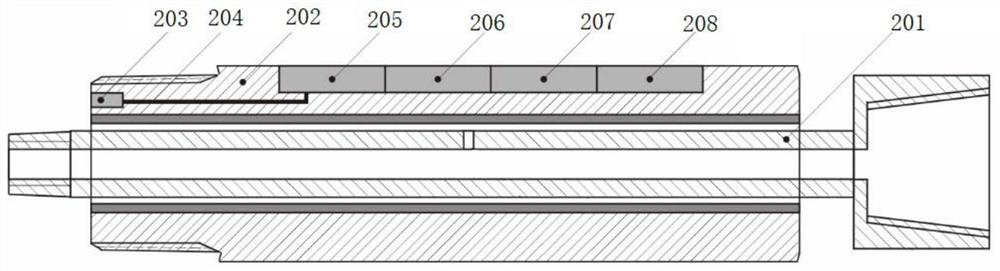

Sealing device for high-gas soft coal seam drilling and sealing method thereof

The invention discloses a sealing device for high-gas soft coal seam drilling and a sealing method thereof. The sealing device comprises a reinforcing supporting layer, a sealing layer and an extraction pipe which are concentrically distributed. The reinforcing supporting layer comprises a first bag, a first grouting pipe and a first slurry return pipe, a first one-way valve is arranged on the first grouting pipe, one end of the first grouting pipe is provided with a first quick joint, the other end of the first grouting pipe is provided with a first blasting valve, and the first slurry returnpipe is provided with a first stop valve. The sealing layer comprises a second bag, a third bag, a second grouting pipe and a second grouting pipe, the second grouting pipe is provided with a secondone-way valve, a third one-way valve and a second blasting valve, one end of the second grouting pipe is provided with a second quick joint, and the second grouting pipe is provided with a second stopvalve. The sealing device is simple in structure, reasonable in design, convenient to use and low in cost, can be effectively applied to sealed extraction of high-gas soft coal seam drilling, and isgood in use effect and convenient to use and popularize.

Owner:SHANXI LUAN MINING GRP +2

Recyclable anti-collapse type polymer mud and preparation method thereof

PendingCN110591665ASolve shrinkageSolve the problem of collapsed holesChemical/physical/physico-chemical stationary reactorsDrilling compositionFiberSodium Bentonite

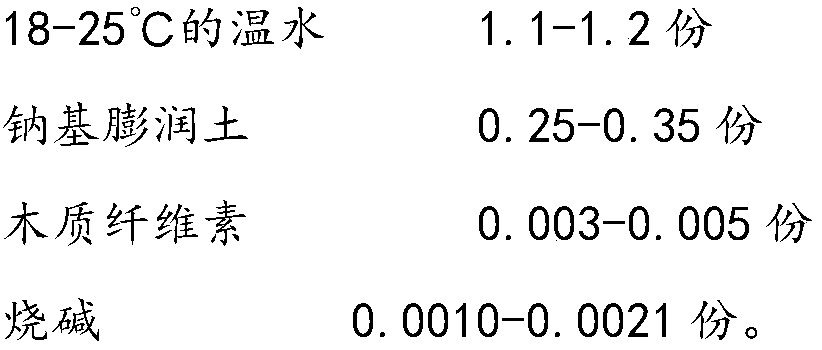

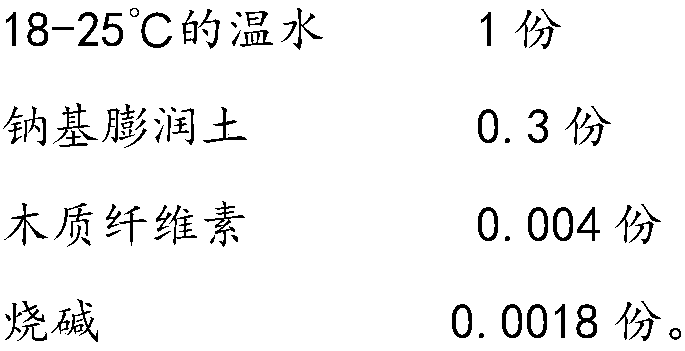

The invention discloses recyclable anti-collapse type polymer mud and a preparation method thereof. The recyclable anti-collapse type polymer mud is prepared from the following raw materials in partsby weight: 2.5-5 parts of a tackifier, 4-11 parts of a filtrate reducer, 70-80 parts of a solid phase film formation agent, 0.05-0.1 part of a dispersant, 0.1-0.2 part of a lubricant, 30-60 parts of sodium carbonate and 70-110 parts of water. The anti-collapse type polymer mud which comprises vegetable gum as a main tackifying component, a sulfonate copolymer as the filtrate reducer and plant fiber powder as a main solid phase film formation component has a filter loss less than 15mL within 30 minutes, a viscosity of 18-30s, a mud film thickness of 2-4mm and a sand content smaller than 5%, a mud film can be uniform and dense, and compared with common polymer mud and conventional bentonite mud, the mud solves the problems of hole shrinkage and hole collapse in water-sensitive geological hole drilling construction.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Groundwater observation well pipe and observation method for geotechnical investigation and surveying

PendingCN111809594AEffectively separate stagnant water infiltrationGuaranteed observation accuracyIn situ soil foundationObservational methodSoil science

The invention provides a groundwater observation well pipe and an observation method for geotechnical investigation and surveying. The groundwater observation well pipe comprises an observation well hole, a telescopic well pipe, and telescopic push rods placed in the telescopic well pipe, wherein the telescopic well pipe comprises an outer layer solid wall pipe body and one or two or more telescopic perforated pipes in mutual sleeving connection; the end of the most outer layer telescopic rod of each telescopic push rod is connected with the most inner layer telescopic perforated pipe; the length of the outer layer solid wall pipe is greater than or equal to the distance between the openings of the observation well hole and the top surface of a water containing layer to be tested; and after the telescopic well pipe is mounted in the observation well hole, a rotary switching sealing ring is arranged outside the outer layer solid wall pipe body in a sleeving manner to realize sealing ofthe outer wall of the well pipe above the water containing layer to be tested and the hole wall of the observation well hole, and after the groundwater water level in the holes is stable, observationof the water level can be performed. Clay balls do not need to be backfilled, observation accuracy can be guaranteed, primary pipe sinking in place can be realized, the problem that the well pipe is mounted to cause subsidence of the hole wall can be solved, and the groundwater level can be observed in a layering manner.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Self-drilling type single-liquid and double-liquid grouting reinforcement device and using method

PendingCN114033426AShort anchoring timeAlleviate the problem of tension in miningUnderground chambersDirectional drillingMaterial resourcesSlurry

The invention discloses a self-drilling type single-liquid and double-liquid grouting reinforcement device and a using method and belongs to the technical field of coal and rock mass grouting support. The reinforcing device comprises a self-drilling hollow pipe body and a grouting joint, wherein the grouting joint comprises a sleeve, a liquid guide device and a liquid inlet pipe; a front end of the hollow pipe body is connected with a drill bit, so characteristics of the anchor rod are realized, a drill rod can be replaced, the rod does not need to be withdrawn after drilling to the designed depth, a tail end of the pipe body is connected with a grouting connector and then direct grouting is conducted, a problem of hole collapse possibly occurring when the drill rod is withdrawn under the condition that surrounding rock is broken is solved, and repeated through-hole in the hole collapse position is avoided; or the surrounding rock is disturbed after multiple times of re-drilling nearby, so investment of manpower and material resources is reduced, and normal implementation of the original design is ensured; according to site conditions, single-liquid or double-liquid grouting can be selected, and part of injected grout can permeate into surrounding rock cracks, so the anchoring quality is improved. The method can be realized through manual operation of a machine and a full-automatic mode, and accords with the development trend of intelligent automation of mines.

Owner:LIAONING TECHNICAL UNIVERSITY

Diameter-expanding fixing cylinder for preventing hole collapse of pile foundation pit

PendingCN113152451ASolve the problem of collapsed holesImprove reliabilityBulkheads/pilesRatchetPush out

The invention discloses a diameter-expanding fixing cylinder for preventing hole collapse of a pile foundation pit. The diameter-expanding fixing cylinder comprises a cylinder wall I, a cylinder wall II and a forked lowering rod; the cylinder wall I and the cylinder wall II are formed by equally dividing a cylinder, and ratchet and pawl structures are arranged on the corresponding vertical edges of the cylinder wall I and the cylinder wall II; the forked lowering rod comprises a sliding groove and a push rod installed in the sliding groove, the lower end of the push rod is hinged to two supporting legs, and clamping ends are arranged at the ends of the supporting legs. The diameter-expanding fixing cylinder is ingenious in design, after the diameter-expanding fixing cylinder is placed at a proper position, a cover buckle can be jacked out through the push rod, and the push rod can be smoothly retracted after the cover buckle is jacked out; in the pushing-out process of the push rod, the two half cylinder walls can be pushed out, and the cylinder walls can be driven to be separated in one direction after being pushed out; the push rod plays a lifting role in the lowering process of the diameter-expanding fixing cylinder, the cylinder walls on the two sides can be fixed through the design of the ends, the design is ingenious, the adaptability is high, and the diameter-expanding fixing cylinder is worthy of popularization.

Owner:CHONGQING UNIV

Profound unconsolidated formation visualized detection method

ActiveCN101285781BSolve the problem of collapsed holesOptical prospectingMaterial analysis by optical meansRetaining wallSteel tube

The invention relates to a visual detection method for a deep loose bed. The method comprises the following steps: A. drilling is performed on the loose bed by adoption of the general drilling and wall retaining method, namely one section of steel pipe retaining wall is followed when one section is drilled; the steel pipe retaining wall is followed to the bottom of a hole, and then a wall retaining machine is run to the inside of the hole by the up-down means or the down-up means; an outer steel pipe is lifted out on a hole section for pickup; B. the hole section with the wall retaining machine is cleaned; C. after cleaning, pickup is performed on the hole section in which the wall retaining machine is positioned. The method successfully manufactures a high transparent PMMA pipe into the wall retaining machine and uses the general drilling technique to drill the deep loose bed, and then obtains the geological materials of the loose bed, thereby effectively solving the problem of hole collapse of the deep loose bed during the drilling process; moreover, the material compositions and the structural characteristics of the loose bed can be known really and intuitively through the pickup, and the method is a great breakthrough of the drilling technique for the deep loose bed.

Owner:长江三峡勘测研究院有限公司(武汉)

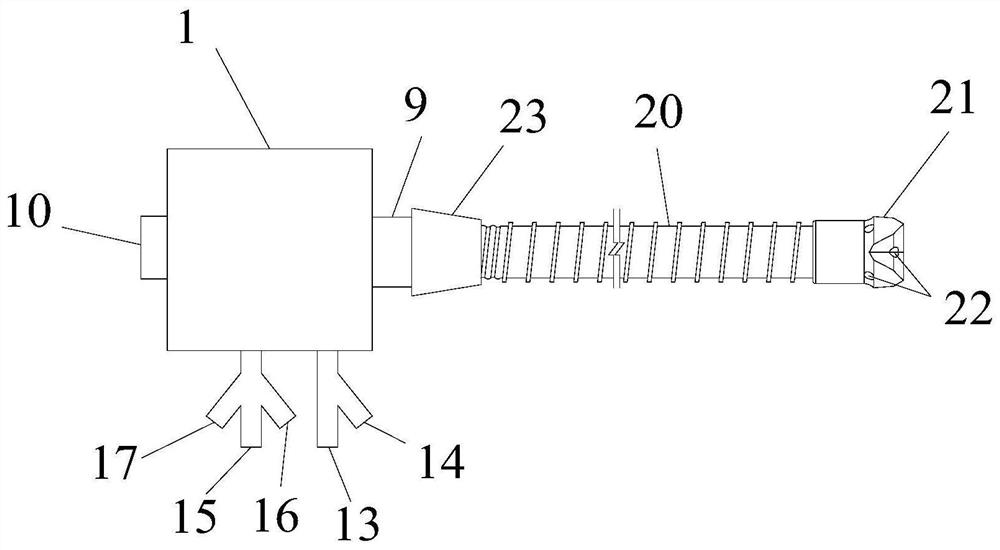

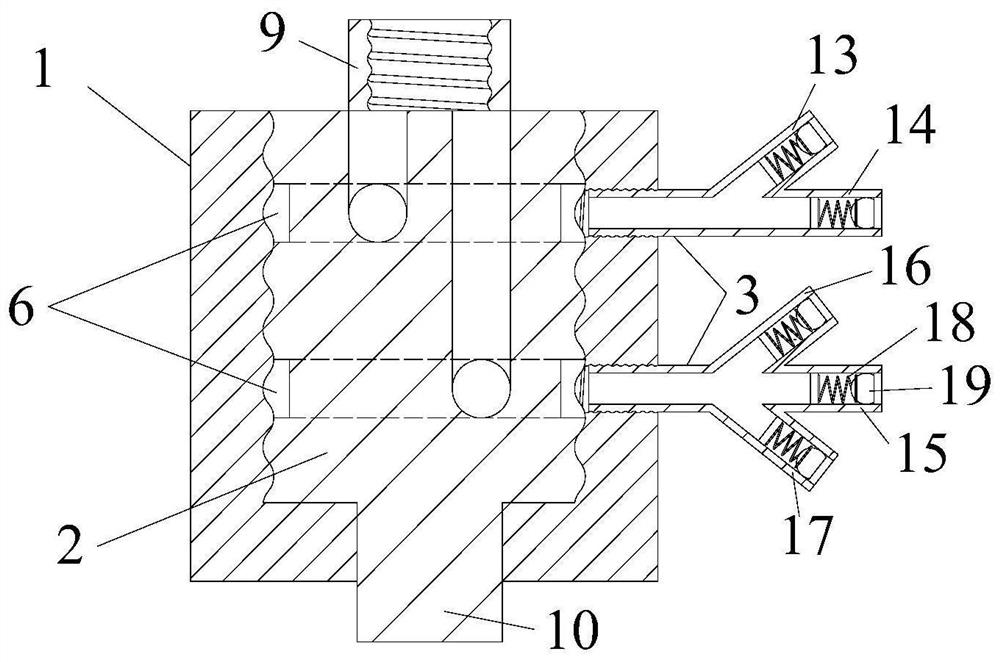

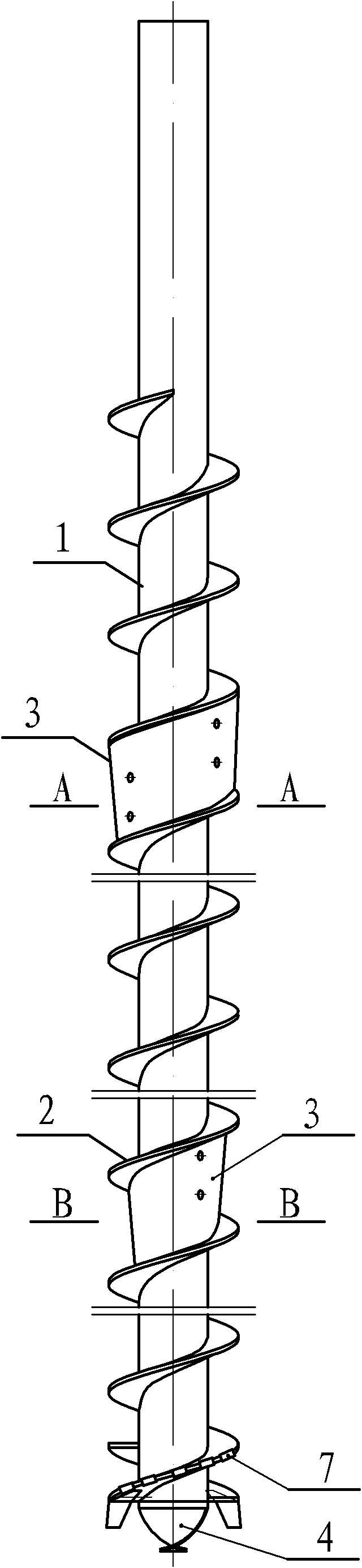

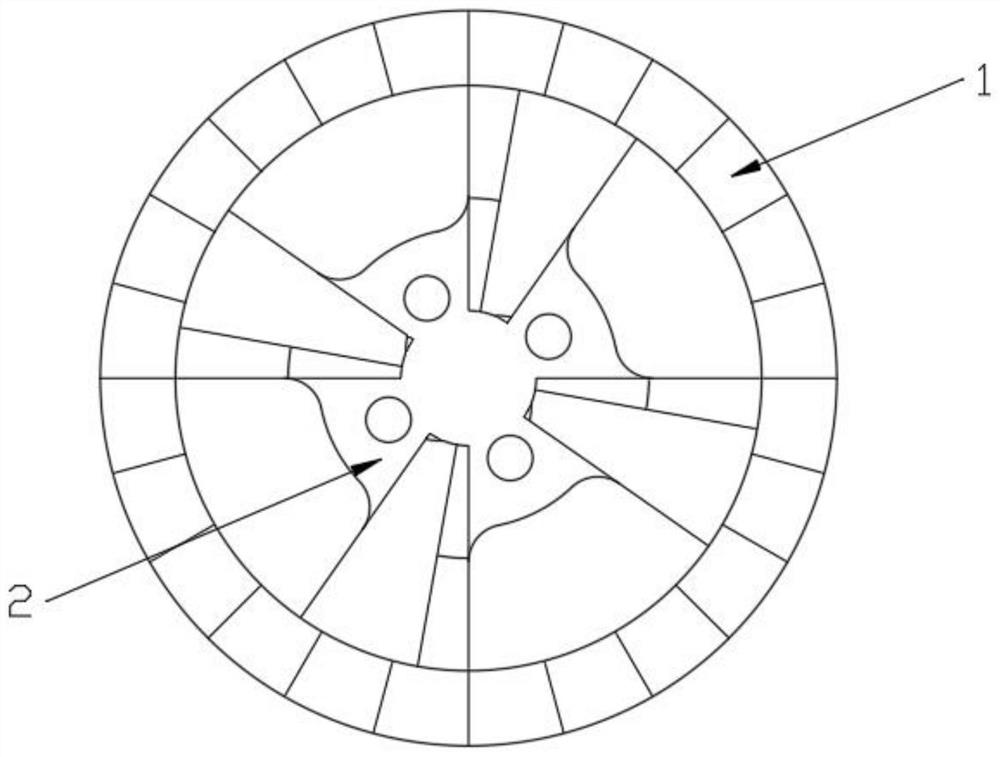

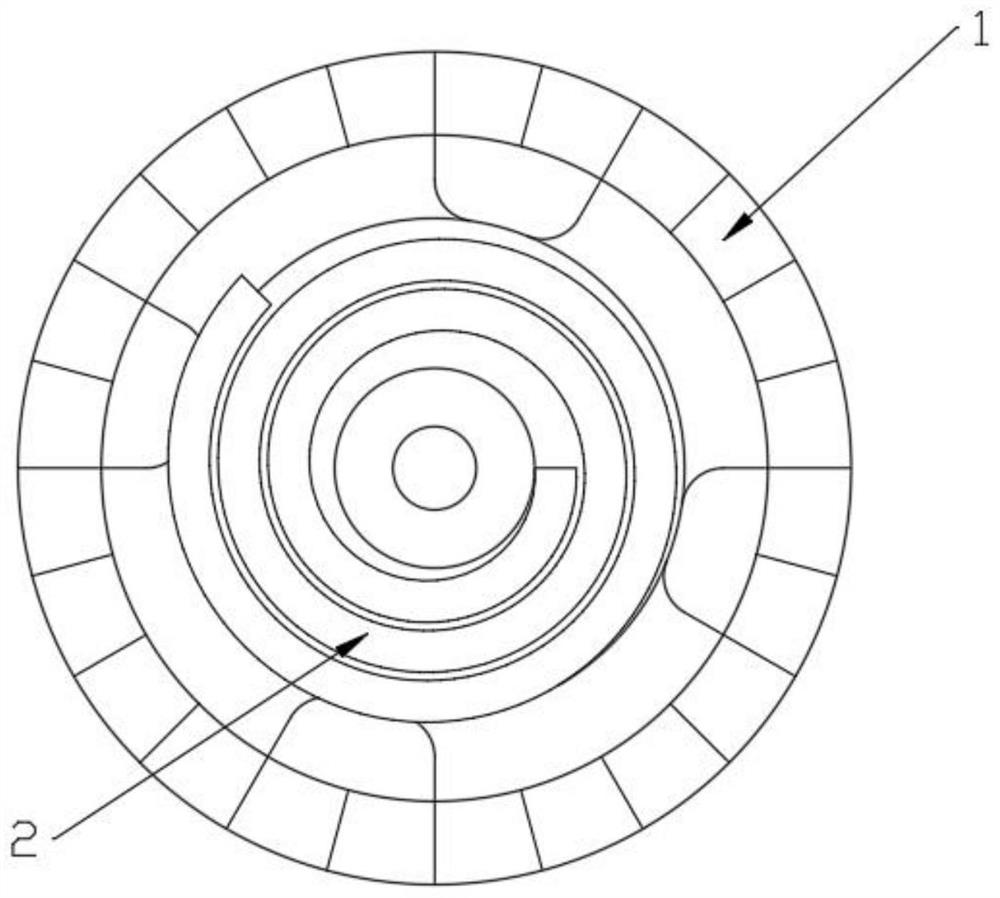

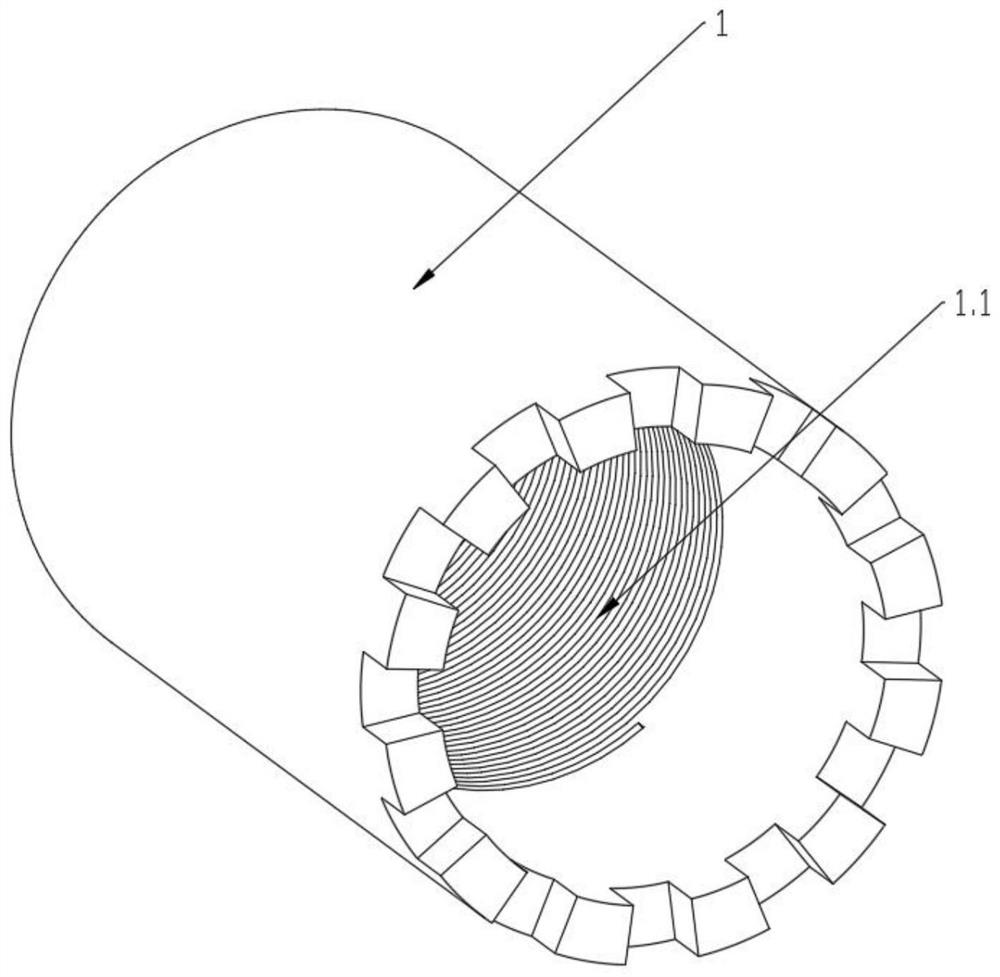

Adjustable multiple coil extruding and expanding drilling tool

ActiveCN101812976BStrong penetrating pore forming abilityWide formation adaptabilityDrilling rodsDrilling casingsHelical lineHelical blade

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

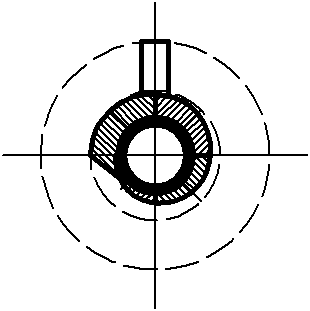

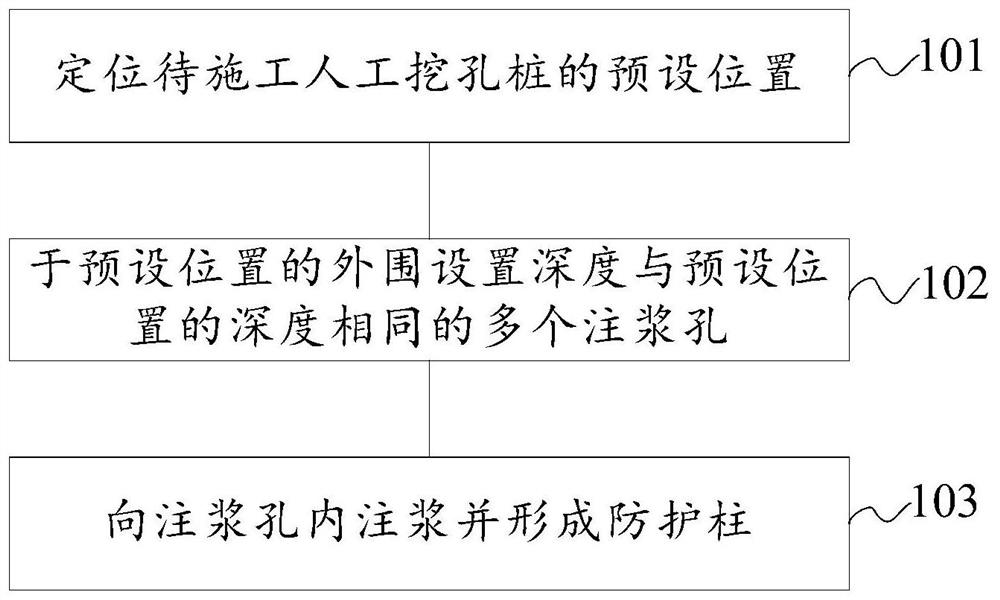

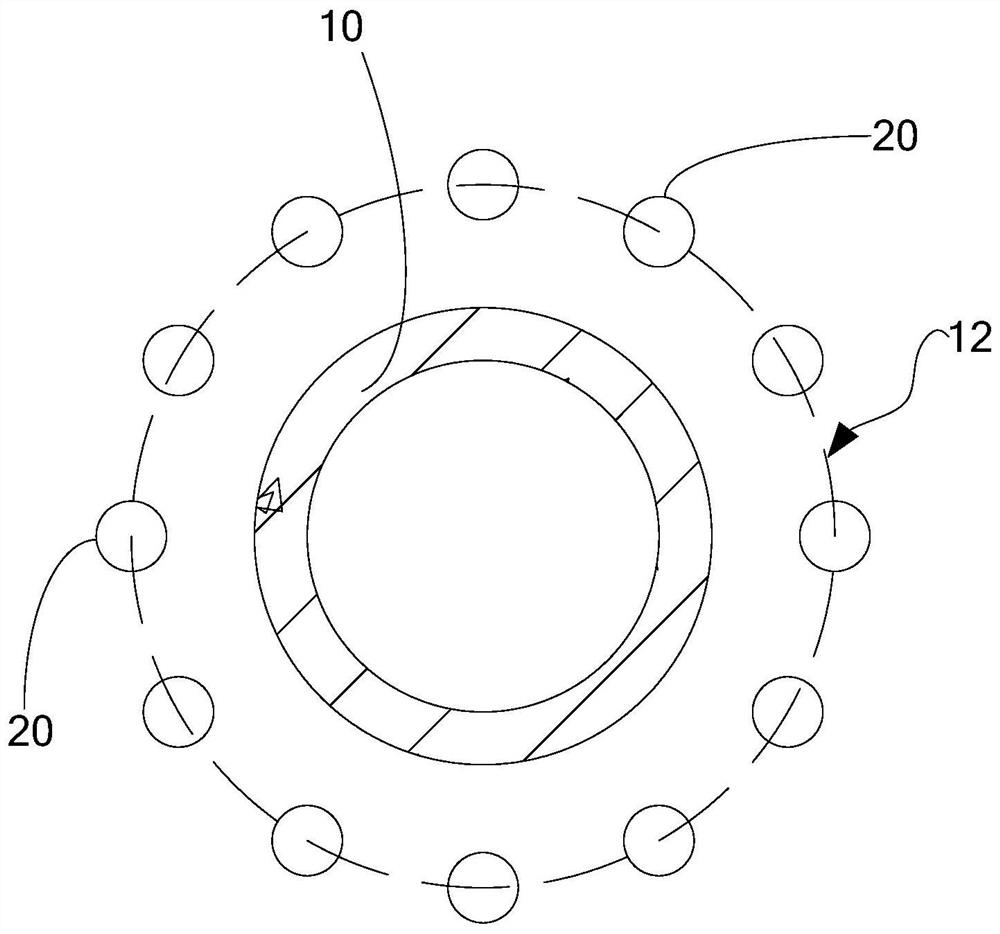

Protective method and protective structure of argillaceous siltstone geology with manual digging piles

ActiveCN108560540BReduce water permeabilitySolve the problem of collapsed holesBulkheads/pilesStructural engineeringSlurry

Owner:中建八局华中建设有限公司

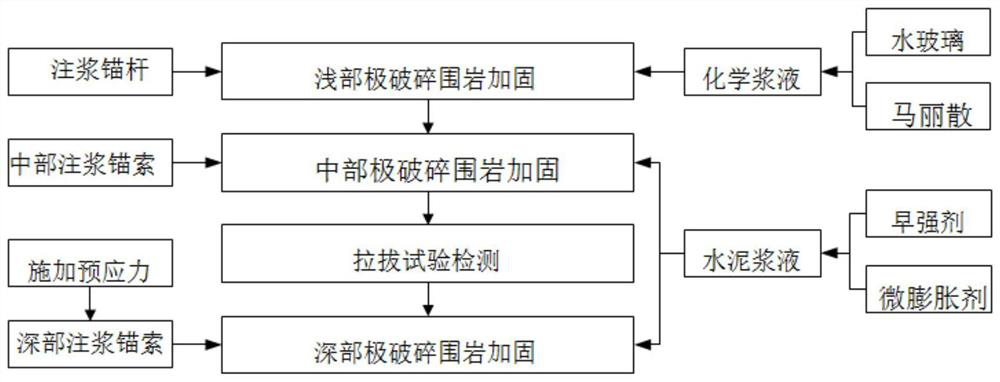

A step-by-step grouting reinforcement method for extremely broken surrounding rock in underground engineering

ActiveCN110017152BFast reinforcementEffective reinforcementUnderground chambersTunnel liningClassical mechanicsUltimate tensile strength

The invention discloses a step-by-step grouting reinforcement method for extremely broken surrounding rocks in underground engineering, which comprises the following steps: S1, grouting reinforcement for shallow extremely broken surrounding rocks; Surrounding rocks are reinforced by grouting; S3. Perform a pull-out test on the grouted anchor cable in the middle to determine whether the pull-out force reaches the set range. If yes, execute step S4; if not, execute step S5; S4. The extremely broken surrounding rock in the deep part is reinforced by grouting; S5, adjusting the parameters of the grouting anchor cable support in the middle part. The invention can quickly and effectively reinforce the extremely broken surrounding rock in underground engineering; quickly condense the extremely broken surrounding rock in the shallow part into a whole, improve the integrity of the surrounding rock, and effectively solve the phenomenon of hole collapse and drill sticking in the surrounding rock; make the central part And deep extremely broken surrounding rock enhances its own bearing capacity, improves the initial support strength of surrounding rock, improves the mechanical properties of extremely broken surrounding rock and controls its deformation and failure.

Owner:新汶矿业集团有限责任公司孙村煤矿 +2

Pile foundation hole collapse treatment method

InactiveCN112049127ASolve the problem of collapsed holesMeet the time limit requirementsExcavationsBulkheads/pilesRetaining wallArchitectural engineering

The invention discloses a pile foundation hole collapse treatment method. The pile foundation hole collapse treatment method comprises the steps that a rotary drilling rig is adopted to dig to a holecollapse part, silt generated by hole collapse is removed, concrete is adopted for recharging, recharging is carried out to the hole collapse top, after the concrete is solidified, a middle part of the solidified concrete is taken out, and the rest parts form a concrete retaining wall to prevent intensifying of hole collapse. According to the treatment method, the concrete is adopted for recharging to form a hole, the hole collapse problem can be effectively solved according to a project situation, and the construction period requirement is met.

Owner:CHINA MCC5 GROUP CORP

Combined drill

InactiveCN112012660AEnsure smoothEnsure integrityDrill bitsConstructionsMining engineeringWater flow

The invention discloses a combined drill. The combined drill comprises a first drill bit and a second drill bit, wherein the first drill bit is cylindrical; the second drill bit connected with the first drill bit is coaxially arranged in the first drill bit; a plurality of drainage grooves used for outputting slag flow from the interiors of the drill bits are formed between the first drill bit andthe second drill bit; the drainage grooves are evenly formed in the outer ring of the second drill bit in the axial direction of the second drill bit; a through hole used for inputting water flow isformed in the middle of the second drill bit; the head of the second drill bit is arranged at the position, close to one end of the head of the first drill bit by a certain distance in the axial direction; the tail of the first drill bit is flush with the tail of the second drill bit; and the second drill bit is connected with a drill rod. Through cooperative work of two different drill bit functional combinations and change of drill bit cutting and de-slagging ways, smoothness and completeness of the inner wall face of a drill hole are guaranteed, the hole forming rate of the drill hole is increased, the length of the drill hole is increased, and the problems of hole collapse and drill jamming in the stratum drilling process are effectively solved.

Owner:郑乃国

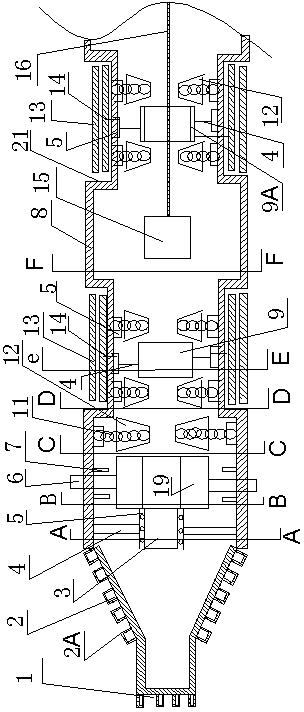

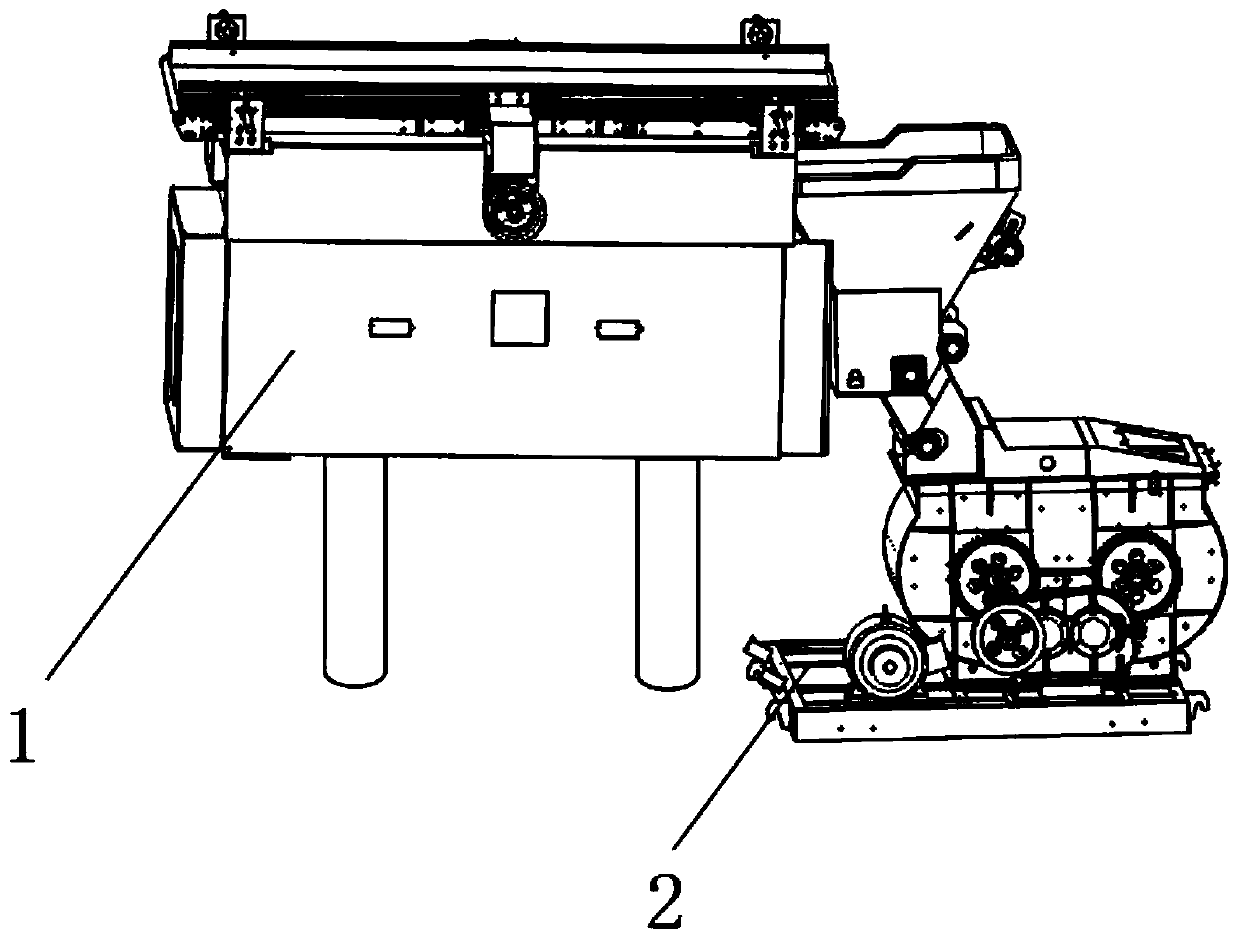

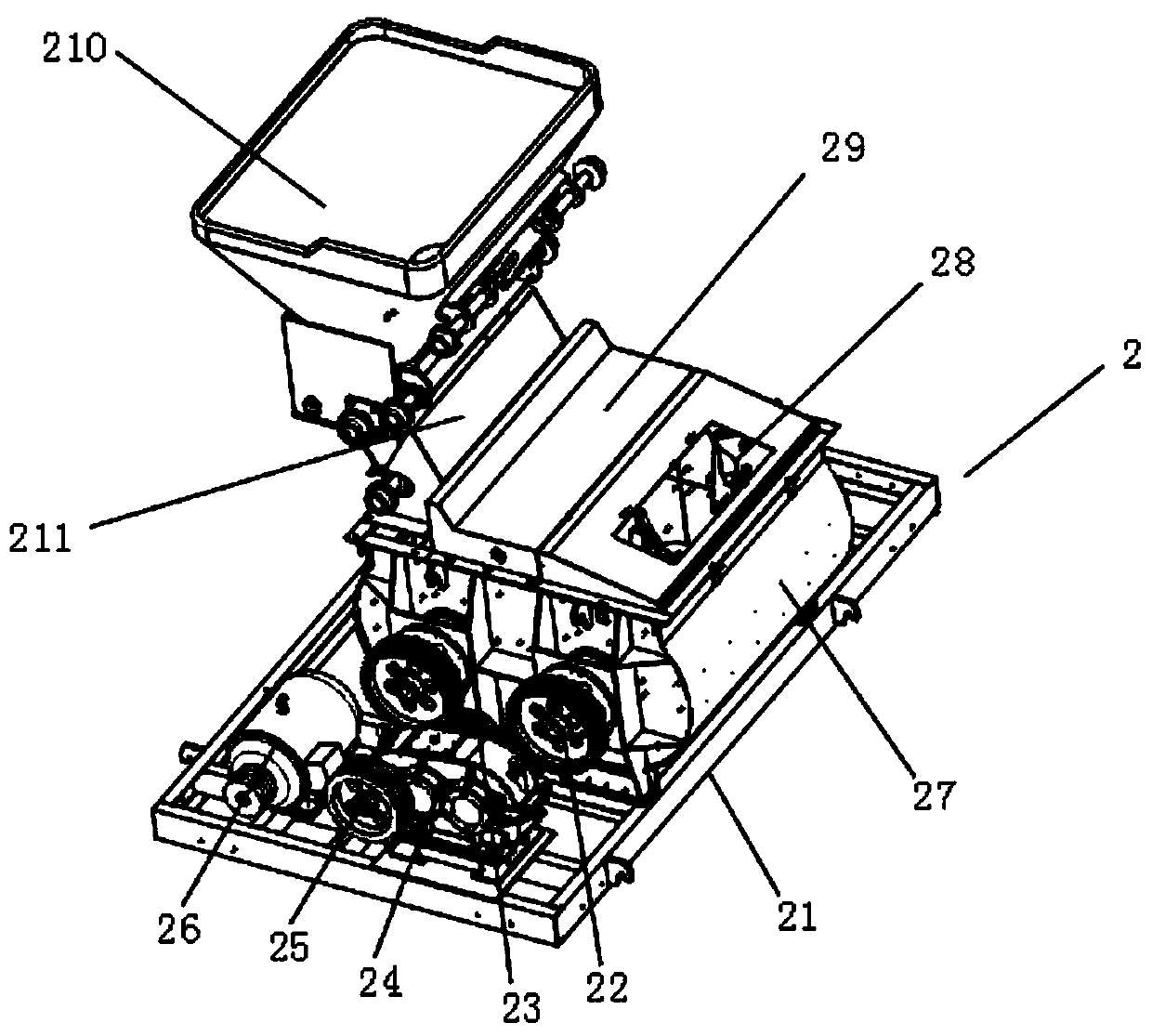

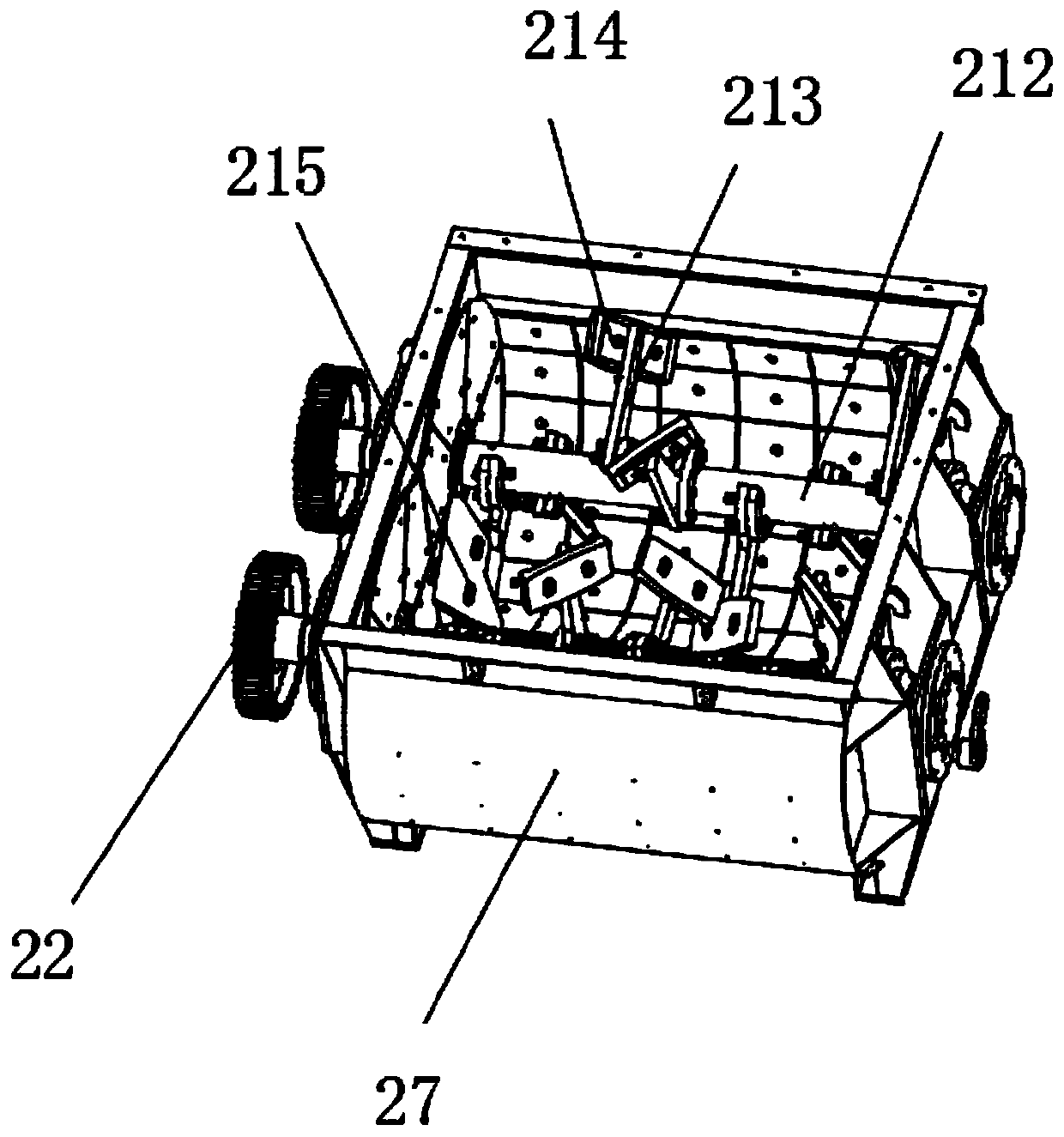

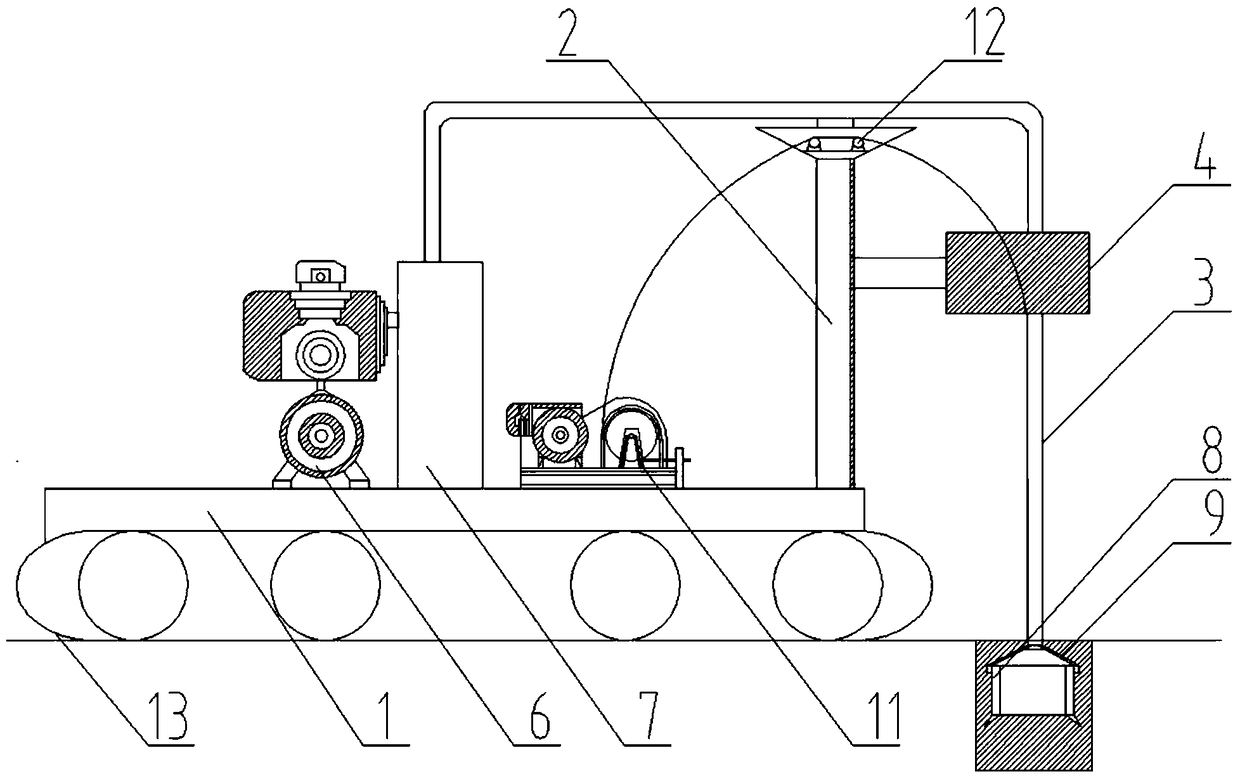

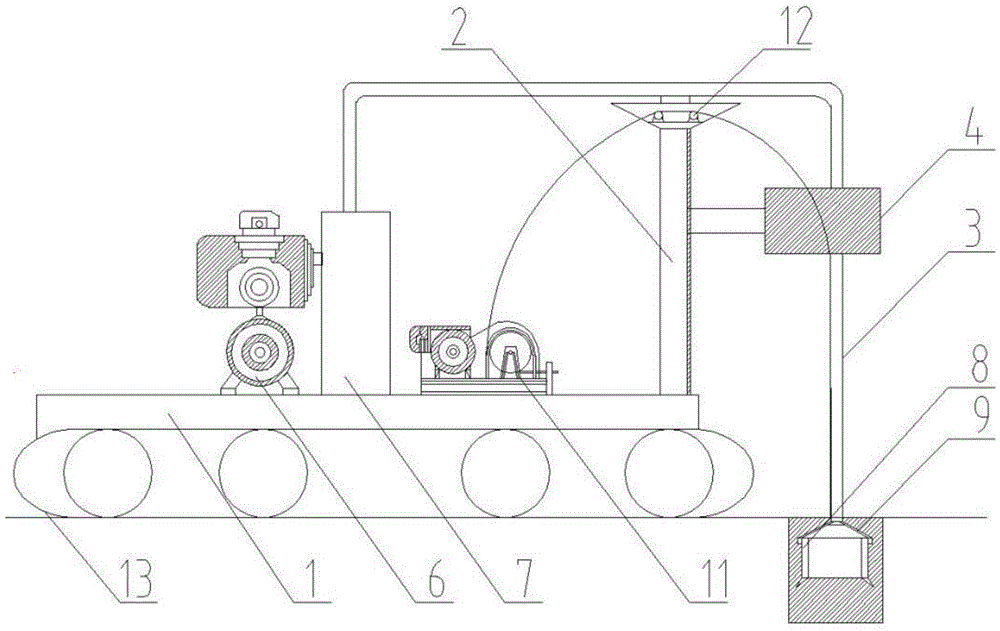

An integrated machine for pile foundation casing embedding and pile hole drilling

ActiveCN106032669BSolve the problem of collapsed holesFast drilling speedDrilling rodsDrilling casingsReinforced concreteDouble wall

The invention relates to a pile foundation casing embedding and pile pole drilling all-in-one machine. The machine comprises a bearing system, a drilling system, a casing embedding system and a guide tube lifting system; the drilling system comprises an air compressing machine set, a drill rod device, a revolving device and a drill bit; the casing embedding system comprises a casing and a casing connector; the casing comprises an inner wall and an outer wall; the casing connector is connected with the casing through a circumferential screw thread; the casing embedding drill rod is installed between the drill rod and the casing connector; the lower part of the casing embedding drill rod is connected with the casing connector; the casing has a double-wall hollow structure; the casing connector has a double-wall hollow structure; the guide tube lifting system comprises a hoist and a guide tube carrying steel bar concrete; the hoist is connected with the guide tube through wire ropes. The invention provides a pile foundation casing embedding and pile pole drilling all-in-one machine and solves the technical problems that hole collapse may occur during soft ground pile foundation drilling, and embedded casing is too long and cannot be pulled out so that material is wasted.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +2

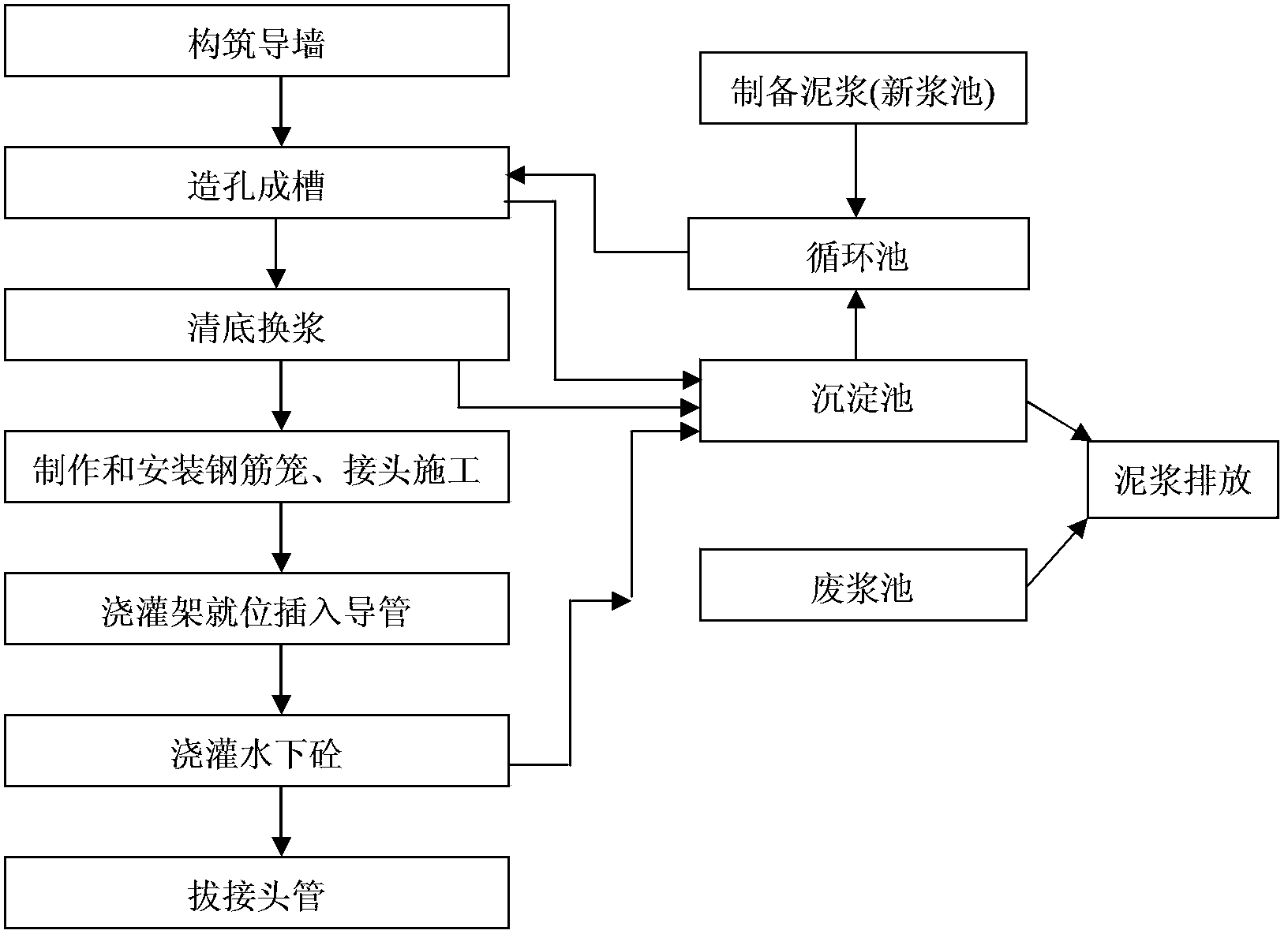

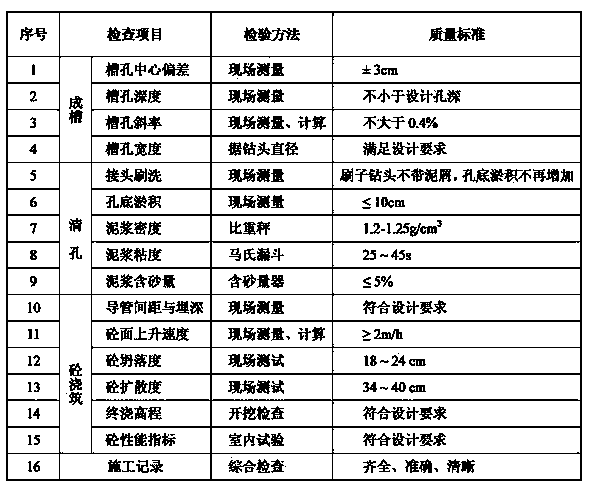

Construction method of concrete cut-off wall in sludge soil with high water content

InactiveCN102677630BSolve the problem of collapsed holesMeet the design requirementsDamsDykesSludgeSlurry

The invention relates to a construction method of a concrete cut-off wall in sludge soil with high water content. The construction method mainly comprises the steps of building a guide wall, preparing high-specific-gravity slurry, carrying out joint drilling to form grooves by an abrasion drill and an impact drill which are combined with each other, cleaning the bottom and replacing slurry, carrying out joint construction, manufacturing and installing a steel reinforcement cage, pouring concrete and the like. A construction technology of the concrete cut-off wall designed by the invention is suitable for carrying out high-quality drilling and grooving on river dams under the condition of a soft soil foundation by virtue of an abrasion drill and a percussion drill which are combined; the construction mechanism is clear and the construction quality is easy to control; after the construction is finished, a strict detection means and a reliable reinforcement measure can ensure that the engineering quality meets the design requirements, and the possible problem of hole collapse of the cut-off wall on the river dam can be thoroughly solved; multiple groups of devices can be easily organized to enter sites for construction, so that the construction period is ensured; and the construction method is easy to popularize in large area and especially applicable to river dam engineering in the sludge soil with the high water content.

Owner:ZHEJIANG HYDROPOWER CONSTR & INSTALLATIONCO

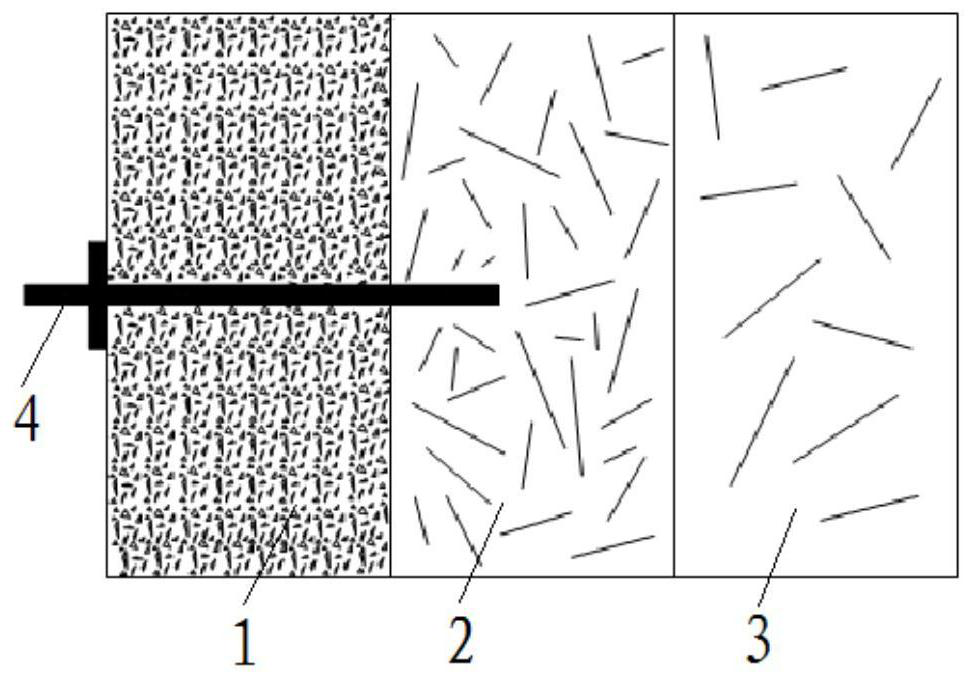

Step-by-step strengthening method by anchoring and forming hole in downward sleeve of cracking medium

InactiveCN102900446BSolve the problem of collapsed holesSmall overall deformationSealing/packingAnchoring boltsSlurryMechanical engineering

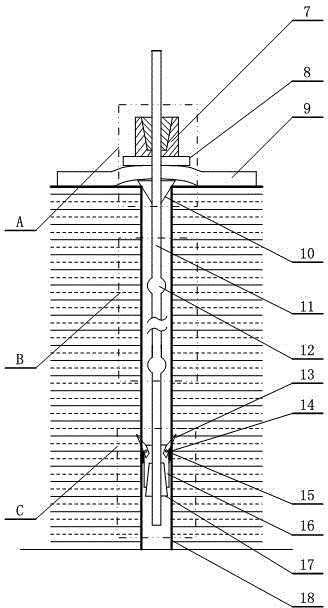

The invention relates to a step-by-sep strengthening method by anchoring and forming a hole in a downward sleeve of cracking medium. According to the strengthening method, a hollow grouting anchor rope of a related large-aperture pretension bottom plate comprises a fastening section A, a grouting section B and an anchoring section C, and the strengthening method mainly aims at solving the difficulties that holes are not easy to form in a weak and broken roadway bottom plate, a hole forming wall is poor in stability and suffers from hole collapse easily, and the bottom plate is difficult to anchor and strengthen. According to the strengthening method, the large-aperture wall protecting sleeve at the shallow part is grouted, so that the problems of hole collapse of the hole wall is solved, meanwhile high-flow high-pressure grouting is realized, the grouting time is saved, the slurry dispersion range is enlarged, a whole support structure is formed by utilizing a grouting anchor rope and a steel beam, the anchoring and the common loading of the anchor rope are realized simultaneously when a cracking rock body is grouted for fixing, and the great deformation of the bottom plate is solved effectively, and in addition, according to the method, the construction is easy, the operation is simple and convenient, the effect is obvious, the safety and the reliability are realized, and wide practicability is achieved.

Owner:CHINA UNIV OF MINING & TECH

Construction technology of cast-in-place piles in silt stratum with low temperature and high water content

InactiveCN108035340ASolve the problem of collapsed holesSolve the problem of too thick sediment at the bottom of the holeBulkheads/pilesCement slurryHigh water content

The invention belongs to the technical field of construction of cast-in-place piles and discloses a construction technology of the cast-in-place piles in the silt stratum with low temperature and highwater content with an aim to solve the problem about poor pile-forming quality in construction of cast-in-place piles in the silt stratum with low temperature and high water content. The technology includes the steps of 1), performing wall retaining of pile hole walls with high-viscosity wall retaining mud during drilling; 2), after wall retaining, grouting concrete in pile holes; 3), after concrete is grouted and formed, performing post-grouting with grouting cement slurry. With the technology, cast-in-place pile forming quality can be improved, and bearing capacity is improved by more than30%.

Owner:中冶成都勘察研究总院有限公司

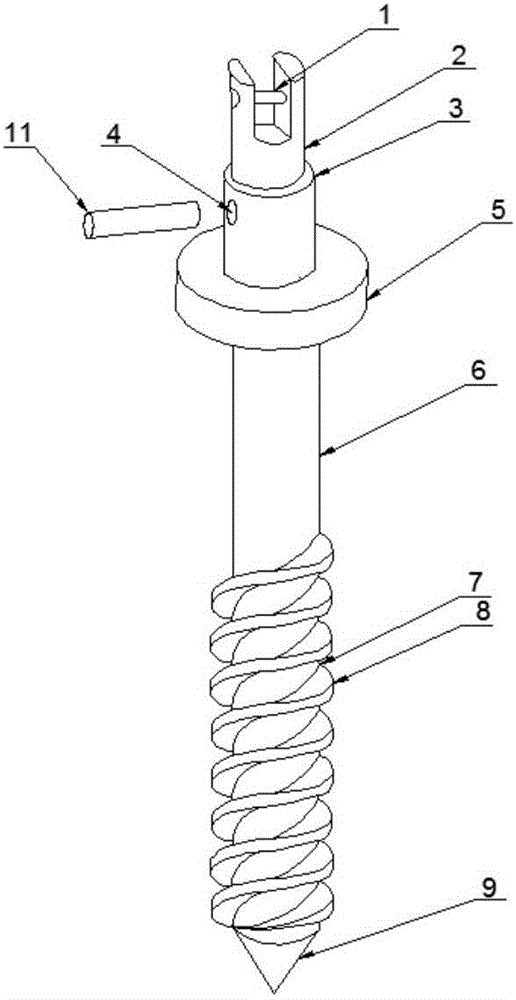

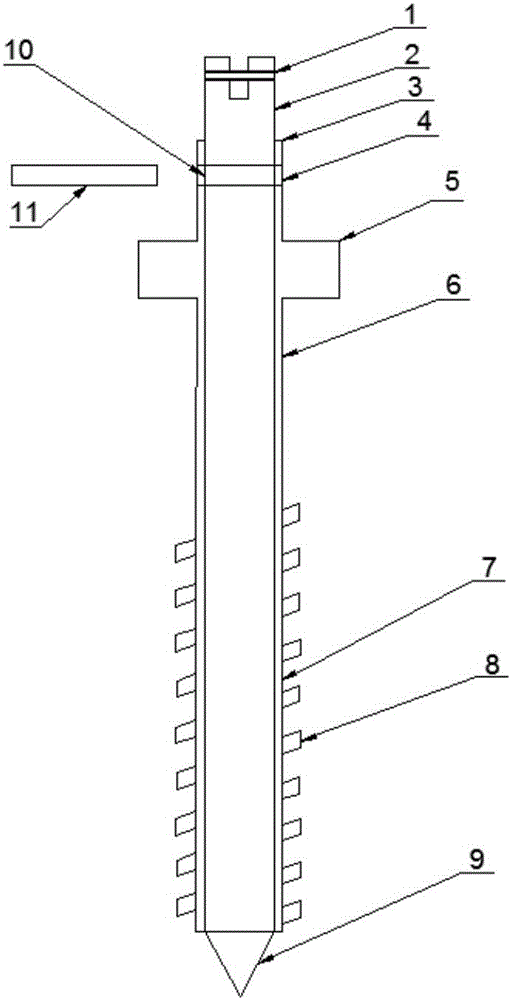

Novel screw grout pile construction tool capable of being repeatedly utilized

InactiveCN106498937ASolve the problem of collapsed holesSolve the sediment thicknessBulkheads/pilesHelical bladeArchitectural engineering

The invention provides a novel screw grout pile construction tool capable of being repeatedly utilized. The novel screw grout pile construction tool comprises an outer pipe body (6) and an inner pillar body (2), wherein an outer pipe neck ring (5) and a concrete inlet (3) are arranged at the upper end of the outer pipe body (6); a helical blade (8) is arranged at the lower end of the outer pipe body (6); a hook (1) is arranged at the upper end of the inner pillar body (2); a drill (9) is arranged at the lower end of the inner pillar body (2); an outer pipe connecting hole (4) is formed in the upper end of the outer pipe body; an inner pillar connecting hole (10) is formed in the inner pillar body; the two ends of the inner pillar connecting hole are through; the outer pipe body (6), the helical blade (8) and the drill (9) are manufactured through high-carbon steel; and the screw pitch of the helical blade (8) is smaller, and the thread of the helical blade (8) is denser. The novel screw grout pile construction tool has the advantage that the problems that holes collapse, the sediment is thick, piles are broken, the holes cannot be formed due to high underground water level, and excess concrete is utilized, of pile foundations of swivel-driven piles are solved.

Owner:廖梓婷

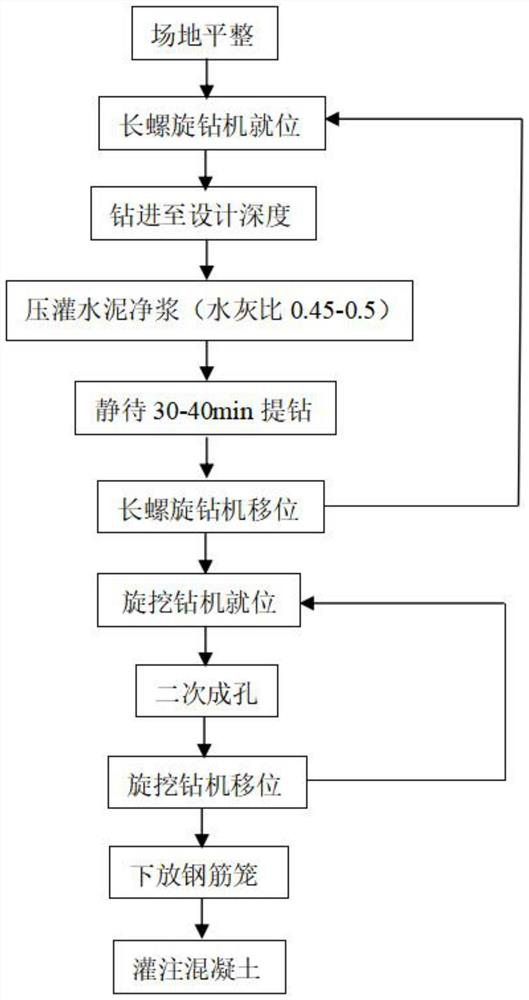

Dry sandy gravel stratum cast-in-place pile construction method

PendingCN114837171AAvoid the effects of side frictionImprove bearing capacityBulkheads/pilesCement pasteRebar

The invention discloses a construction method for a cast-in-place pile in a dry sandy gravel stratum. The construction method comprises the following steps that a site is leveled; a long spiral drilling machine is adopted for pre-forming holes, and cement paste is poured in a pressing mode; the method is suitable for the technical field of pile foundation hole forming, effectively combines the advantages of a long spiral and a drilling rig, effectively solves the problem of hole collapse, avoids the influence of mud cake on pile side friction resistance, improves the pile foundation bearing capacity, improves the pile foundation construction quality, reduces the construction cost and improves the construction efficiency. And the construction cost is effectively reduced.

Owner:CHINA COAL GEOLOGY GRP CO LTD

Pile foundation casing embedding and pile pole drilling all-in-one machine

ActiveCN106032669ASolve the problem of collapsed holesFast drilling speedDrilling rodsDrilling casingsReinforced concreteDouble wall

The invention relates to a pile foundation casing embedding and pile pole drilling all-in-one machine. The machine comprises a bearing system, a drilling system, a casing embedding system and a guide tube lifting system; the drilling system comprises an air compressing machine set, a drill rod device, a revolving device and a drill bit; the casing embedding system comprises a casing and a casing connector; the casing comprises an inner wall and an outer wall; the casing connector is connected with the casing through a circumferential screw thread; the casing embedding drill rod is installed between the drill rod and the casing connector; the lower part of the casing embedding drill rod is connected with the casing connector; the casing has a double-wall hollow structure; the casing connector has a double-wall hollow structure; the guide tube lifting system comprises a hoist and a guide tube carrying steel bar concrete; the hoist is connected with the guide tube through wire ropes. The invention provides a pile foundation casing embedding and pile pole drilling all-in-one machine and solves the technical problems that hole collapse may occur during soft ground pile foundation drilling, and embedded casing is too long and cannot be pulled out so that material is wasted.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +2

The Construction Method of Using Grouting Steel Pipe Pile to Strengthen Complicated Strata

ActiveCN112049102BImprove curing effectSimple preparation processBulkheads/pilesSoil preservationSlurryPipe

The invention relates to the technical field of construction engineering, in particular to a construction method for reinforcing complex strata by using grouted steel pipe piles. The method comprises the following steps: (1) compacting the site to ensure that the site is level, and performing measurement and positioning; (2) The position to be positioned is drilled with a drilling machine to form a pile hole; (3) The grouting pipe is inserted to the bottom of the pile hole and the slurry is injected until the pure slurry emerges from the pile hole by using the grouting method at the bottom of the hole. out, terminate the grouting; (4) install the steel pipe at the pile hole position. The invention has the advantages of short curing time and excellent mechanical properties.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com