Construction method of concrete cut-off wall in sludge soil with high water content

A technology for concrete cut-off walls and silty soils, applied in dikes, dams, coastline protection, etc., can solve the problems of discontinuous cut-off walls, inability to form continuous curtains, and no reliable detection means, etc., to achieve easy control of construction quality, The effect of solving the collapse hole of the anti-seepage wall and being easy to promote in a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

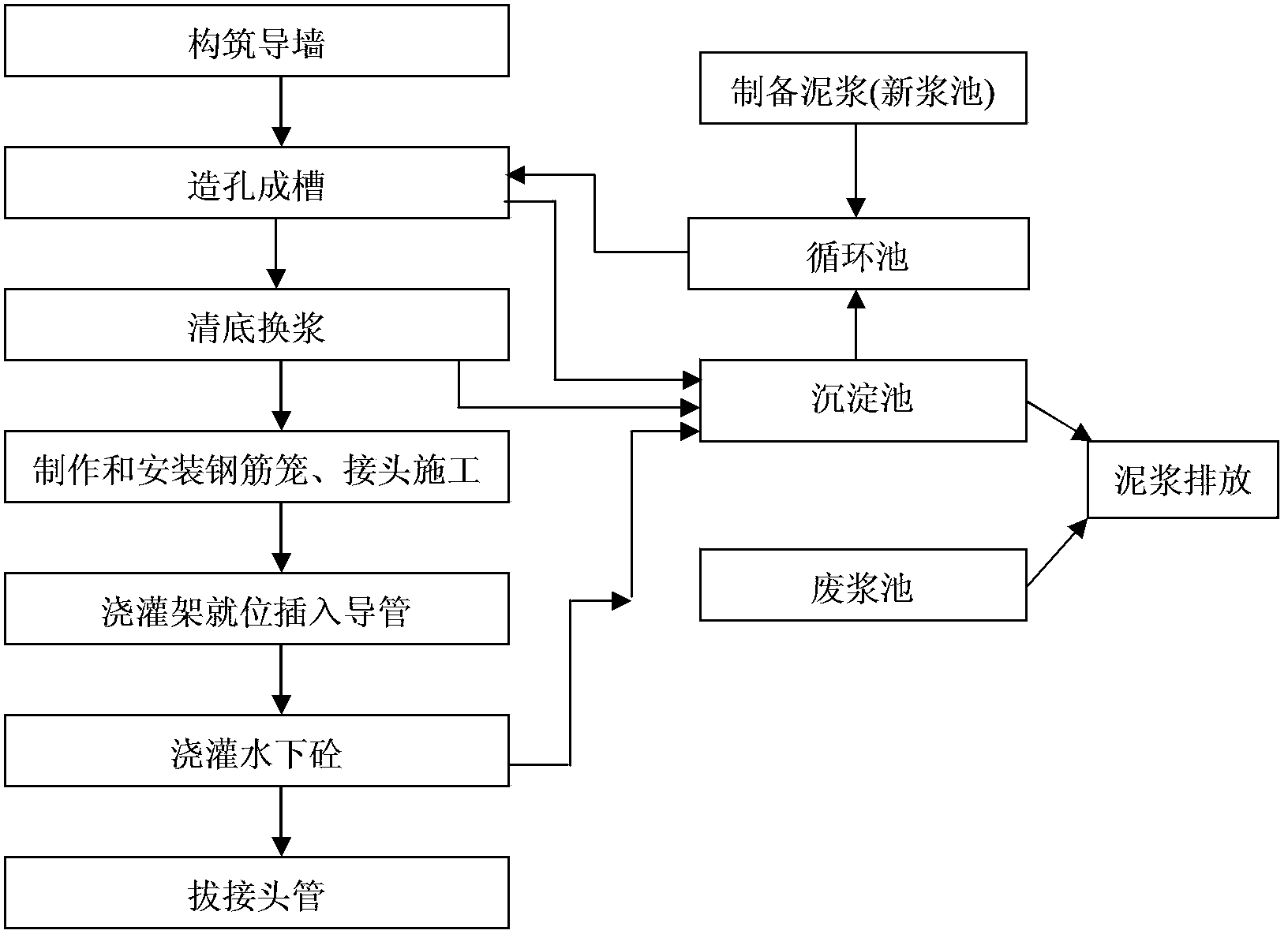

[0023] Embodiment 1 The construction method of the concrete anti-seepage wall of the Golden Bay Regulating Reservoir, see figure 1 , including the following steps:

[0024] (1) Construct the guide wall: use the total station to release the axis of the anti-seepage wall, and release the position of the guide wall. According to the requirements of the design drawings of the guide wall, the excavation of the guide wall is excavated by a small excavator, and the bottom is cleaned manually to withstand the ground. To load and stabilize the mud level, use a small excavator to excavate a guide wall with a width of 90 cm and a top surface 10 cm above the ground.

[0025] (2) Preparation of large specific gravity mud: Rotary drilling is used to make holes. The mud is mainly made from the original hole, and the slurry made of high-quality bentonite and CMC chemical agent are properly added to improve the mud performance. 3 The newly configured mud contains 106kg of bentonite, 1.06kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com