Construction technology of cast-in-place piles in silt stratum with low temperature and high water content

A technology with high moisture content and construction technology, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor quality of piles, achieve the effects of improving forming quality, good condensation effect, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The construction technology of cast-in-place pile in silt formation with low temperature and high water content of the present invention comprises the following steps:

[0054] (1) Use high-viscosity wall-protecting mud to protect the wall of the pile hole during the drilling process;

[0055] (2) Concrete is poured into the pile hole behind the retaining wall;

[0056] (3) Post-grouting with grouting cement slurry after concrete pouring and molding.

Embodiment 2

[0058] The construction technology of cast-in-situ piles in silt formation with low temperature and high moisture content of the present invention comprises the following steps:

[0059] (1) Use high-viscosity wall-protecting mud to protect the wall of the pile hole during the drilling process;

[0060] (2) Concrete is poured into the pile hole behind the retaining wall;

[0061] (3) Post-grouting with grouting cement slurry after concrete pouring;

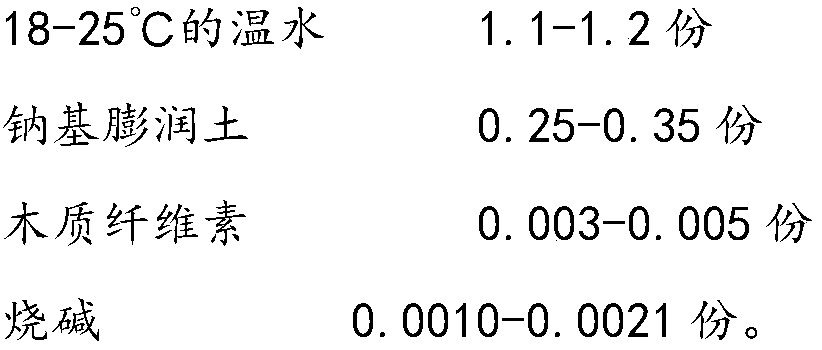

[0062] Wherein the high-viscosity wall protection mud in the above-mentioned steps (1) is made up of the raw material of following weight ratio:

[0063]

Embodiment 3

[0065] The construction technology of cast-in-situ piles in silt formation with low temperature and high moisture content of the present invention comprises the following steps:

[0066] (1) Use high-viscosity wall-protecting mud to protect the wall of the pile hole during the drilling process;

[0067] (2) Concrete is poured into the pile hole behind the retaining wall;

[0068] (3) Post-grouting with grouting cement slurry after concrete pouring;

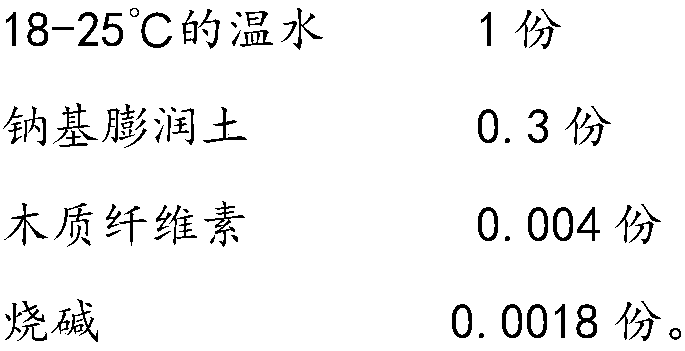

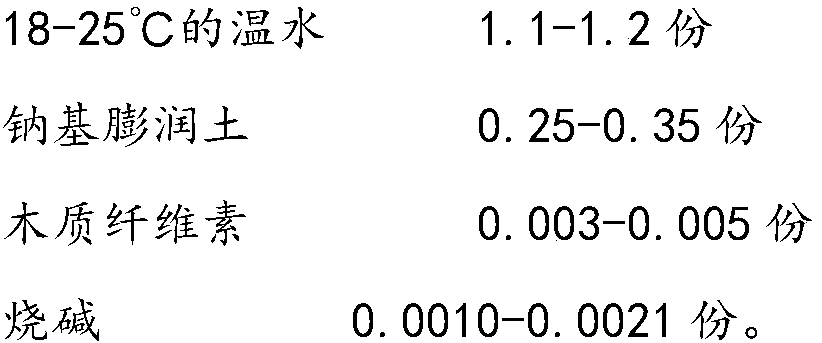

[0069] Wherein the high-viscosity retaining wall mud in the above-mentioned steps (1) is made up of the raw material of following weight ratio:

[0070]

[0071]

[0072] Wherein the grouting cement slurry in the above-mentioned steps (3) is made up of the raw material of following weight ratio:

[0073] 2-3.5 parts of tap water at 1-3°C

[0074] 0.8-1.2 parts of warm water at 18-25°C

[0075] Chlorine-free antifreeze 0.001-0.003 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com