Step-by-step strengthening method by anchoring and forming hole in downward sleeve of cracking medium

A casing and hole-forming technology, which is applied in earthwork drilling, installation of bolts, wellbore/well parts, etc., can solve problems such as large deformation of the bottom plate, achieve large deformation, increase the range of grout diffusion, and save grouting the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

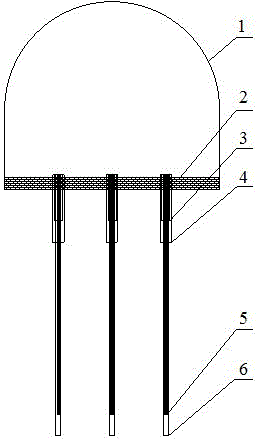

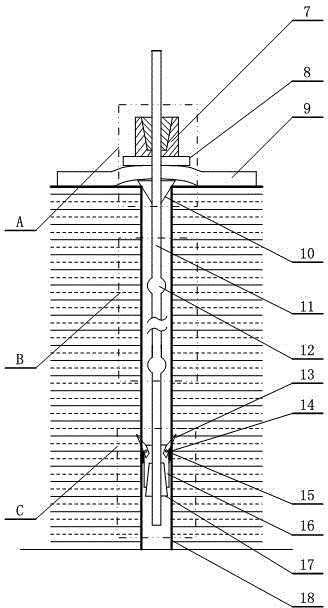

[0020] In the figure, the large-aperture pre-tensioned bottom plate hollow grouting anchor cable involved in the fragmented medium down casing hole forming and anchor injection step-by-step reinforcement method includes a fastening section A, a grouting section B and an anchoring section C, The fastening section A includes an outer anchor section lock 7, a gasket 8, a tray 9 and a hole sealer 10. The outer anchor section lock 7 is set on the cable body 11, and the bottom of the cable body 11 is fixed with a gasket 8, The disc-shaped tray 9 arched upward in the middle and the hole sealer 10 in the shape of an inverted cone, the hole sealer 10 is firmly pressed on the hole of the anchor hole, so as to realize the full anchor and grouting anchor cable 5 in the entire drilling depth. The closure of; the grouting section B includes a cable body 11 and a birdcage grouting section 12, and the birdcage grouting section 12 is formed by combining a plurality of steel strands and a grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com