Offshore wind power batter pile rock-socketed construction hole collapse treatment device, using method and treatment method

An offshore wind power and processing device technology, which is applied to drilling equipment and methods, wind power generation, and configuration of installation/support of wind turbines, etc., can solve problems such as ship machinery materials and personnel consumption, inability to guarantee construction progress, and increase construction difficulty. , to ensure the safety of offshore operations, convenient and fast construction, and fast construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

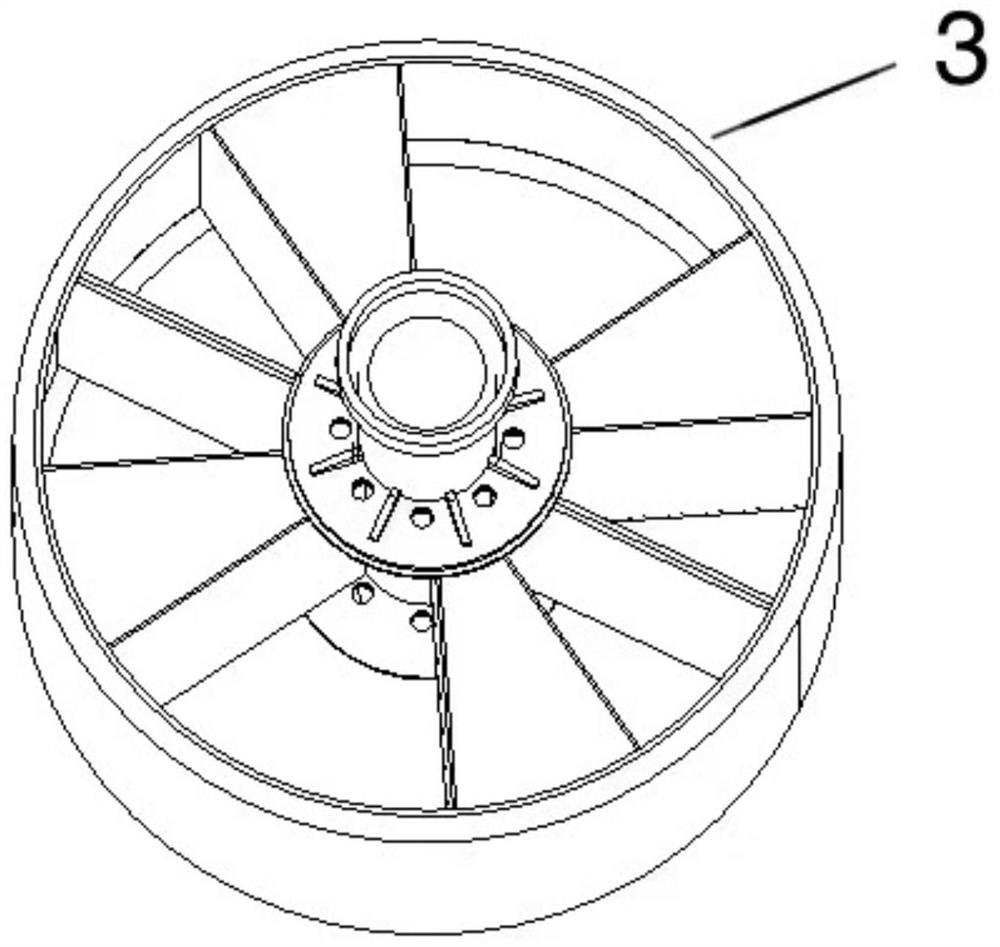

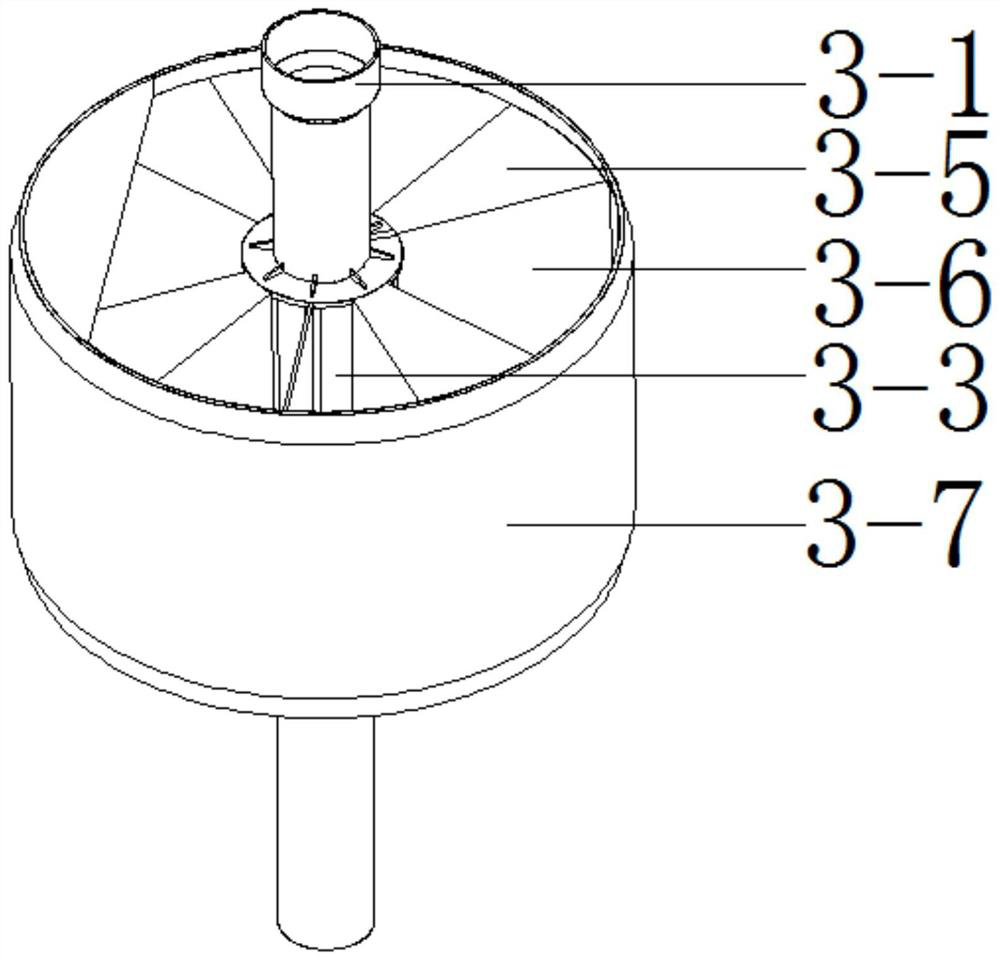

[0058] The operation and construction steps of the inner casing follower 3 are as follows:

[0059] Step A, welding and fixing the center drill pipe and the upper and lower baffles together, the rollers are evenly distributed around the center drill pipe through the pin shaft, and form a combination with the center drill pipe;

[0060] Step B, connecting the central cylinder with the wing plate, the web, and the annular steel ring to form a casing pressing device, which is divided into two symmetrical parts, which are connected by flanges;

[0061] Step C, connecting the casing pressing device with the center drill pipe through the central casing, and connecting all the components together to form the inner casing follower 3;

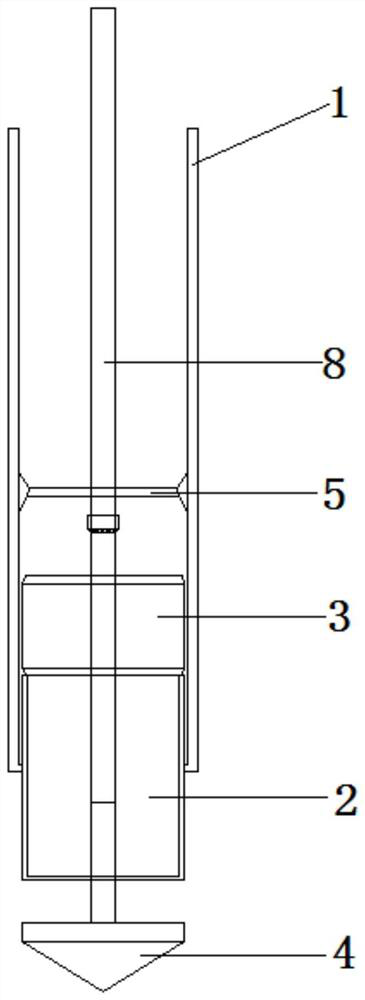

[0062] Step D. Transport the follow-up device to the sea. The central drill pipe and the matching drill pipe 8 are lowered into the steel pipe pile 1 through screw connection, the drilling rig is started, and the center structure of the inner casing fol...

Embodiment 2

[0064] When the inclined pile collapses, the drilling rig is used to promptly raise the drill bit 4, and the steel pipe pile 1 is continuously injected with water to keep the water head in the steel pipe pile 1 higher than the sea level as much as possible to form a pressure difference and prevent further expansion of the collapsed area. The steel pipe pile 1 has a well-processed casing, and the hole collapse position is generally 1-3 meters away from the steel pipe pile 1 pile end, and the inner casing is generally 4-6 meters long. Drill down and lower the casing follower. Here, the position of the follower should be calculated in advance according to the length of the inner casing to ensure that the drill bit is always about 50cm below the inner casing during the pressing down of the inner casing. Then, start sand pumping to clear the hole. At the same time, driven by the drilling rig, the casing follower pushes down against the inner casing. The position of the inner casing...

Embodiment 3

[0066] During a drilling construction process, the hole collapsed when drilling to 45m. The designed hole depth is 47m, the steel pipe pile 1 is 38m long, the collapsed hole is at 1.2m from the end of the steel pipe pile 1, and the steel pipe pile 1 has been raised by the drill bit. Now use this method to deal with the hole collapse of offshore wind power inclined pile rock-socketed construction, and the specific construction steps are as follows:

[0067] Step 1, processing and guiding the side wall of the inner casing 2: open some small holes on the side wall of the inner casing 2, and use iron wires to vertically bind some guiding steel bars 6 to the outside of the inner casing 2 to achieve the guiding purpose. The guiding steel bars 6 are wide, The average height is 4cm, the length is 4m, the length of the inner casing 2 is 5m, and the diameter is 1.9m. Three overflow holes 7 are respectively opened at 2m and 3m from the bottom of the inner casing 2.

[0068] Step 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com