Patents

Literature

33results about How to "Strong waterproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

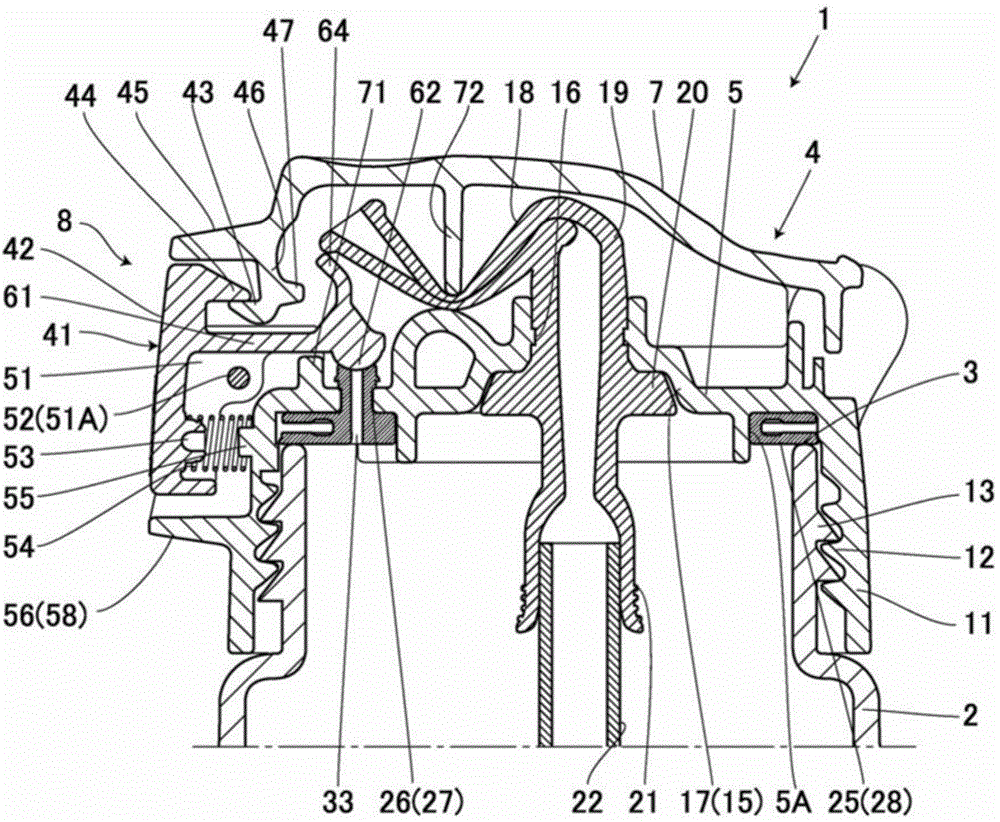

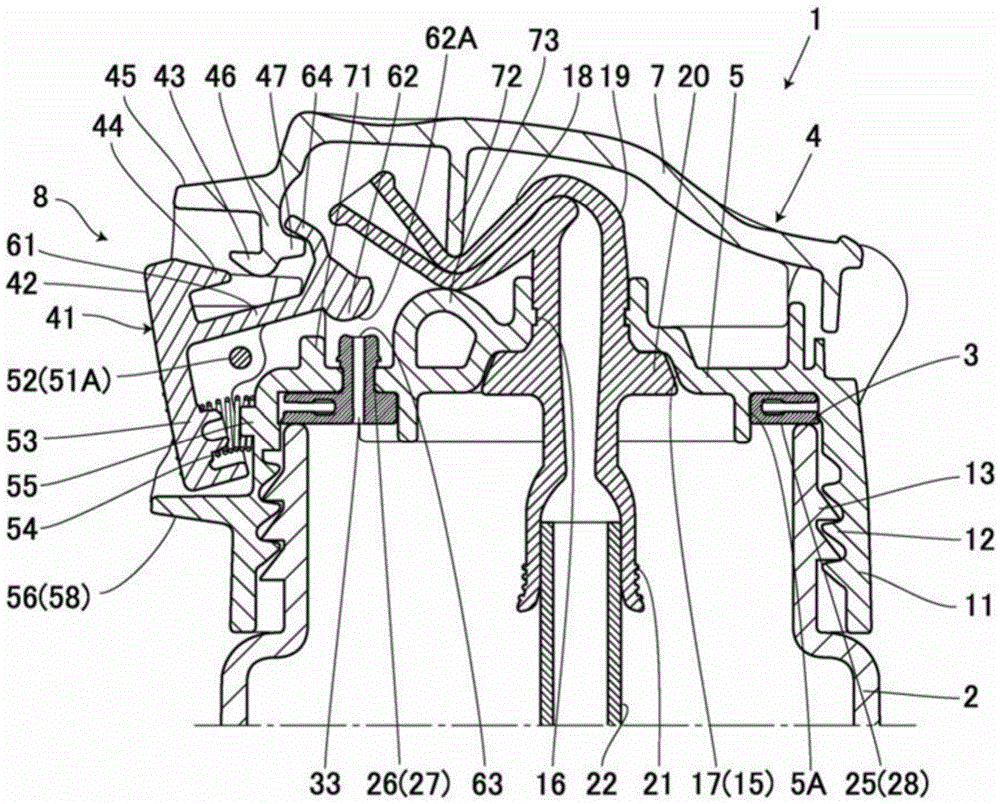

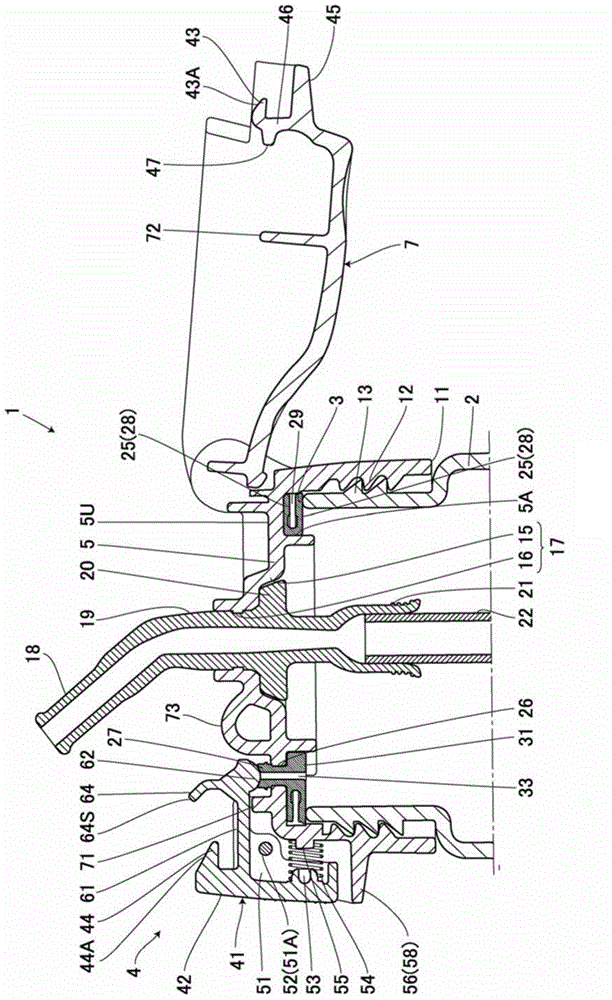

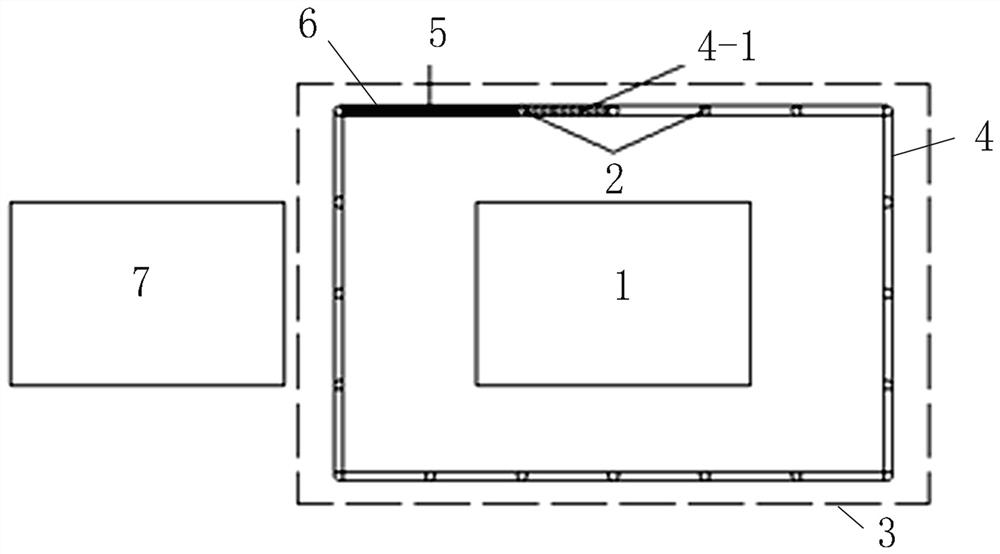

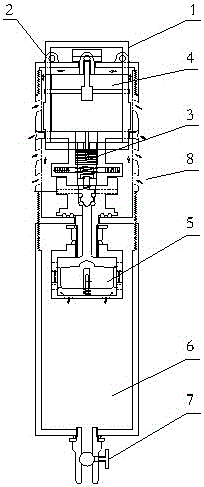

Beverage container

ActiveCN104417958ASimple and efficient operationStrong waterproofNon-removalbe lids/coversThermally-insulated vesselsDrinking strawInternal pressure

The invention provides a beverage container, wherein the liquid beverage is prevented from bursting out of the container and leaking to the outside only based on the simple operation, while the inner pressure of the container is reduced during the attraction removing process. The rotating end of a cover body (7) is inwardly provided with an inner clamping piece (47), and an inner clamping part (64) clamped / seperated from the inner clamping piece (47) is arranged on a button component (42). Through pressing down the button component (42), the closed state of the cover body (7) is released. A vent hole (33) is opened to be communicated with the external air, and then the inner clamping piece (47) is clamped with the inner clamping part (64). In this way, the cover body (7) is in a temporarily stopping state. After that, the button component (42) is not pressed down any more, and then the cover body (7) is not in the temporarily stopping state.

Owner:THERMOS CHINA HOUSEWARES +1

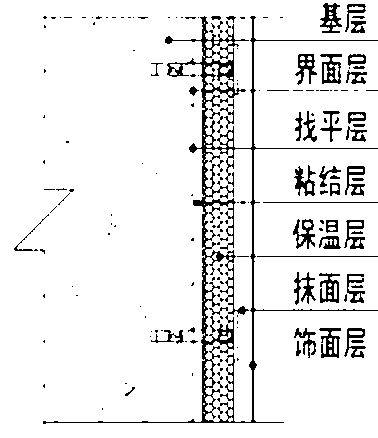

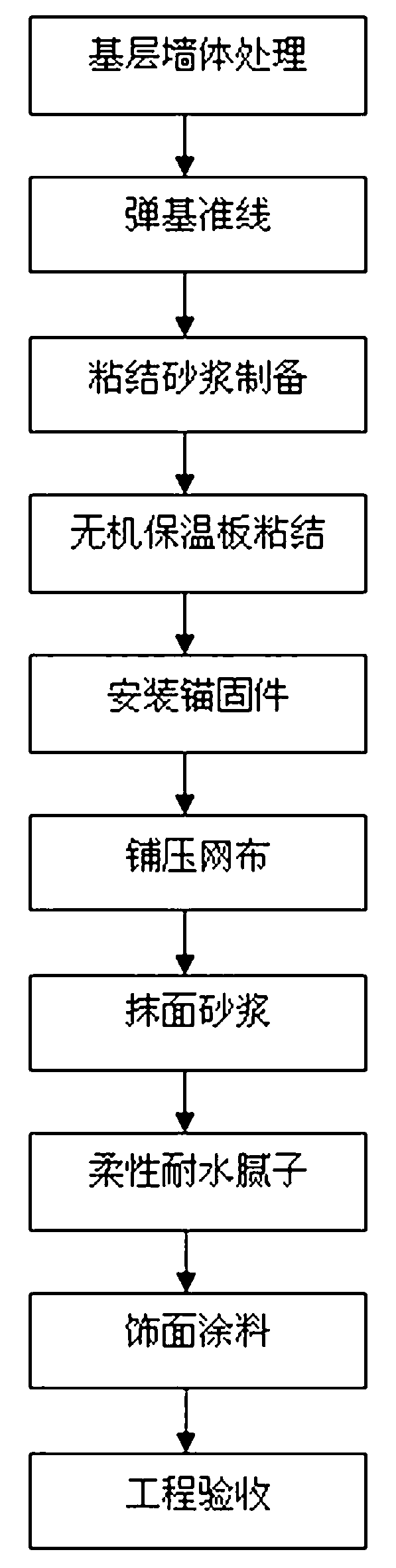

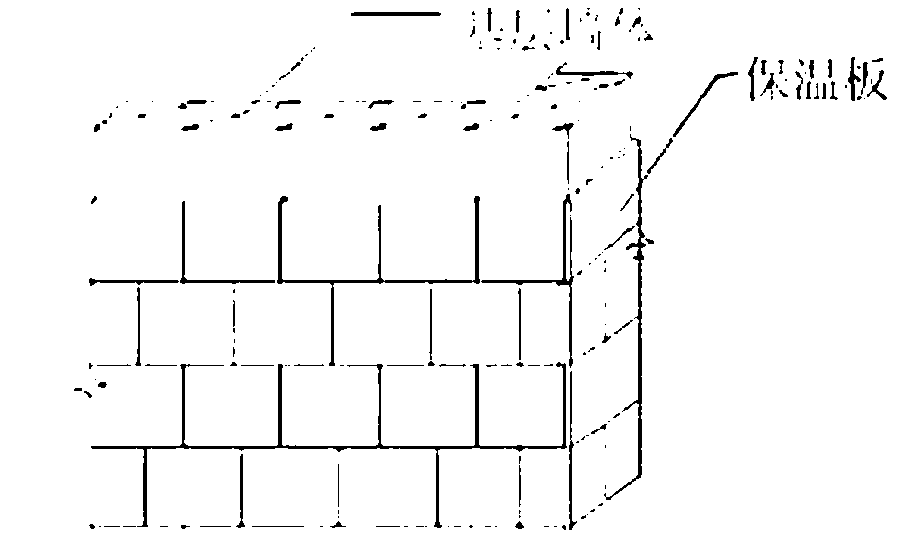

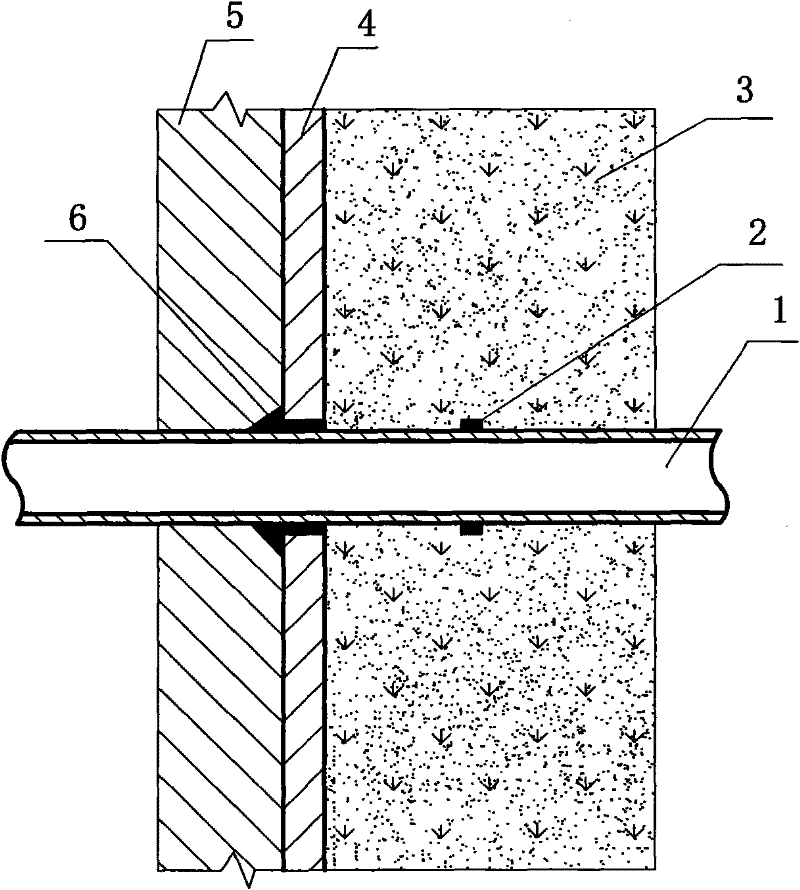

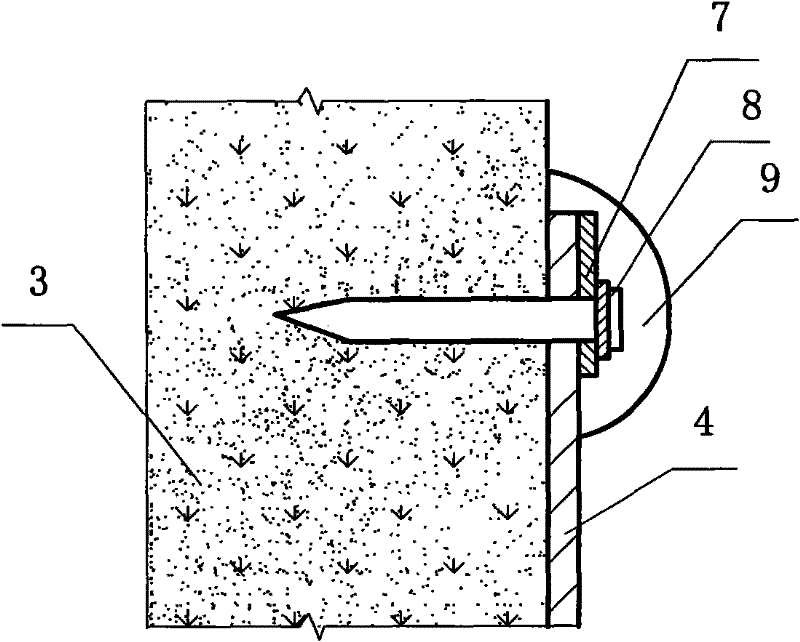

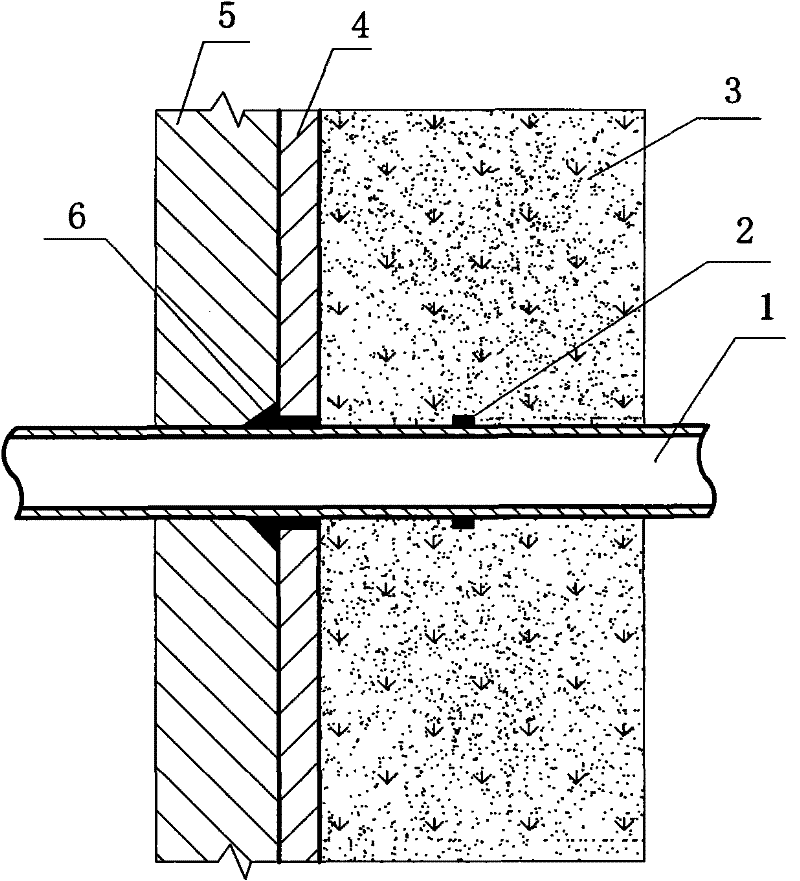

Inorganic fireproof insulation board and manufacturing method and application thereof and external thermal insulation system

InactiveCN103224376AGood thermal insulation and energy saving effectStrong waterproofHeat proofingFire proofingThermal insulationSodium silicate

The present invention provides an inorganic fireproof insulation board and a manufacturing method and application thereof, wherein the inorganic fireproof insulation board comprises glass beads, sodium silicate, a water repellent, water, calcium carbonate powder and hydroxymethyl cellulose; the preparation process comprises raw materials preparing, mixing and stirring, pressing and molding, drying and packaging etc. The inorganic fireproof insulation board provided by the present invention can be applied in an external thermal insulation system, and has advantages of good effects of heat-preservation, insulation and energy saving, excellent fire-resistant performance and weathering resistance, high cost-performance radio, superior anti-cracking and water-resistance, convenient and rapid construction, and is comfortable and environment-protective.

Owner:NO 1 BRANCH ZHUOZHOU BOYIN METAL STRUCTURE

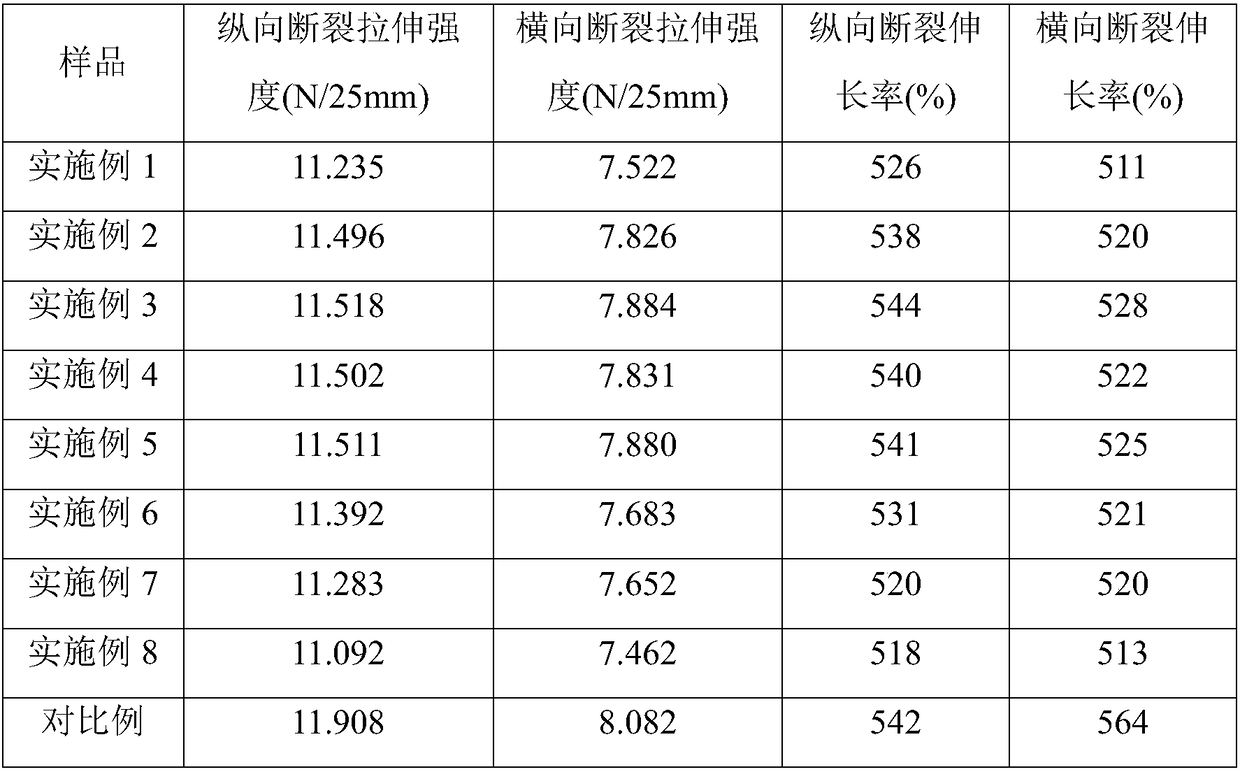

Ultrathin cast film as well as preparation method thereof and application thereof

InactiveCN108129735AImprove water barrier effectEasily brokenFlexible coversWrappersCast filmsMaterials science

The invention discloses an ultrathin cast film. According to the technical scheme, the key point isThe ultrathin cast film is characterized that the ultrathin cast filmby comprises comprising the following components: 7-12 parts of LDPE, 20-25 parts of LLDPE, 30-55 parts of HDPE, 3-5 parts of MLLDPE, 1-3 parts of PP and 5-8 parts of color master batch. The invention further discloses a preparation method for the ultrathin cast film, and the preparation method comprises the following steps: adding materials; performing extrusion plastifying; , extrusion casting, calendaring, setting and cooling; performing corona treatment; and trimming and rolling, wherein during calendaring, setting and cooling, the temperature of a rubber roller is set to be 50-55 DEG C, the temperature of an embossed steel stick is set to be 60-65 DEG C and pulling speed is 60-80 m / min. On the premise of keeping barrier properties, waterproof properties, softness, tensile properties and breakage properties of the cast film, the thickness of the cast film is reduced, the unit weight yield is increased, and the cost is reduced.

Owner:天津市德利塑料制品有限公司

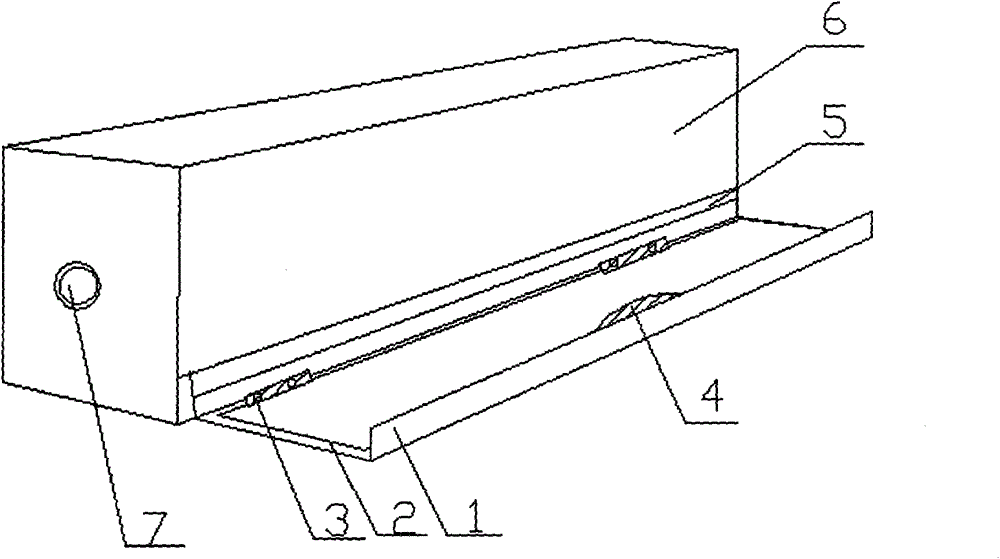

Modified asphalt compound waterproof rolling material

InactiveCN101701486AStrong waterproofEasy constructionRoof covering using flexible materialsBituminous waterproofingBuilding material

The invention relates to the technical field of building materials, in particular to a modified asphalt compound waterproof rolling material with high strength and difficult aging. The modified asphalt compound waterproof rolling material consists of a modified asphalt waterproof layer, an upper surface layer and a lower surface layer, wherein a non-woven fabric layer is arranged in the modified asphalt waterproof layer, adhesive layers are arranged on the upper surface and the lower surface of the non-woven fabric layer, and a filler is arranged in the modified asphalt waterproof layer. Due to that the asphalt waterproof layer is adopted as a main material of the rolling material, the rolling material has stronger waterproof property and convenient construction. The modified asphalt layer can not only effectively utilize a large number of industrial, civil and other waste plastic and other items, but also play the environmental protection role and be characterized by low production cost and long working life. The product is applicable to the leak-proof building materials of a variety of top floors, and can greatly reduce the cost of a construction project and realize simple operation, thereby being applicable to popularization and having broad market application prospects.

Owner:陶春森

High-intensity waterproof putty powder

The invention discloses high-intensity waterproof putty powder, which comprises the following raw materials in parts by weight: 55-60 parts of mineral powder, 1.8-2.5 parts of adhesives, 3-5 parts of citric acid, 1-3 parts of alkali water, 7-9 parts of talcum powder, 3-5 parts of brightening agents, 4-6 parts of emulsion and 8-15 parts of waterproof power. The high-intensity waterproof putty powder, provided by the invention, has the advantages of high compression strength, strong waterproof property, scrubbing resistance, no toxicity and bad smell, capability of never changing the color and effectively avoid damage on a human body, convenient and quick operation, and low cost.

Owner:HAIAN GUOLI CHEM

Guide rail protective cover suitable for numerical control machine tool

InactiveCN104608001ASimple structureStrong waterproofLarge fixed membersMaintainance and safety accessoriesEngineeringHigh pressure

The invention discloses a guide rail protective cover suitable for a numerical control machine tool. The guide rail protective cover comprises a protective plate, a protective layer, a hinge, a wedging block, a spring shaft, a protective cover body and a guide rail hole, wherein the protective layer is arranged on the protective plate; the protective plate is connected with the protective cover body through the hinge; the wedging block is arranged in the middle of the top end of the protective plate; the spring shaft is arranged at the lower end of the protective cover body; and the guide rail hole is formed in the middle of the protective cover body. The guide rail protective cover suitable for the numerical control machine tool has the advantages of simple structure, wear resistance, high temperature and high pressure resistance, strong waterproof performance and capability of effectively protecting a guide rail of the numerical control machine tool.

Owner:TAIZHOU TONGFANG NUMERICAL CONTROL MACHINE TOOL CO LTD

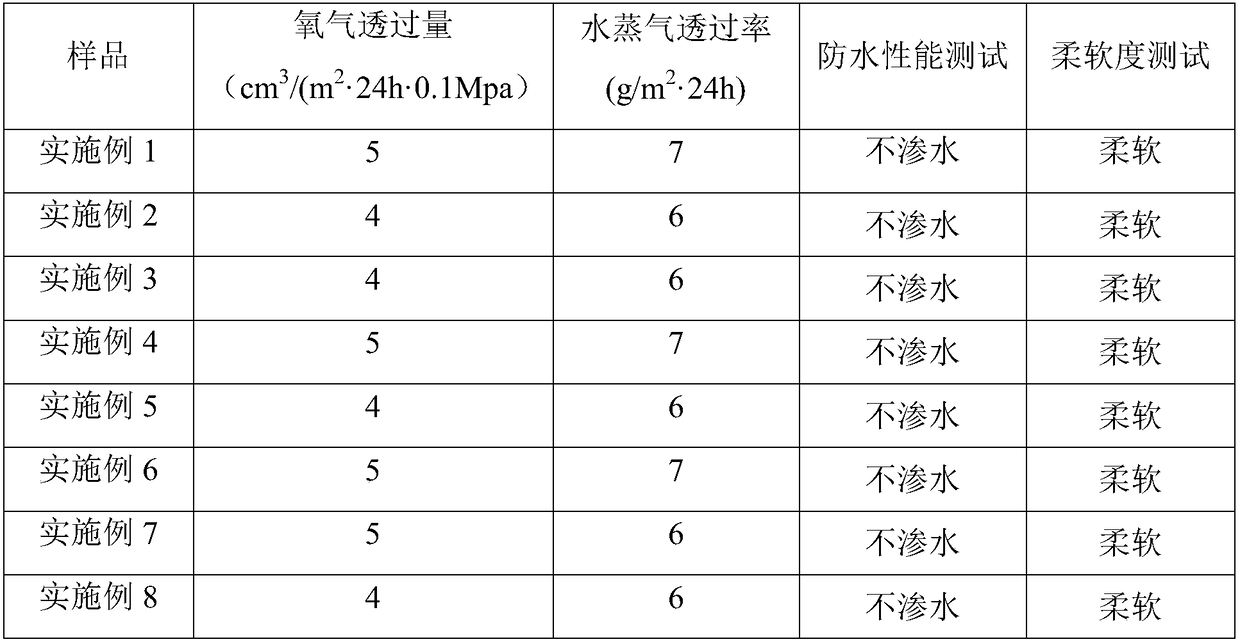

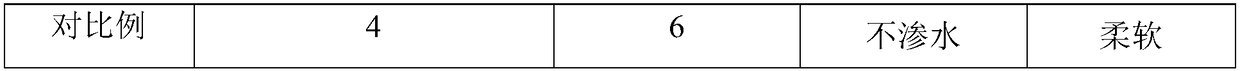

Waterproof flexible material for external insulating wall space

InactiveCN107446404AStrong water resistance and adhesionStrong waterproofFilling pastesWeather resistanceEnvironmental resistance

The invention discloses a waterproof flexible material for an external insulating wall space. The material is prepared from the following raw materials in parts by weight: 235-245 parts of silicate cement, 568-570 parts of sand, 14-152 parts of ground calcium carbonate powder, 18-22 parts of redispersible rubber powder 5044N, 14.5-15.5 parts of redispersible rubber powder 8034H, 1.8-2.2 parts of cellulose ether, 2.7-3.4 parts of wood fibers and 0.8-1.2 parts of an organosilicone water repellent. The waterproof flexible material for the external insulating wall space disclosed by the invention not only has extremely high water resistance and caking property, but also has the advantages of high-low temperature change resistance, crack resistance and the like, solves the problem that existing external wall putty powder is relatively poor in weather resistance, is free of phenomena of hollowing, peeling, cracking and falling if encountering with water and being moisturized, is extremely high in waterproofness, green and environment-friendly, good in flexibility, difficult to pulverize, is fine and smooth in surface texture if being scraped, and is safe and environment-friendly and long in service life.

Owner:合肥翠鸟节能建材有限公司

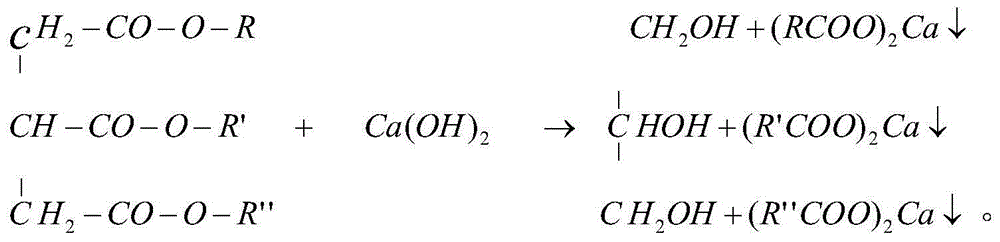

Penetrating waterproof agent prepared by taking gutter oil as raw material as well as preparation method and application method thereof

The invention relates to a penetrating waterproof agent prepared by taking gutter oil as a raw material as well as a preparation method and application method thereof. The raw material of the penetrating waterproof agent includes the gutter oil pretreatment liquid. The raw material is subjected to reaction emulsification to form a non-ionic emulsion, and most of the colloidal particles have remarkably high hydrophobicity. The grease particles and rosin particles can react with the hydration product calcium hydroxide of cement or concrete to form an insoluble calcium soap complex adsorption layer, so that the cement or concrete and the products thereof are dense and waterproof. Due to the remarkably strong non-ionic feature, the emulsion can penetrate into the innermost layer through the pores in the surface layer, and the oily particles and calcium soap complex in the emulsion are adsorbed on the cement or concrete from the surface layer to the innermost layer in the penetration process to form a tight and dense calcium soap surface layer and realize perfect waterproofing and anti-seepage effects.

Owner:嘉兴市燕知网络科技有限公司

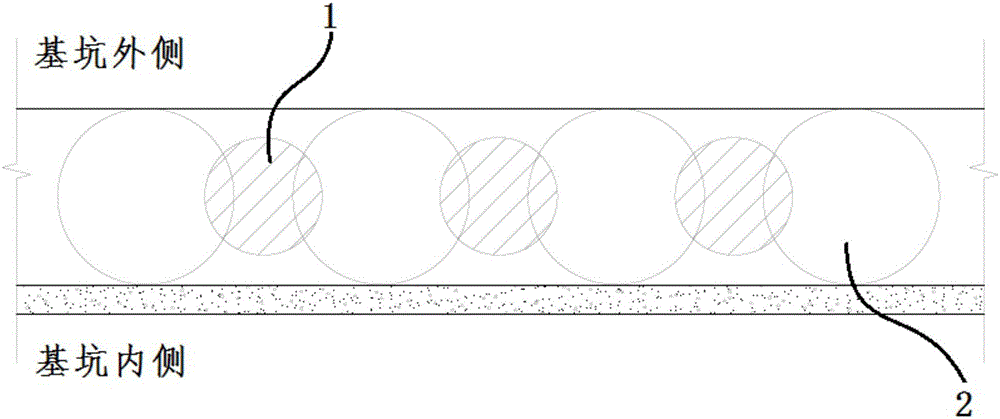

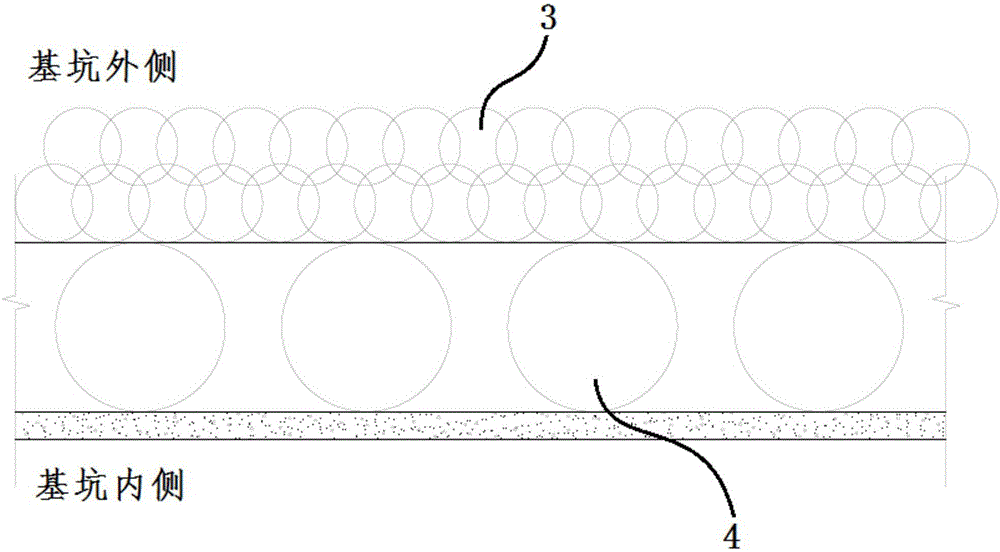

Foundation pit bracing water stopping structure with support pile and three-axis stirring pile arranged in cased drilling manner

Provided is a foundation pit bracing water stopping structure with a support pile and a three-axis stirring pile arranged in a cased drilling manner. The support pile is constructed on the outer side of a foundation pit; the stirring pile is constructed in a support pile area in a three-axis stirring manner; and the support pile directly cuts a pile body on the three-axis stirring pile for construction, and the whole bracing water stopping structure is formed. The three-axis stirring pile is large in power, and can perform stirring in strong-weathered rock and the above stratum. Compared with a conventional small diameter cement stirring pile, the beneficial effects of being small in number of lap joints, good in water stopping effect, high in construction efficiency, high in stratum adaptability and the like are achieved; and compared with a jet grouting pile, the beneficial effects that the water stopping effect is good, and price is low are achieved. According to the foundation pit bracing water stopping structure with the support pile and the three-axis stirring pile arranged in the cased drilling manner, the support pile and the three-axis stirring pile are combined together, construction is performed in the manner that the support pile and the three-axis stirring pile arranged in the cased drilling manner, the stratum condition can be improved, the problem of hole collapse of the support pile is effectively solved, a water stopping effect better than that of the conventional stirring pile and the jet grouting pile can also be achieved, meanwhile the occupied space of a supporting structure is saved, and the water stopping capacity of an existing pile-in-row bracing water stopping structure is enhanced.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

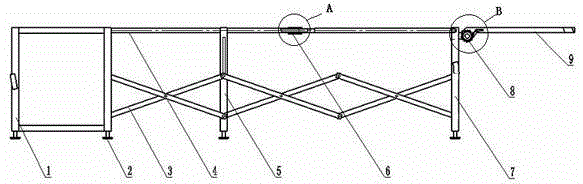

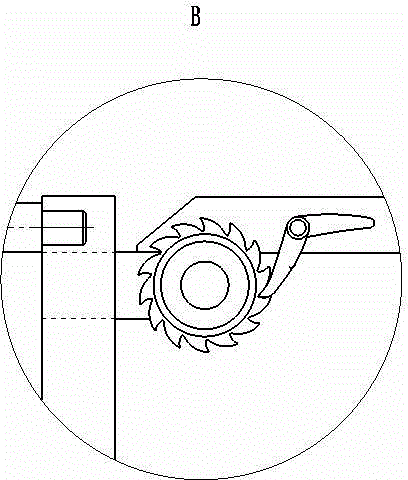

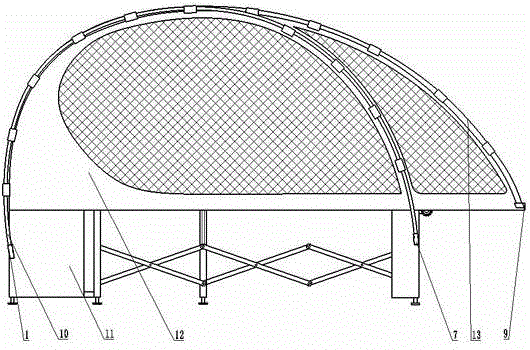

Multifunctional travel tent

The invention discloses a multifunctional travel tent and relates to the technical field of manufacture of travel accessories. The multifunctional travel tent comprises a box rack and a box wall surrounding the box rack, wherein two sides of one end of the box frame are connected with a rear frame through a plurality of groups of cross connection rods which are sequentially hinged to one another respectively, each group of cross connection rods comprise two rod pieces, middles of the two rod pieces are connected with each other through a hinge shaft, the upper end of the rear frame is connected with a tail frame through a hinge shaft, and a rotation limiter is installed between the rear frame and the tail frame to limit the rotation position of the tail frame around the rear frame. In the state of prop-up of a tarpaulin, at least two of support rods are inserted between the box rack and the rear frame, and one end of each of the at least two of support rods is inserted in the outer end of the tail frame. According to the multifunctional travel tent, the problem that existing outdoor tents are easy to destroy and single in function can be solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

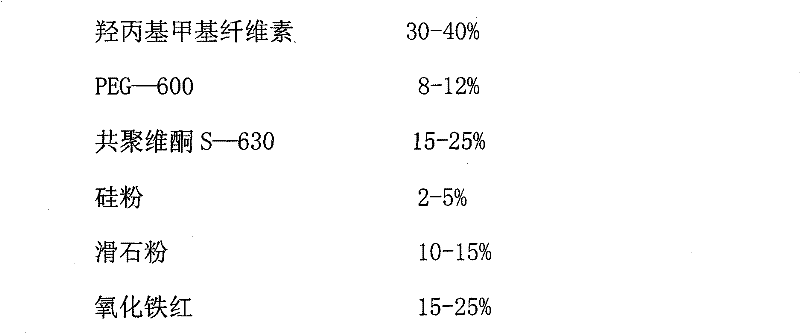

Method for coating gastralgia tablets

ActiveCN101618217ASolve the difficult problem of coatingStrong waterproofDigestive systemInorganic non-active ingredientsEmulsionAdditive ingredient

The invention relates to the preparation technology of medicines and mainly provides a method for coating gastralgia tablets. In the method for coating gastralgia tablets, the coating powder for coating the gastralgia tablets comprises the following ingredients in the mass percent: 30-40 of hydroxypropyl methylcellulose, 8-12 of PEG-600, 15-25 of S-630, 2-5 of silicon powder, 10-15 of talcum powder and 15-25 of iron oxide red. The method for coating gastralgia tablets comprises the following steps: directly mixing the powdered ingredients according to the proportion; adding water the amount of which is 6 times of that of the mixture and being milled for two times by an emulsifying colloid mill to prepare uniform emulsion; and then, coating the tablets by a spraying film coating method. Each coated film tablet has uniform color on the surface, has regular edges, has strong toughness and can achieve the requirements. The purposes of water resistance and cracking prevention can be achieved by an accelerating test.

Owner:LUOYANG JUSN PHARMA

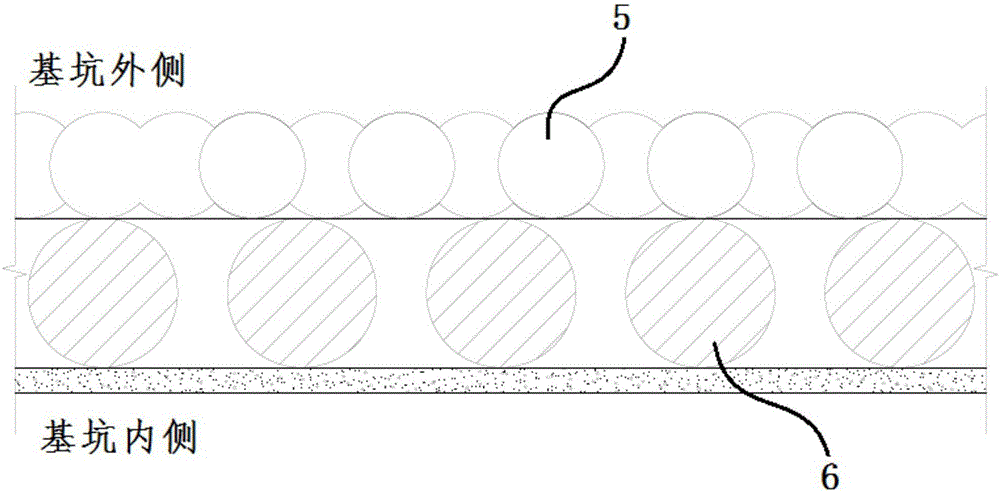

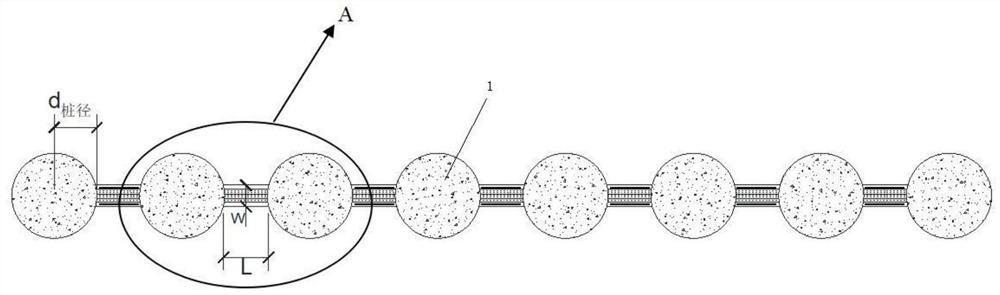

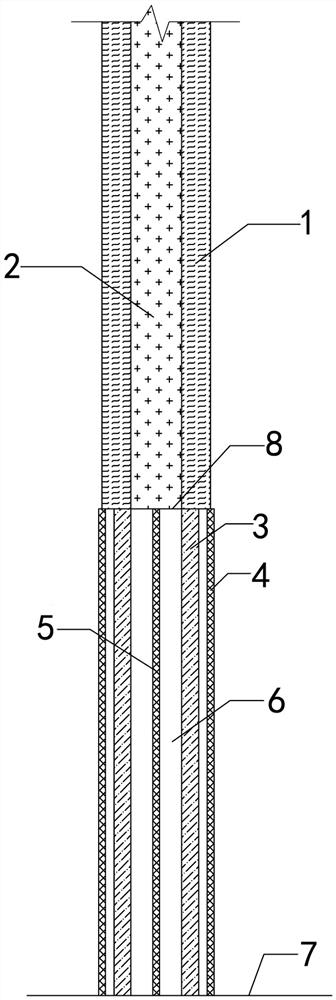

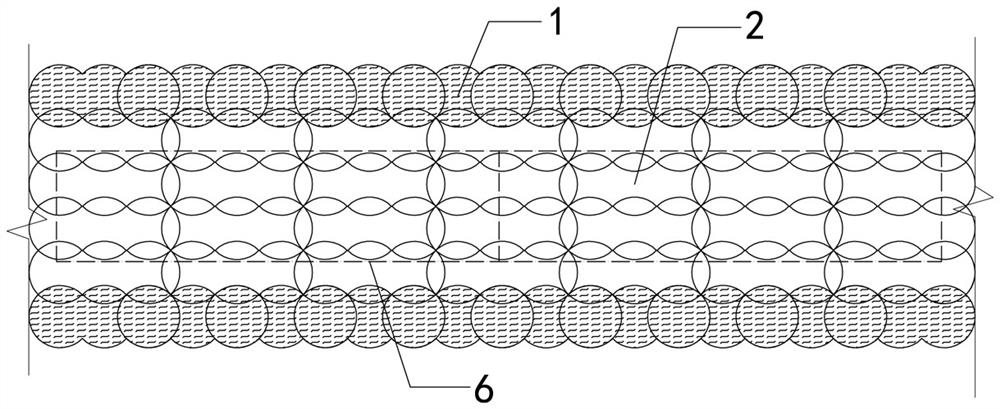

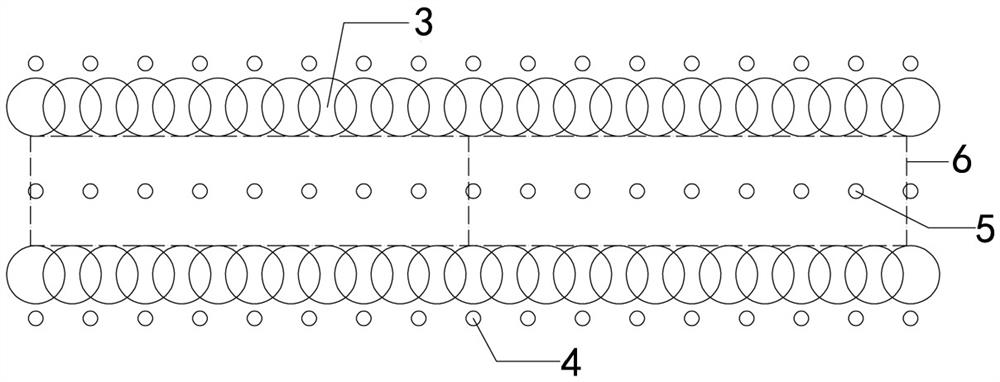

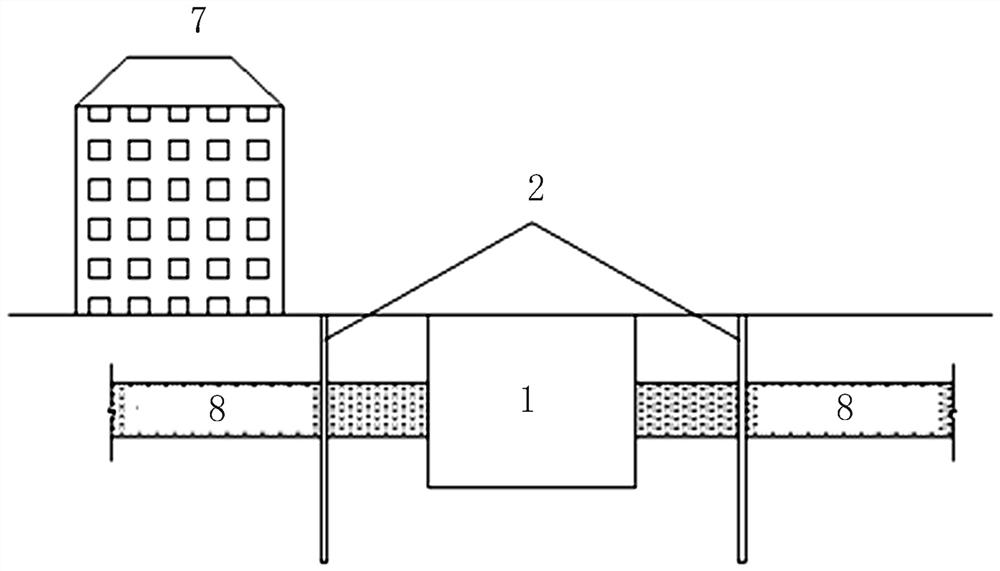

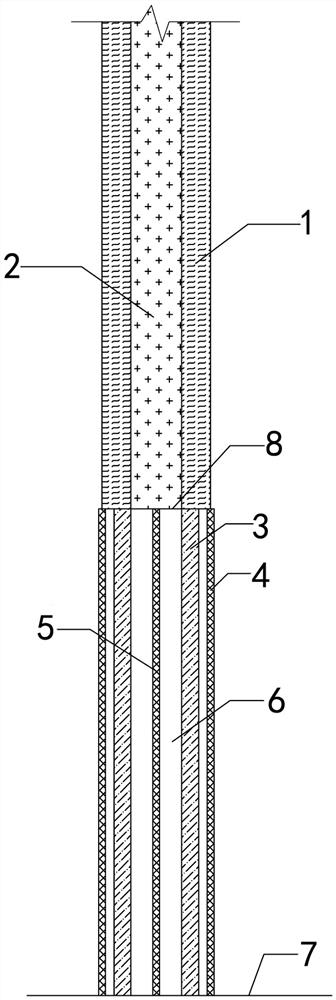

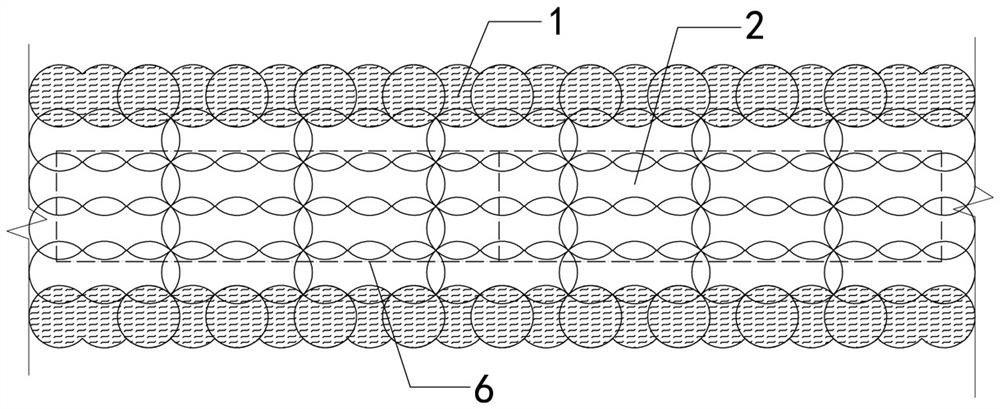

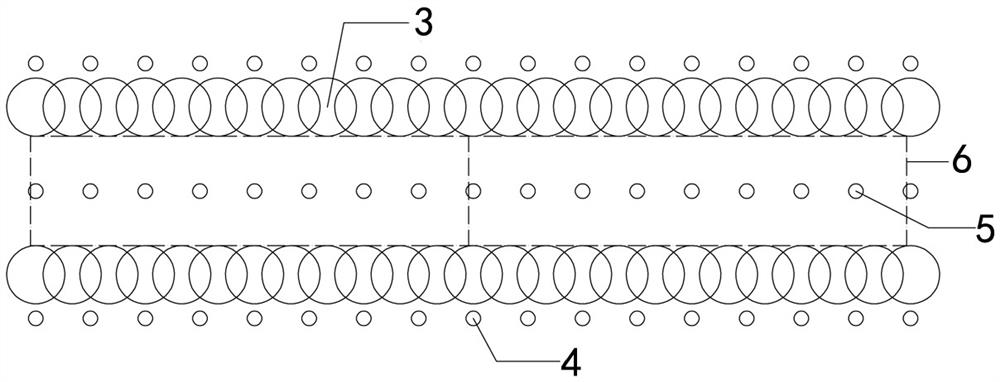

Multi-layer bonding composite three-dimensional fabric foundation pit waterproof curtain supporting structure and construction method thereof

InactiveCN112211200AHigh strengthGood water stop effectExcavationsBulkheads/pilesEpoxyReinforced concrete

The invention relates to the technical field of building construction, in particular to a multi-layer bonding composite three-dimensional fabric foundation pit waterproof curtain supporting structureand a construction method thereof. The multi-layer bonding composite three-dimensional fabric foundation pit waterproof curtain supporting structure comprises a plurality of cast-in-situ bored piles and foundation pit connecting parts arranged among the cast-in-situ bored piles and used for connecting the cast-in-situ bored piles; the plurality of cast-in-situ bored piles are uniformly arranged atintervals; and each foundation pit connecting part comprises a strip-shaped foundation trench and a reinforcement cage arranged in the strip-shaped foundation trench, and a plurality of layers of composite three-dimensional fabrics are horizontally arranged in the reinforcement cage; The piles are connected into a whole through the composite three-dimensional fabrics and reinforced concrete, thestrength is improved, and the water stop performance is enhanced; the water stopping capability is improved by about 30%; and the supporting strength of the cast-in-situ bored piles is improved by 15%-20%; Compared with a large-volume concrete structure, the used composite three-dimensional fabric has the advantages that the use amount of concrete is saved, the construction cost is reduced by about 10%, and the environment is improved; and epoxy asphalt is used as an adhesive of each layer of three-dimensional fabric, so that the composite three-dimensional fabric is endowed with relatively strong water stop performance and bonding stability.

Owner:NANTONG UNIVERSITY

Grooving reinforcing structure for ultra-deep underground diaphragm wall in coastal reclamation area and construction method thereof

ActiveCN113026768AWeak stabilityWeak sealing performanceExcavationsBulkheads/pilesSlurry wallSleeve valve

The invention provides a grooving reinforcing structure for an ultra-deep underground diaphragm wall in a coastal reclamation area and a construction method thereof. The structure comprises an upper reinforcing structure within the range of 30m and a lower reinforcing structure within the range of 30m or below. The upper reinforcing structure is reinforced and formed through a three-axis mixing pile, the quality is good, and a good reinforcing and water stopping effect is achieved. Within the range of 30m or below, due to the fact that the water and soil pressure of the coastal reclamation area is large, the reinforcing effect cannot be guaranteed through a single groove wall reinforcing manner, a high-pressure jet grouting pile is adopted for reinforcing firstly, and then the defects possibly existing in the high-pressure jet grouting pile are overcome through sleeve valve grouting. The grooving reinforcing structure combines the advantages of the three-axis mixing pile, the high-pressure jet grouting pile and sleeve valve pipe grouting, a good groove wall reinforcing effect can be achieved during underground diaphragm wall construction, the grooving reinforcing structure is particularly suitable for grooving reinforcing of the ultra-deep underground diaphragm wall in the coastal reclamation area, and the groove wall reinforcing method is safe, effective, economical and reasonable.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Active protection method for eliminating influence of stratum settlement on existing building

ActiveCN113431110AImprove ductilityStrong waterproofSoil-shifting machines/dredgersFoundation repairArchitectural engineeringSlurry

The invention discloses an active protection method for eliminating the influence of stratum settlement on an existing building, and belongs to the technical field of engineering construction protection. The active protection method comprises the following steps that 1, a protection range which is not affected by stratum settlement around the building needing to be protected is determined; 2, a circle of vertical drill holes are constructed at intervals near the critical position of the protected range around the protected building; 3, grooves are formed between the adjacent vertical drill holes in a milling manner, and milling groove sections and protective layer groove bodies are formed; 4, replacing and filling are carried out on slurry in the grooves from bottom to top by adopting a ductile waterproof material to form replacing and filling sections; and 5, after the ductile waterproof material is solidified and formed, end-to-end connection is carried out, and a circle of active protection layer with high ductile performance and high waterproof performance is formed near the range of a excavation influence area of a newly-built project. According to the method, the building can be prevented from being influenced by the surrounding stratum settlement, and the influence of additional stress generated by the stratum settlement and the uneven settlement on the building is prevented. If the technology is adopted around a newly-excavated foundation pit, the influence of the stratum settlement caused by excavation on the surrounding building can be reduced, and therefore the active protection effect on the existing building is achieved.

Owner:CHINA UNIV OF MINING & TECH

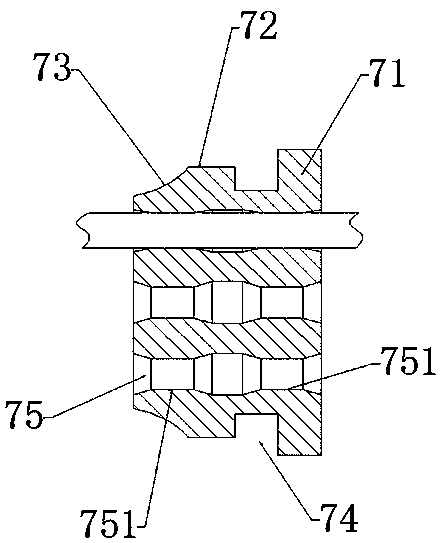

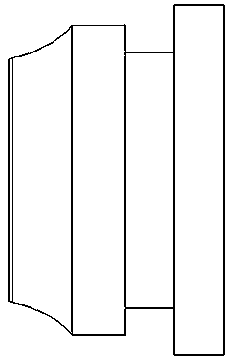

Waterproof ring used for electric skateboard controller

InactiveCN107645878ASimple structureStrong waterproofHermetically-sealed casingsEngineeringMechanical engineering

The invention provides a waterproof ring used for an electric skateboard controller. The overall waterproof ring has a cylindrical structure, and the waterproof ring comprises a first stop ring, a second stop ring and a conical structure which are arranged from the left to the right in turn. The diameter of the first stop ring is greater than that of the second stop ring, and an annular clamp groove is arranged between the first stop ring and the second stop ring. The cylindrical structure is internally provided with multiple threading holes used for threading. Each threading hole is internally provided with step ring structures which are arranged at the two ends of the threading hole. The defects in the prior art can be overcome, the annular clamp groove is matched with the circular holeon the controller shell and used for sealing of the controller shell; and the threading holes are used for threading of leads, the two ends of the threading holes are set into the step ring structure,an annular cavity appears in the threading holes when the leads are inserted in the threading holes, the cavity internally has gas and the effect of secondary sealing can be formed by the gas in thecavity so that the structure is simple and the waterproofness is high.

Owner:李文

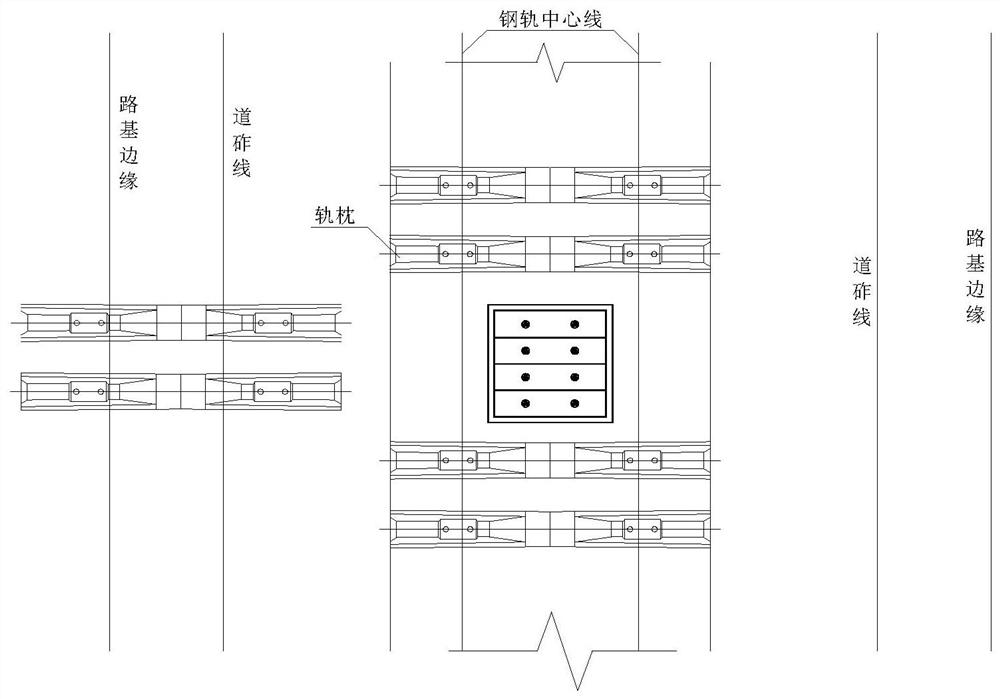

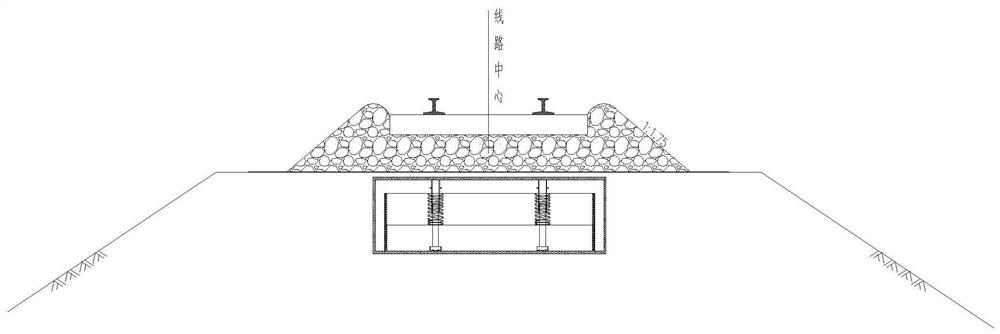

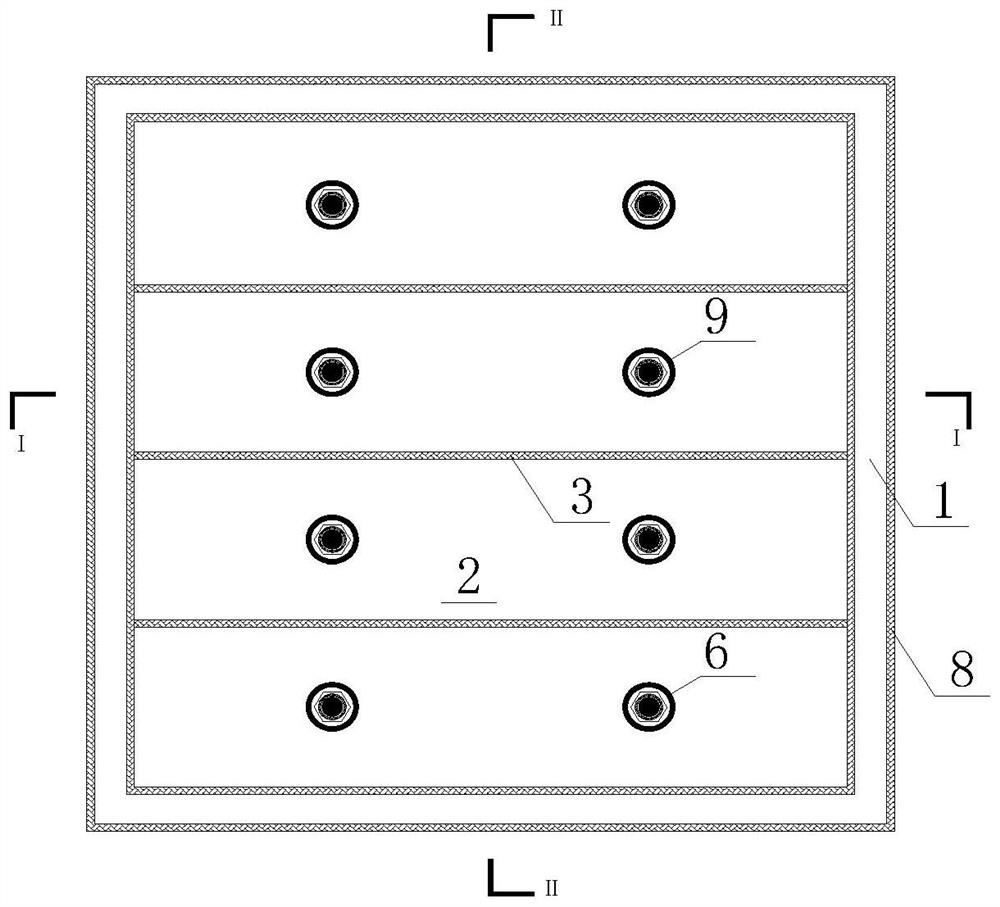

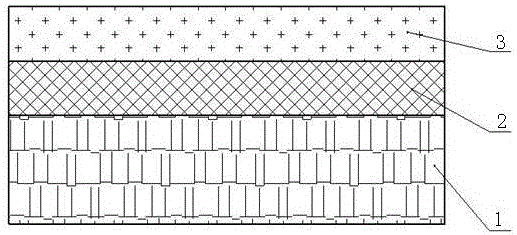

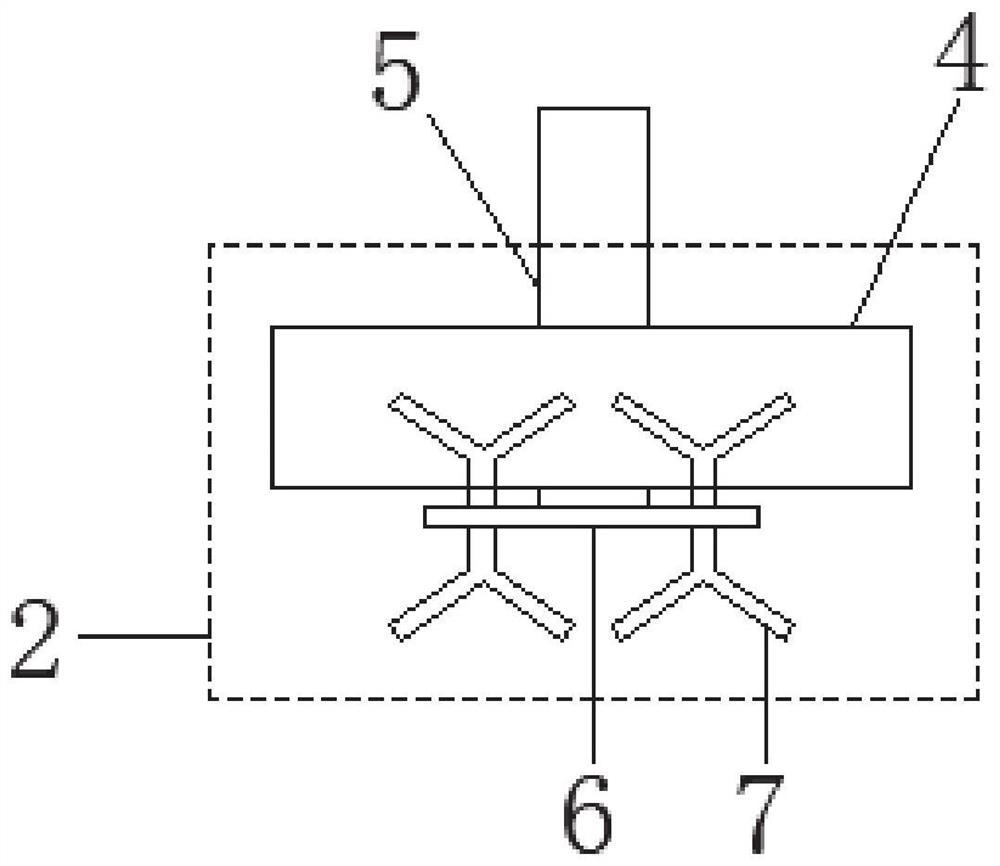

Roadbed freezing injury treatment device capable of vertically partitioning and gradually reducing pressure

ActiveCN112376328AIncrease stiffnessAlleviate upliftClimate change adaptationRailway tracksSoil scienceReinforced concrete

In combination with frost heaving and thaw collapse diseases of railroad beds in seasonal frozen soil areas in China, a railroad bed freezing injury treatment device capable of releasing frost heavingforce step by step in a vertical partition mode is provided. The device is composed of a reinforced concrete supporting box body, a plurality of reinforced concrete movable panels, a low-friction-coefficient isolation layer, a spring set, an embedded sleeve with a thread, a guide rod with a thread, an embedded sleeve and a rubber protection layer. The panel of the device is designed in a layeringand blocking mode, the number of blocks can be flexibly determined according to specific use conditions, the panel block design can release frost heaving force in a blocking mode in the soil body freezing process to enable springs to store energy, and when the soil body melts, the energy storage springs can push movable plates at the corresponding melting positions to move outwards to extrude thesoil body, and the roadbed rigidity is improved; the subgrade thaw collapse amount is reduced, the improvement effect is more obvious, the conditions that the whole panel inclines, so that the devicefails, frost heaving force is not released in time and the like are avoided, and the working performance and reliability of the device are improved.

Owner:LANZHOU JIAOTONG UNIV

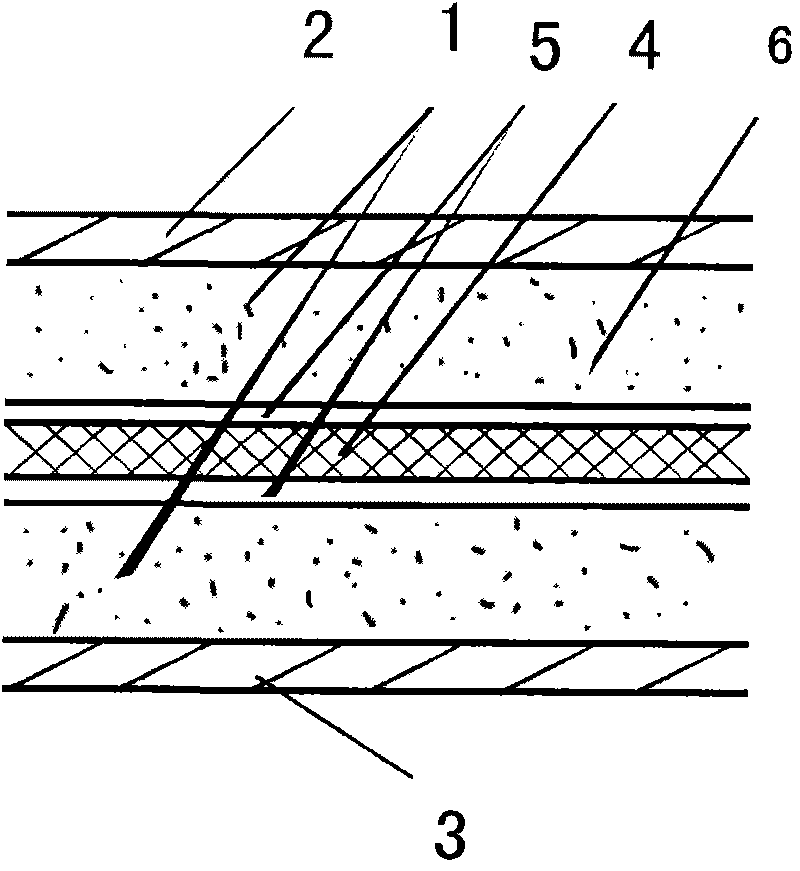

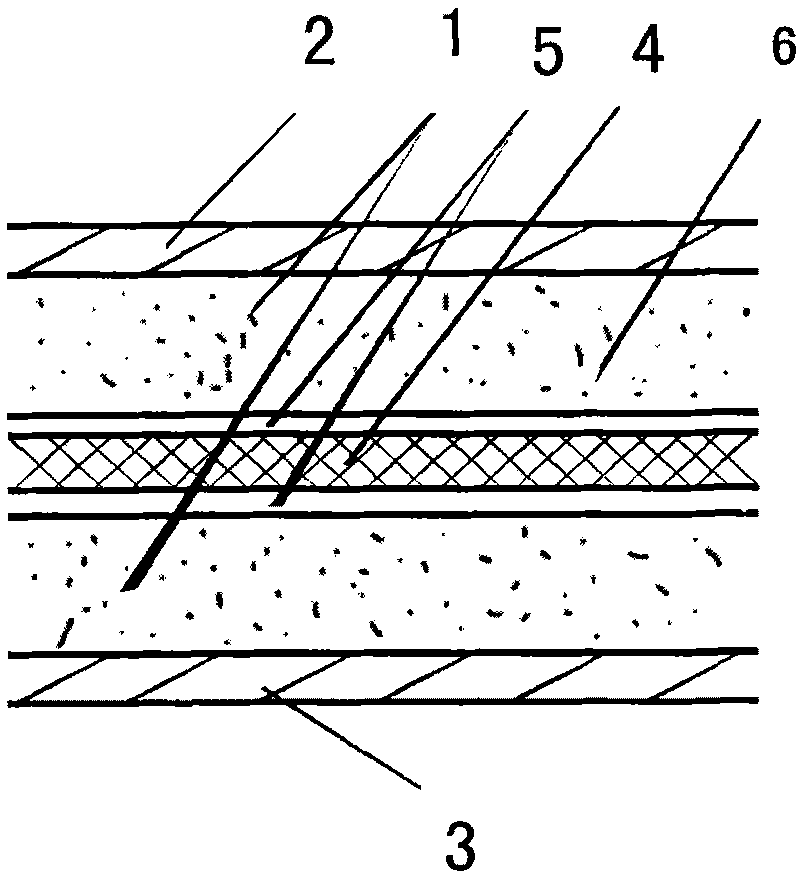

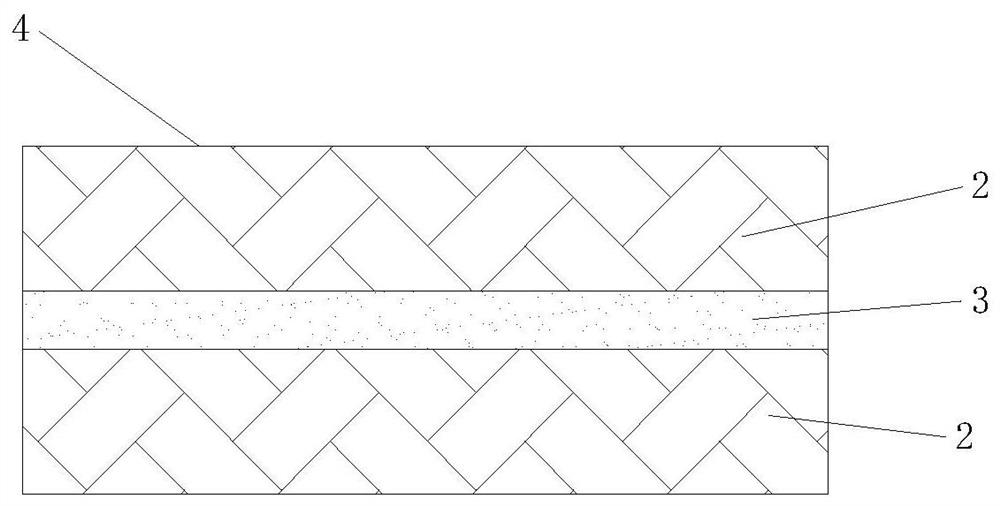

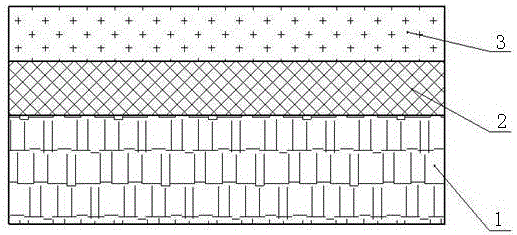

Transfer print waterproof fabric

InactiveCN106240072AStrong waterproofComfortable to wearSynthetic resin layered productsClothingsEngineeringFiber

The invention relates to a transfer print waterproof fabric. The transfer print waterproof fabric comprises a base layer (1), and the surface of the base layer (1) is provided with an antibacterial layer (2) and a waterproof layer (3) in order. The antibacterial layer (2) is made of bamboo fiber. The waterproof layer (3) is a TPU coating. The back of the base layer is provided with a lining fabric layer, and the lining fabric layer is a fabric transfer film, the fabric transfer film includes a biaxially oriented polyester BOPET film, the surface of the BOPET film is sequentially provided with a release layer, a coloring layer, an aluminized layer and a base glue layer. The transfer print waterproof fabric provided by the invention is breathable, comfortable, waterproof, breathable and antibacterial. And the transfer print waterproof fabric is mainly used for transfer printing.

Owner:JIANGYIN ZHONGMA PACKING MATERIAL

A kind of coating method of anwei tablet

ActiveCN101618217BSolve the difficult problem of coatingStrong waterproofDigestive systemInorganic non-active ingredientsEmulsionAdditive ingredient

The invention relates to the preparation technology of medicines and mainly provides a method for coating gastralgia tablets. In the method for coating gastralgia tablets, the coating powder for coating the gastralgia tablets comprises the following ingredients in the mass percent: 30-40 of hydroxypropyl methylcellulose, 8-12 of PEG-600, 15-25 of S-630, 2-5 of silicon powder, 10-15 of talcum powder and 15-25 of iron oxide red. The method for coating gastralgia tablets comprises the following steps: directly mixing the powdered ingredients according to the proportion; adding water the amount of which is 6 times of that of the mixture and being milled for two times by an emulsifying colloid mill to prepare uniform emulsion; and then, coating the tablets by a spraying film coating method. Each coated film tablet has uniform color on the surface, has regular edges, has strong toughness and can achieve the requirements. The purposes of water resistance and cracking prevention can be achieved by an accelerating test.

Owner:LUOYANG JUSN PHARMA

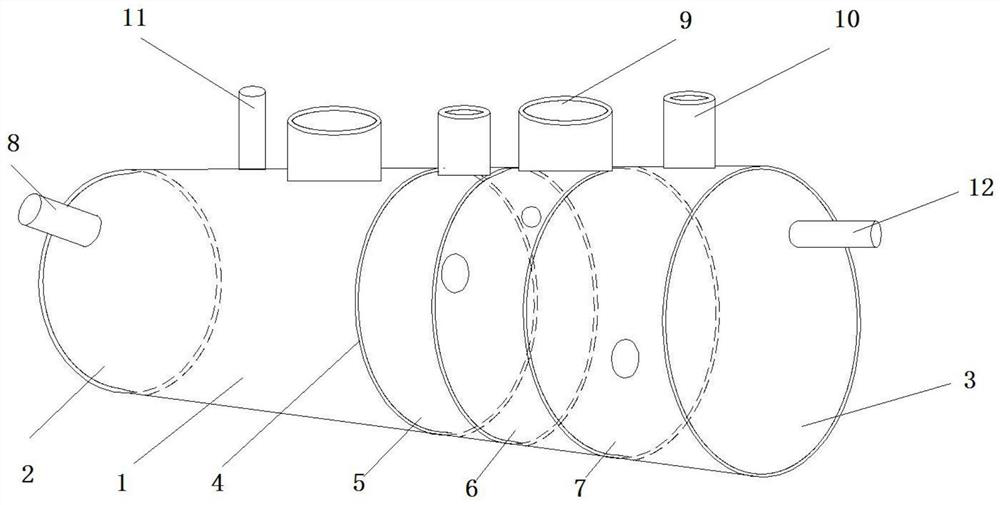

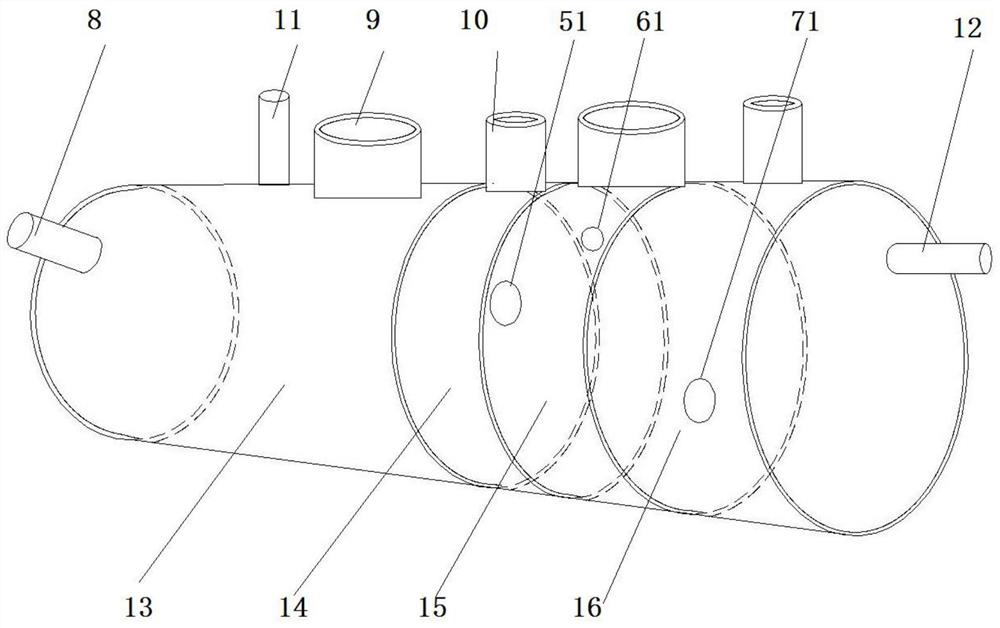

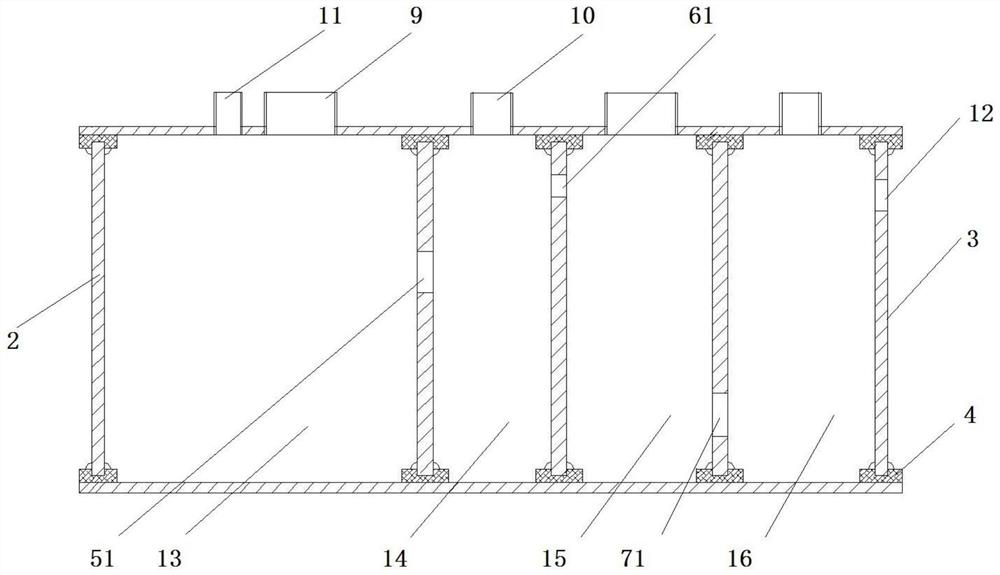

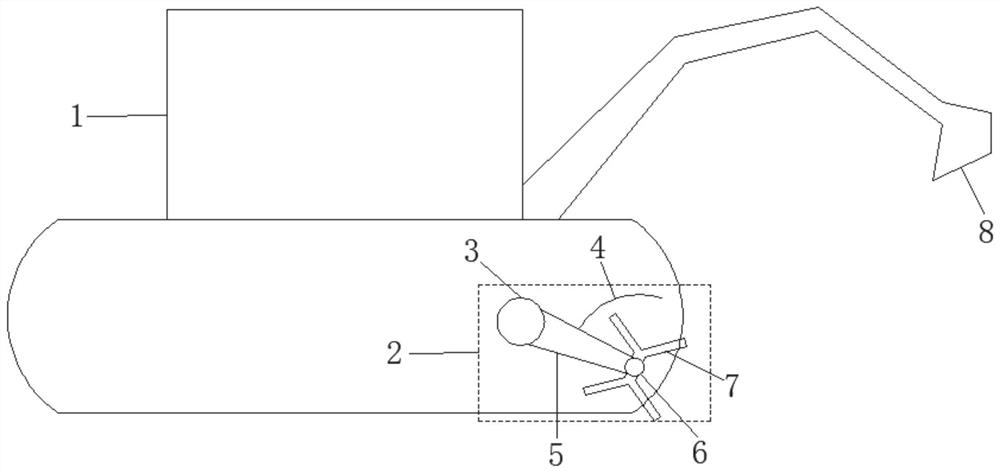

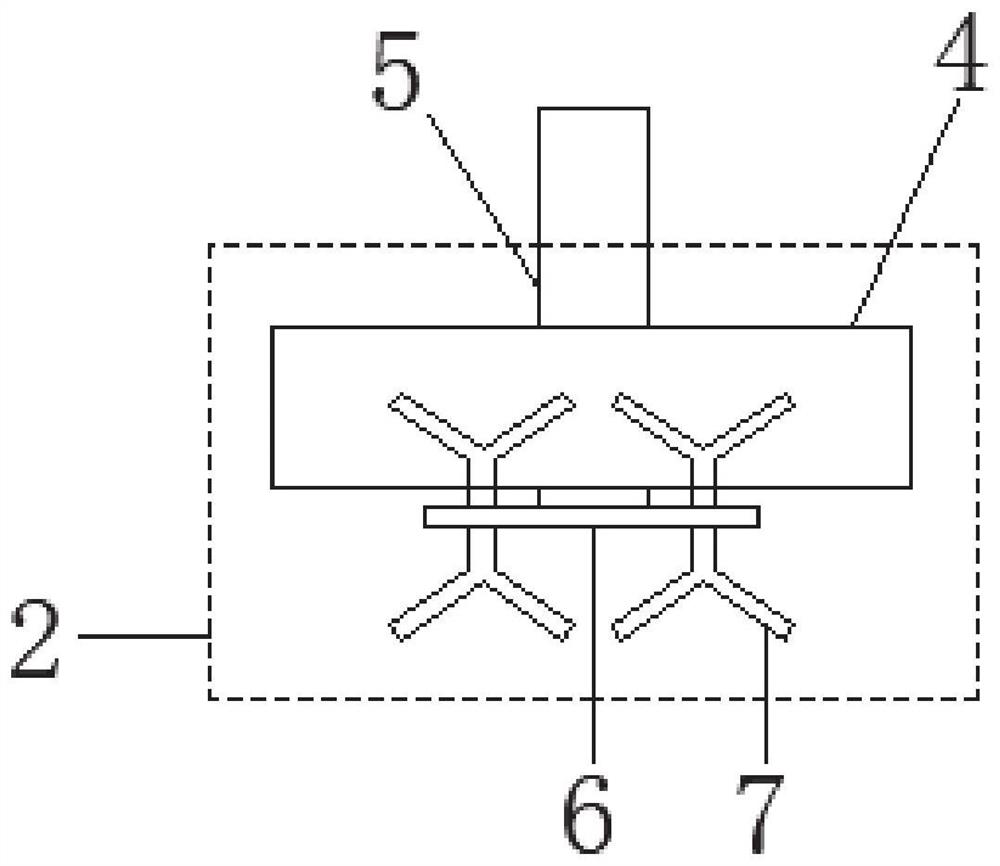

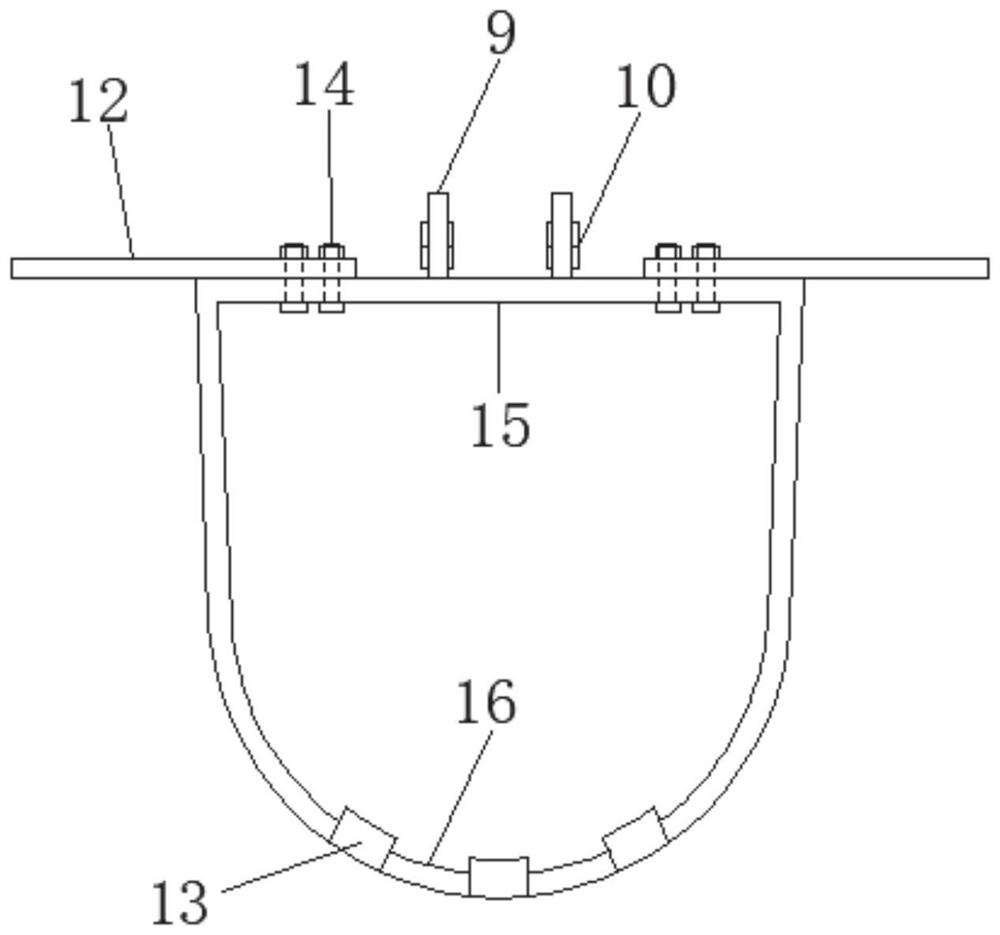

Plastic four-grid septic tank

PendingCN111960631APlay a supporting roleStrong waterproofBiological sludge treatmentThermodynamicsEngineering

The invention discloses a plastic four-grid septic tank which comprises a cylinder body, a left sealing plate, a right sealing plate, fixing ribs, a first partition plate, a second partition plate, athird partition plate, a water inlet, a cleaning opening, an inspection opening, an exhaust opening and a water outlet, the cylinder body is divided into a first septic tank, a second septic tank, a third septic tank and a fourth septic tank by the first partition plate, the second partition plate and the third partition plate; the first partition plate, the second partition plate, the third partition plate, the left sealing plate and the right sealing plate are connected with the cylinder body through fixing ribs, a circle of thermal fuse wires are arranged on the outer surfaces of the fixingribs, and the fixing ribs are connected with the cylinder body through the thermal fuse wires in a hot melting mode. According to the plastic septic tank, the fixing ribs and the thermal fuses are inhot melting connection with the cylinder body, so that the water isolation capability is high, the sealing performance is improved, meanwhile, the fixing ribs play a role in supporting, the structural strength is improved, and the problems that an existing plastic septic tank with a complex structural form is not qualified in quality, and a spliced part is prone to leakage are solved.

Owner:HEBEI TONGTAO PIPE CO LTD

Luminous waterproof fabric

The invention relates to a luminous waterproof fabric, which comprises a basic layer (1), wherein an antibacterial layer (2) and a waterproof layer (3) are sequentially arranged on the surface of the basic layer (1); the antibacterial layer (2) is made of bamboo fiber; the waterproof layer (3) is a TPU coating; the back side of the basic layer is provided with a lining fabric layer; the lining fabric layer is a luminous fabric, and comprises at least one passive luminous yarn and at least one active luminous yarn; the active luminous yarn and the passive luminous yarn are mutually interwoven, or the passive luminous yarn is covered and wound by the active luminous yarn. The luminous waterproof fabric has the advantages that a ventilation and comfort effect, a waterproof and ventilation effect and an antibacterial function are achieved; the luminous waterproof fabric is luminous.

Owner:JIANGYIN DUJUAN BEADED

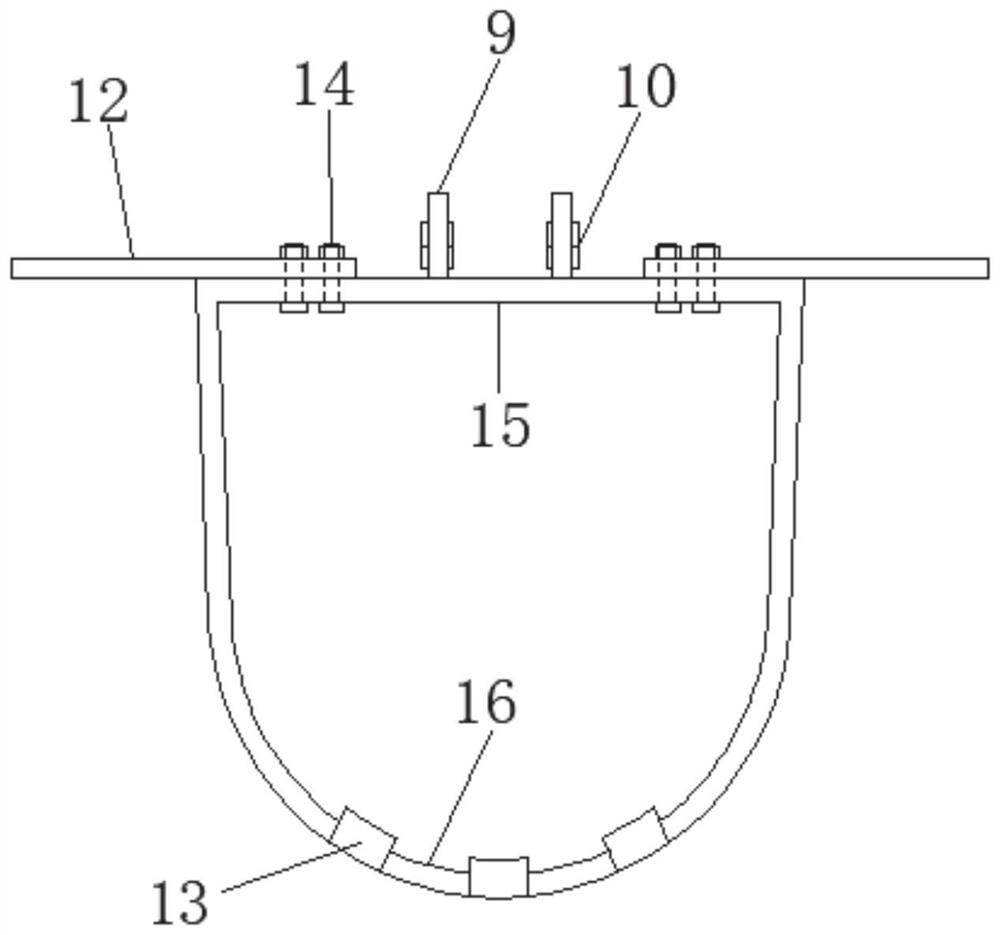

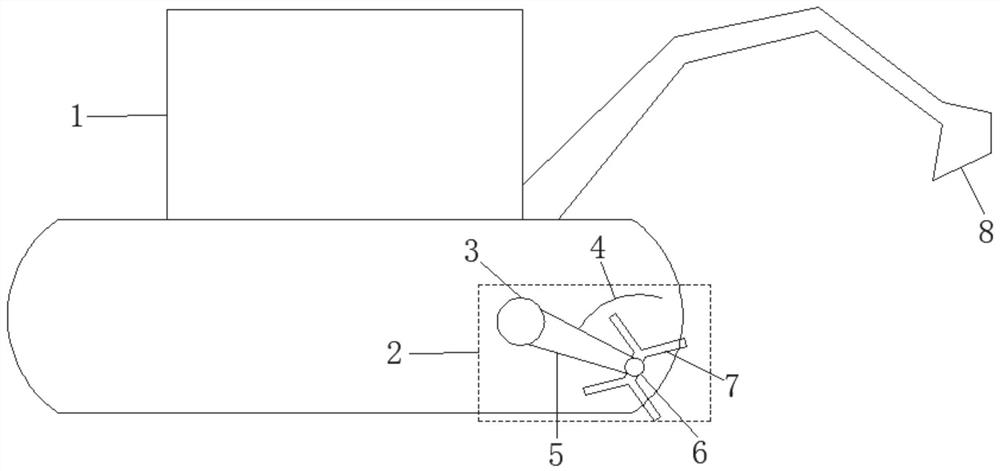

Construction method of prefabricated assembly and cast-in-place concrete topping for irrigation channels

ActiveCN112681257BEnhanced digging and cutting abilitySmooth slopeSoil-shifting machines/dredgersIrrigation ditchesTetrafluoroethyleneArchitectural engineering

The invention relates to a construction method for prefabricated assembly and cast-in-situ concrete topping of irrigation canals, comprising steps: step 1, use an excavator to excavate at the design position, when excavating, first use the loose soil arranged at the front end of the excavator chassis The device loosens the pre-excavated trench soil, and then cooperates with the U-shaped bucket to easily excavate the U-shaped trench foundation pit; step 2, after the bottom of the U-shaped trench is compacted, the cushion layer is laid, and the cushion layer is laid between the soil bodies with concrete. The upper part of the layer is sprayed with polytetrafluoroethylene coating. The beneficial effects of the present invention are: the groove can be formed at one time under the construction conditions of hard soil and frozen soil, the slope surface is smooth and flat, the slope top is straight and beautiful, and no manual trimming is required; the prefabricated U-shaped groove can be produced in an assembly line, and the production efficiency Higher; reduces the workload of on-site construction; reduces the demand for hoisting accuracy and reduces the difficulty of construction; solves the problems of water permeation in the connection gap of prefabricated U-shaped grooves, weak connection strength of traditional concrete topping and concrete channels, and easy falling off of topping.

Owner:ZHEJIANG UNIV CITY COLLEGE

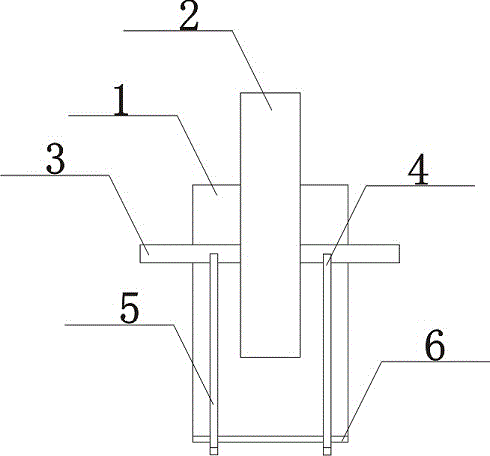

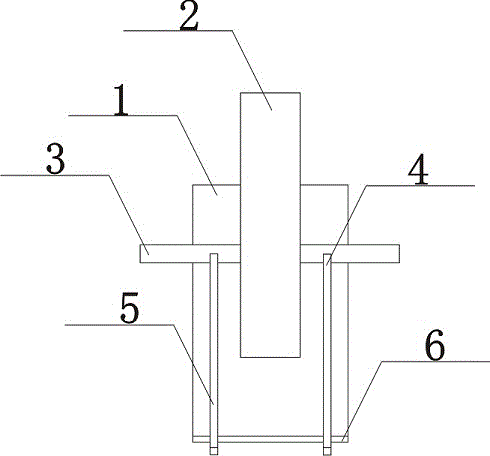

Grouting foundation structure

The invention discloses a grouting foundation structure. The grouting foundation structure comprises a grouting pipe body, wherein an anchoring pipe is arranged in the grouting pipe body; the top part of the anchoring pipe extends out of the outer side surface of the top of the grouting pipe body; the bottom of the anchoring pipe penetrates through a connecting pipe; the connecting pipe is transversely arranged on the grouting pipe body, and the connecting pipe extends out of the two outer side surfaces of the grouting pipe body; a left supporting member and a right supporting member are vertically arranged on the connecting pipe respectively; the bottoms of the left supporting member and the right supporting member penetrate through the bottom of the grouting pipe body; a bottom protecting plate is arranged at the bottom of the grouting pipe body; the bottom protecting plate and the grouting pipe body are connected detachably. According to the grouting foundation structure, the frictional force between the grouting pipe and an anchoring rod hole is effectively increased, so that the effect of preventing the grouting pipe being ejected outside by pressure is realized, strong reinforcing performance is realized, the construction cost is reduced correspondingly, the water sealing effect is very strong, the strength of the foundation is higher, and the mixing mode of the grout is easy to control.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +2

A trough reinforcement structure of ultra-deep underground diaphragm wall in coastal reclamation area and its construction method

ActiveCN113026768BImprove stabilityStrong waterproofExcavationsBulkheads/pilesSlurry wallSleeve valve

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Construction method for prefabricated assembly of irrigation channel and cast-in-place concrete coping

ActiveCN112681257AEnhanced digging and cutting abilitySmooth slopeSoil-shifting machines/dredgersIrrigation ditchesArchitectural engineeringAssembly line

The invention relates to a construction method for prefabricated assembly of an irrigation channel and a cast-in-place concrete coping. The construction method comprises the steps that 1, an excavator is used for excavation at a designed position, during excavation, a soil loosening device arranged at the front end of a chassis of the excavator is used for scarifying pre-excavated groove soil, and then a U-shaped groove foundation pit is easily excavated in cooperation with a U-shaped excavator bucket; and 2, a cushion layer is arranged after the bottom of a U-shaped groove is compacted, the cushion layer is laid between soil bodies through concrete, and a polytetrafluoroethylene coating is sprayed to the upper portion of the cushion layer. The construction method has the beneficial effects that the groove can be formed at a time under the construction condition of hard soil frozen soil, the slope surface is smooth and flat, the slope top is straight and attractive, and manual finishing is not needed; the prefabricated U-shaped groove can be produced through an assembly line, and the production efficiency is high; the on-site construction workload is reduced; the requirement for hoisting precision is reduced, and the construction difficulty is lowered; and the problems that a connecting gap of the prefabricated U-shaped groove is permeable, a traditional concrete coping and a concrete channel are weak in connecting strength, and the coping is prone to falling off are solved.

Owner:ZHEJIANG UNIV CITY COLLEGE

Grouting foundation structure

The invention discloses a grouting foundation structure. The grouting foundation structure comprises a grouting pipe body, wherein an anchoring pipe is arranged in the grouting pipe body; the top part of the anchoring pipe extends out of the outer side surface of the top of the grouting pipe body; the bottom of the anchoring pipe penetrates through a connecting pipe; the connecting pipe is transversely arranged on the grouting pipe body, and the connecting pipe extends out of the two outer side surfaces of the grouting pipe body; a left supporting member and a right supporting member are vertically arranged on the connecting pipe respectively; the bottoms of the left supporting member and the right supporting member penetrate through the bottom of the grouting pipe body; a bottom protecting plate is arranged at the bottom of the grouting pipe body; the bottom protecting plate and the grouting pipe body are connected detachably. According to the grouting foundation structure, the frictional force between the grouting pipe and an anchoring rod hole is effectively increased, so that the effect of preventing the grouting pipe being ejected outside by pressure is realized, strong reinforcing performance is realized, the construction cost is reduced correspondingly, the water sealing effect is very strong, the strength of the foundation is higher, and the mixing mode of the grout is easy to control.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +2

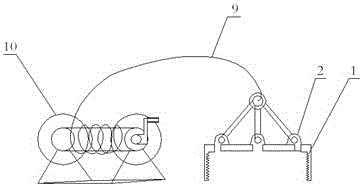

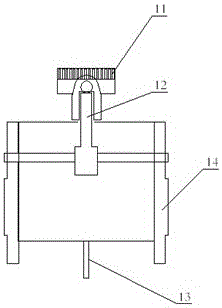

Timed deep water layered water intake device

The invention discloses a method and a device for timing deepwater layering water taking. A water taking machine is adopted by the method and the device. The water taking machine is provided with a timing transmission device (4) capable of opening a water inlet (8) of the water taking machine at a preset time, and is also provided with a pressurized type open / close cone valve assembly capable of closing the water inlet path of a water storage drum (6) before water taking. The opening of the water inlet path of the water storage drum (6) is provided with an anti-blocking seepage-proofing buoyant valve capable of automatically closing the water inlet path of the water storage drum (6) after the water storage drum (6) is filled with water. By adoption of the method and the device, the water taking machine is isolated with water in advance before reaching a water taking depth in a water taking process, and begins to take water when arriving the water taking depth, and prevents mixing between a took water sample and outside water body after the water taking process is finished.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

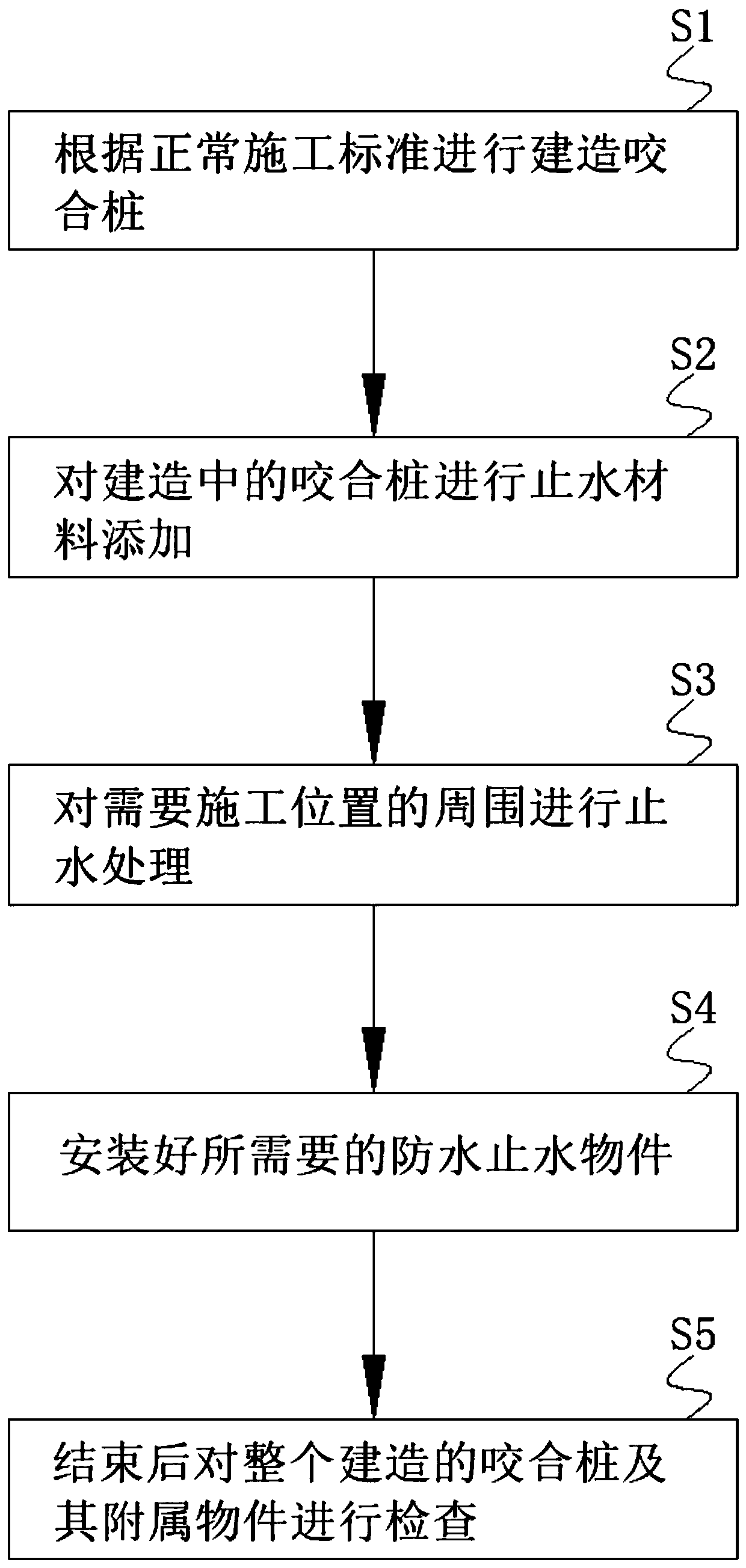

Foundation pit lock pile water stop construction method

InactiveCN110295606ASolve complexitySolve practicalityFoundation testingProtective foundationEngineeringUltimate tensile strength

The invention discloses a foundation pit lock pile water stop construction method, and relates to the technical field of lock pile construction. The foundation pit lock pile water stop construction method specifically comprises the following steps that firstly, the position where a lock pile needs to be built is detected, various data of the position are measured, and according to the data and theexisting standard, the lock pile is poured; and the strength of the lock pile is improved. According to the foundation pit lock pile water stop construction method, the surrounding of the position where the lock pile needs to be built is subjected to exploration detection, when the lock pile is poured, and after the lock pile is poured, effective and portable water stop can be carried out, the water stop effect is high, the phenomenon that due to involvement of water, the poured lock pile cannot be used is greatly avoided, a worker can more conveniently work, meanwhile, fewer faults appear inthe engineering, use cost is reduced, use by a user is facilitated, and the problems that at present, an existing foundation pit lock pile waterstop construction method is complex and poor in practicability are solved.

Owner:广州穗岩土木科技股份有限公司

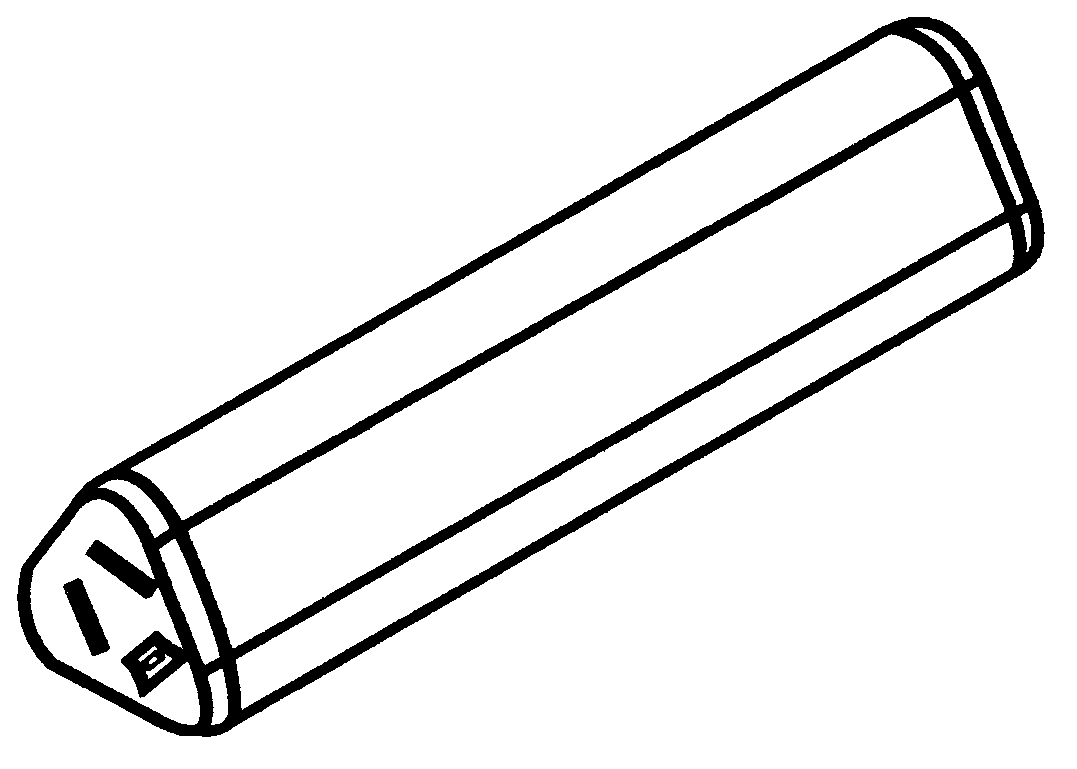

Multifunctional mobile power supply

InactiveCN103633676AStrong waterproofImprove waterproof performanceBatteries circuit arrangementsPoint-like light sourceElectrical batteryMultiple function

The invention discloses a multifunctional mobile power supply which is composed of a main PCB board, an assistant PCB board, a battery, a charging device, an LED module and an LED controller. The main PCB board is the control board of lighting, early warning and charging, and is electrically connected with the LED controller. The assistant PCB board is used for adjusting the power supply voltage of a lighting device, an early warning device and a charging device, and a flash mode. Voltage input by the battery is converted into voltage suitable for mobile phone charging. Mobile phone charging is carried out through the charging device. A control order output by the LED controller is converted into ever lighting and flickering of the LED module.

Owner:屈海强

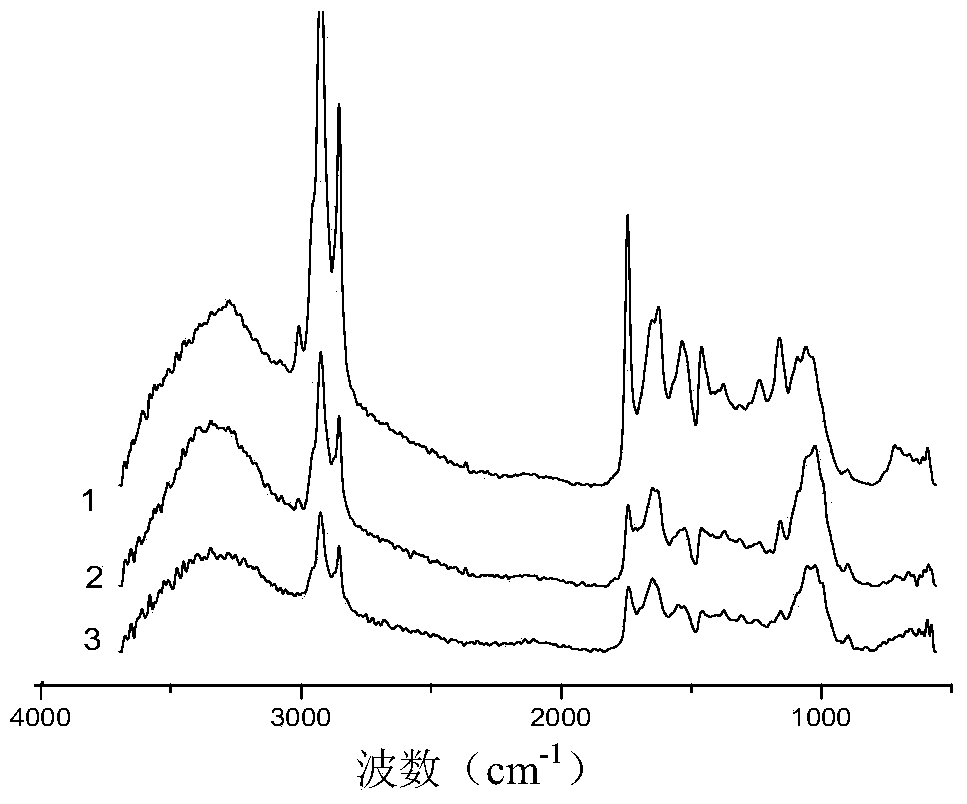

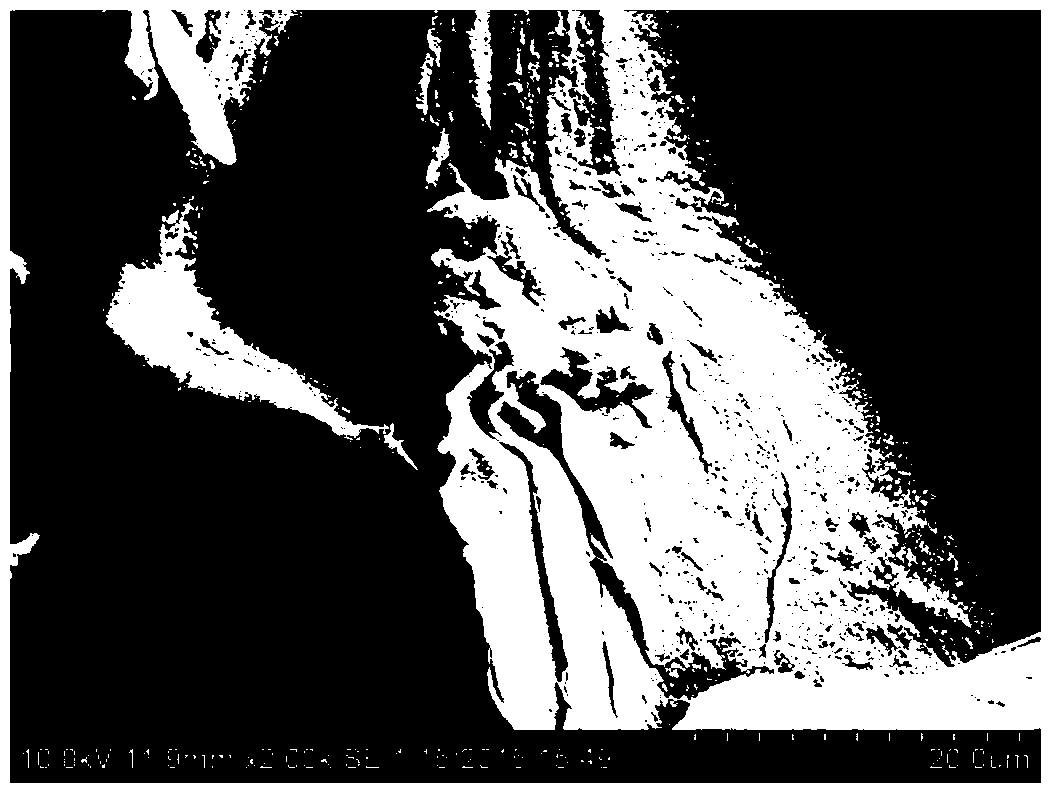

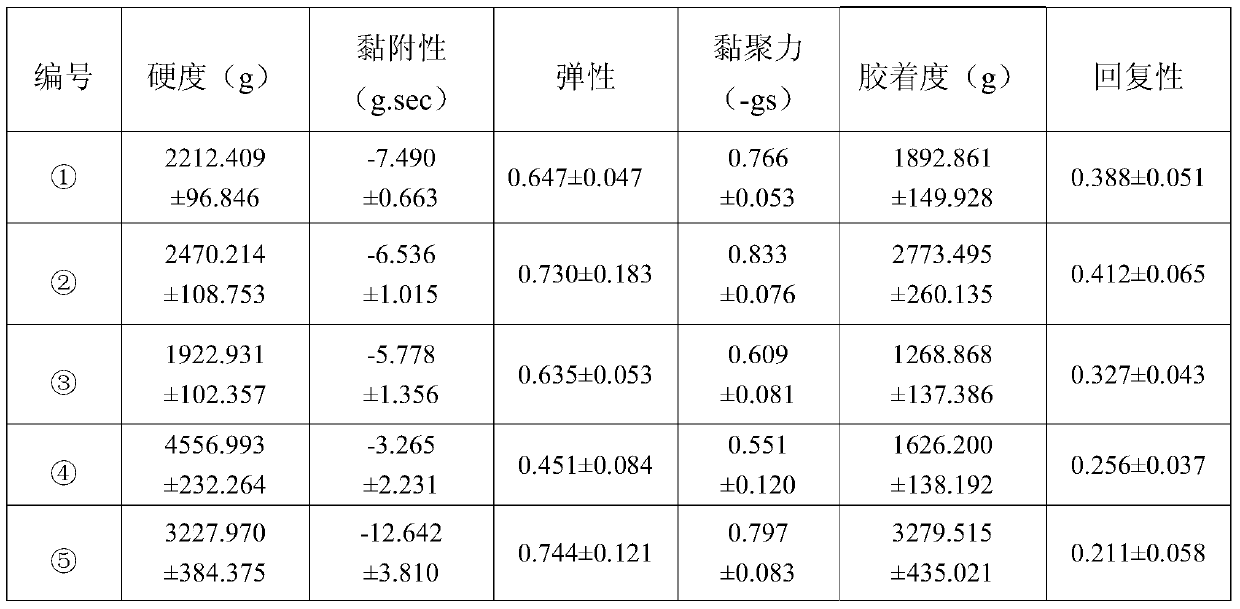

Modified hydrogel of pineapple pomace fiber grafted with soybean protein and its preparation method and application

InactiveCN105295072BImprove water holding capacityFlat surfaceSemi-permeable membranesAbsorbent padsCelluloseFiber

The invention belongs to the technical field of composite hydrogel, and discloses a modified hydrogel grafted with soybean protein by pineapple skin residue fiber, as well as its preparation method and application. The present invention extracts cellulose through pineapple pomace, then uses soybeans to separate out protein, then adds pineapple pomace cellulose and soybean protein isolate into a reaction vessel, oscillates and mixes evenly, then quickly adds ionic liquid, stirs and mixes, and seals to form Gel reaction, cooling, adding isopropanol aqueous solution for soaking, pouring off the soaking solution, adding distilled water to continue soaking, changing the water until the soaking solution does not contain ionic liquid, pre-freezing, vacuum freeze-drying, and obtaining a modified hydrogel. The modified hydrogel of the present invention forms a dense three-dimensional network structure due to the reaction of cellulose and soybean protein. The performance is strong, and the performance in terms of texture is superior, and it has potential applications in wound dressings and other aspects.

Owner:SOUTH CHINA UNIV OF TECH

Construction method of bentonite waterproof blanket

InactiveCN101748757BGuaranteed integrityReasonable workmanshipProtective foundationSodium BentoniteEngineering

The invention relates to a construction method of a bentonite waterproof blanket. The method includes the steps of base surface treatment, waterproof blanket laying, lap seam treatment, head swing protection and connection, end closing treatment, hollowing treatment and the like. When dealing with lap seams, it is required that the waterproof blankets be naturally lapped, the lap width should not be less than 100mm, and the lap seams cannot be set at the corners; the reserved length of waterproof blankets should be 200-400mm longer than that of steel bars, and should be greater than 500mm. ~800mm, and sealed with edge strips; temporary protection is provided for façade head shakes and plane head shakers; waterproof blankets are laid to the top of the facade for end closure treatment, and the closures are fixed. The construction method of the invention has reasonable technology, can be permanently waterproofed, is simple in method, saves labor and materials, has the same long service life as the structure, has secondary waterproofness, and can form an active waterproofing system. The construction cost is low, the benefit is high, and the application range is wide, and it is suitable for various waterproof requirements of underground waterproof projects.

Owner:HENAN GUOJI CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com