Modified asphalt compound waterproof rolling material

A technology of modified bitumen and waterproof coiled material, applied in the field of building materials, can solve the problems of poor tensile performance and elongation of waterproof coiled material, easy cracking or deformation, complicated construction process, etc., to achieve broad market application prospects, reduce Dosage, effect suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

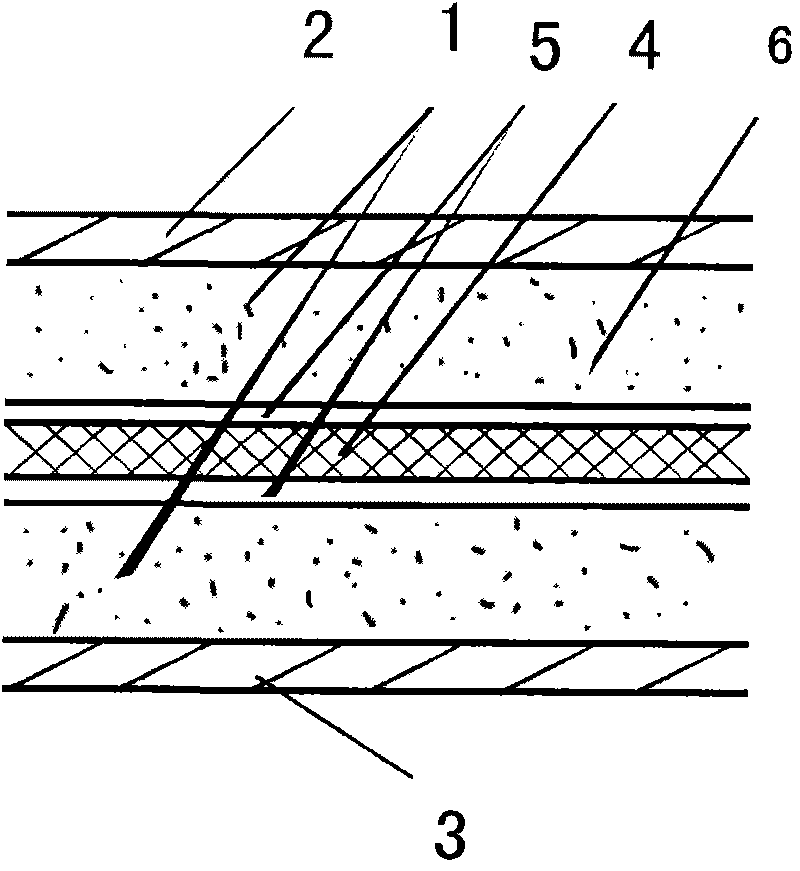

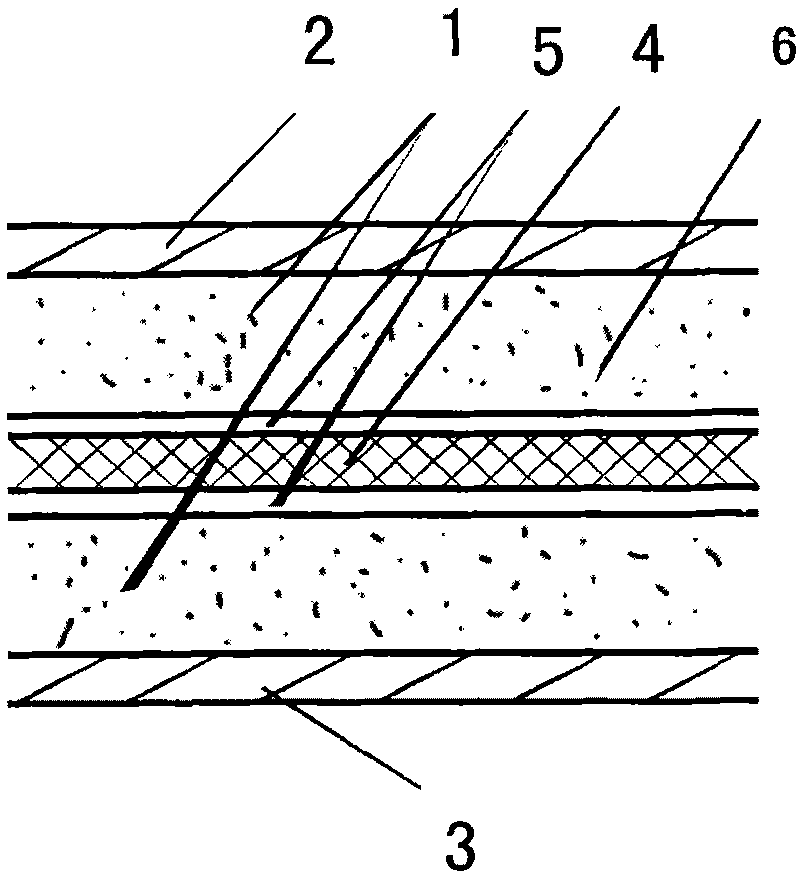

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the present invention.

[0017] The present invention is a modified asphalt composite waterproof coiled material, which is composed of a modified asphalt waterproof layer 1 with filler 6 inside, an upper layer 2 is arranged on the modified asphalt waterproof layer 1, and a lower layer 3 is arranged below Composition, the modified asphalt waterproof layer 1 is provided with a non-woven fabric layer 4, the non-woven fabric layer 4 is a polyester non-woven fabric layer, and the upper and lower sides of the non-woven fabric layer 4 are provided with an adhesive layer 5 .

[0018] The modified asphalt waterproof layer 1 of the present invention is composed of asphalt, polypropylene resin, waste woven bags, waste plastic bags and waste rubber.

Embodiment 2

[0020] In specific implementation, the non-woven fabric layer 4 described in the present invention can also be a polypropylene non-woven fabric layer. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com