Inorganic fireproof insulation board and manufacturing method and application thereof and external thermal insulation system

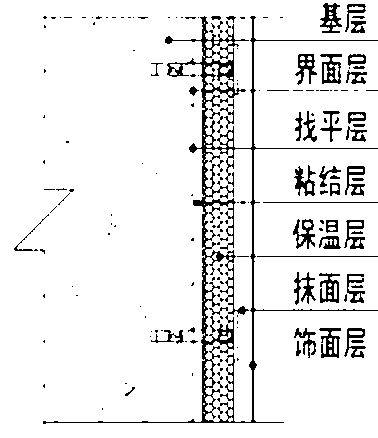

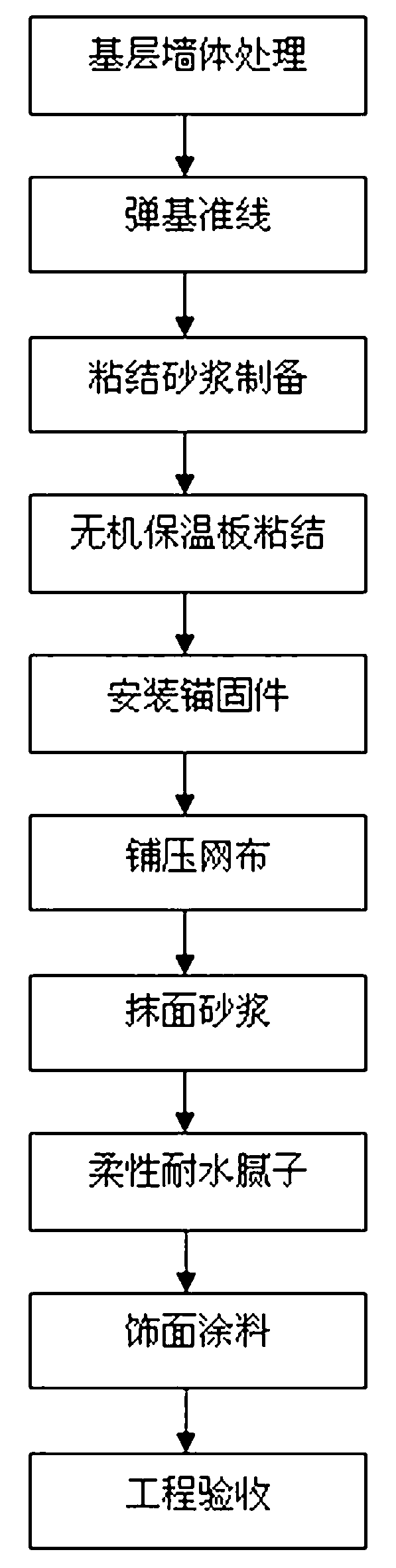

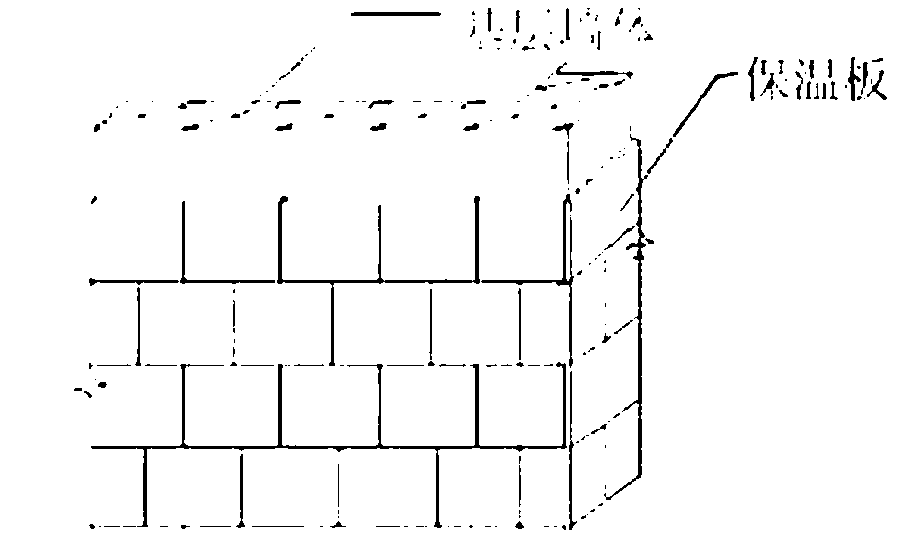

A technology of fireproof insulation board and external wall insulation, which is applied in the direction of insulation, fire prevention, building components, etc. It can solve the problems of not being able to meet the construction requirements of thin plastering external insulation, the heat resistance temperature not meeting the requirements, and restricting the application field. Achieve good heat insulation and energy saving effects, stable physical and chemical properties, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] An inorganic thermal insulation board comprises hollow vitrified microspheres, sodium silicate, polysiloxane emulsion, water, calcium carbonate powder and hydroxymethyl cellulose, and its preparation process is as follows:

[0101] 1) Raw material preparation: hollow vitrified microspheres 10kg, magnesium silicate 0.4kg, aluminum silicate 0.2kg, montmorillonite 0.2kg, bentonite 0.2kg, diatomite 2kg, light calcium carbonate 1kg, carboxymethyl fiber Sulfate 0.1kg, silica sol 4kg, sodium silicate 2kg, polysiloxane emulsion 0.2kg, sodium sulfosuccinate 0.1kg, water 1.8kg;

[0102] 2) Mixing and stirring: Add magnesium silicate, aluminum silicate, montmorillonite, bentonite, diatomaceous earth, silica sol, sodium silicate, polysiloxane emulsion, sodium succinate sulfonate and water into the mixer Stir for five minutes to form a mixed glue; add hollow vitrified microspheres, light calcium carbonate, and hydroxymethyl cellulose into the stirrer and stir for three minutes, then...

Embodiment 2

[0110] 1) Raw material preparation: hollow vitrified microspheres 10kg, glass fiber 0.03kg, aluminum carbonate fiber 0.1kg, calcium carbonate powder 2kg, polysiloxane emulsion 0.08kg, hydroxymethyl cellulose 0.12kg, sodium silicate 6kg, 1.5kg of water;

[0111] 2) Mixing and stirring: Add glass fiber, aluminum silicate fiber, polysiloxane emulsion, sodium silicate and water into the mixer and stir for five minutes to form a mixed glue; mix hollow vitrified microspheres, calcium carbonate powder, Add the hydroxymethyl cellulose to the stirrer and stir for three minutes, then add the mixed glue, and stir for another five minutes;

[0112] 3) Put the evenly stirred raw materials into the mold;

[0113] 4) Press the raw materials put into the mold in step 3) according to the ratio of 1.8:1; extrusion length 100 mm, width 100 mm, thickness 50 mm;

[0114] 5) Send the pressed and formed insulation board into a microwave drying oven, the temperature is controlled between 180°C and...

Embodiment 3

[0119] An inorganic thermal insulation board comprises hollow vitrified microspheres, sodium silicate, polysiloxane emulsion, water, calcium carbonate powder and hydroxymethyl cellulose, and its preparation process is as follows:

[0120] 1) Raw material preparation: hollow vitrified microspheres 8kg, magnesium silicate 0.4kg, aluminum silicate 0.2kg, montmorillonite 0.2kg, bentonite 0.2kg, diatomite 2kg, light calcium carbonate 1kg, carboxymethyl fiber Sulfate 0.15kg, silica sol 4kg, sodium silicate 4kg, polysiloxane emulsion 0.2kg, sodium succinate sulfonate 0.1kg, water 1.8kg;

[0121] 2) Mixing and stirring: Add magnesium silicate, aluminum silicate, montmorillonite, bentonite, diatomaceous earth, silica sol, sodium silicate, polysiloxane emulsion, sodium succinate sulfonate and water into the mixer Stir for five minutes to form a mixed glue; add hollow vitrified microspheres, light calcium carbonate, and hydroxymethyl cellulose into the stirrer and stir for three minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com