Non-combustible fireproof insulation board and preparation method thereof

A technology of fireproof insulation board and inorganic flame retardant, which is applied in ceramic products, other household utensils, applications, etc., can solve the problems of high water absorption, high thermal conductivity, poor tensile strength, etc., and achieve light weight and good safety performance , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

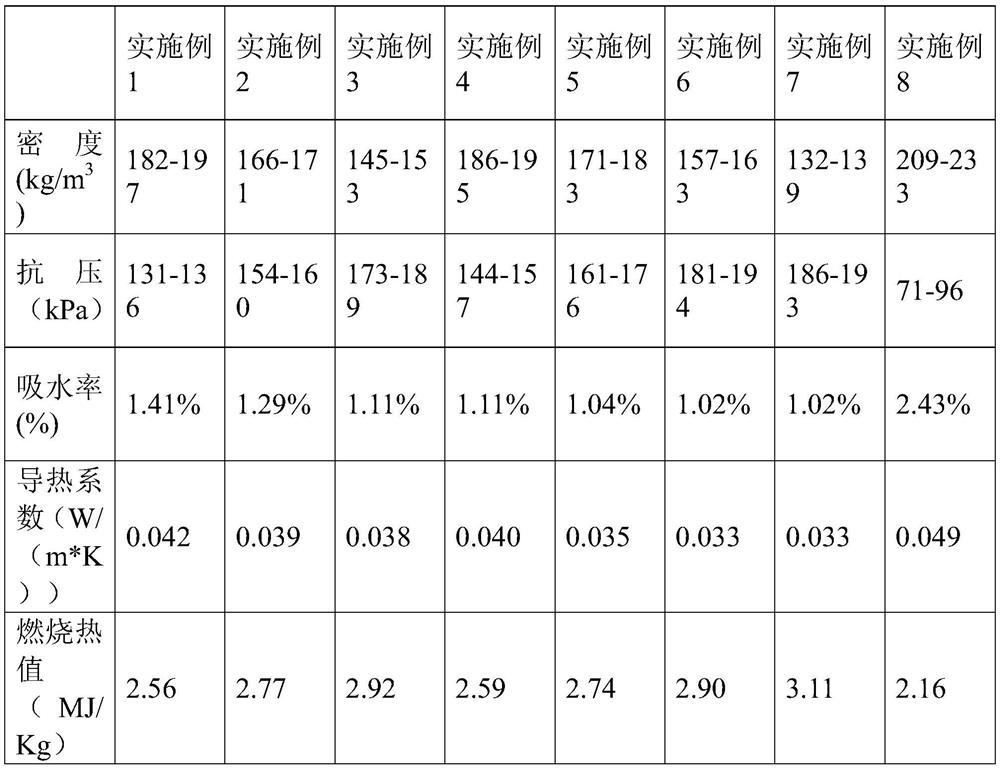

Examples

Embodiment 1

[0029] A non-flammable fire-insulated sheet, according to the weight ratio includes the following components: 95% of the inorganic flame retardant, 0.5% of the binder, 4.5% of the polystyrene powder.

[0030] Specifically, the density of the inorganic flame retardant is ≥1.5g / cm 3 , Good chemical stability, insoluble in water and organic solvent, decomposition temperature> 120 ° C, and inorganic flame retardant is inorganic, metal oxide flame retardant, preferably true density ≥ 3.5 g / cm 3 , Decomposition temperature> 200 ° C.

[0031] Specifically, the inorganic flame retardant is a powder, a particle size of 10-500 mesh, and a purity of 70-100%.

[0032] Specifically, the inorganic flame retardant is a powder, a particle size of 100-300 mesh, and the purity is 85-95%.

[0033] Specifically, the polystyrene powder has a particle size of from 100 to 2,000, the bubble magnification is 10-200 times, and the flame retardant level reaches the national standard B1 level; wherein th...

Embodiment 2

[0036] A non-flammable fire-insulated sheet, including the following components according to the weight ratio: 92% inorganic flame retardant, 0.8% binder, 7.2% of the polystyrene powder.

[0037] Specifically, the density of the inorganic flame retardant is ≥1.5g / cm 3 , Good chemical stability, insoluble in water and organic solvent, decomposition temperature> 120 ° C, and inorganic flame retardant is inorganic, metal oxide flame retardant, preferably true density ≥ 3.5 g / cm 3 , Decomposition temperature> 200 ° C.

[0038] Specifically, the inorganic flame retardant is a powder, a particle size of 10-500 mesh, and a purity of 70-100%.

[0039] Specifically, the inorganic flame retardant is a powder, a particle size of 100-300 mesh, and the purity is 85-95%.

[0040] Specifically, the polystyrene powder has a particle size of from 100 to 2,000, the bubble magnification is 10-200 times, and the flame retardant level reaches the national standard B1 level; wherein the particle si...

Embodiment 3

[0043] A non-flammable fire-insulated sheet, according to the weight ratio includes the following components: an inorganic flame retardant 90.7%, an adhesive 1.3%, and 8% of polystyrene powder.

[0044] Specifically, the density of the inorganic flame retardant is ≥1.5g / cm3 , Good chemical stability, insoluble in water and organic solvent, decomposition temperature> 120 ° C, and inorganic flame retardant is inorganic, metal oxide flame retardant, preferably true density ≥ 3.5 g / cm 3 , Decomposition temperature> 200 ° C.

[0045] Specifically, the inorganic flame retardant is a powder, a particle size of 10-500 mesh, and a purity of 70-100%.

[0046] Specifically, the inorganic flame retardant is a powder, a particle size of 100-300 mesh, and the purity is 85-95%.

[0047] Specifically, the polystyrene powder has a particle size of from 100 to 2,000, the bubble magnification is 10-200 times, and the flame retardant level reaches the national standard B1 level; wherein the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com