Grooving reinforcing structure for ultra-deep underground diaphragm wall in coastal reclamation area and construction method thereof

An underground diaphragm wall and reinforcement structure technology, which is applied in infrastructure engineering, sheet pile walls, buildings, etc. Water-stopping performance, good reinforcement and water-stopping effect, and the effect of preventing the collapse of the groove wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

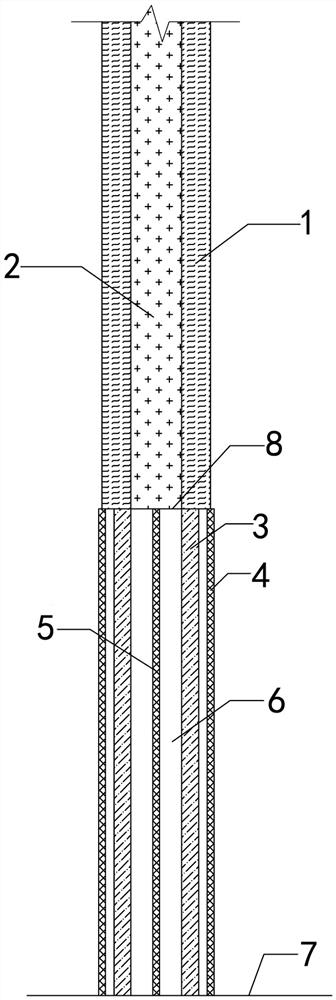

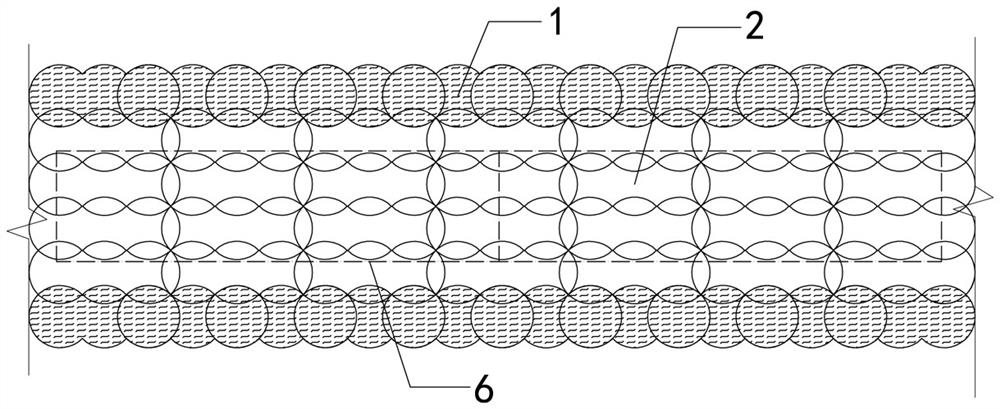

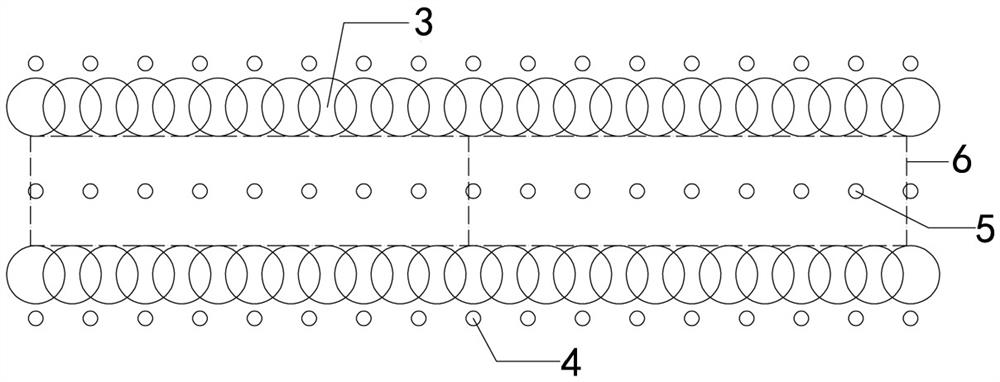

[0038] Examples see Figure 1-3 As shown, an ultra-deep underground diaphragm wall trough reinforcement structure in the seaside push fill area is formed in the groove section of the underground diaphragm wall 6 and in the soil around the groove section, and includes a combined reinforcement structure. The combined reinforcement structure includes upper and lower The upper reinforcement structure and the lower reinforcement structure are connected as a whole, with a fixed height as the dividing line. In this embodiment, the height dividing line 8 between the upper reinforcement structure and the lower reinforcement structure in the combined reinforcement structure is 30m.

[0039] The upper reinforcement structure includes a three-axis stirring pile 1 outside the tank and a three-axis stirring pile 2 inside the tank, and the reinforcement depth of the upper reinforcement structure ranges from the ground to 30m underground. The three-axis stirring pile 1 outside the tank and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com