Guide rail and sliding block mechanism for cantilever beam

A technology of guide rail sliders and cantilever beams, which is applied in the field of rehabilitation robots, can solve the problems of reducing the rehabilitation effect of patients wearing weight-loss clothing, the impact of patients' rehabilitation effects, and untargeted application, so as to facilitate rehabilitation training, procurement and processing The effect of low cost and increased practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

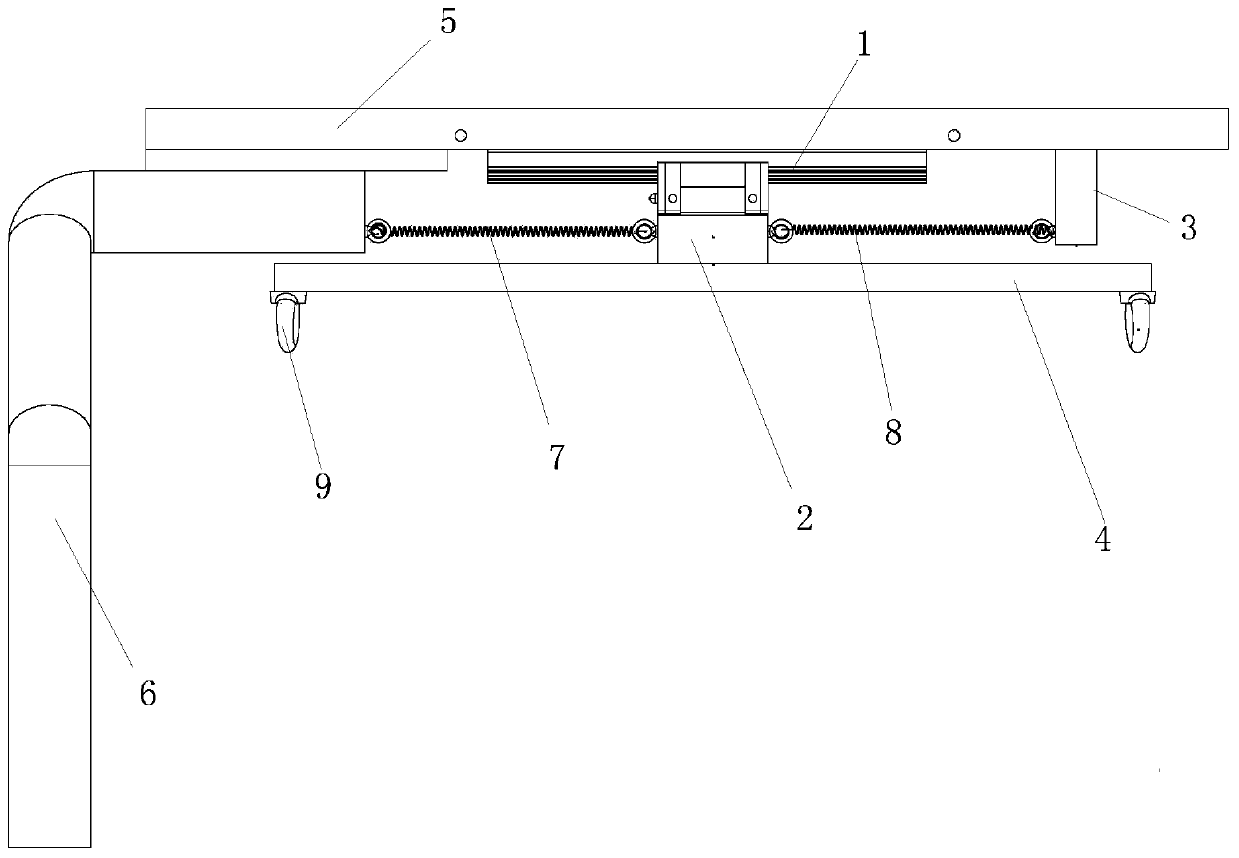

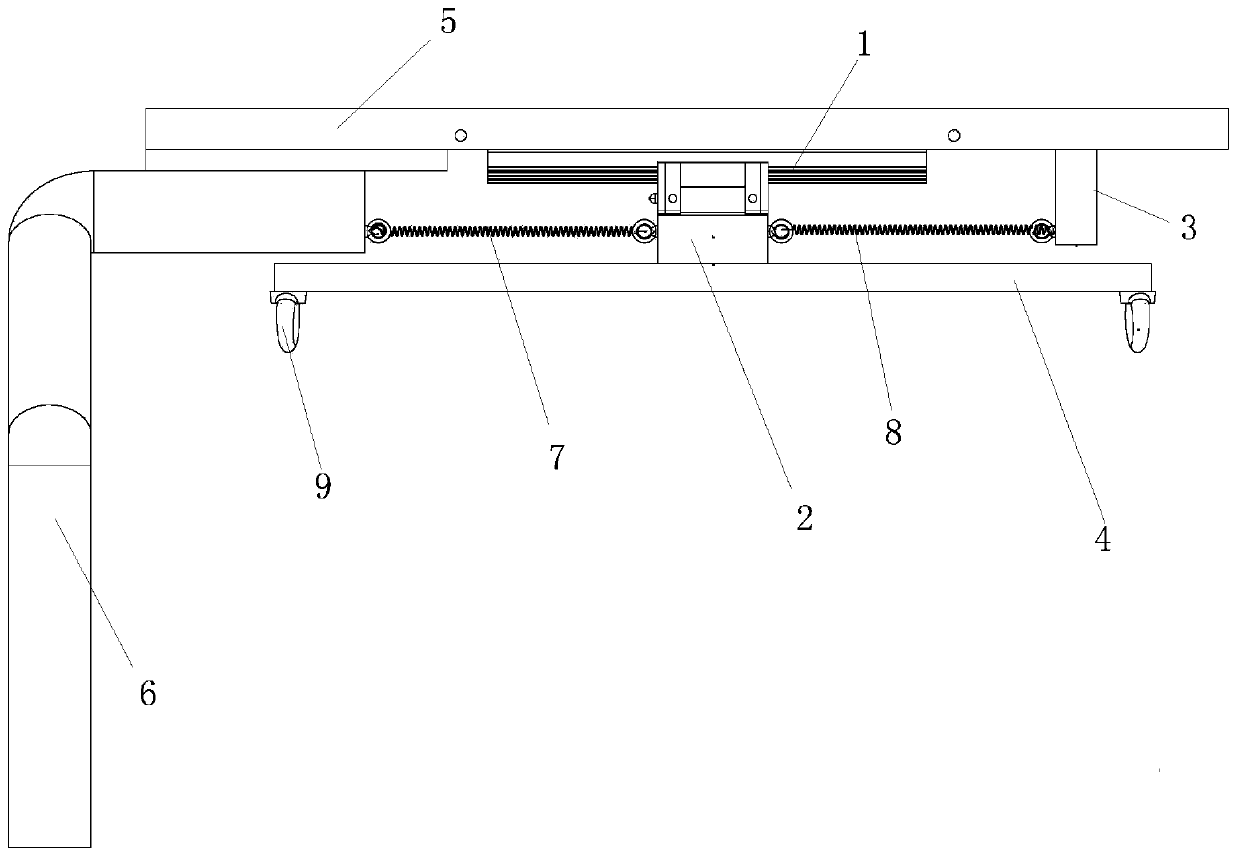

[0016] A guide rail slider mechanism for a cantilever beam, comprising a linear guide rail 1, a slider 2, a limit block 3, and a force plate 4, wherein the linear guide rail 1 and the limit block 3 are respectively fixed and installed on the cantilever beam through bolt connection 5, the slider 2 is set on the linear guide rail 1, the slider 2 can slide left and right along the linear guide rail 1, the slider 2 and the force plate 4 are fixedly connected by bolts; the slider 2 and the frame 6, the limit block 3 are respectively Through the spring connection, the two ends of the slider 2 are fixed to prevent the slider 2 from moving freely. Hook bolts, the two ends of spring one 7 are respectively connected with the hook bolts on the left end face of frame 6 and slide block 2, and the two ends of spring two 8 are respectively connected with the hook bolts on the limit block 3 and the right end face of slide block 2, Wherein, the length of spring one 7 is equal to that of spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com