Salix psammophila cellulose nanofibers, aerogel ball, preparation and application

A nanofiber and cellulose technology, applied in the field of nanocellulose modification, can solve the problems of polluting environmental resources, troublesome treatment, low utilization rate, etc., and achieves the effects of high activity, preventing self-aggregation, and improving adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] This embodiment provides a salix microcrystalline cellulose, which is prepared according to a preparation method comprising the following specific steps:

[0107] (1) Weigh 10 g of Salix salix powder, add it into distilled water at a ratio of 1:60 (mass volume ratio, units are g and mL), and heat at 80°C for 1 h to remove surface impurities and part of the water-soluble components, and then the resulting solution was filtered, and the filtered filtrate was dried at 105°C to obtain a dried sample with a yield of 87%;

[0108] (2) The dried sample of step (1) is placed in a three-necked flask, and nitric acid ethanol solution (1:3v / v) is added into the three-necked flask, wherein, the mass of the dried sample and nitric acid ethanol solution The volume ratio is 1:43, the units are g and mL respectively, condensed and refluxed at 90°C, the sample is taken out, washed with distilled water and absolute ethanol until neutral, and dried at 105°C to constant weight; among them,...

Embodiment 2

[0115] This embodiment provides a series of salix cellulose nanofibers, which are prepared according to the preparation method comprising the following specific steps:

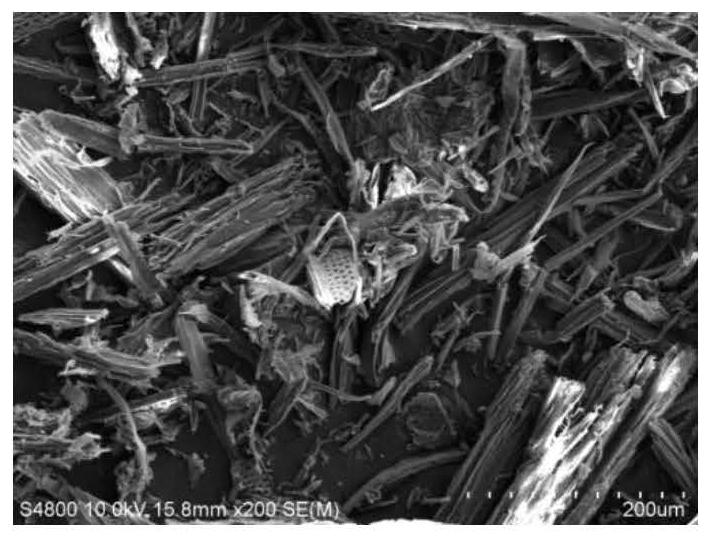

[0116] 1) the Salix microcrystalline cellulose (as Figure 17 Shown), TEMPO, sodium bromide, and salix microcrystalline cellulose, TEMPO and sodium bromide and 100mL distilled water are placed in the 250mL three-necked flask, stirred for 30min, and then added sodium hypochlorite solution (effectively Chlorine mass content is 10%)), and the pH of solution is adjusted between 10.0-10.5 with the sodium hydroxide solution of 0.5mol / L, keeps this pH range until reaction finishes and adds 20mL anhydrous methanol termination reaction; Wherein, TEMPO / NaBr / NaClO oxidation mechanism diagram Figure 9 Shown, step 1) obtained salix microcrystalline cellulose sample after oxidation is as Figure 18 shown;

[0117] 2) Adjust the pH value of the oxidized Salix microcrystalline cellulose solution obtained in step 1) to 10...

Embodiment 3

[0133] This embodiment provides a series of Salix microcrystalline cellulose / Sawillow cellulose nanofiber airgel balls, which are prepared according to the preparation method comprising the following specific steps:

[0134] 1. Weigh 4g of Salix microcrystalline cellulose prepared in Example 1 and 6.672g of sodium hydroxide, and dissolve the two in 77.76mL of distilled water, stir until the cellulose solution is in a homogeneous state, and then add 11.52 g of thiourea, stir again until the thiourea dissolves and place the gained solution in a -12.5°C refrigerator to refrigerate, take out and obtain a salix microcrystalline cellulose solution with a concentration of 4wt%;

[0135] 2. Take the salix microcrystalline cellulose solution prepared in step 1 of a certain quality and combine it with the salix cellulose nanofiber (TOCNF prepared under preferred conditions in Example 2) aqueous solution with a concentration of 0.05 mg / mL (g) Mix well, and then use a 5mL syringe to add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com