Patents

Literature

55 results about "Cellulose formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259AImprove toughnessGood film formingOther chemical processesWater/sewage treatment by sorptionFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

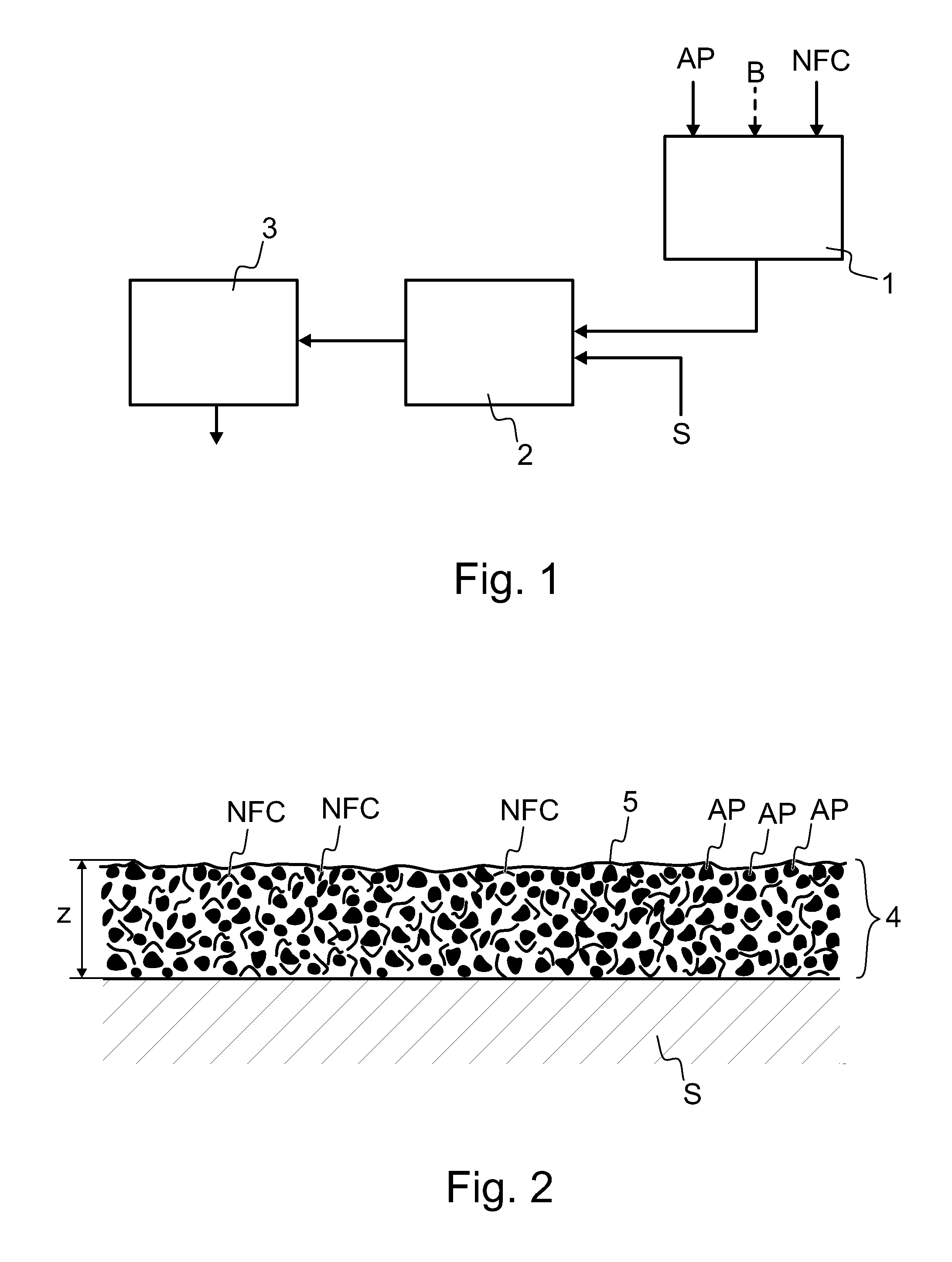

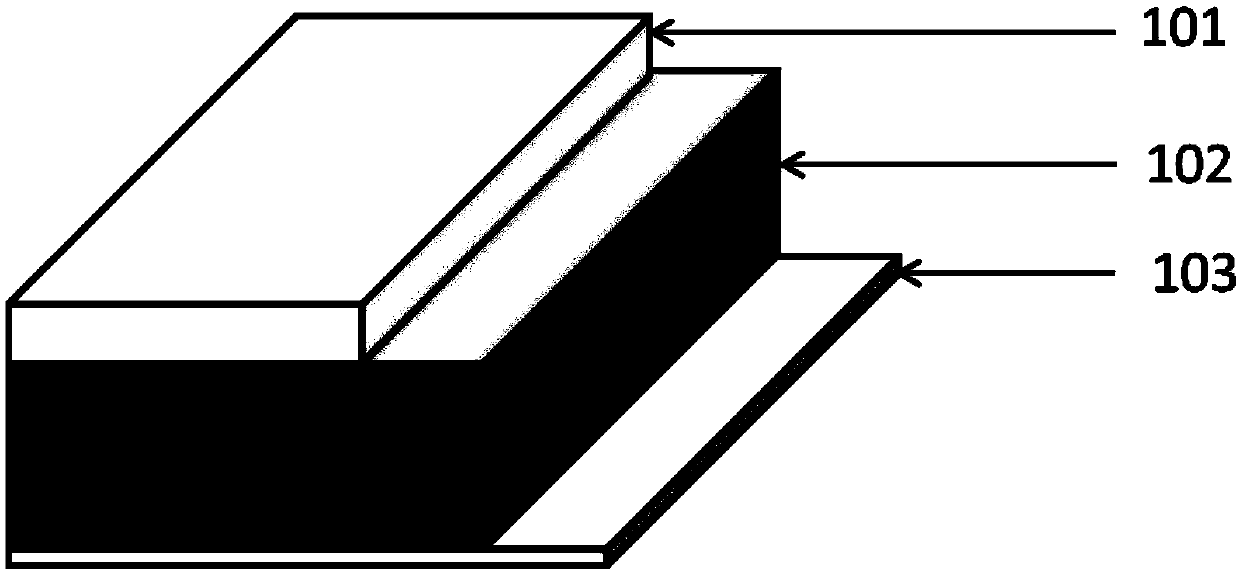

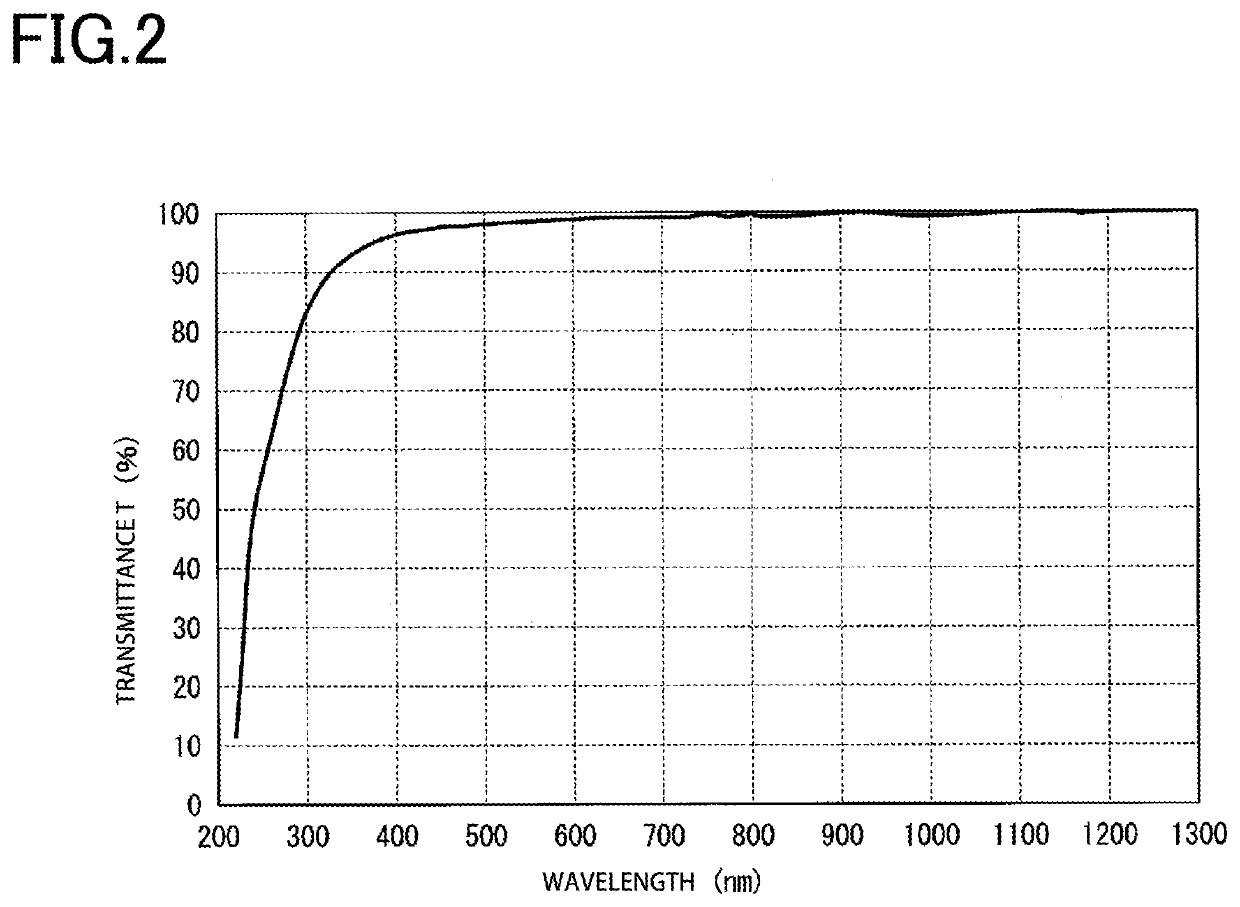

Method for the preparation of NFC films on supports

InactiveUS20140255688A1Excellent oxygen barrier propertiesReduce porosityCellulose coatingsCellulosic plastic layered productsCellulosePolymer science

The present invention concerns a method of preparing a film of nanofibrillated cellulose (NFC) on at least one surface of a support material, wherein the film is applied and spread directly onto a surface of the plastic support material in the form of a suspension of nanofibrillated cellulose, whereby the nanofibrillated cellulose forms a film. Further, the invention concerns a structure containing or consisting of a film of nanofibrillated cellulose prepared using said method.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Preparation method of antibacterial hydrogel

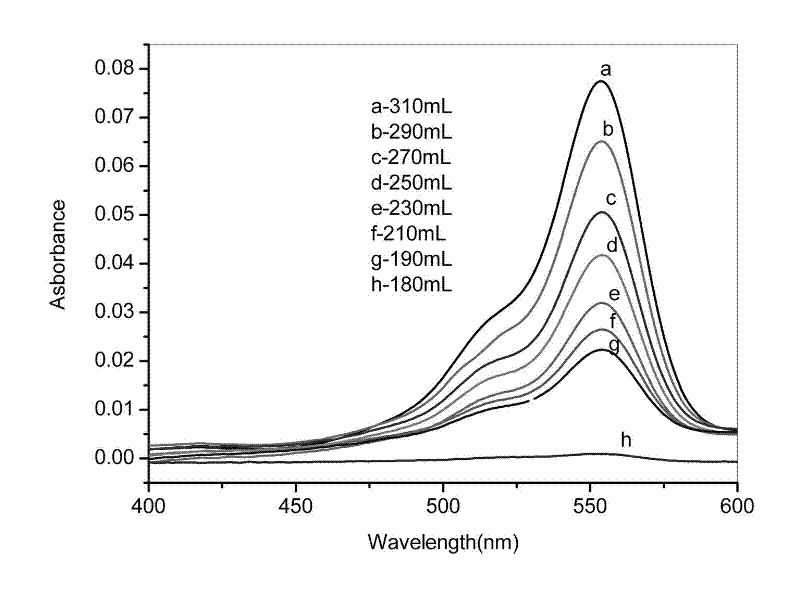

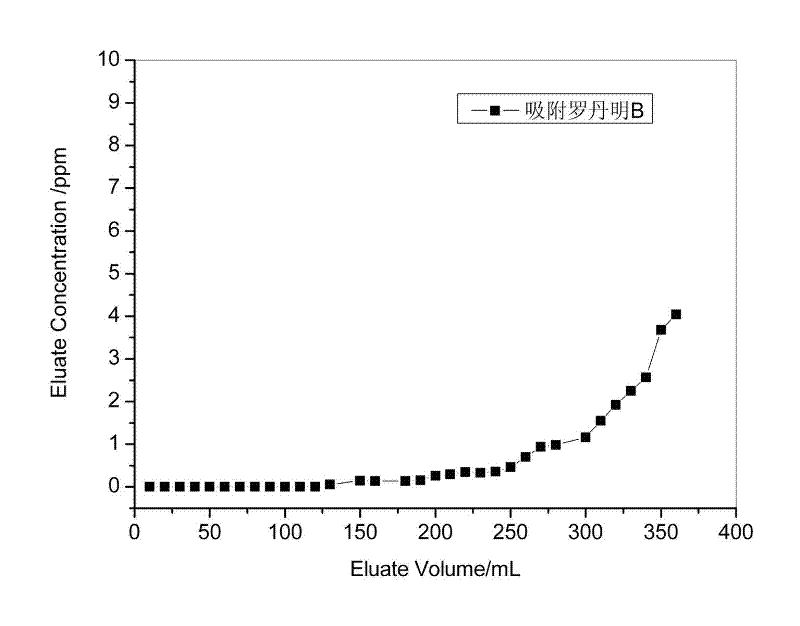

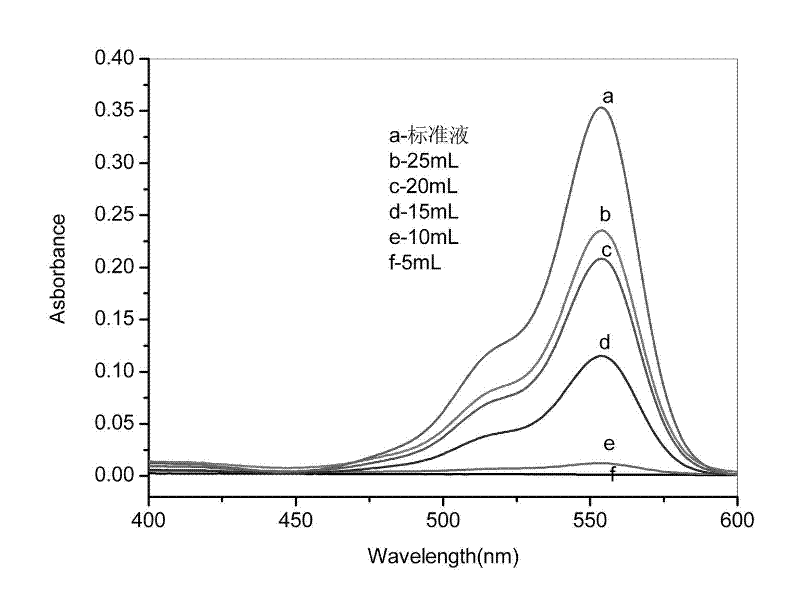

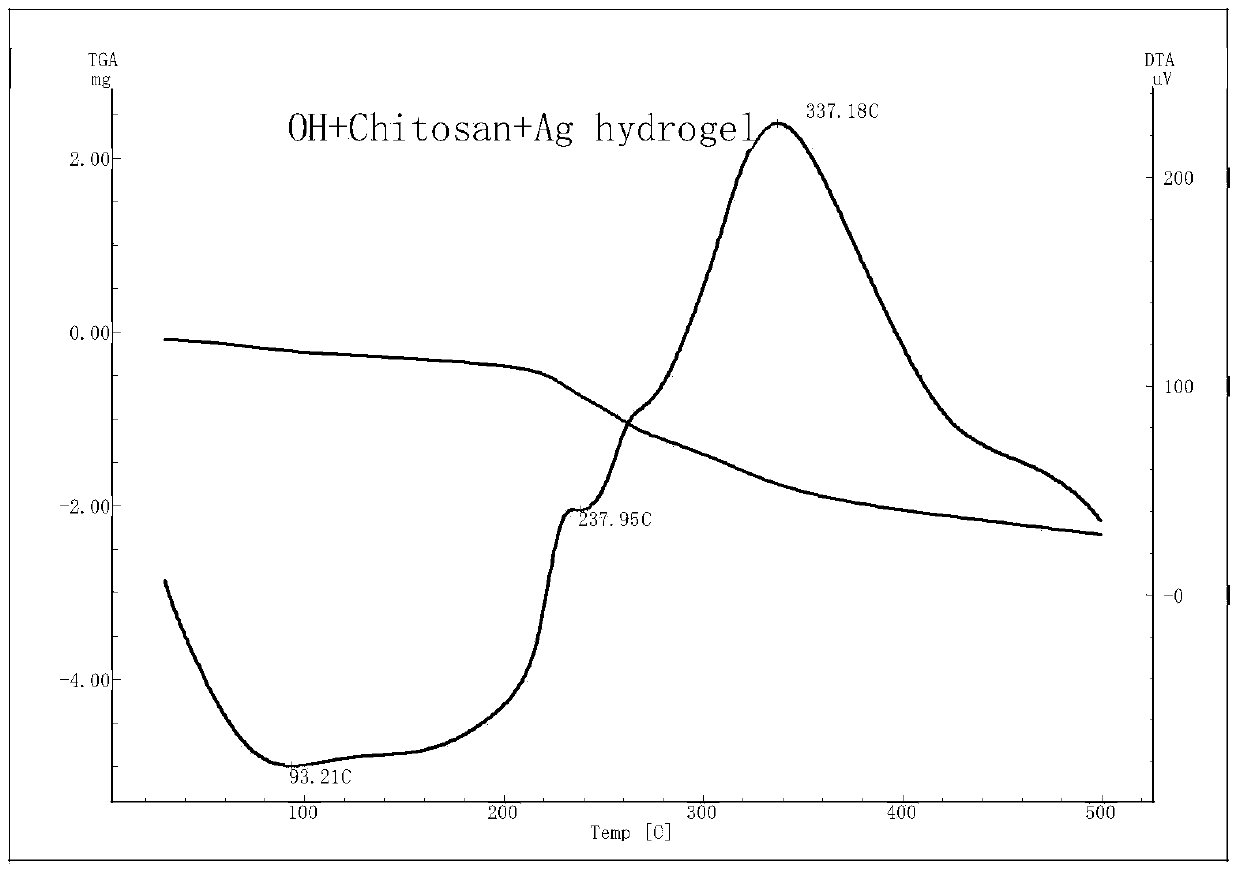

ActiveCN104045843ALow reaction temperatureReduce energy consumptionReaction temperatureNetwork structure

The invention discloses a preparation method of an antibacterial hydrogel. The preparation method comprises the following steps: step 1, oxidizing active hydroxyl in hemicellulose into an aldehyde group by using an oxidant to obtain dialdehyde hemicellulose; step 2, enabling an excessive dialdehyde hemicellulose solution to react with a chitosan solution, and forming a mixture of the hydrogel and remained dialdehyde hemicellulose; and step 3, soaking the mixture into a solution containing silver ions to ensure that silver particles are adsorbed on the surface of a hydrogel network structure, thus preparing the antibacterial hydrogel. By adopting the method disclosed by the invention, hemicellulose is modified by using the oxidant and is provided with a functional group, so that hemicellulose is beneficial for performing a Schiff base reaction with an amino group in chitosan. The preparation method of the antibacterial hydrogel is low in reaction temperature condition and low in energy consumption, and is easy to put into industrial production. In addition, the silver particles adsorbed by the prepared antibacterial hydrogel reach nano-level and have excellent antibacterial effects.

Owner:BEIJING FORESTRY UNIVERSITY

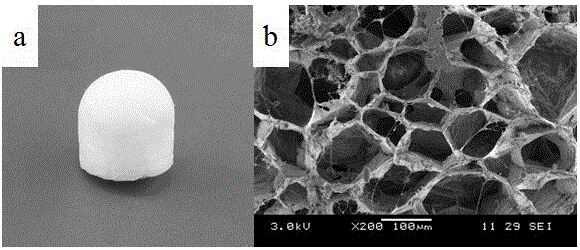

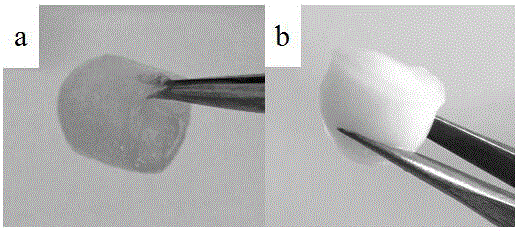

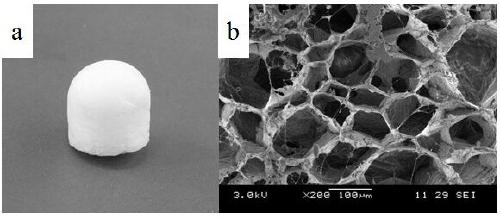

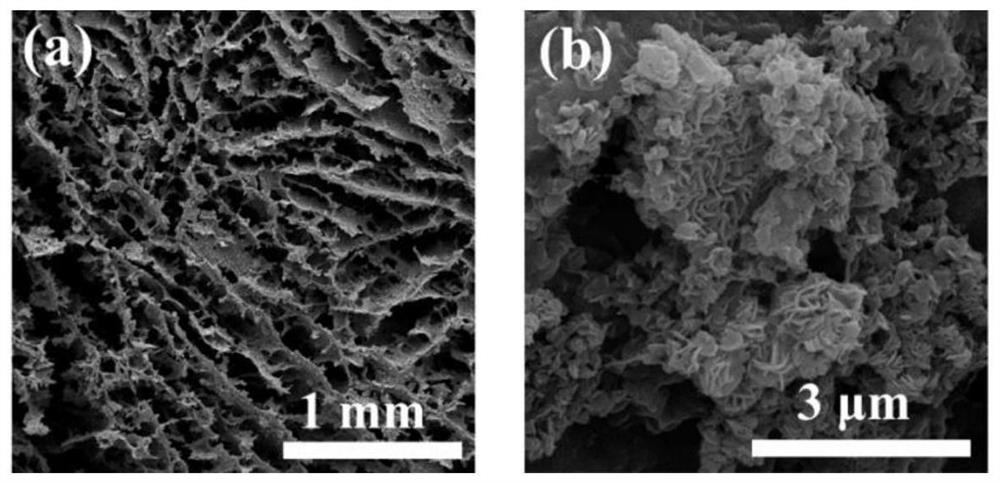

Preparation method of nanocellulose and polymer composite aerogel

The invention discloses a preparation method of nanocellulose and polymer composite aerogel. The preparation comprises the steps that a Pickerin emulsion containing a polymer in an oil phase of which the nanocellulose is stable is subjected to gelation firstly, freeze drying is conducted, and the nanocellulose and polymer composite aerogel which is high in porosity and low in density is obtained. The preparation method is suitable for nanocellulose which is extracted and prepared from various raw materials and has different morphology and various water insoluble polymers, and large-scale popularization is easy to achieve. For most composite aerogel materials formed by water-soluble polymers and cellulose at present, composite aerogel materials formed by the water insoluble polymers and cellulose are obtained. Meanwhile, reagents used in the preparation method are common reagents, the price is low, the preparation process is simple, convenient and rapid, and the obtained nanocellulose and polymer composite aerogel has the advantages of being high in porosity, low in density and low in heat conductivity coefficient, having water absorption oil absorption performance and the like.

Owner:桂林奇宏科技有限公司

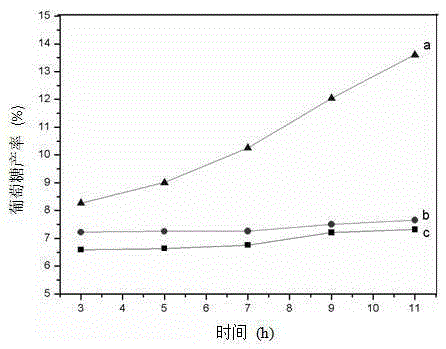

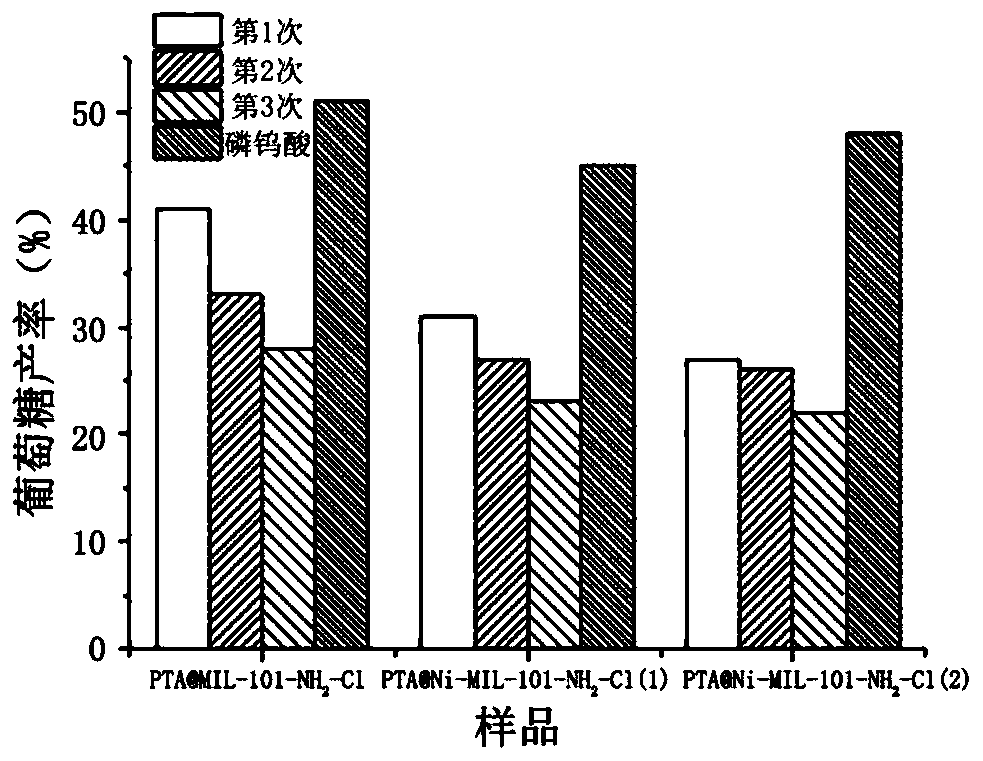

Phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and preparation method and application thereof

InactiveCN105344378AEnsure loading efficiencyEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsGlucose productionCellulosePolymer science

The invention discloses a phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and a preparation method and application thereof. According to the invention, organic ligand with strongly electronegative groups and basic groups is screened out and participates in coordination reaction of a metal organic skeletal material so as to realize functionalization, phospho-tungstic acid is directly added into a synthesis system, and immobilization is realized in the process of synthesis. The prepared phosphotungstic acid-metal organic skeleton reduces the frequency of contact with glucose through formation of a hydrogen bond with cellulose so as to reduce side reaction of glucose under the catalysis of acid, high glucose selectivity is obtained, and oriented conversion of cellulose to glucose can be realized; meanwhile, the effect of the hydrogen bond can weaken the effect of a hydrogen bond in cellulose, reduces the crystallization degree of cellulose, enables cellulose to be easier to hydrolyze and improves hydrolysis efficiency.

Owner:SOUTH CHINA UNIV OF TECH

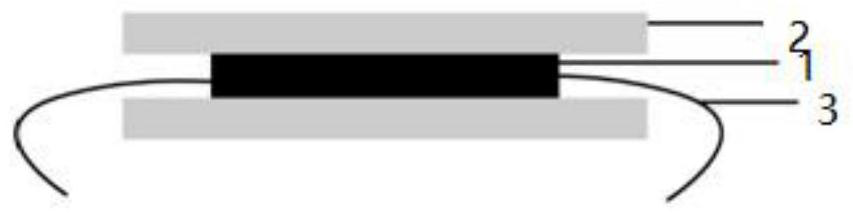

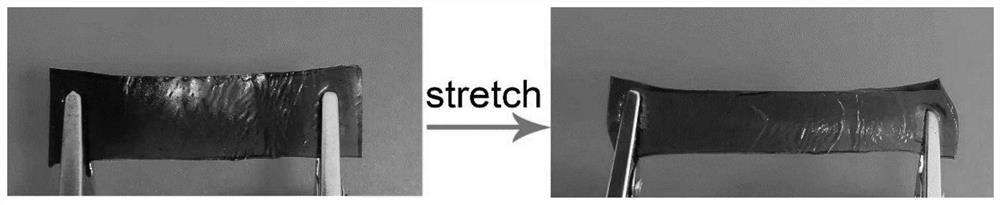

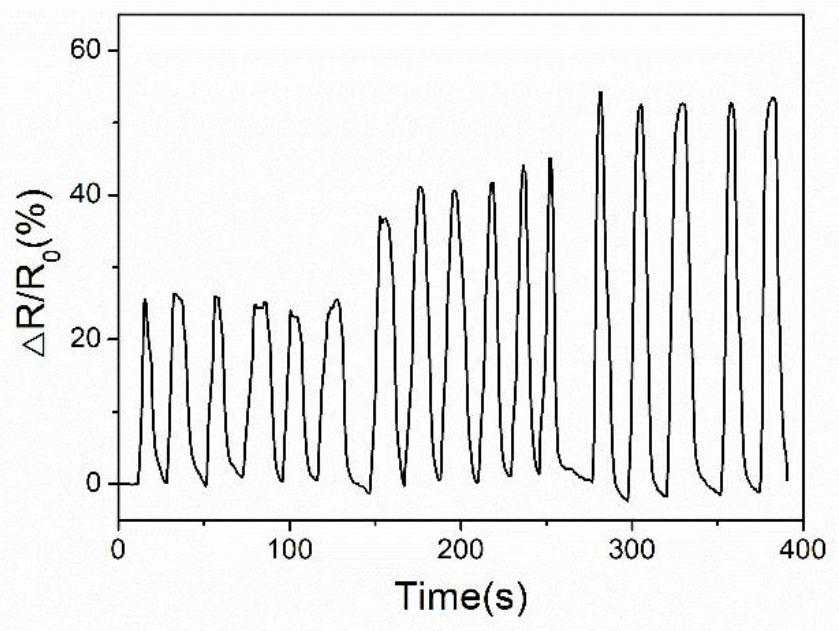

Anti-freezing self-repairing conductive hydrogel and preparation method thereof and flexible sensor

InactiveCN112608508ALow freezing pointStrong frost resistanceElectrical/magnetic solid deformation measurementSensor materialsAqueous solution

The invention relates to the technical field of flexible sensor materials, particularly to an anti-freezing self-repairing conductive hydrogel and a preparation method thereof, and a flexible sensor. According to the preparation method, a conductive nanofiller / nanocellulose / polyacrylamide hydrogel is soaked in a composite modifier aqueous solution containing an anti-freezing agent and a metal salt, wherein the metal salt cooperates with the anti-freezing agent component to replace water molecules in a hydrogel network system, so that the freezing point of water in a composite hydrogel network structure is reduced, and the freezing resistance is improved; metal cations and cellulose in the composite hydrogel form reversible ionic bonds, the cellulose and polyacrylamide form reversible hydrogen-bond interaction, and the prepared hydrogel is endowed with excellent self-repairing performance through a formed multiple reversible network; and the metal salt cooperates with the conductive nano-filler to endow the prepared hydrogel with excellent conductivity, sensitive sensing performance and mechanical flexibility meeting the requirements of corresponding application scenarios.

Owner:南京柔速科技有限公司

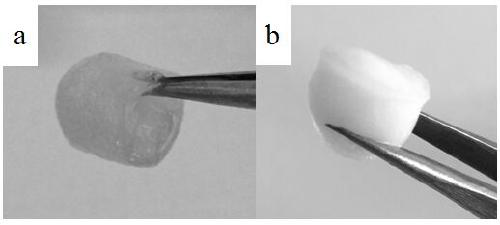

Capsule comprising low-substituted cellulose ether and method for preparing the same

ActiveUS20050142186A1Quick displayHardly undergoes deteriorationPharmaceutical non-active ingredientsCapsule deliveryCelluloseHard Capsule

Owner:SHIN ETSU CHEM IND CO LTD

Method for preparing membrane with excellent ion conductivity

The invention discloses a method for preparing a battery membrane with the excellent ion conductivity. The method of the invention comprises the following steps: cellulose with the degree of polymerization of 500 to 1600 is dissolved in a solvent to form a solution; alkyl cellulose is dissolved in the solvent to form a solution; the two solution are mixed into a solution which has the polymer with the weight concentration of 25 to 50 percent, then polyethylene glycol and zinc chloride solutions are added; a gel membrane containing the alkyl cellulose which is dispersed in the regenerated cellulose continuous phase is formed; and the gel membrane is dried to prepare the battery membrane. The battery membrane which is prepared by the invention can be resistant to the alkaline electrolyte and not be penetrated by zinc ions; furthermore, the battery membrane contains the polymer region with the hydrogen penetration rate.

Owner:SHENZHEN SENIOR TECH MATERIAL

Processing technology of crease-resistant fabric for western-style clothes

The invention discloses a processing technology of a crease-resistant fabric for western-style clothes. The technology concretely comprises the following steps: weaving cotton / wool blended yarns usedas warp yarns and cotton / XLA fiber core-spun yarns as weft yarns; treating a base cloth in a treatment bath containing sodium pyrophosphate and hydrogen peroxide; polymerizing maleic acid and an acrylic emulsion to obtain a finishing agent; mixing the crease-resistant finishing agent, disodium hydrogen phosphate, sodium borofluoride, an osmotic agent and active polypeptides to prepare a finishingsolution; and treating the hydrogen peroxide treated base cloth in the finishing solution, and pre-drying and drying the treated base cloth to obtain the crease-resistant fabric for western-style clothes. The crease-resistant finishing agent is harmless to human bodies and the environment, and the crease-resistant finishing agent and cellulose can form a macromolecular network structure compound to make the cellulose have a large relative slip space when meeting outside force in order to improve the crease-resistant finishing effect; and the fabric has the advantages of good drapability, goodcrease resistance, good breathability and excellent washing resistance.

Owner:海盐派特普科技有限公司

Preparation method of wet strength agent for papermaking

InactiveCN106638144AHigh strengthHigh tear performanceReinforcing agents additionPaper/cardboardCellulosePhosphoric acid

The invention relates to a preparation method of a wet strength agent for papermaking and belongs to the technical field of preparation of wet strength agents. Chitosan is subjected to swelling treatment with anhydrous ethanol firstly and then modified with maleic anhydride and phosphoric acid, and modified chitosan is obtained; modified chitosan reacts with isocyanate, and a chitosan polymer is obtained; hydroxyl and amino in the chitosan polymer can form hydrogen bonds with cellulose in paper and can perform bridging and film formation among cellulose to enhance the wet strength and the tearing strength of paper; then, methyl benzene sulfonic chloride and other substances are utilized to modify hydroxypropyl guar gum, and modified guar gum is obtained; finally, modified guar gum is mixed with a chitosan polymer concentrated solution and other substances for ageing, and the wet strength agent for papermaking is obtained. The wet strength agent solves the problem that a conventional wet strength agent cannot improve the wet strength and the tear resistance of paper, improves the wet strength and the tear resistance of paper greatly, and can realize expanded production.

Owner:梅庆波

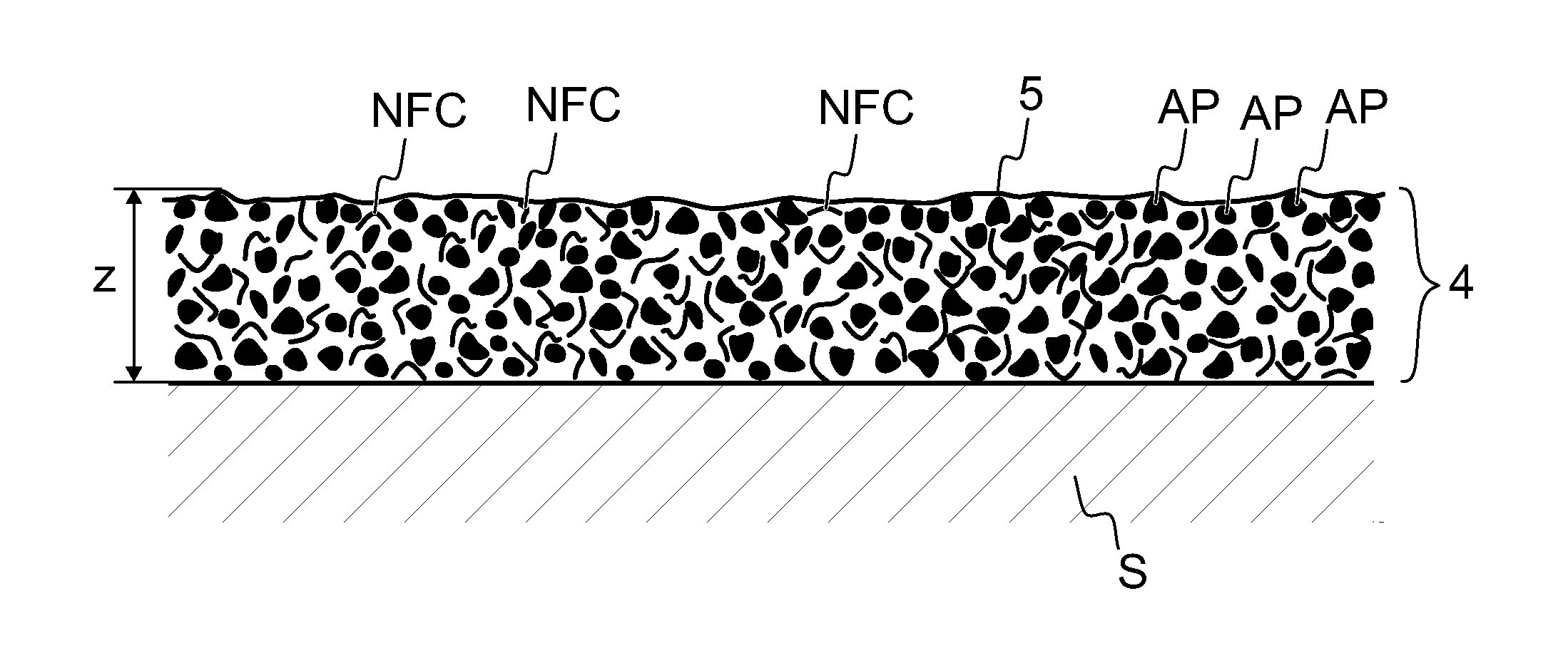

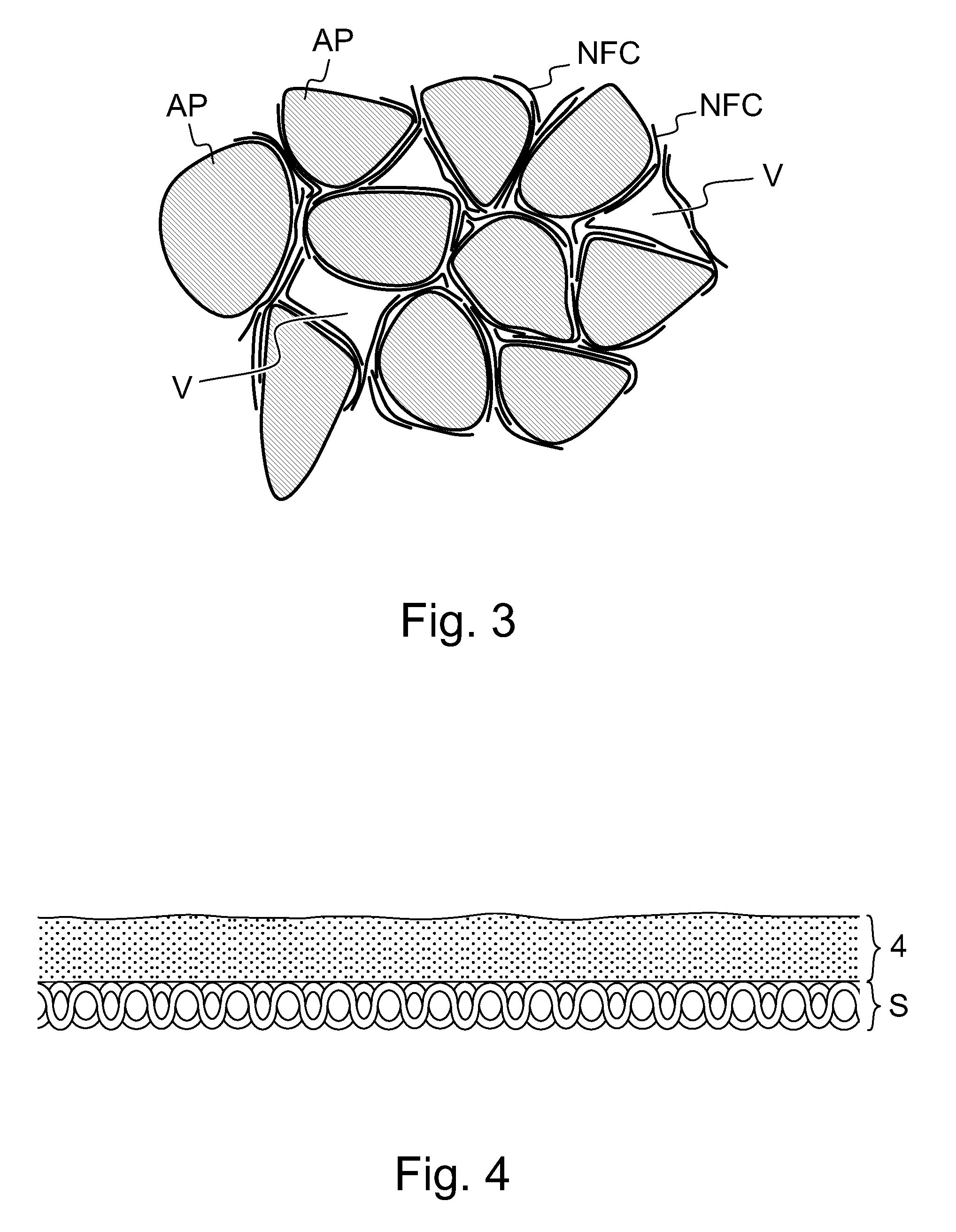

Composite body and method of manufacturing it

ActiveUS20160208153A1Improve waterproof performanceSolve Porosity InsufficiencyOther chemical processesAbrasion apparatusCelluloseMohs scale of mineral hardness

Composite body comprises nanofibrillar cellulose (NFC) together with abrasive particles (AP). The nanofibrillar cellulose forms a 3-dimensional connecting network for the abrasive particles (AP). The abrasive particles have a hardness above 7 on Mohs scale. The composite body is used for grinding, polishing or cutting.

Owner:KWH MIRKA

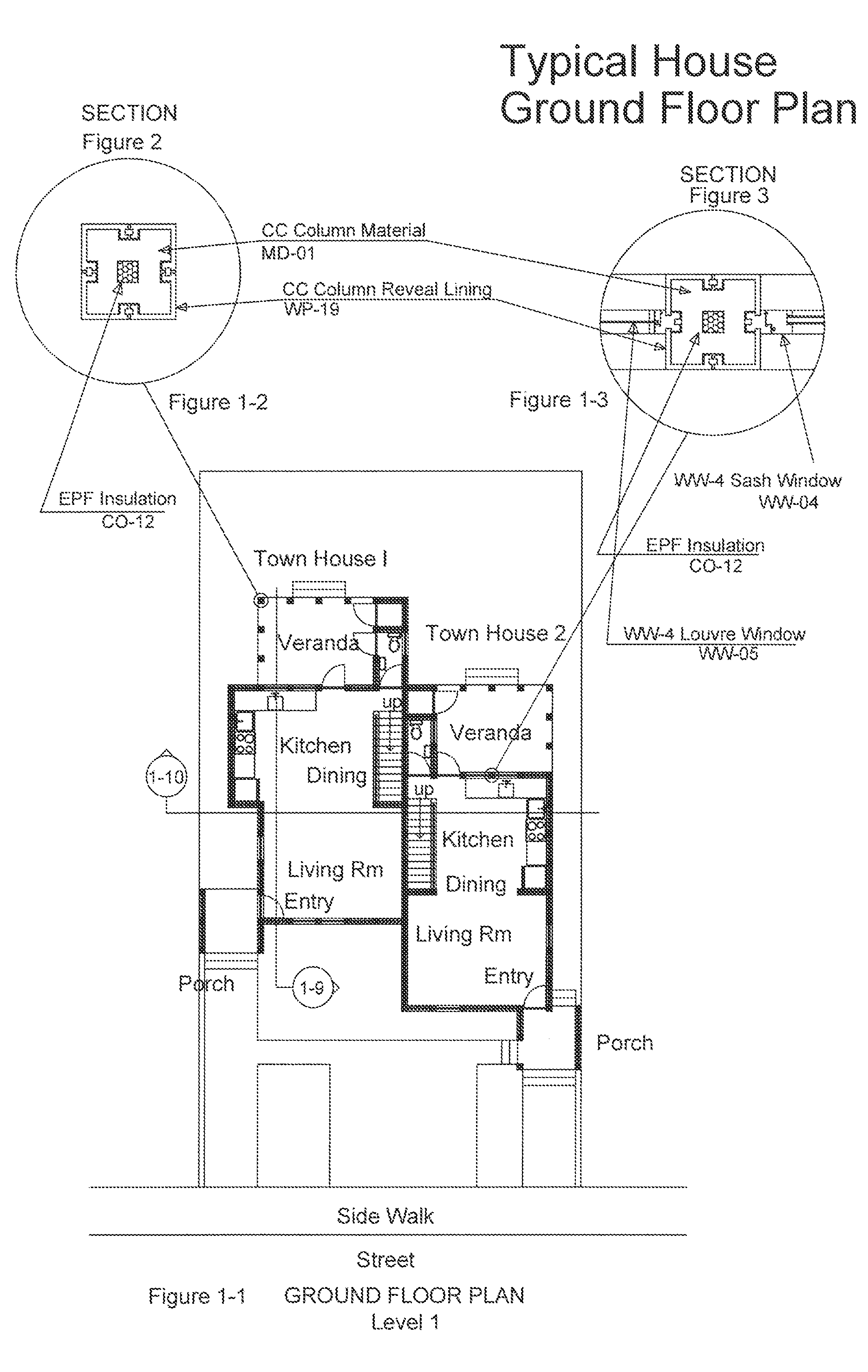

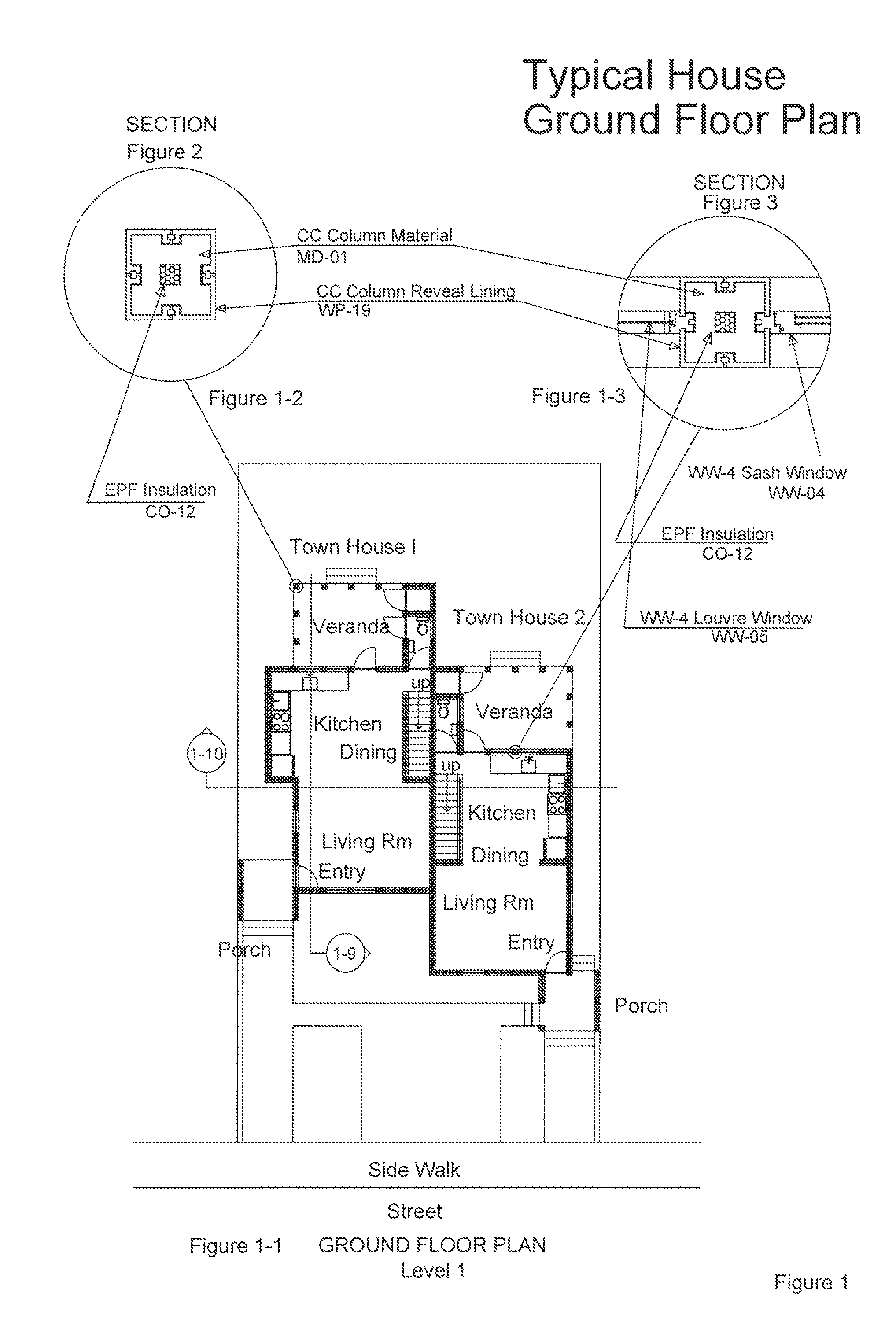

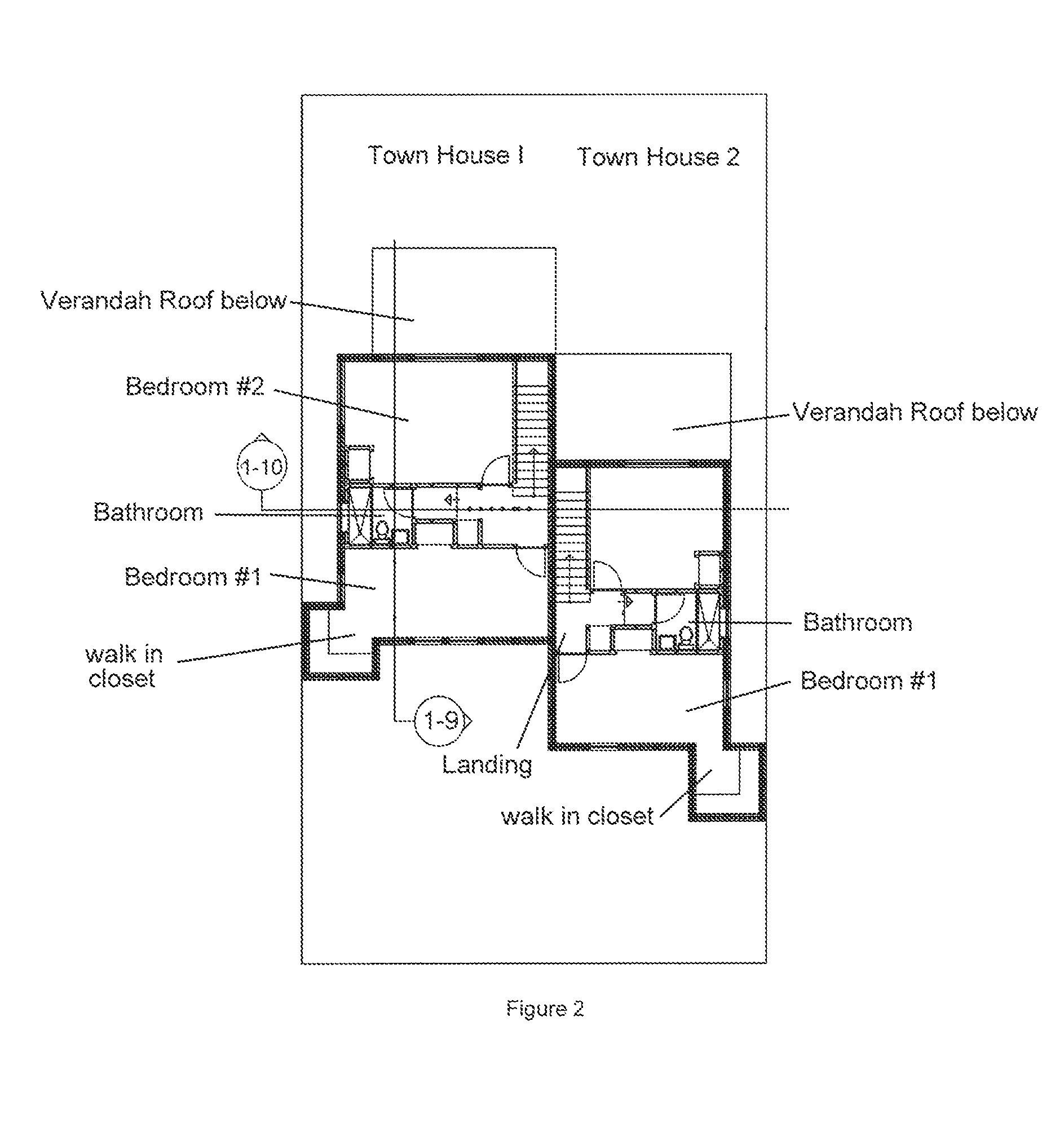

Cellulose construction system

InactiveUS20120144764A1Roof covering using slabs/sheetsRoof covering using tiles/slatesCelluloseCellulose formation

The invention is directed to a system for constructing a building that includes a plurality of components formed substantially of cellulose and configured to be arranged together to form the walls, roof, and floor of the building. Further, reinforcements are molded into the plurality of components and a plurality of joint structures arranged along at least one of edge of at least two of the plurality to components, the joint structures configured to connect the plurality of components together.

Owner:HANNA JAMES

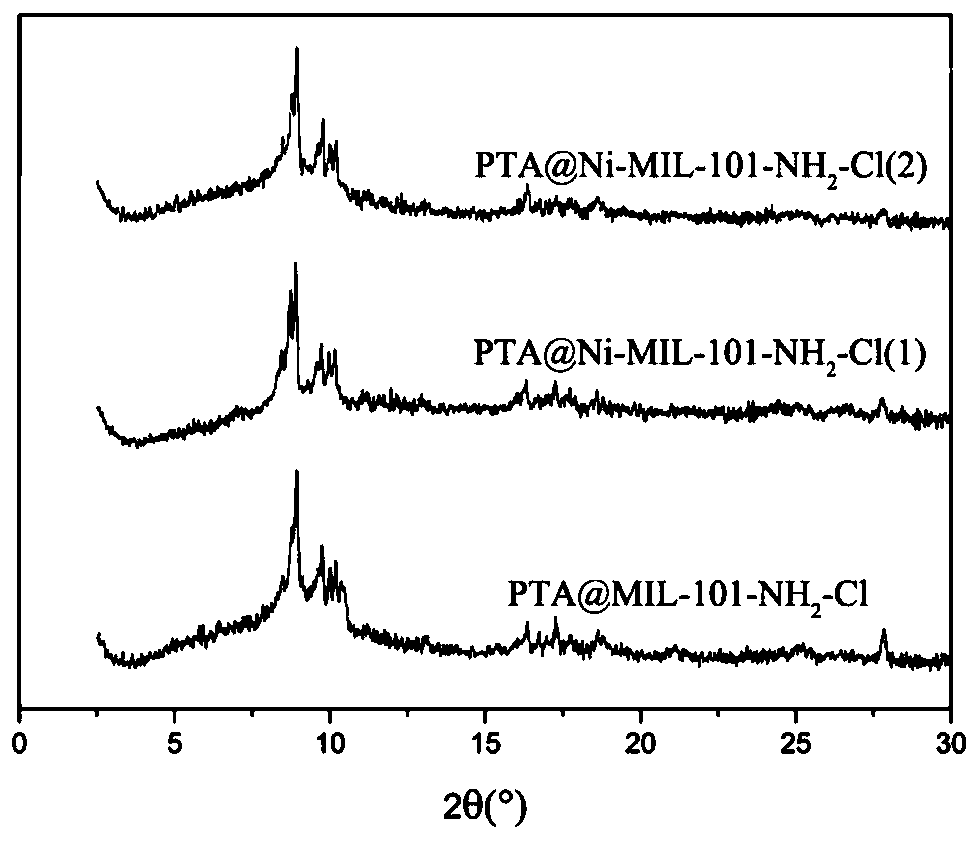

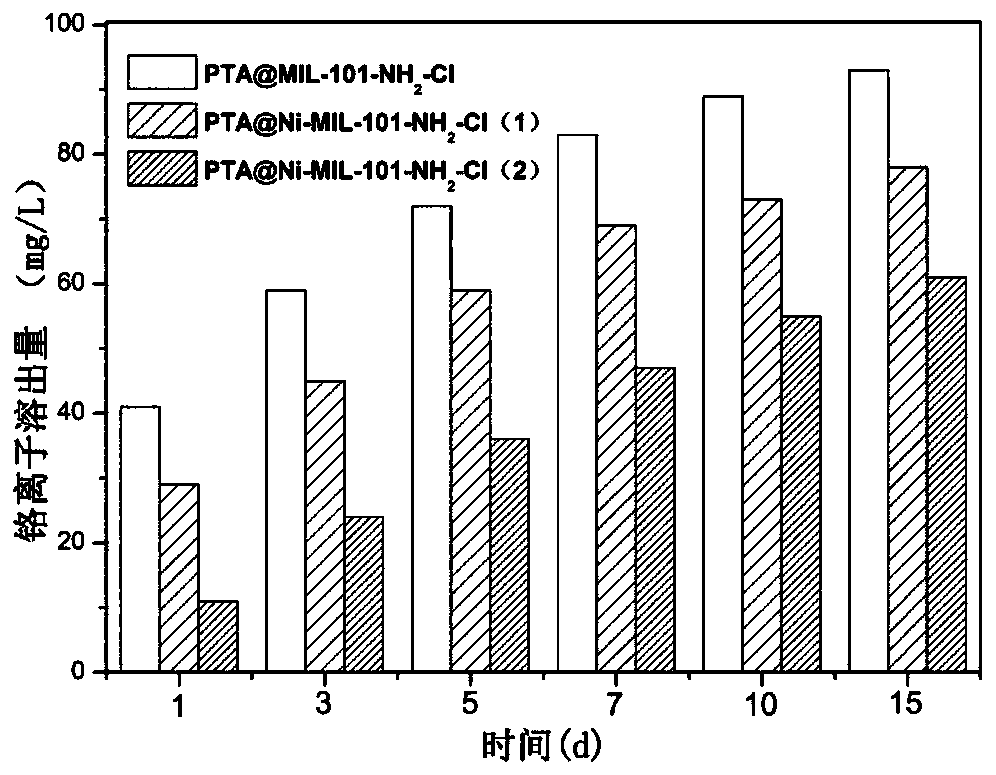

Double-metal material supported phosphotungstic acid catalyst as well as preparation method and application thereof to cellulose hydrolysis

ActiveCN109759138ARaise the ratioComplete structure with high stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCelluloseMetal-organic framework

The invention discloses a double-metal material supported phosphotungstic acid (PTA) catalyst as well as a preparation method and application thereof to cellulose hydrolysis. The method comprises thefollowing steps: introducing transition metal ions Ni<2+> when an organic ligand is coordinated with metal to form competition coordination with central metal ions Cr<3+>; adding organic acid to accelerate the coordination of composite double-metal MOFs (Metal Organic Frameworks) and realize the effect of a mineralizing agent; introducing -NH2 and phosphotungstic acid to realize chemical supporting of PTA through electrostatic interactions, so as to synthesize the catalyst. According to the catalyst disclosed by the invention, a hydrogen bond is formed through a heavy-current negative group and cellulose to adsorb the cellulose, so that directed transformation from the cellulose to glucose is realized. Meanwhile, an inner hydrogen bond effect of the cellulose also can be weakened through the hydrogen bond effect and the crystallization degree is reduced so that the catalyst is easier to hydrolyze and the hydrolysis efficiency is improved. In a catalyst synthesis process, solutions of HF (Hydrofluoric Acid) acid, sodium hydroxide and the like are not added, so that the catalyst is green and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

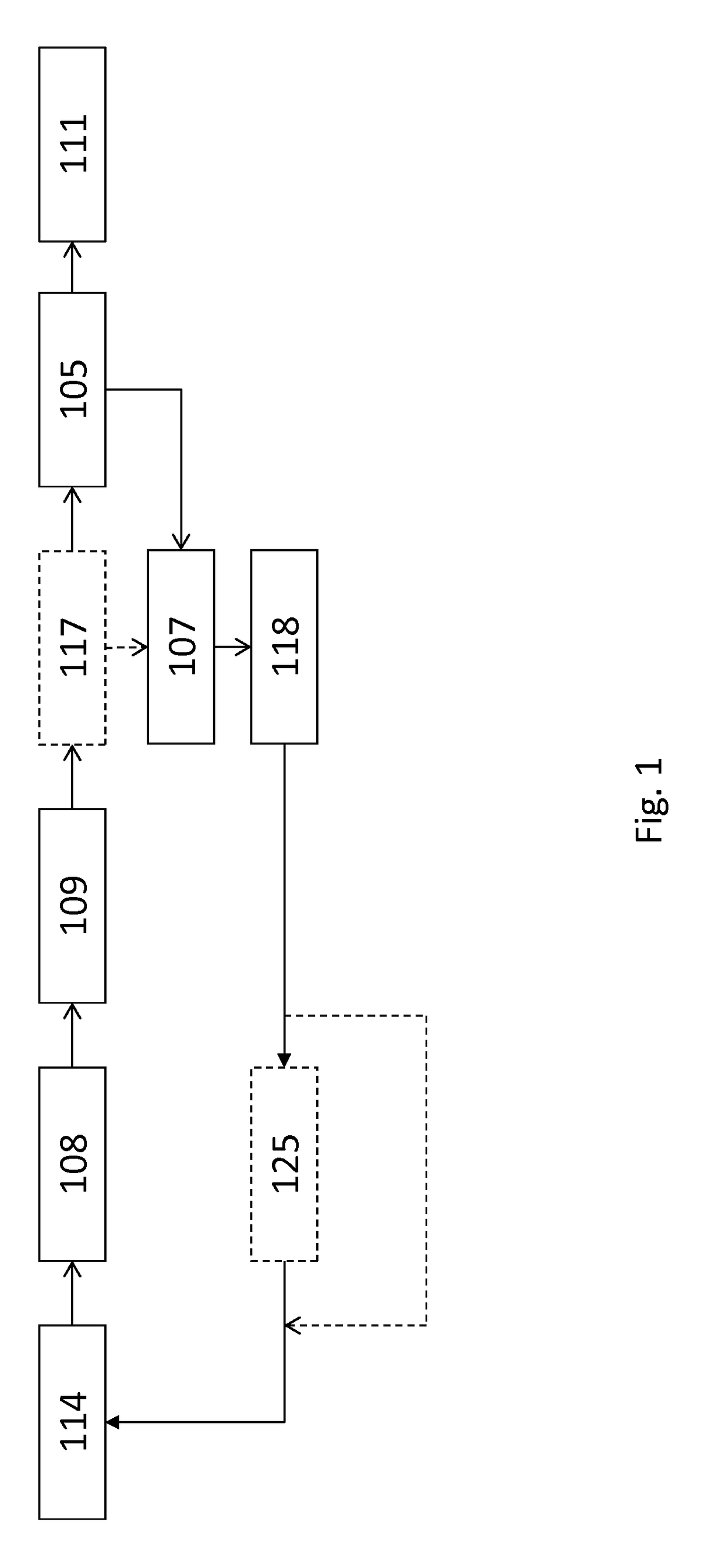

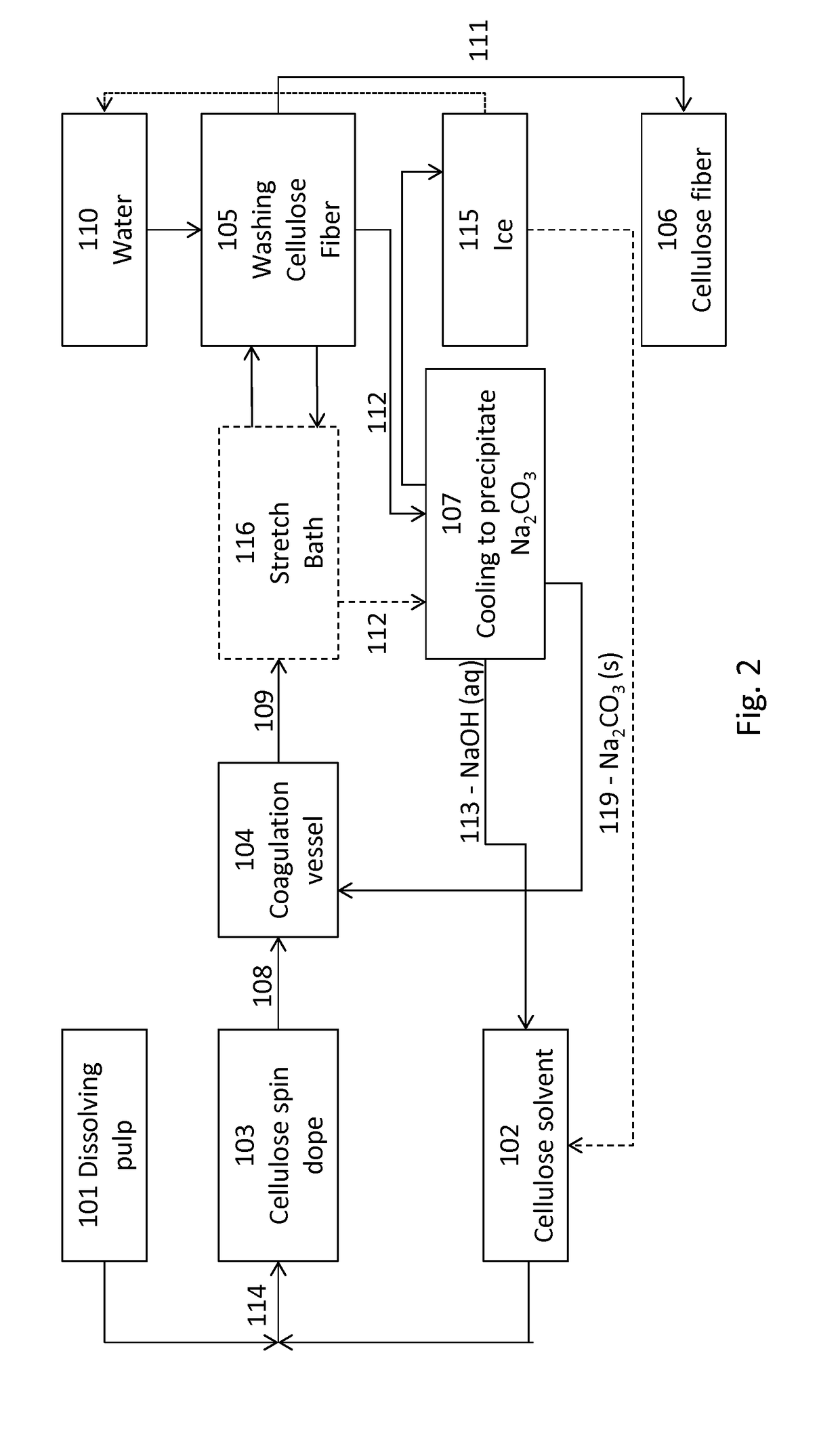

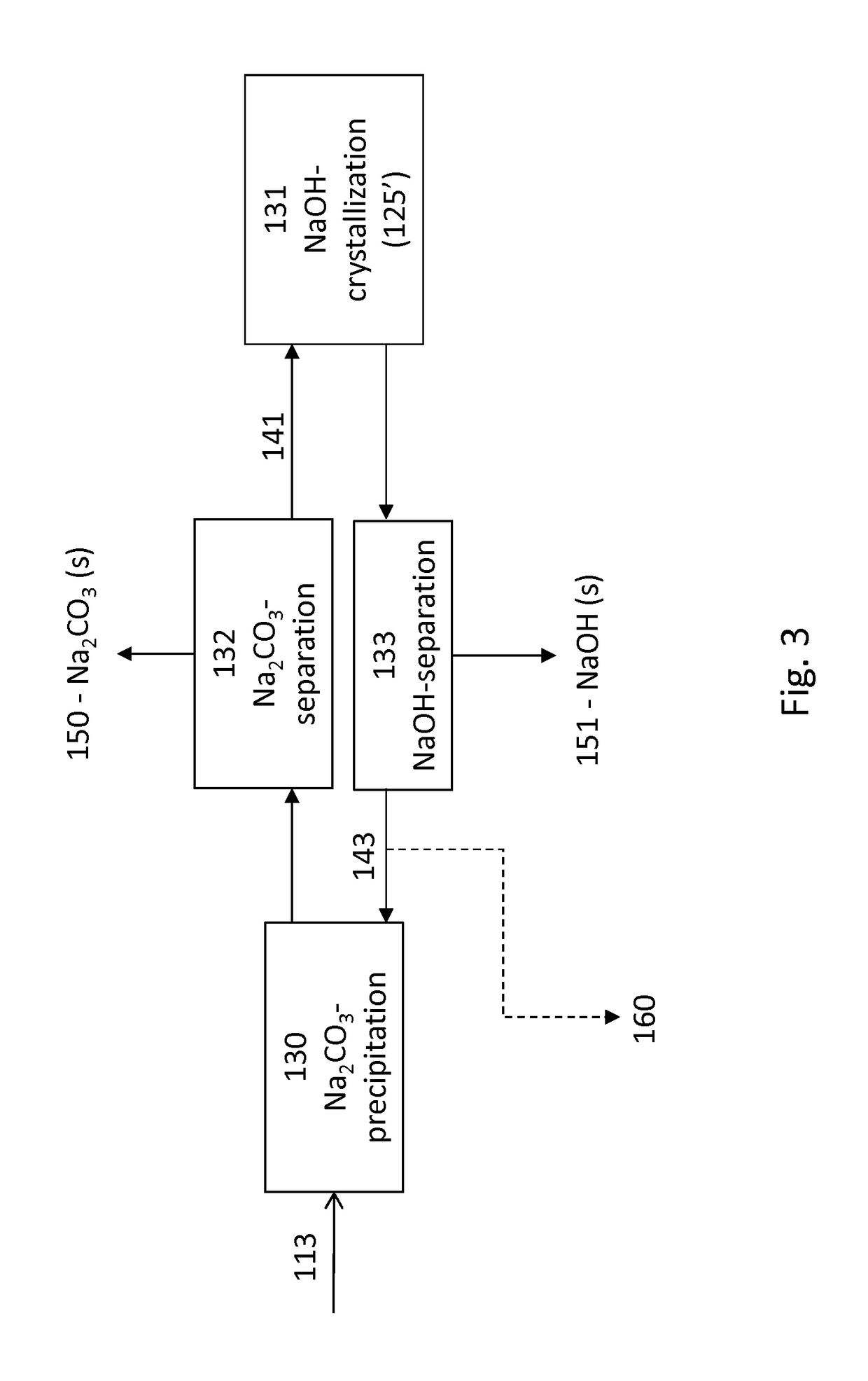

Process for spinning dissolved cellulose

ActiveUS20190062950A1Reduce concentrationIncrease concentrationArtificial filaments from cellulose solutionsArtificial filament recoveryCellulose fiberAqueous solution

The present invention relates to a process for forming cellulose fibers or film from dissolved cellulose. The process comprises the steps of: dissolving cellulose in an aqueous coagulation sodium salt solution to provide a cellulose spin dope; extruding the cellulose spin dope into a coagulation bath liquid comprising an aqueous coagulation sodium salt solution to provide cellulose fibers or film; withdrawing a portion of the coagulation bath comprising coagulation sodium salt and sodium hydroxide (NaOH); cooling the withdrawn portion of the coagulation bath to precipitate solid coagulation sodium salt to recover sodium hydroxide (NaOH) substantially free from the coagulation salt; and using at least a portion of the recovered sodium hydroxide (NaOH) in dissolving the cellulose to provide the cellulose spin dope.

Owner:TREETOTEXTILE AB

Method for the preparation of NFC films on supports

InactiveUS10000614B2Avoids slow dewatering and shrinkageExcellent oxygen barrier propertiesCellulose coatingsCellulosic plastic layered productsPolymer scienceNanofiber

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

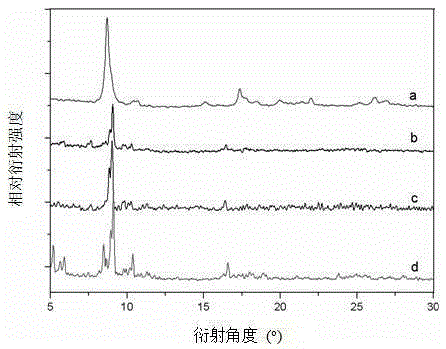

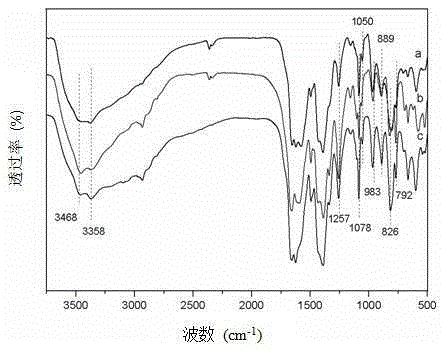

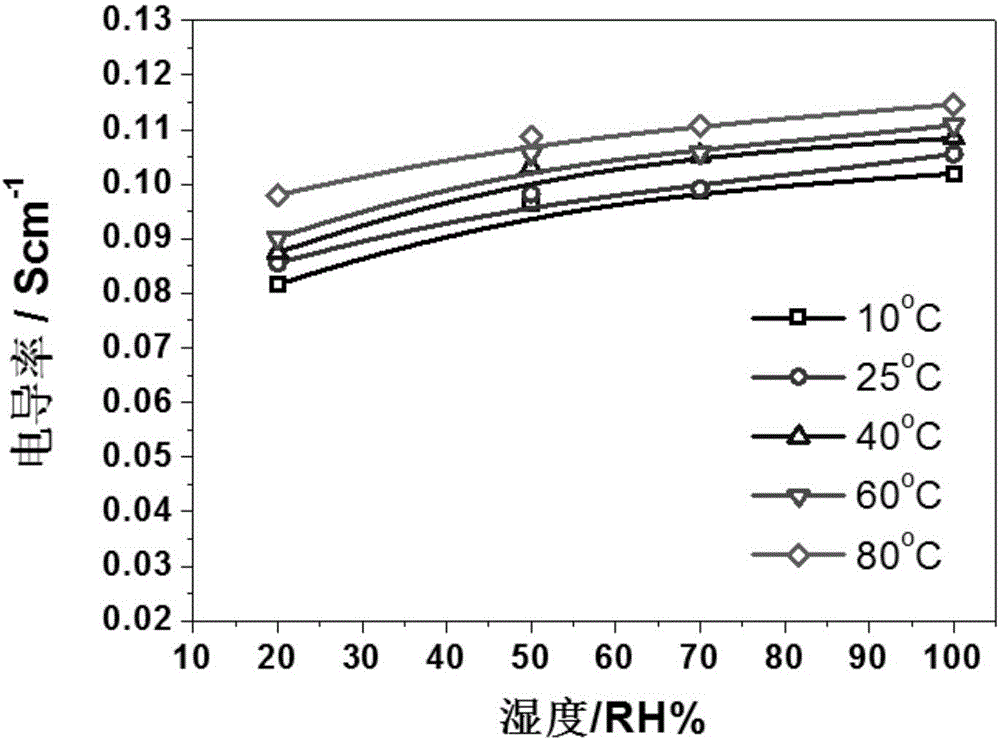

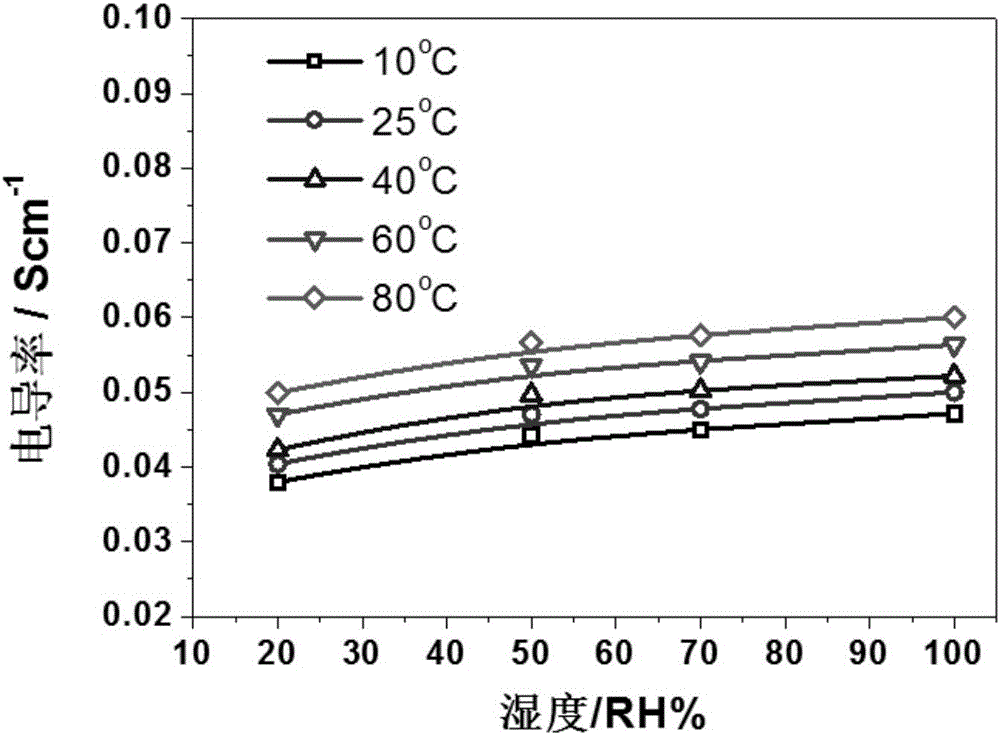

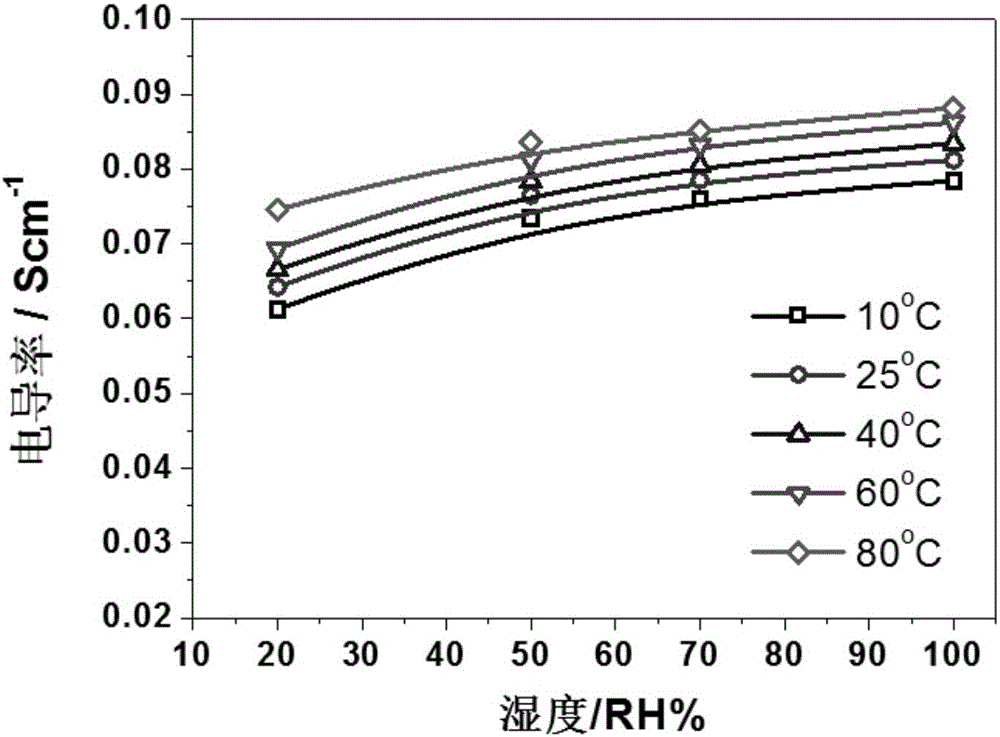

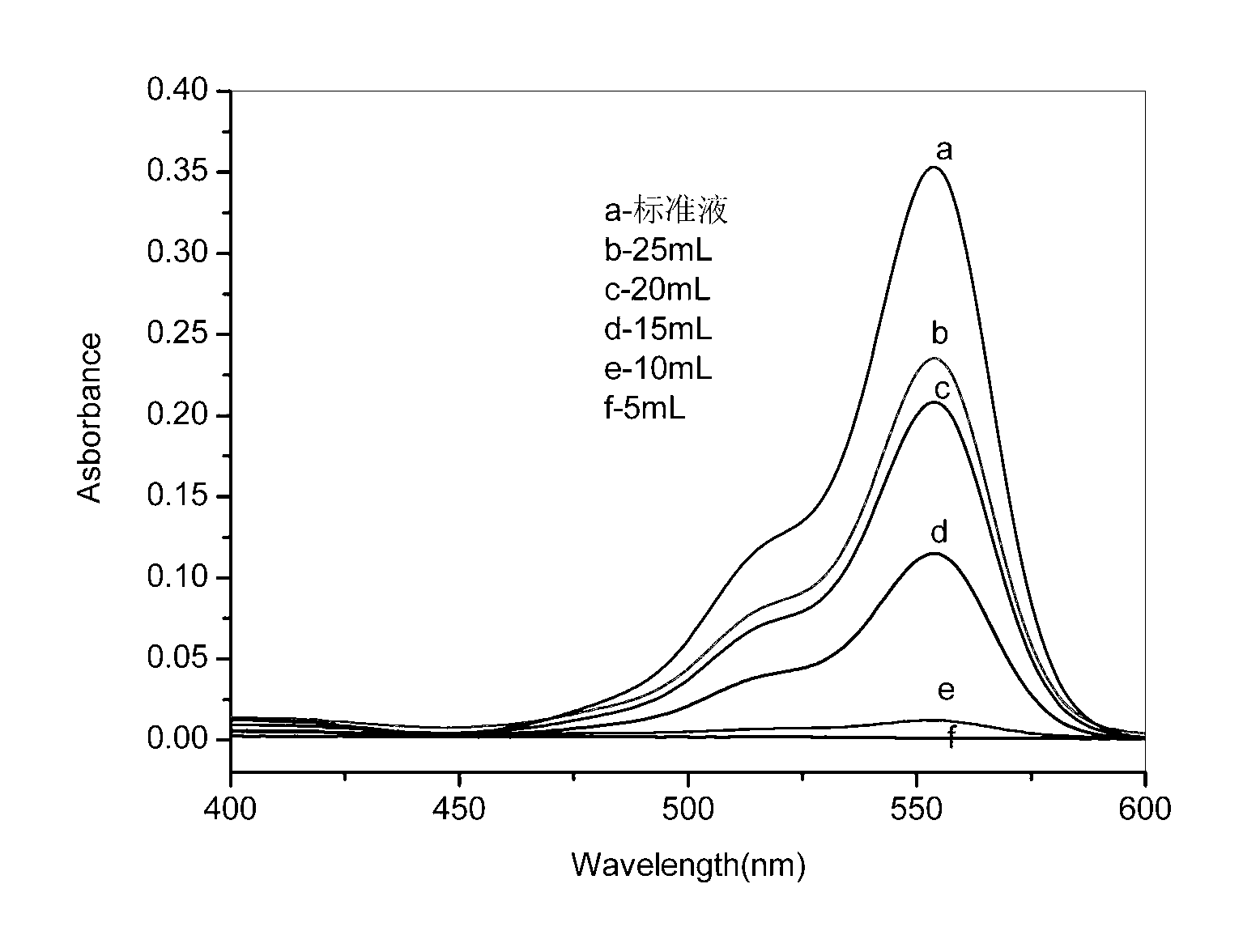

Cellulose-heteropoly acid proton exchange membrane for electrochemical sensor and preparation method therefor

ActiveCN105136892AStable structureGood chemical stabilityMaterial analysis by electric/magnetic meansCarbamateHeteropoly acid

The invention discloses a cellulose-heteropoly acid proton exchange membrane for an electrochemical sensor and a preparation method therefor. Heteropoly acid is loaded on functional groups of cellulose derivatives through an ion self assembly technology, then acid processing is carried out, the cellulose derivatives is regenerated into cellulose and the cellulose-heteropoly acid proton exchange membrane is formed. The preparation method comprises the following steps: cellulose, sodium hydroxide and urea are dissolved in water in proportions and cellulose carbamate is formed; then heteropoly acid is added and self assembly of the heteropoly acid and cellulose carbamate is carried out, a liquid membrance is formed through tape casting or blade coating, after drying is carried out, cellulose regeneration in sulfuric acid is carried out, washing is carried out, drying is carried out again and the proton exchange membrane is obtained. The prepared cellulose-heteropoly acid proton exchange membrane is applied in an electrochemical sensor, a storage tank structure is not needed, there is no electrolyte loss, the system is simple and there is no influence on a catalysis layer. In addition, because heteropoly acid proton conduction is independent of humidity, the conductivity change value is small under a condition that temperature and humidity change.

Owner:广东南海普锐斯科技有限公司

Lightweight foam composite material having high water storage capacity and achieving continuous water supply

ActiveCN108207604AImprove water storage capacitySustainable water supplyAgriculture gas emission reductionCultivating equipmentsCelluloseFiber

The invention relates to a building or wall material suitable for plant growth, in particular to a lightweight foam composite material having the high water storage capacity and achieving continuous water supply. The components of the material comprise two or more of polymer, hydrogel particles, cellulose and hard fiber, and the material is obtained by mixing and foaming all the components; holesformed through material foaming and hydrogel or cellulose swelling after water absorption form water channels; after water absorption, the whole volume expansion ratio of the material is smaller than5%. The material is high in water storage capacity, high in strength, small in contour expansion after water absorption, good in water mobility and suitable for plant growth.

Owner:邬瑛 +5

Preparation method of multilayer antibacterial fibers based on negative ions

PendingCN111636118AImprove stabilityAchieve interpenetration effectFilament/thread formingConjugated cellulose/protein artificial filamentsCelluloseFiber

The invention discloses a preparation method of multilayer antibacterial fibers based on negative ions. The preparation method comprises the following steps of adding bamboo carbon particles into absolute ethyl alcohol, uniformly stirring, and adding ethyl cellulose to form a first slurry; adding chitosan into anhydrous acetic acid, and carrying out low-temperature ultrasonic treatment for 10 to 20min to form a second viscous liquid; performing two-gradient extrusion spinning by taking the second viscous liquid as an outer-layer liquid and the first slurry as an inner-layer liquid to obtain afirst fiber yarn; adding polyvinyl alcohol into distilled water, stirring at a constant temperature to form a dissolving solution, spraying the dissolving solution on the surface of the first fiber yarn, standing at a constant temperature for 10-20 minutes, and heating and sintering for 10-20 minutes to obtain a second fiber yarn; and soaking the second fiber yarn in the absolute ethyl alcohol, and performing low-temperature ultrasonic treatment for 10-20min to obtain the multilayer antibacterial fiber. An insoluble system formed after high-temperature polymerization of the polyvinyl alcohol is utilized to cure an antibacterial material in the inner layer, and meanwhile, a stable internal adsorption antibacterial system is formed based on the adsorbability and electronegativity of bamboo carbon particles in combination with the characteristics of chitosan.

Owner:MINJIANG UNIV

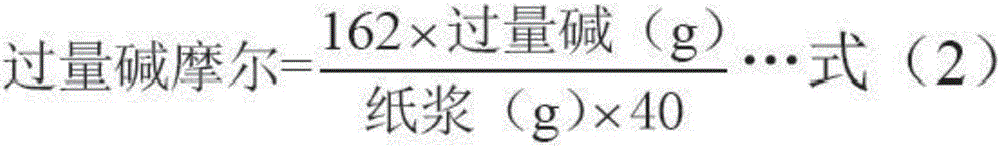

Method for producing carboxymethyl cellulose salt for electrodes of nonaqueous electrolyte secondary batteries, electrode for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

ActiveCN106573991AAvoid streaksImprove adhesion strengthLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentCellulose

The purpose of the present invention is to provide a carboxymethyl cellulose salt for electrodes of nonaqueous electrolyte secondary batteries, which is capable of achieving a good balance between prevention of defects such as streaks and pin holes on a coated electrode surface and excellent bonding strength to a collector or excellent bonding strength between active materials. A production method which comprises: (1) an alkali cellulose formation reaction step wherein a mixed solvent that contains an alcohol having 3 or less carbon atoms and water at a mixing ratio (mass ratio) of from 75:25 to 95:5 is used and the alkali concentration relative to water is 25-40% by mass; (2) an etherification reaction step wherein a reaction is carried out in the presence of an excess alkali of 0.2-0.5 mol per unit of an anhydroglucose of the cellulose; (3) a neutralization step wherein an acid is added after the etherification reaction so that the pH of the reaction mixture is adjusted to 6.0-8.0; and (4) a heating step wherein the mixed solvent is removed and an alkali is added after the neutralization step so that the pH of the reaction mixture is adjusted to 8.0-9.0, and subsequently, a heat treatment is carried out at 40-70 DEG C for 30-120 minutes.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259BRaw materials are cheap and easy to getNo pollution in the processOther chemical processesFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

A kind of preparation method of nanocellulose/polymer composite aerogel

The invention discloses a preparation method of nanocellulose and polymer composite aerogel. The preparation comprises the steps that a Pickerin emulsion containing a polymer in an oil phase of which the nanocellulose is stable is subjected to gelation firstly, freeze drying is conducted, and the nanocellulose and polymer composite aerogel which is high in porosity and low in density is obtained. The preparation method is suitable for nanocellulose which is extracted and prepared from various raw materials and has different morphology and various water insoluble polymers, and large-scale popularization is easy to achieve. For most composite aerogel materials formed by water-soluble polymers and cellulose at present, composite aerogel materials formed by the water insoluble polymers and cellulose are obtained. Meanwhile, reagents used in the preparation method are common reagents, the price is low, the preparation process is simple, convenient and rapid, and the obtained nanocellulose and polymer composite aerogel has the advantages of being high in porosity, low in density and low in heat conductivity coefficient, having water absorption oil absorption performance and the like.

Owner:GUILIN QIHONG TECH CO LTD

Baking vanish paint coating metal surface

InactiveCN105219187AReduce consumptionSolve construction difficultiesCellulose coatingsCelluloseProduction line

The invention relates to a baking vanish paint coating a metal surface. The baking vanish paint comprises, by weight, 40 to 50% of acrylic resin, 18 to 25% of amino resin, 6 to 12% of cellulose resin and 3 to 4% of an auxiliary agent, with the balance being a solvent, wherein the solvent is prepared by mixing xylene and ethyl ester according to a weight ratio of 50-60%: 40-50%, the cellulose resin is a resin solution with a concentration of 60%, and the auxiliary agent is one or more selected from the group consisting of a drier, a flexibilizer, an antifoaming agent, a leveling agent, a light stabilizing agent, etc. According to the invention, cellulose is added in novel process for the baking vanish paint coating the metal surface so as to form a novel accelerated-drying paint, so the problem of difficult construction is overcome; and only 30 min is needed from spraying of the baking vanish paint on a workpiece to drying of the workpiece and taking of the workpiece off from a production line, so production and coating time is shortened by about 20 min, output is greatly increased, and energy consumption is substantially reduced.

Owner:江苏飞翔涂料有限公司

Method for preparing fiber-loaded lignin composite adsorption material

InactiveCN105056903ATake advantage ofAvoid wastingOther chemical processesWater/sewage treatmentCelluloseFiber

The invention relates to a method for preparing a fiber-loaded lignin composite adsorption material and belongs to the field of biomass resource utilization and technology. On the hydrolysis conditions, a softened layer is formed between lignin and cellulose; under the effects of sulfur smudging and high temperature, the upper cellulose forms a pore state, the lower lignin undergoes a viscous reaction with sodium chloride and polyaspartic acid water-absorbent resin, so that generated substances enable the cellulose to tightly adhere to the lignin, a structure with the surface only provided with carbonized chemical groups is formed, and the porous surface carbonized cellulose has an adsorption function and can undergo a chemical adsorption reaction with some heavy metals and organic matter remaining in slightly polluted water, so as to transfer surface complexation substances. The method is simple to operate and free of any environmental pollution in the process, the manufactured carbonized cellulose is remarkable in adsorption effect, and it is finally measured that the content of the heavy metals in the slightly polluted water is below 0.8 mg / L.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

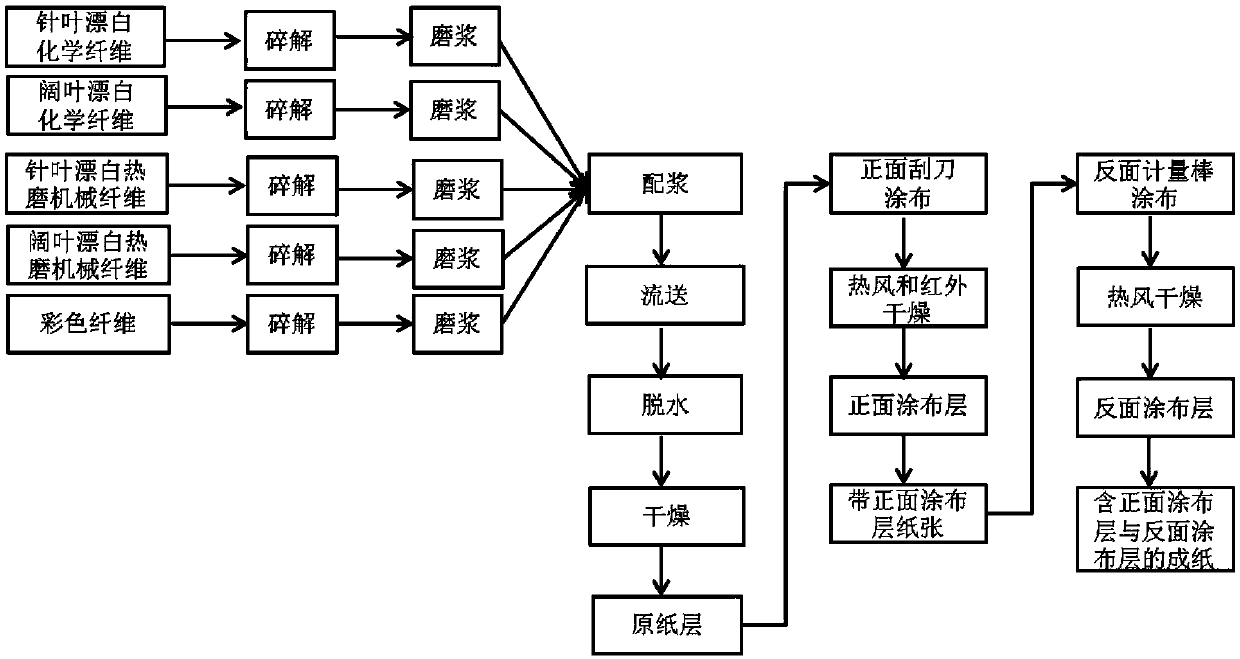

Paint and white cardboard

ActiveCN109577098AAvoid pollutionMeet the gluer performance requirementsFlexible coversWrappersCardboardAcrylonitrile

The invention provides a white cardboard. The white cardboard comprises a surface coating, a crude paper layer and a bottom coating which are successively arranged; the bottom coating is formed by paint; and the paint comprises carboxymethyl cellulose and / or polyvinyl alcohol, starch, esterified hemicellulose, acrylic-acrylonitrile copolymer, high-water-absorption resin and water. Compared with the prior art, the crude paper layer is provided with the bottom coating, on one hand, the carboxymethyl cellulose and / or polyvinyl alcohol, starch and esterified hemicelluloses in the coating are usedto form a high-strength closed biological film to insulate the air, so that the cigarette pollution and fragrance attenuation can be prevented; meanwhile, by using the high water storage capacity of the high-water-absorption resin, the internal humidity in a cigarette box can be kept relatively stable; and the white cardboard is used as the white cardboard for packaging the cigarettes, the problems that the existing cigarette packaging white cardboard cannot effectively maintain the fragrance and humidity and additional aluminum foil lining paper is needed can be solved.

Owner:ASIA SYMBOL SHANDONG PULP & PAPER

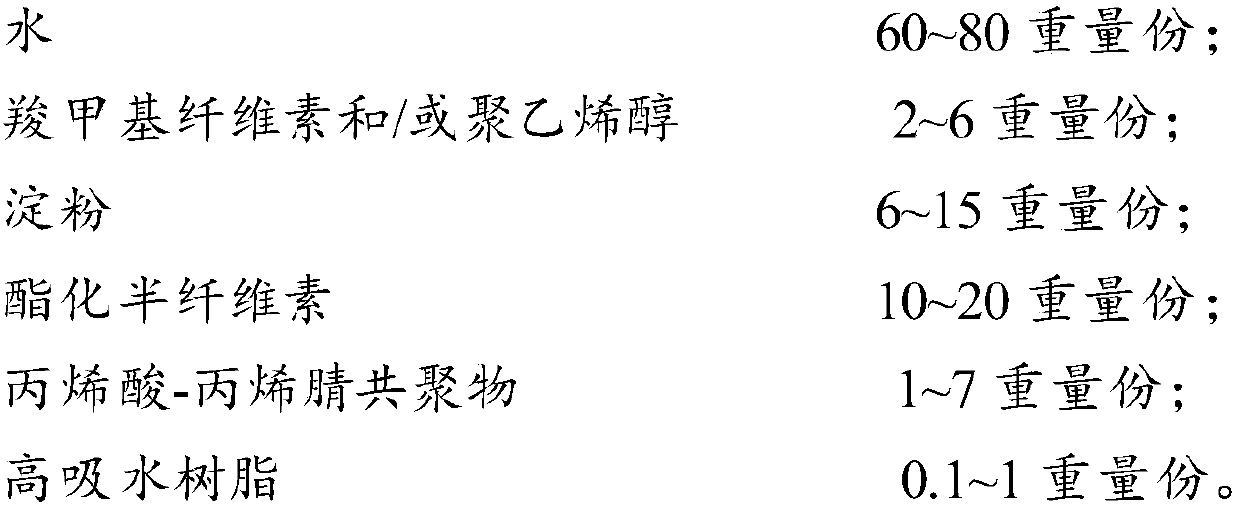

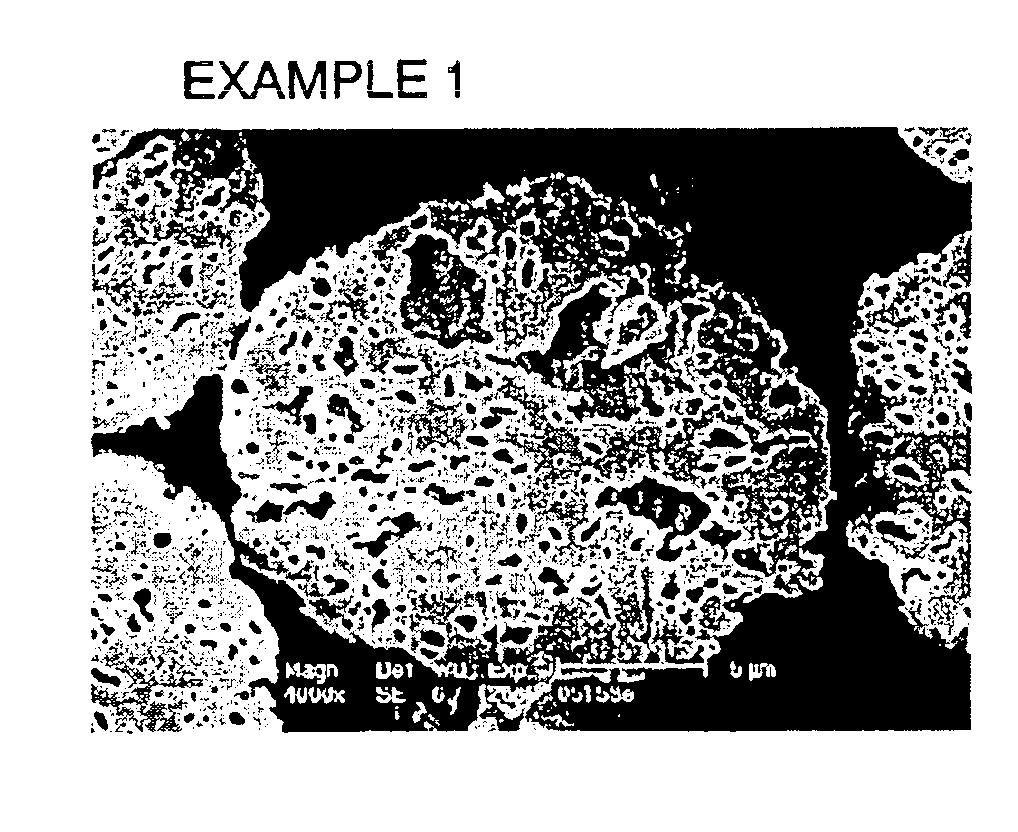

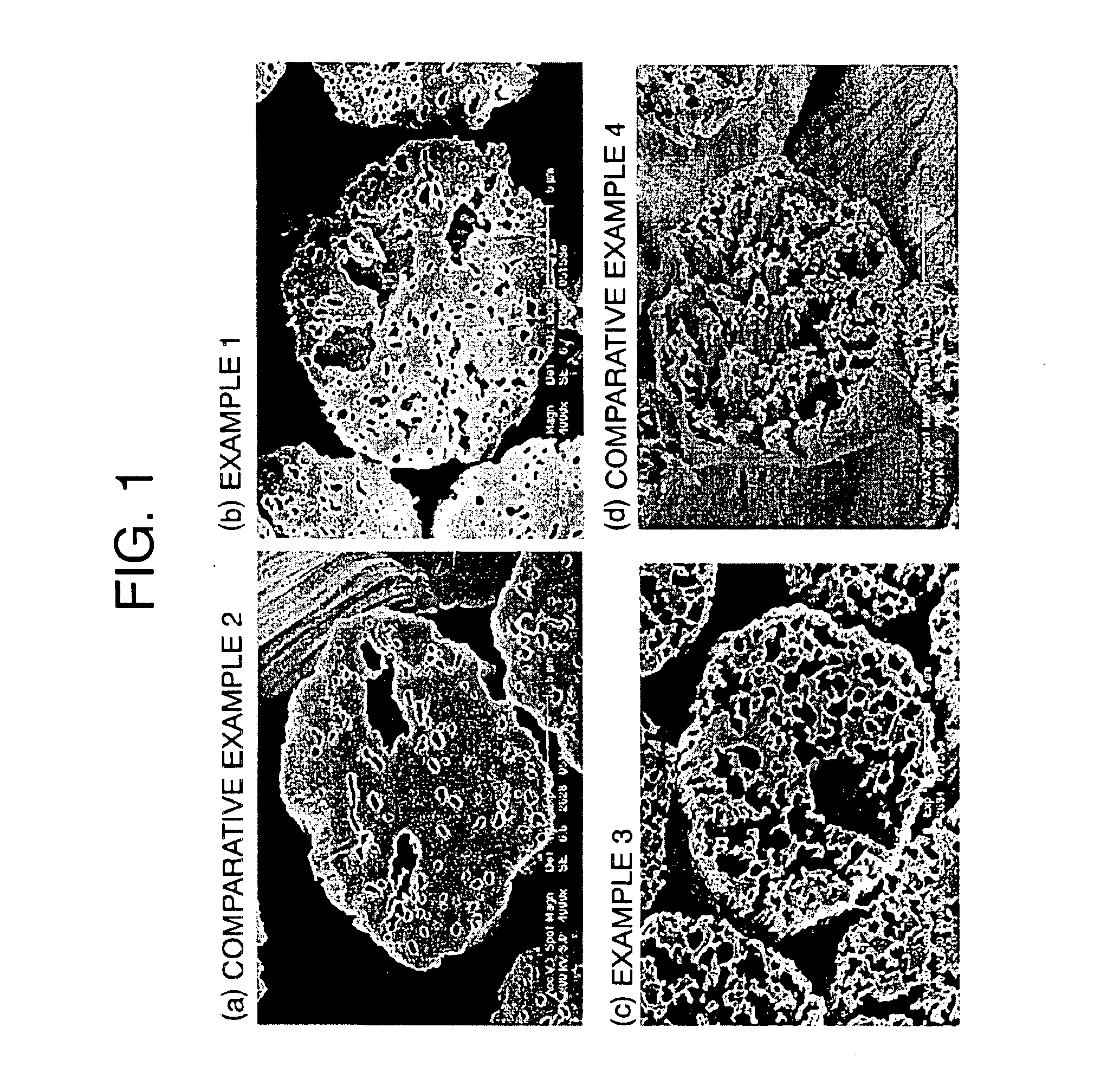

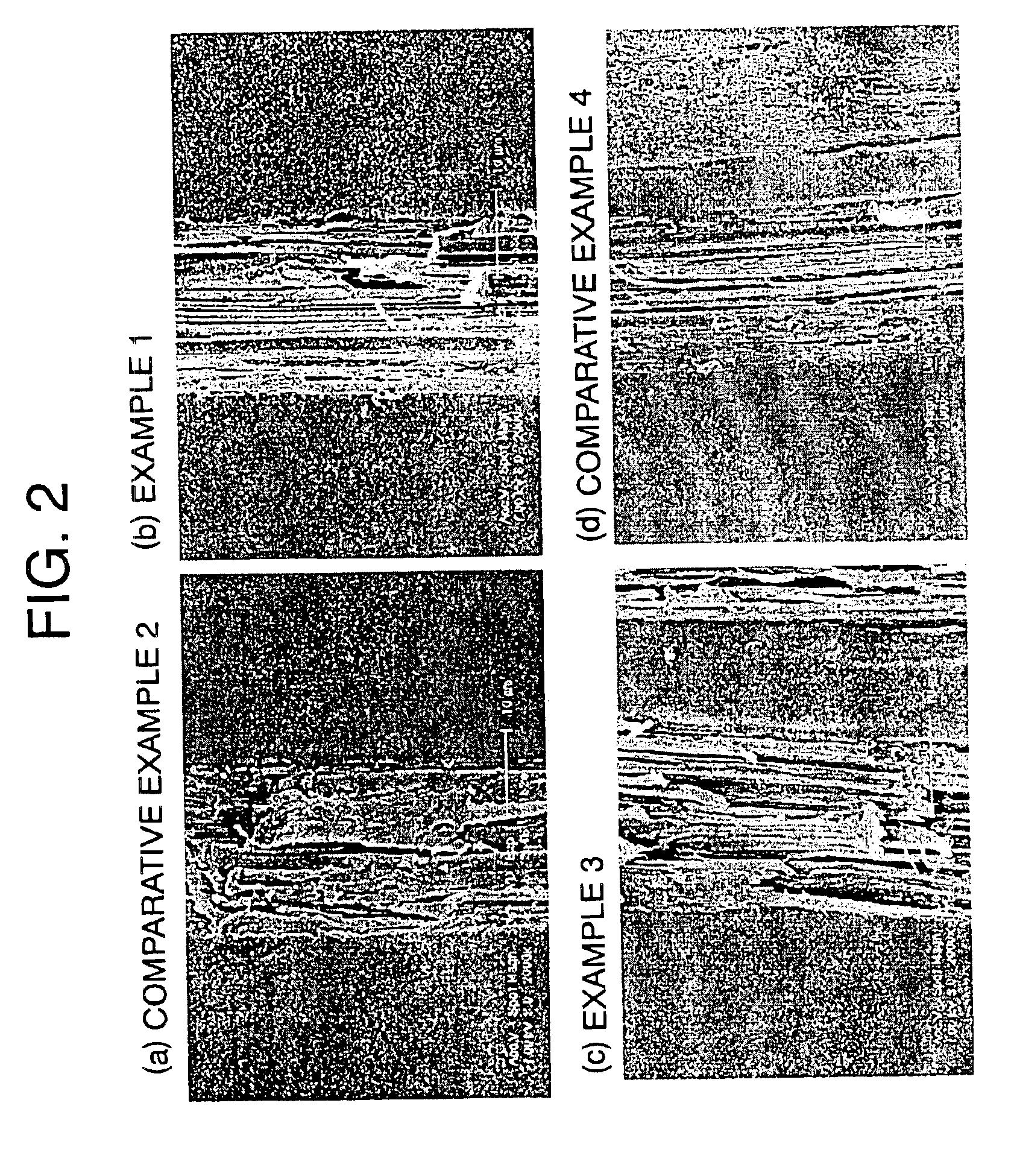

Composite particles, method of producing composite particles, dry powder, and molding resin composition

ActiveUS20200332040A1Easy to operateMaintenance characteristicCosmetic preparationsLiquid surface applicatorsCellulosePolymer science

Owner:TOPPAN PRINTING CO LTD

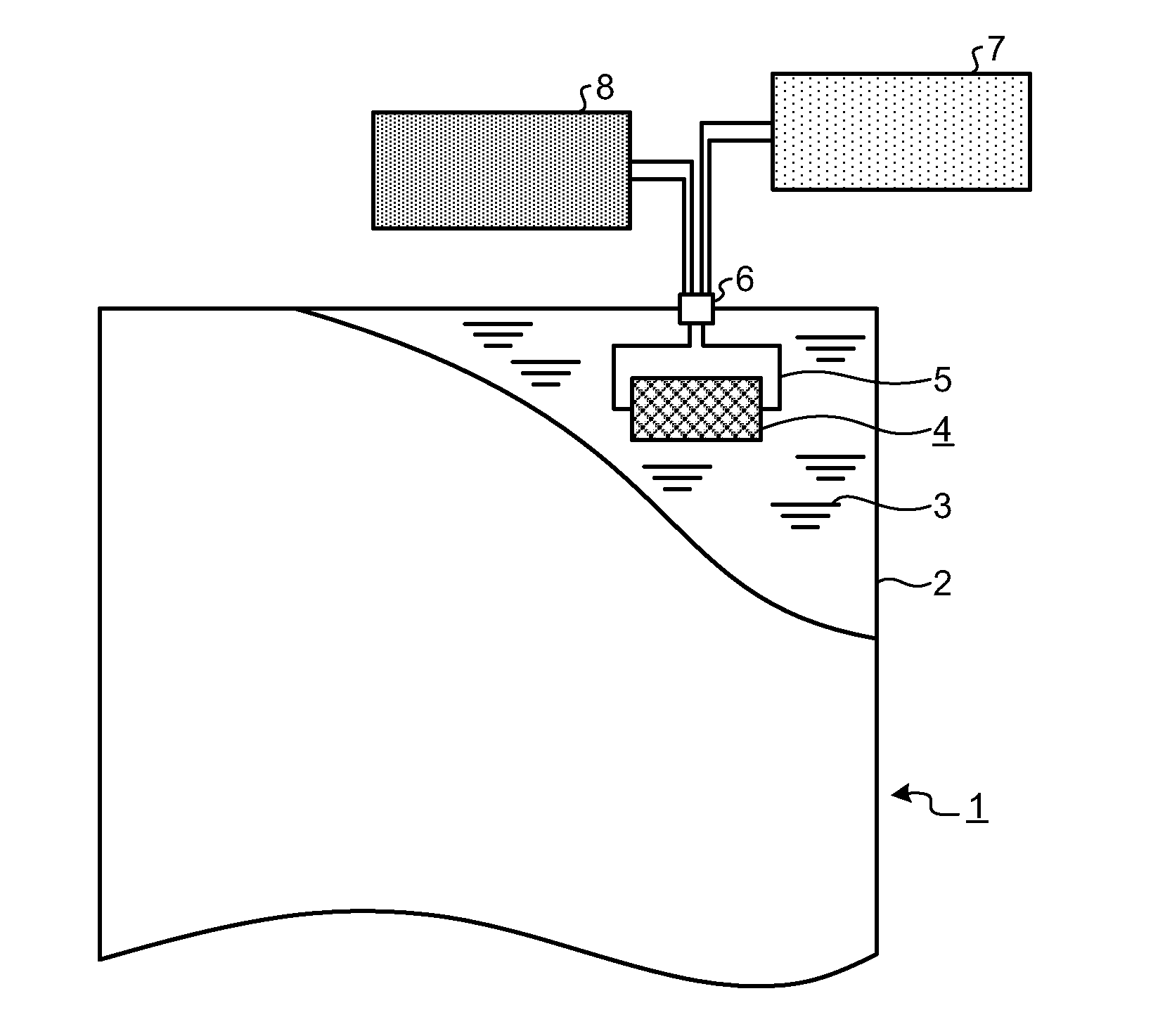

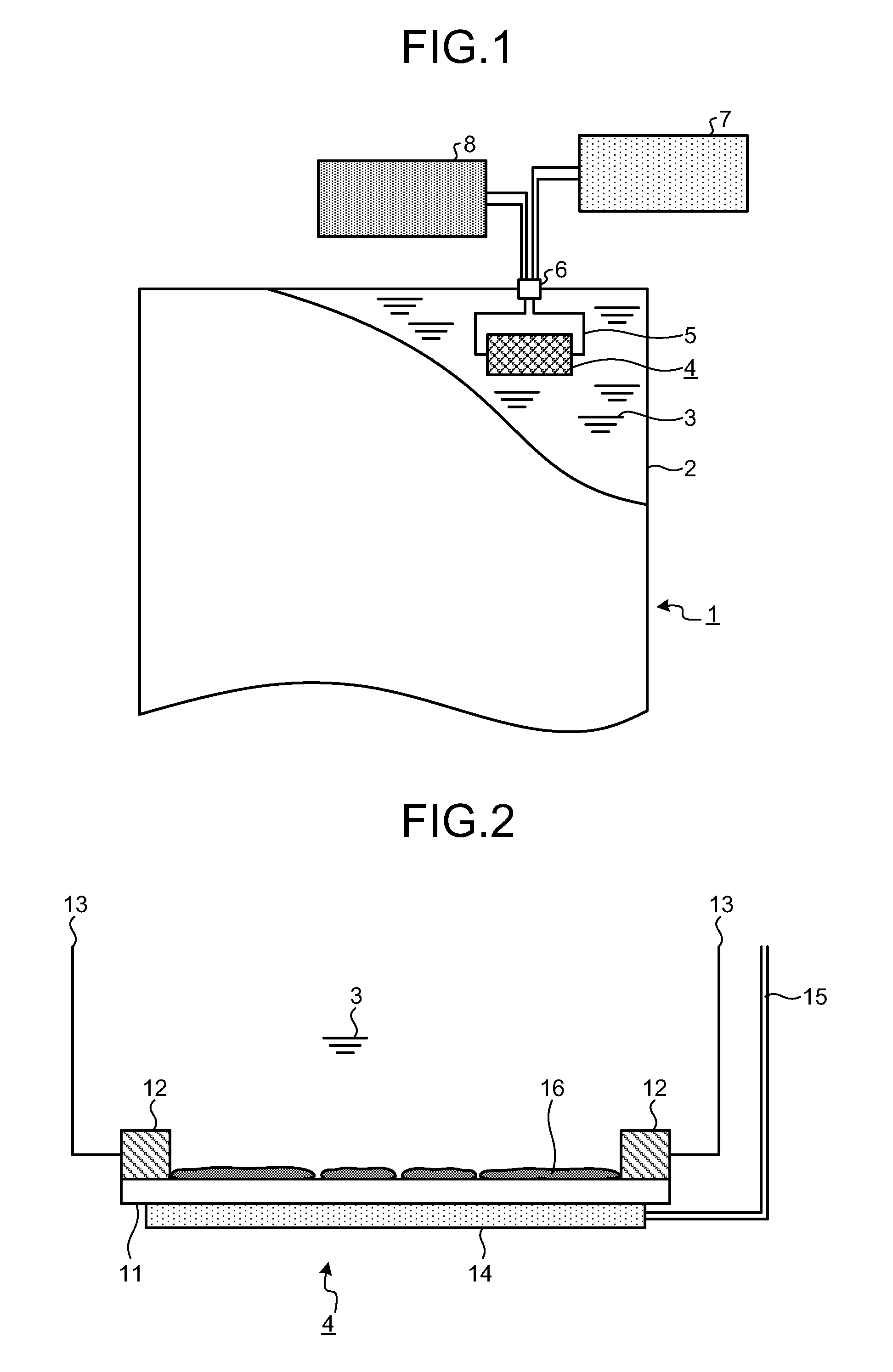

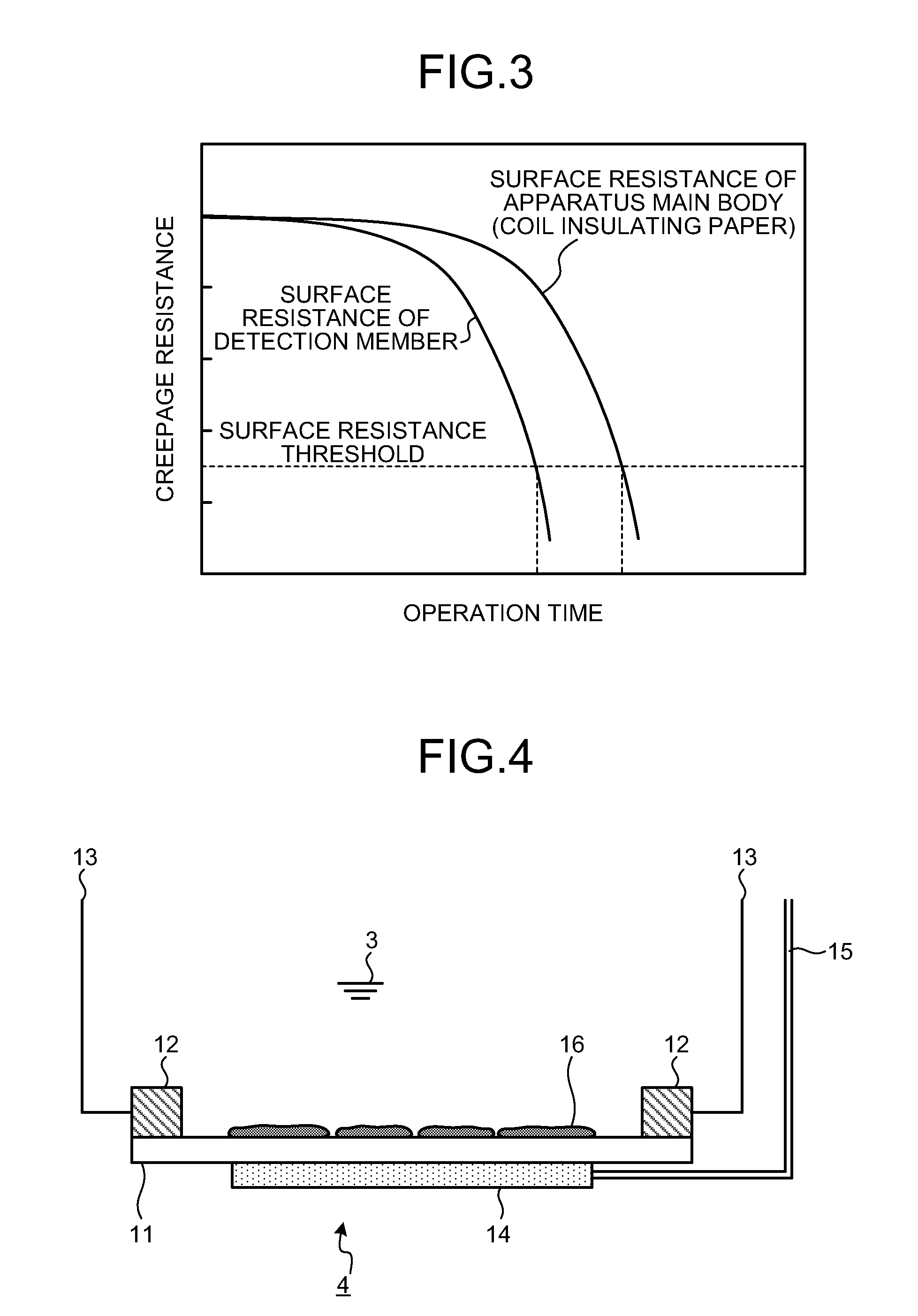

Oil immersed electrical apparatus

ActiveUS20110090034A1Reduced insulation performancePrevent degradationTransformers/inductances coolingElectrical testingCelluloseElectrical resistance and conductance

An oil immersed electrical apparatus such as an oil immersed transformer that can detect copper sulfide precipitated on coil insulating paper is provided. In the oil immersed transformer in which a coil with its surface covered by insulating paper is arranged in a container filled with insulating oil, a detection member is prepared by providing two electrodes on a surface of a plate-like pressboard formed of cellulose, which is a same material as that of the insulating paper, this detection member is arranged in contact with the insulating oil, and generation of copper sulfide is detected from reduction in a surface resistance between the electrodes. The temperature of the detection member is set higher than the temperature of the coil so that copper sulfide is generated thereon prior to generation of copper sulfide on a coil unit.

Owner:MITSUBISHI ELECTRIC CORP

Method for modifying anionic waterborne polyurethane emulsion with carboxyl nanocellulose

ActiveCN113150309AImprove mechanical propertiesImprove water resistancePolyureas/polyurethane adhesivesCellulose adhesivesEmulsionCarboxylic group

Owner:湖北福力德鞋业有限责任公司 +1

Acrylic based composite fiber and method for production thereof, and fiber composite using the same

InactiveUS6866931B2Improve deodorization functionEfficient compositeCellulosic plastic layered productsMonocomponent synthetic polymer artificial filamentYarnCellulose acetate

An object of this invention is to provide an acrylonitrile based composite fiber having a new feeling different from that of an ordinary cellulose acetate fiber, cellulose fiber and acrylic fiber, excellent spinability, fiber properties and process ability of yarn spinning, and excellent functions, in particular, a deodorizing function and a moisture absorbing and retaining property.The composite fiber is comprised of 10 to 40% by weight of cellulose acetate and / or cellulose and 60 to 90% by weight of an acrylonitrile based polymer, and has a structure with the cellulose acetate and / or cellulose forming an island component in a cross section perpendicular to a fiber axis and the acrylonitrile based polymer forming a sea component. Preferably, the cellulose acetate and / or cellulose as the island component communicate with another island component in the fiber axis direction, a vacant hole is provided inside the fiber, or a ratio of the longest diameter and the shortest diameter of the fiber cross section is 2 or less, and 5 or more recess parts of 0.3 μm or more and 3 μm or less width and 0.3 μm or more and 3 μm or less depth are provided in a fiber cross section outer circumferential part. Further preferably, by applying a heat treatment under alkali in a production stage, the moisture absorbing and retaining property can be improved.

Owner:MITSUBISHI CHEM CORP

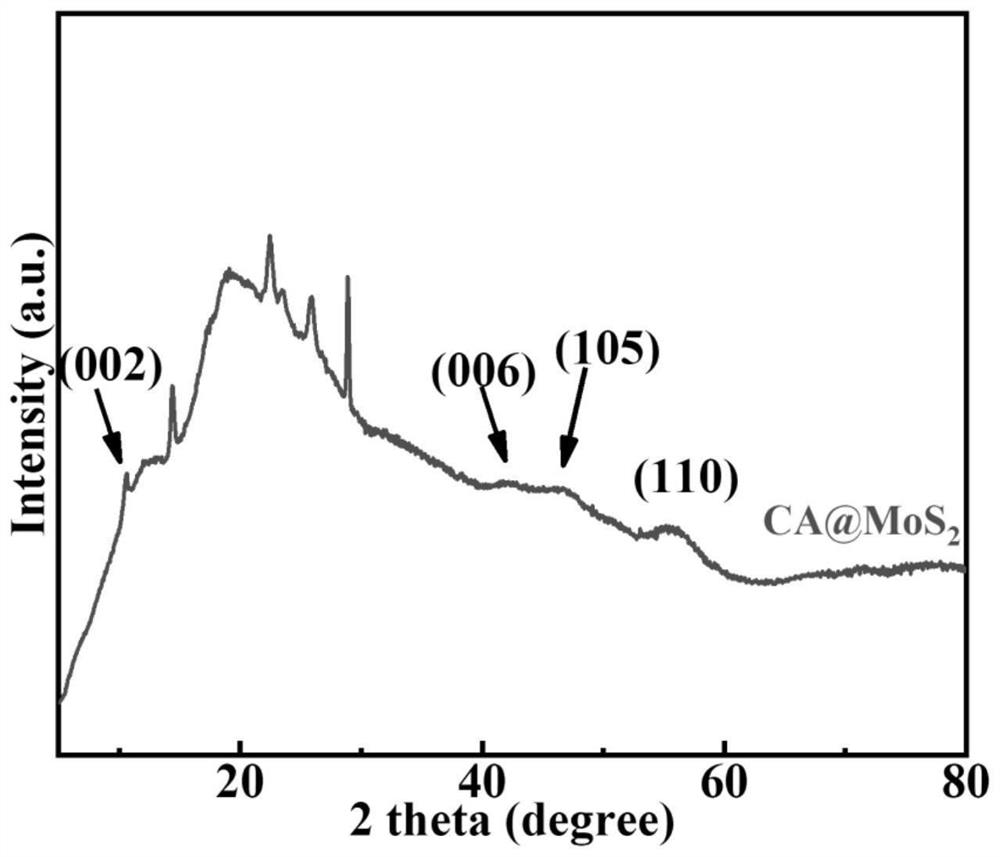

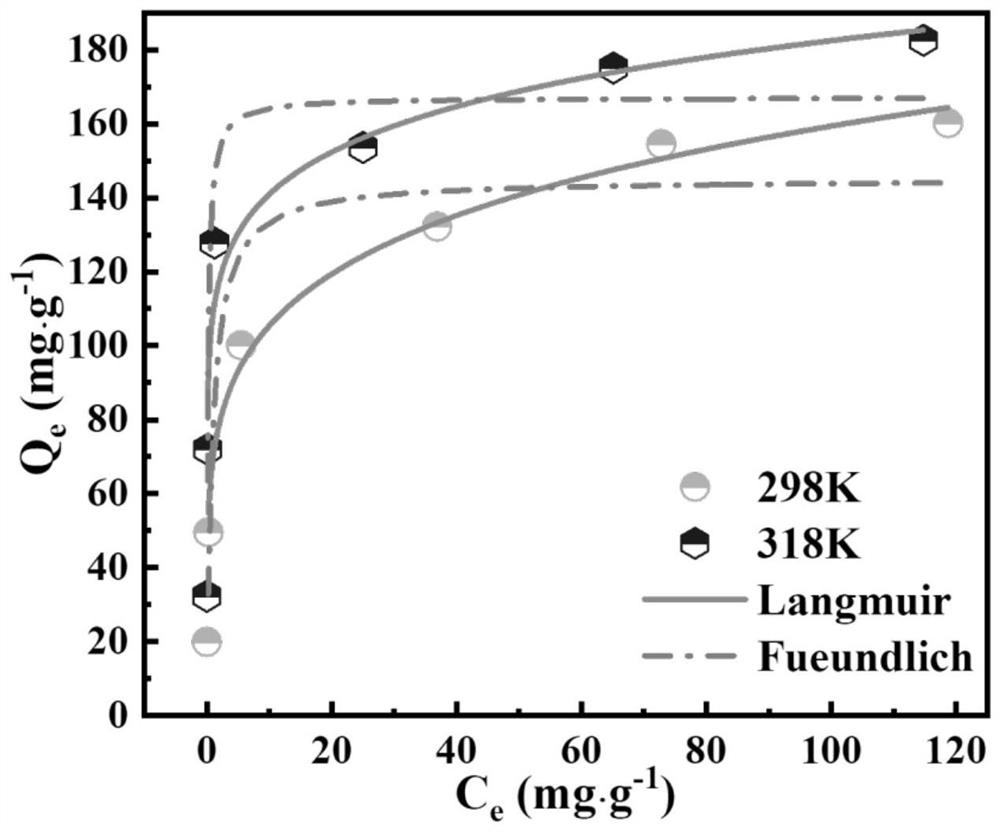

Cross-linked cellulose@molybdenum disulfide aerogel composite adsorbent as well as preparation method and application thereof

ActiveCN113680328AImprove adsorption capacityHigh adsorption selectivityOther chemical processesWater contaminantsCelluloseNanoparticle

The invention discloses a cross-linked cellulose@molybdenum disulfide aerogel composite adsorbent as well as a preparation method and application thereof. Cross-linked cellulose aerogel serves as a carrier, and molybdenum disulfide nanoparticles are directly doped into cellulose suspension liquid through a premixing-cross-linking fixing-freezing pore forming method; and then a cross-linking agent is added to enable cellulose to form a three-dimensional network structure to fix the molybdenum disulfide particles. According to the invention, the technical bottleneck of nanoscale molybdenum disulfide powder in practical engineering application is solved, and good hydraulic properties of the carrier and excellent adsorption selectivity of molybdenum disulfide to lead ions are combined together. And the composite adsorbent has excellent adsorption capacity and rapid adsorption kinetics on the lead ions. The adsorption saturated material can be desorbed and regenerated through an EDTANa2 solution to be repeatedly used, can be stably used in a fixed bed flow system, and has a relatively wide application prospect.

Owner:NANJING TECH UNIV

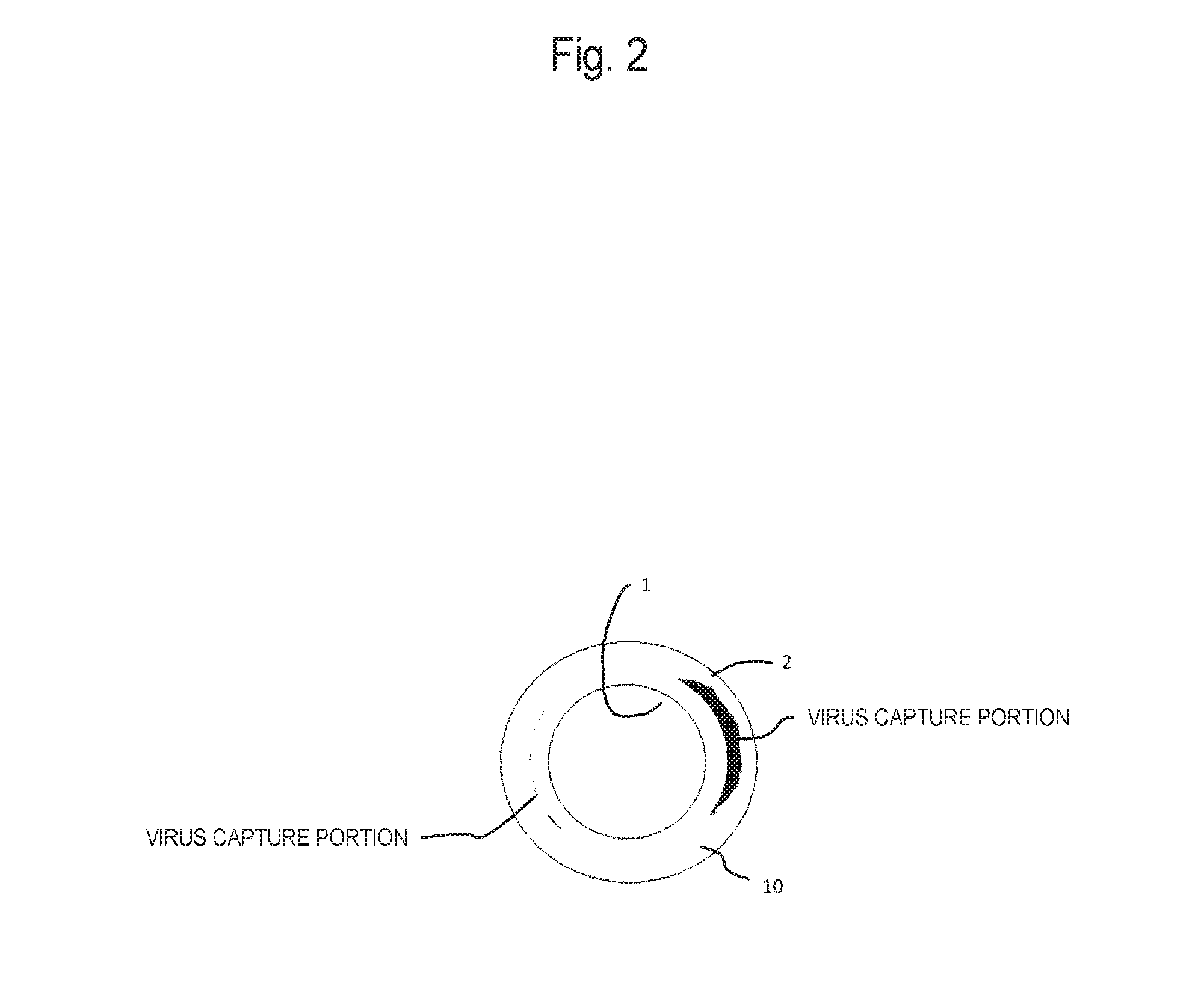

Virus removal membrane

ActiveUS20170028360A1High virus removal propertyImprove filtration efficiencySemi-permeable membranesMembranesCelluloseGold Colloid

A virus removal membrane is formed from cellulose, in which, when a solution containing gold colloids having a diameter of 20 nm is applied through a primary surface to the virus removal membrane to allow the virus removal membrane to capture the gold colloids for measurement of brightness in a cross section of the virus removal membrane, a value obtained by dividing a standard deviation of a value of an area of a spectrum of variation in the brightness by an average of the value of the area is 0.01 or more and 1.5 or less; and a thickness of a portion, where gold colloids having a diameter of 20 nm or more and 30 nm or less are captured, in the cross section of the virus removal membrane in a wet state is 10.0 μm or more and 30.0 μm or less.

Owner:ASAHI KASEI MEDICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com