Paint and white cardboard

A white cardboard and coating technology, applied in the field of papermaking, can solve the problems of increasing the complexity of the packaging process, affecting the packaging efficiency of cigarettes, affecting the fragrance and moisturizing properties, etc., so as to reduce the coating process, prevent the pollution of cigarettes, and prevent the decay of the fragrance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

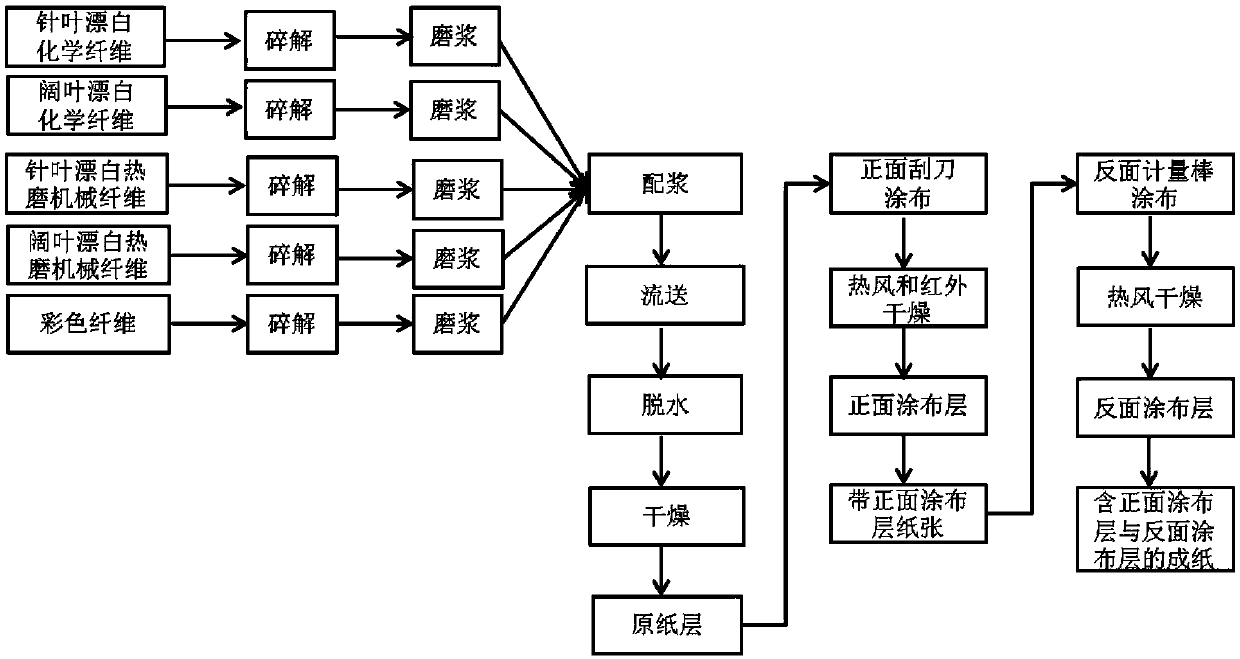

[0045] according to figure 2 The manufacturing steps shown are needleleaf bleached chemical fiber, broadleaf bleached chemical fiber, needleleaf bleached thermomechanical fiber, broadleaf bleached thermomechanical fiber, and colored fiber, which are crushed and refined, and sent to the batching tank for pulping .

[0046] In terms of mass percentage, the overall proportion of various fibers is 6% needleleaf bleached chemical fiber, 55% broadleaf bleached chemical fiber, 8% needleleaf bleached thermal mechanical fiber, 25% broadleaf bleached thermal mechanical fiber, 6% colored fibers.

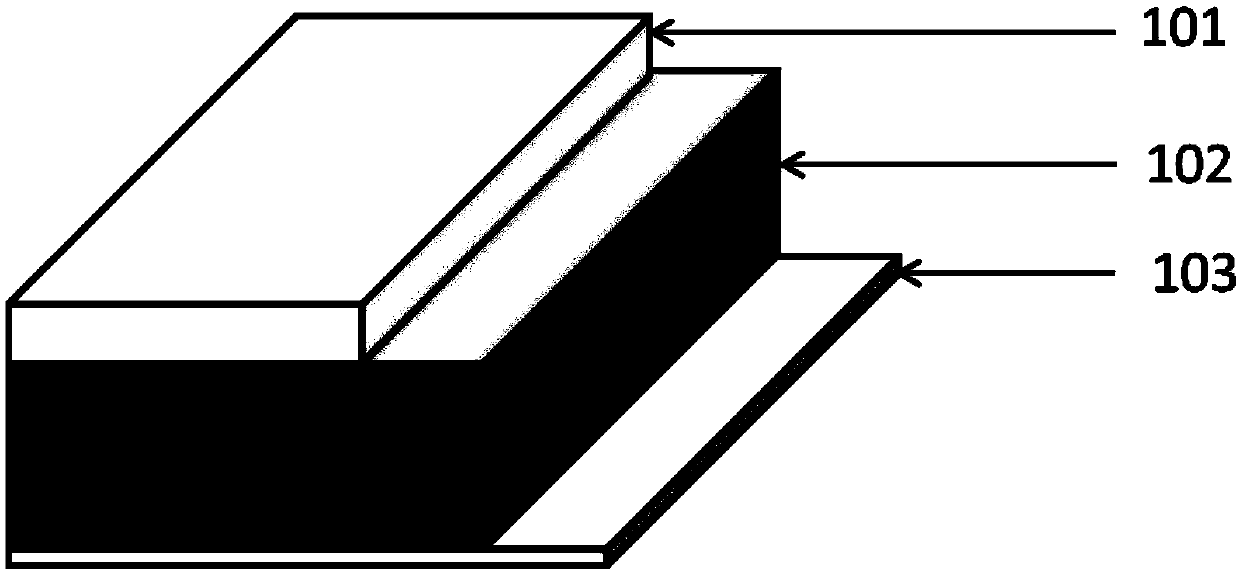

[0047] The prepared slurry flow is sent to the paper machine for dehydration and drying to form a quantitative 195g / m 2 base paper layer 102 .

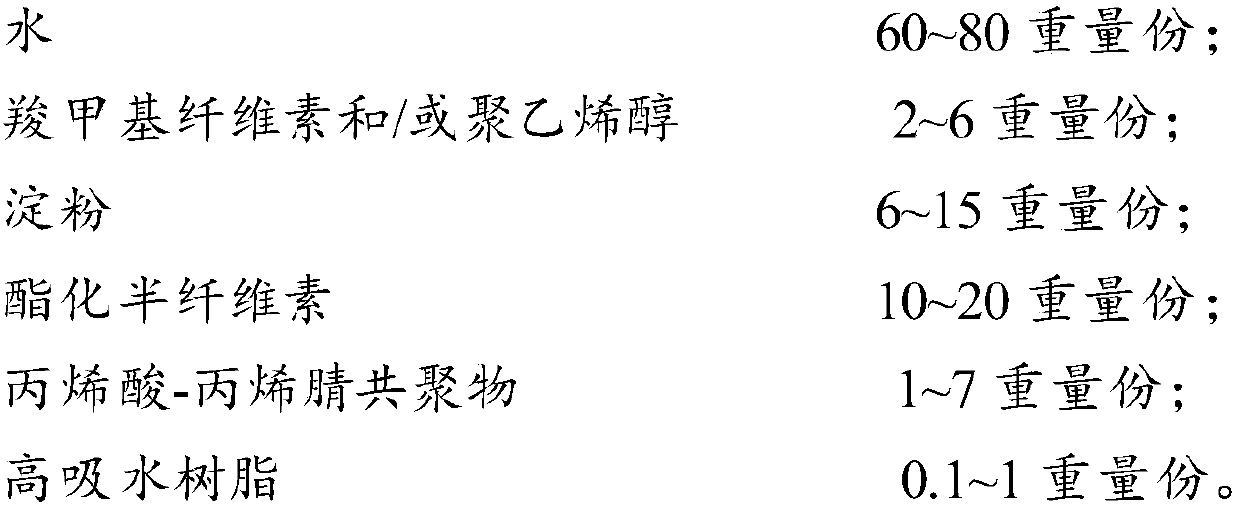

[0048] In terms of mass percentage, according to the coating formula, it is 50% calcium carbonate, 6% china clay, 7% latex, 0.5% starch, and 36.5% water, and the coating for the front coating layer is made by the conventional white card coating pre...

Embodiment 2

[0065] according to figure 2The manufacturing steps shown are needleleaf bleached chemical fiber, broadleaf bleached chemical fiber, needleleaf bleached thermomechanical fiber, broadleaf bleached thermomechanical fiber, and colored fiber, which are crushed and refined, and sent to the batching tank for pulping .

[0066] In terms of mass percentage, the overall proportion of various fibers is 9% needleleaf bleached chemical fiber, 58% broadleaf bleached chemical fiber, 8% needleleaf bleached thermomechanical fiber, and 25% broadleaf bleached thermomechanical fiber.

[0067] The prepared slurry flow is sent to the paper machine for dehydration and drying to form a quantitative 197g / m 2 base paper layer 102 .

[0068] In terms of mass percentage, the paint formula is 52% calcium carbonate, 4% china clay, 7% latex, 1% starch, and 36% water, and the top coat paint is made by the conventional white card paint preparation method.

[0069] The top coat paint is coated with a doct...

Embodiment 3

[0081] according to figure 2 The manufacturing steps shown are needleleaf bleached chemical fiber, broadleaf bleached chemical fiber, needleleaf bleached thermomechanical fiber, broadleaf bleached thermomechanical fiber, and colored fiber, which are crushed and refined, and sent to the batching tank for pulping .

[0082] In terms of mass percentage, the overall proportion of various fibers is 9% needleleaf bleached chemical fiber, 51% broadleaf bleached chemical fiber, 10% needleleaf bleached thermomechanical fiber, and 30% broadleaf bleached thermomechanical fiber.

[0083] The prepared slurry flow is sent to the paper machine for dehydration and drying to form a quantitative 172g / m 2 base paper layer 102 .

[0084] In terms of mass percentage, the paint formula is 48% calcium carbonate, 8% china clay, 8% latex, and 36% water, and the top coat paint is prepared by a conventional white card paint preparation method.

[0085] The top coat paint is coated with a doctor blad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com