Phosphotungstic acid-metal organic skeleton used for catalyzing hydrolysis of cellulose, and preparation method and application thereof

A technology of metal-organic framework and phosphotungstic acid, which is applied in the direction of chemical instruments and methods, applications, physical/chemical process catalysts, etc., can solve the problem of non-selectivity of catalytic performance, easy loss of acid catalytic ability, complex grafting operation of active functional groups, etc. problem, to achieve the effect of reducing the difficulty of hydrolysis, enhancing reusability, and avoiding the occurrence of glucose side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]A phosphoric acid-metal organic skeleton for catalytic cellulose hydrolysis, which is made with the following methods: 0.48g (2mmol) hexal water chloride, 0.23g (1mmol) 2,5-dichloropenzhenylenePigxolic acid, 0.18g (1mmol) 2-amino phenylic acid and 0.125g (0.04 mmol) phosphoric acid to 30 mln, n-two-B-thenmamide, stir well at room temperature, transfer the mixed solution to a clustering four of 100mlThe stainless steel reactor in the fluoride lining is heated from the room temperature to 130 ° C, and the reaction process does not need to be stirred at 130 ° C. After the reaction, it is cooled to the room temperature.The filter liquid is clear and transparent, and the white solid obtained by the filter is dry for 16h at 70 ° C. After drying, the pale yellow powder is a multifunctional material of the phosphoric acid-metal organic skeleton.

Embodiment 2

[0033] A phosphoric acid-metal organic skeleton for catalytic cellulose hydrolysis, use the following methods: 2.25g (8mmol) hexal water chloride, 0.97g (4mmol) 2,5-dichloropenzhenylenePigxolic acid, 0.75g (4mmol) 2-aminophytic dihydramic acid and 1g (0.3 mmol) phosphoric acid to 50 mln, n-di metamimamide, stir well at room temperature, transfer the mixed solution to a polytimonia of 100mlThe stainless steel reactor in the ethylene lining is heated from the room temperature to 110 ° C, and it is maintained for 16h at 110 ° C. The reaction process does not need to be stirred, cooled to room temperature after the reaction, and the sediment that was separated from the centrifugal separation was n, n-di metamimine.After washing, the filter was filtered until the filter liquid was clear and transparent. The dark brown solid obtained by the filter was dried for 16h at a vacuum of vacuum at 80 ° C. After drying, the brown powder was a multifunctional material of the phosphoric acid-metal...

Embodiment 3

[0035] A phosphoric acid-metal organic skeleton for catalytic cellulose hydrolysis, use the following methods: 0.8g (2mmol) hexal water chromium chromium chromium chromium, 0.23g (1mmol) 2,5-dichloropenhebenzeneriPigxolic acid, 0.18g (1mmol) 2-amino phenyl acid and 0.125g (0.04 mmol) phosphoric acid to 15ml0.2 mol / L hydroxide water solution, stir well at room temperature, and transfer the mixed solution to a clustering four of 100mlThe stainless steel reactor in the fluoride lining is heated from the room temperature to 150 ° C, and it is kept 10h at 150 ° C. The reaction process does not need to be stirred. After the reaction, it is cooled to the room temperature.After repeated washing, the filter is filtered until the filter liquid is clear and transparent. The ink green solid obtained by the filter is dried for 16h at 70 ° C. After drying, the yellow-green powder is a multifunctional material of the phosphate tungsten acid-metal organic skeleton.

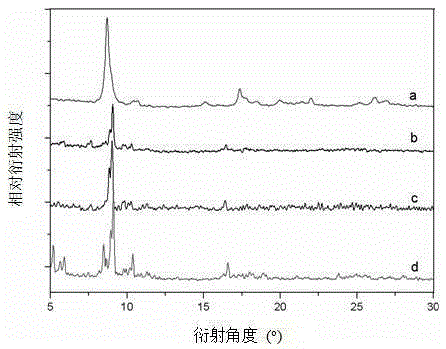

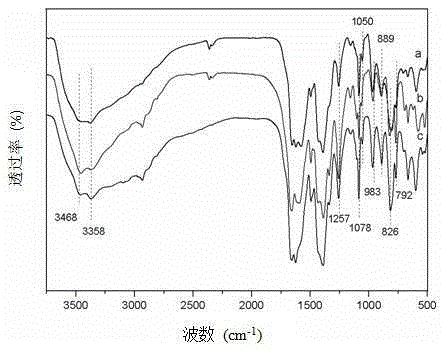

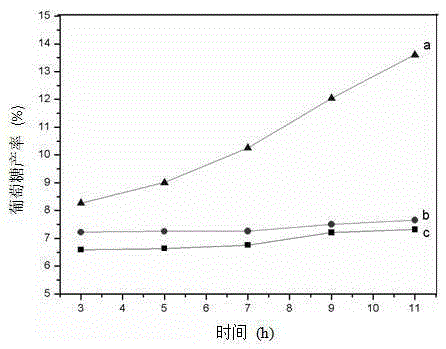

[0036] For the XRD diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com