Patents

Literature

50 results about "Cargo scanning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cargo scanning or non-intrusive inspection (NII) refers to non-destructive methods of inspecting and identifying goods in transportation systems. It is often used for scanning of intermodal freight shipping containers. In the US it is spearheaded by the Department of Homeland Security and its Container Security Initiative (CSI) trying to achieve one hundred percent cargo scanning by 2012 as required by the US Congress and recommended by the 9/11 Commission. In the US the main purpose of scanning is to detect special nuclear materials (SNMs), with the added bonus of detecting other types of suspicious cargo. In other countries the emphasis is on manifest verification, tariff collection and the identification of contraband. In February 2009, approximately 80% of US incoming containers were scanned. In order to bring that number to 100% researchers are evaluating numerous technologies, described in the following sections.

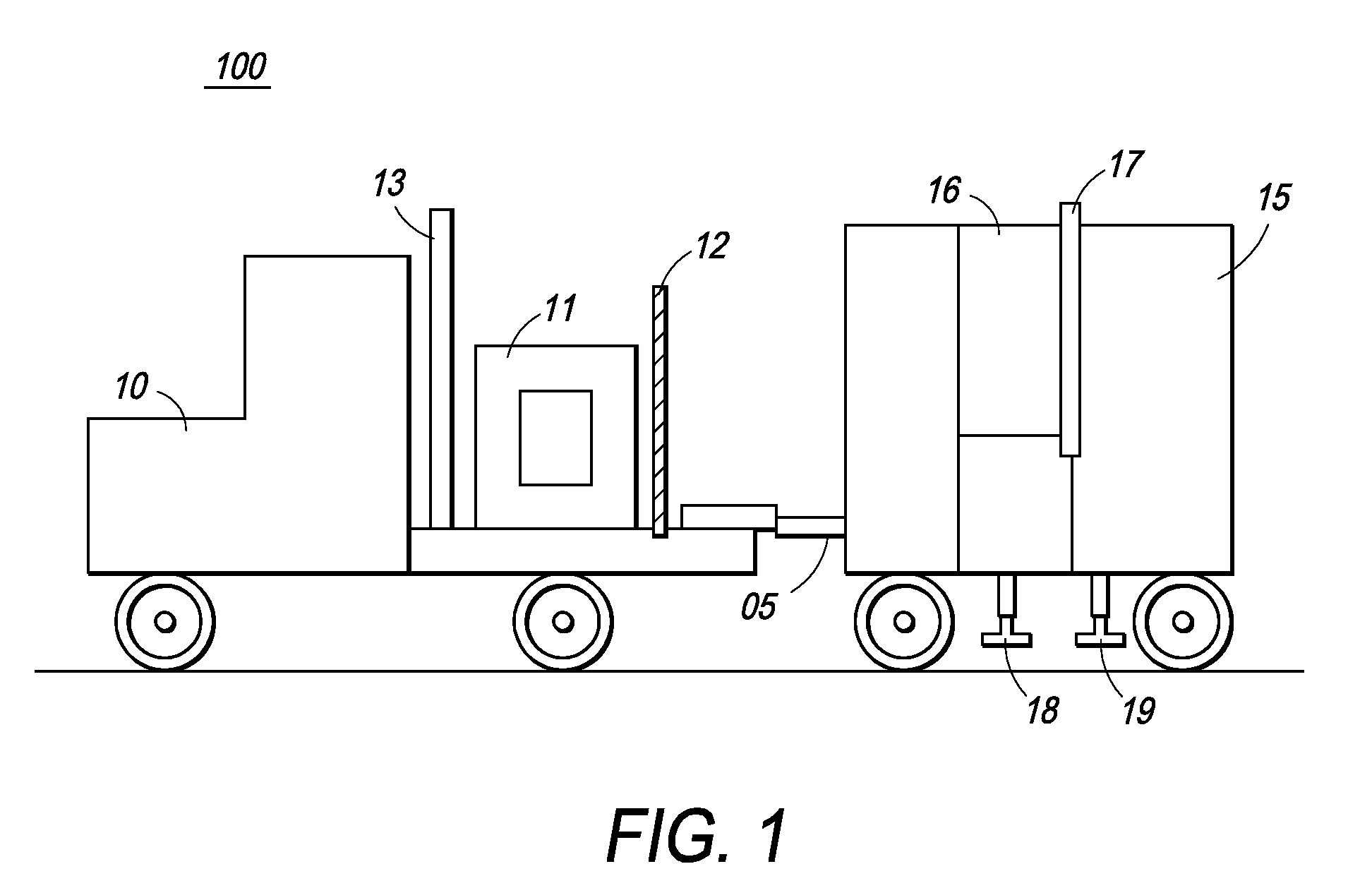

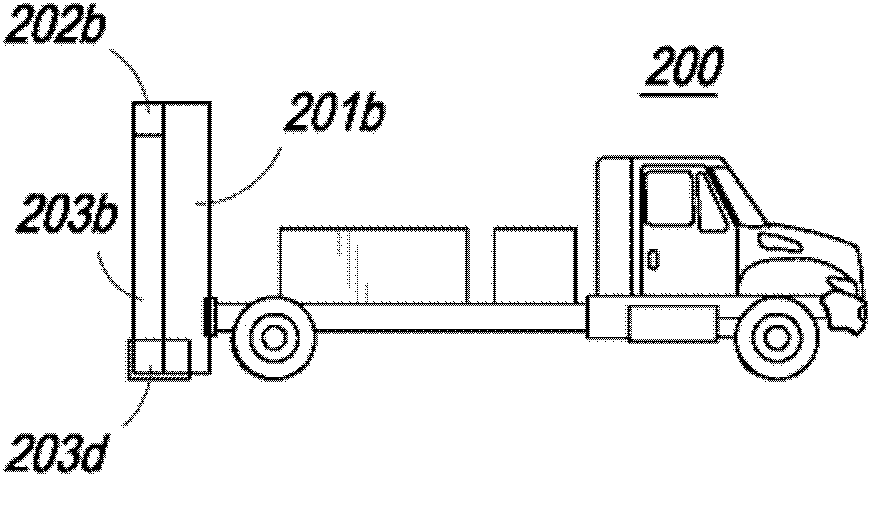

Single boom cargo scanning system

InactiveUS7322745B2Rapidly deployableCost-effectively and accurately on uneven surfaceRadiation/particle handlingParticle suspension analysisMobile vehicleDetector array

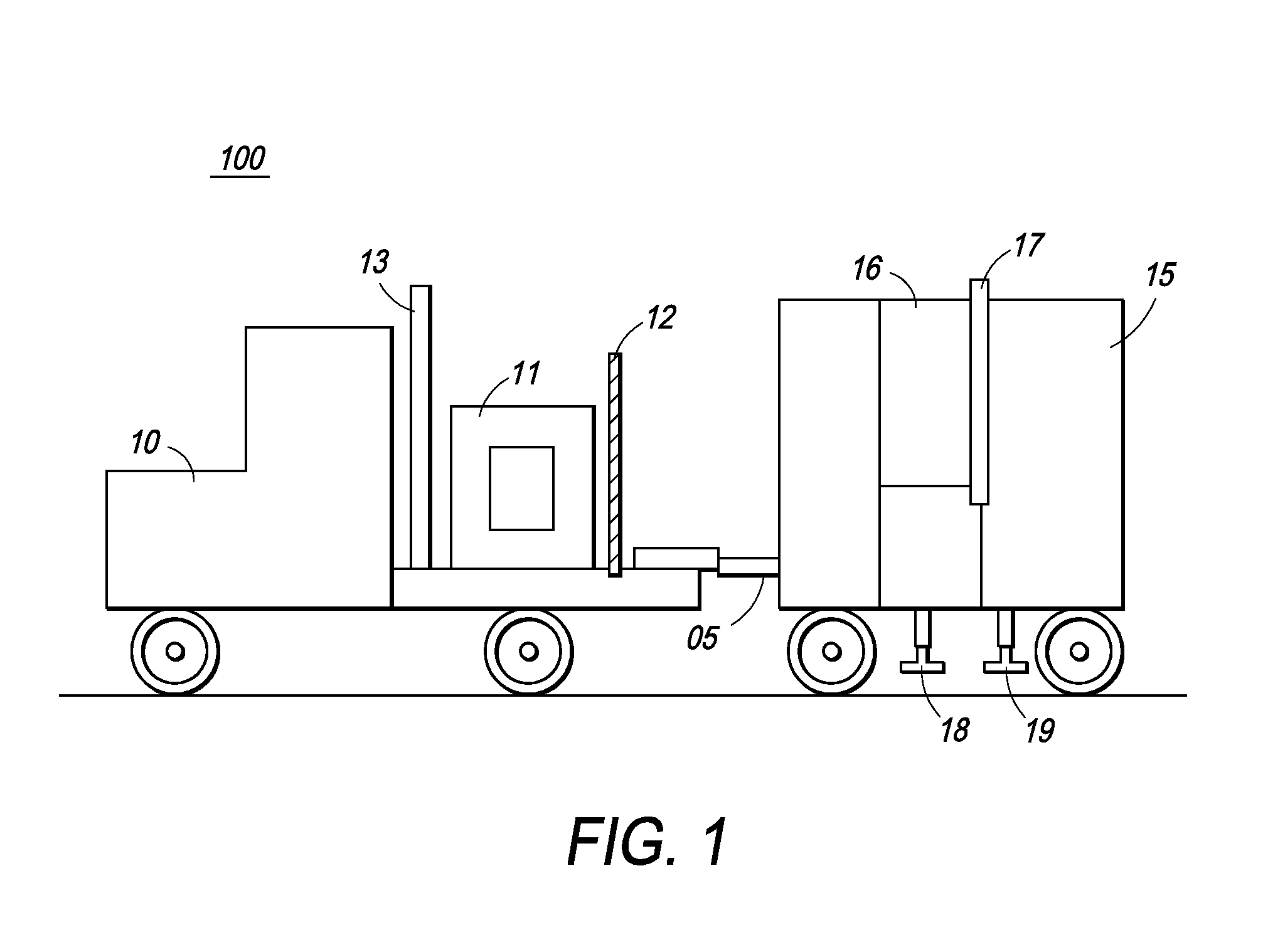

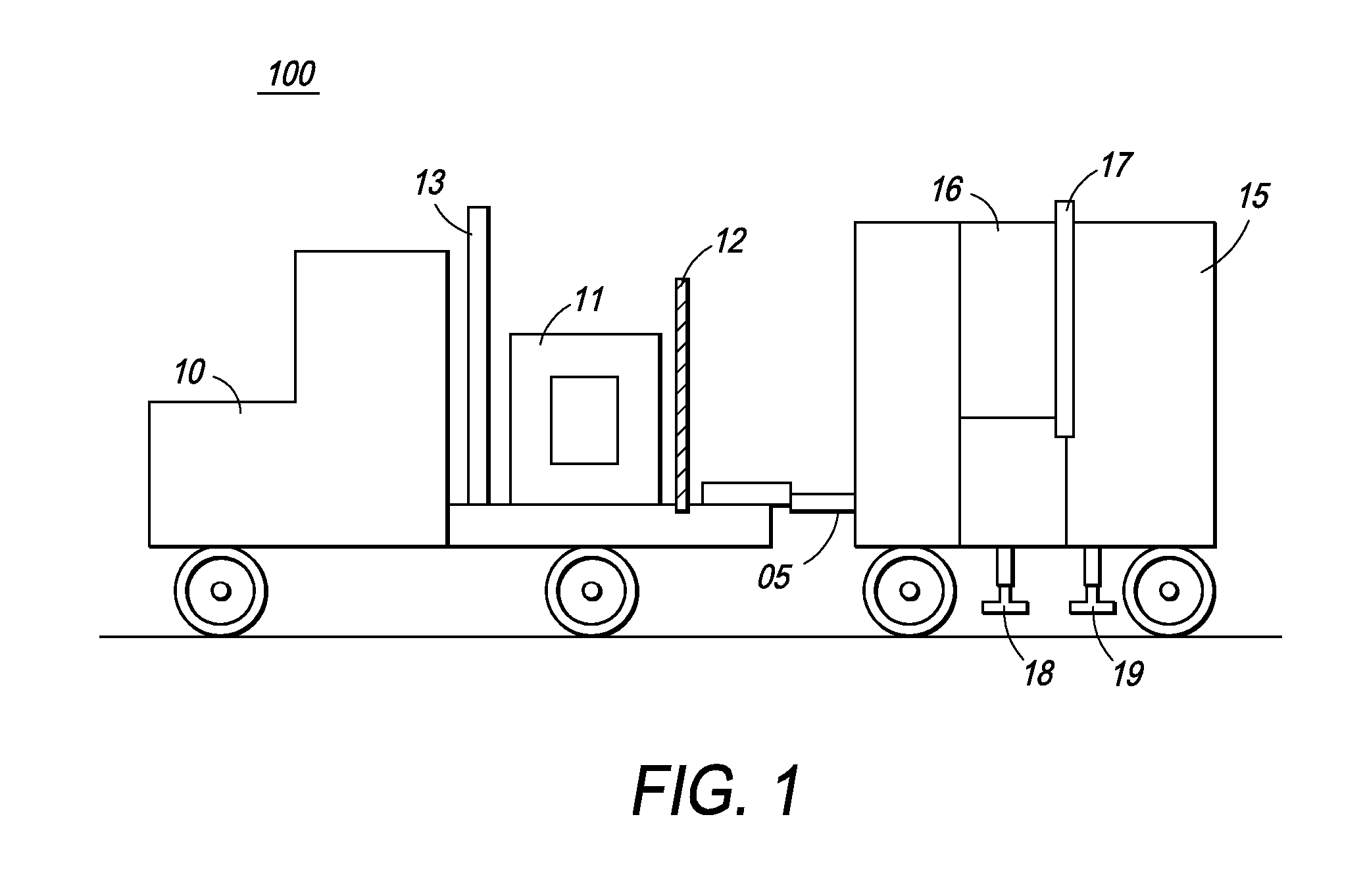

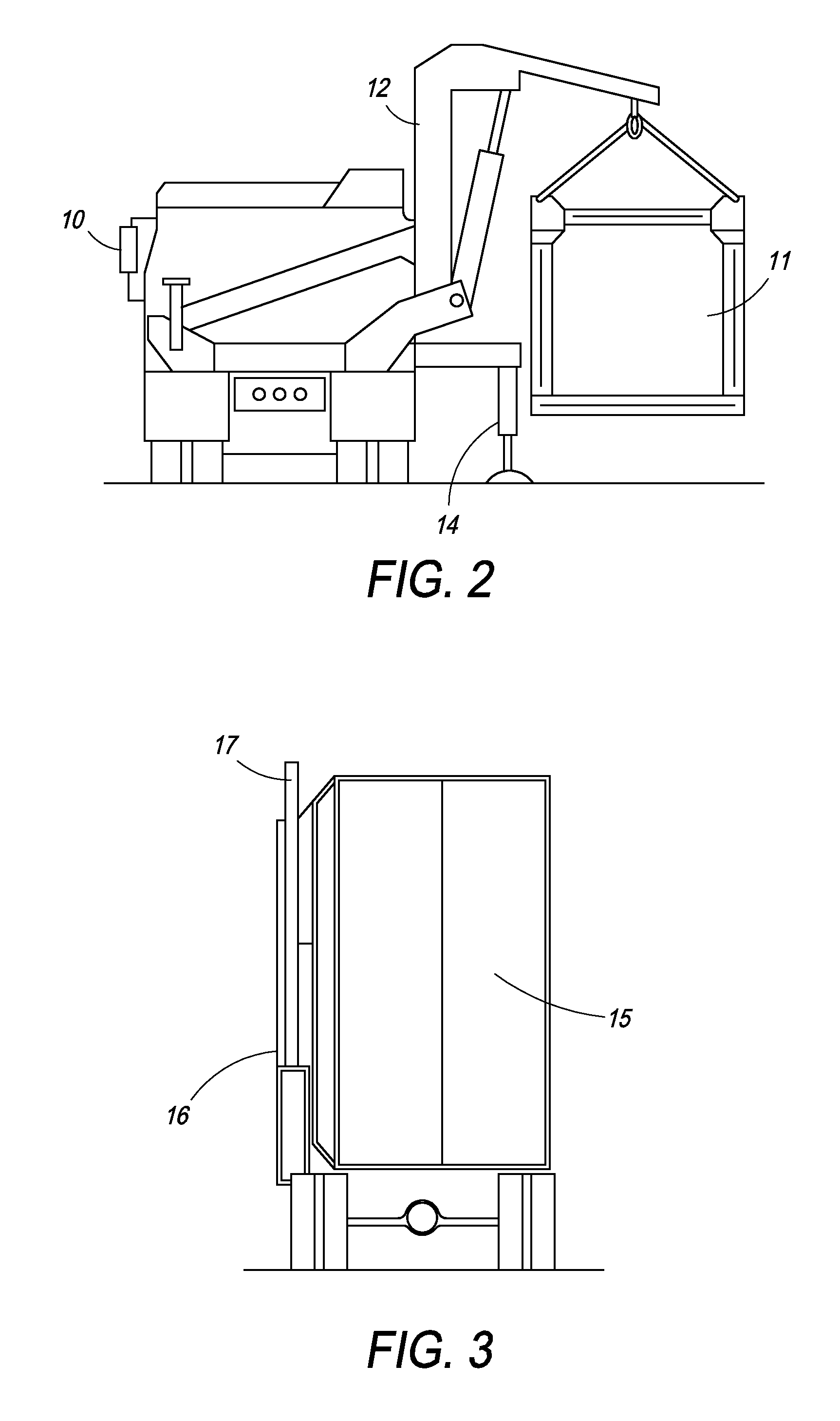

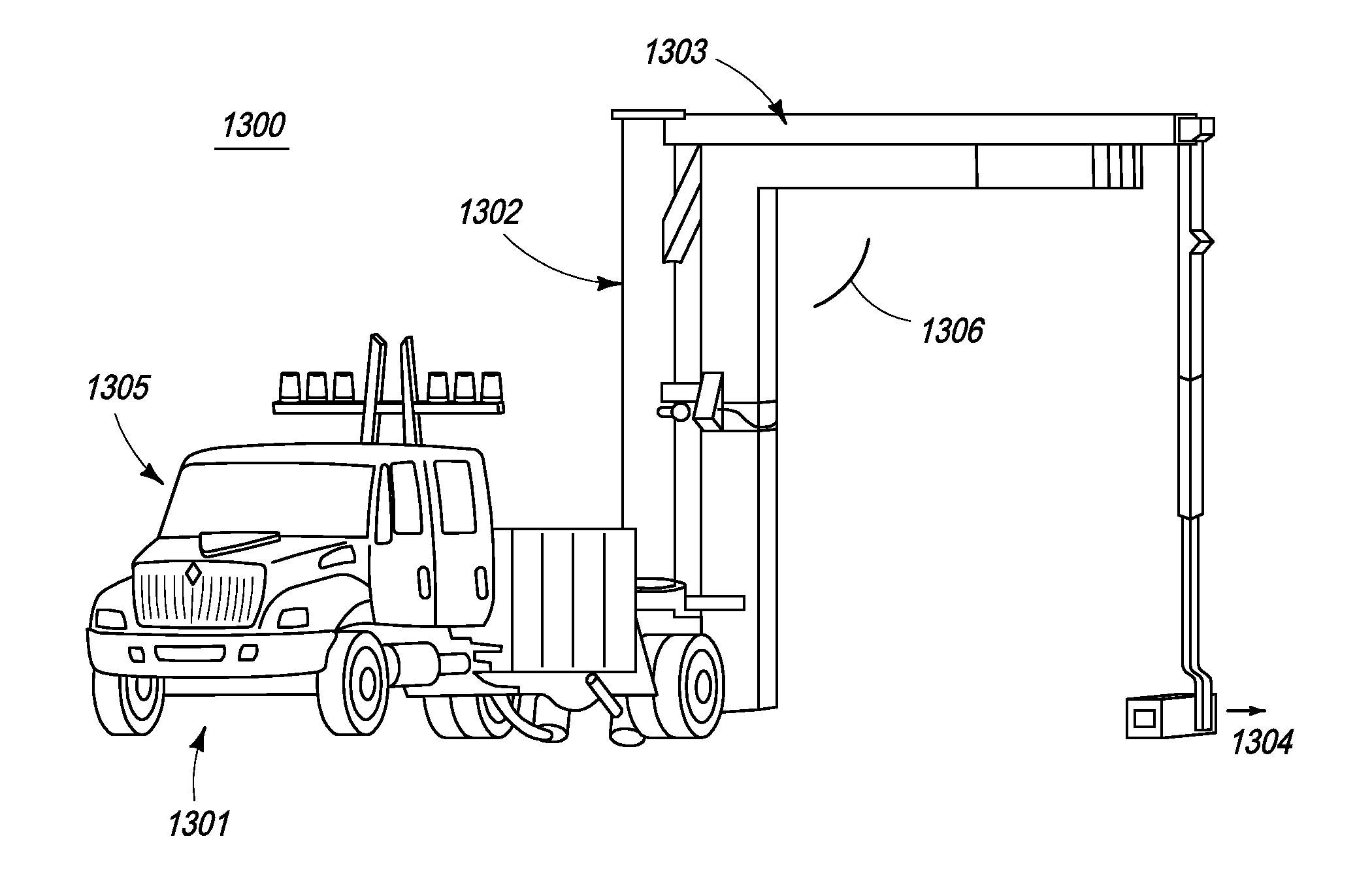

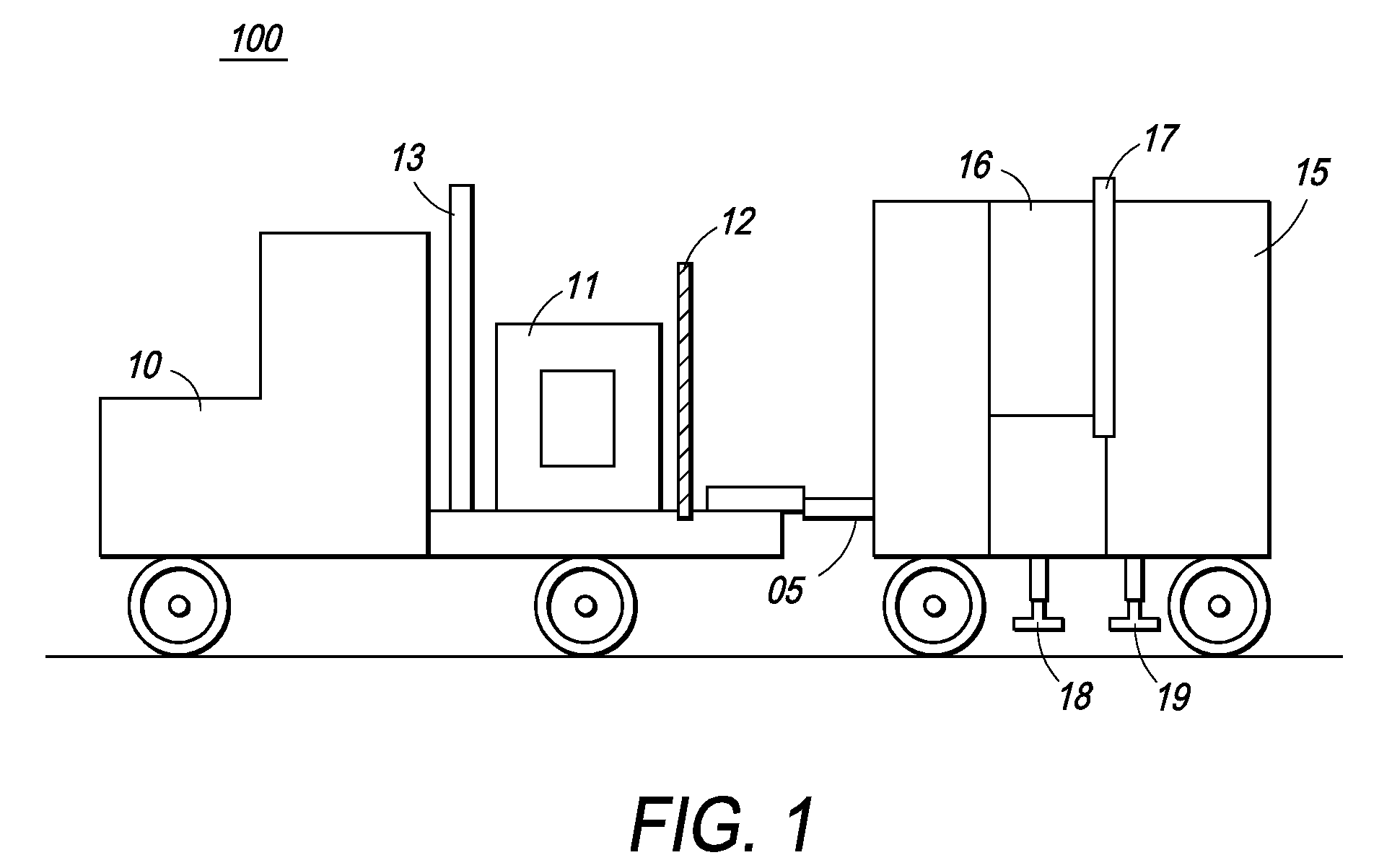

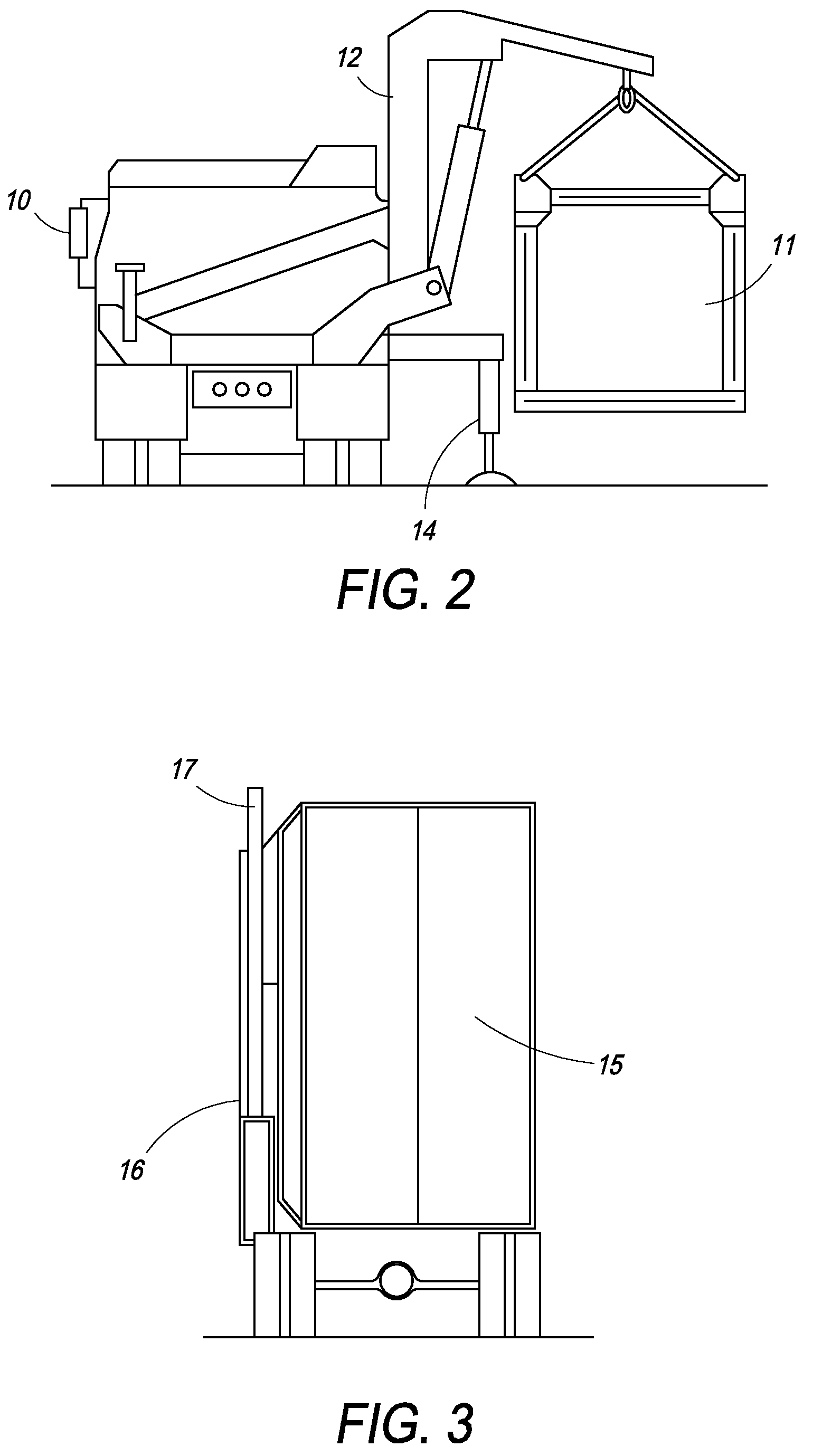

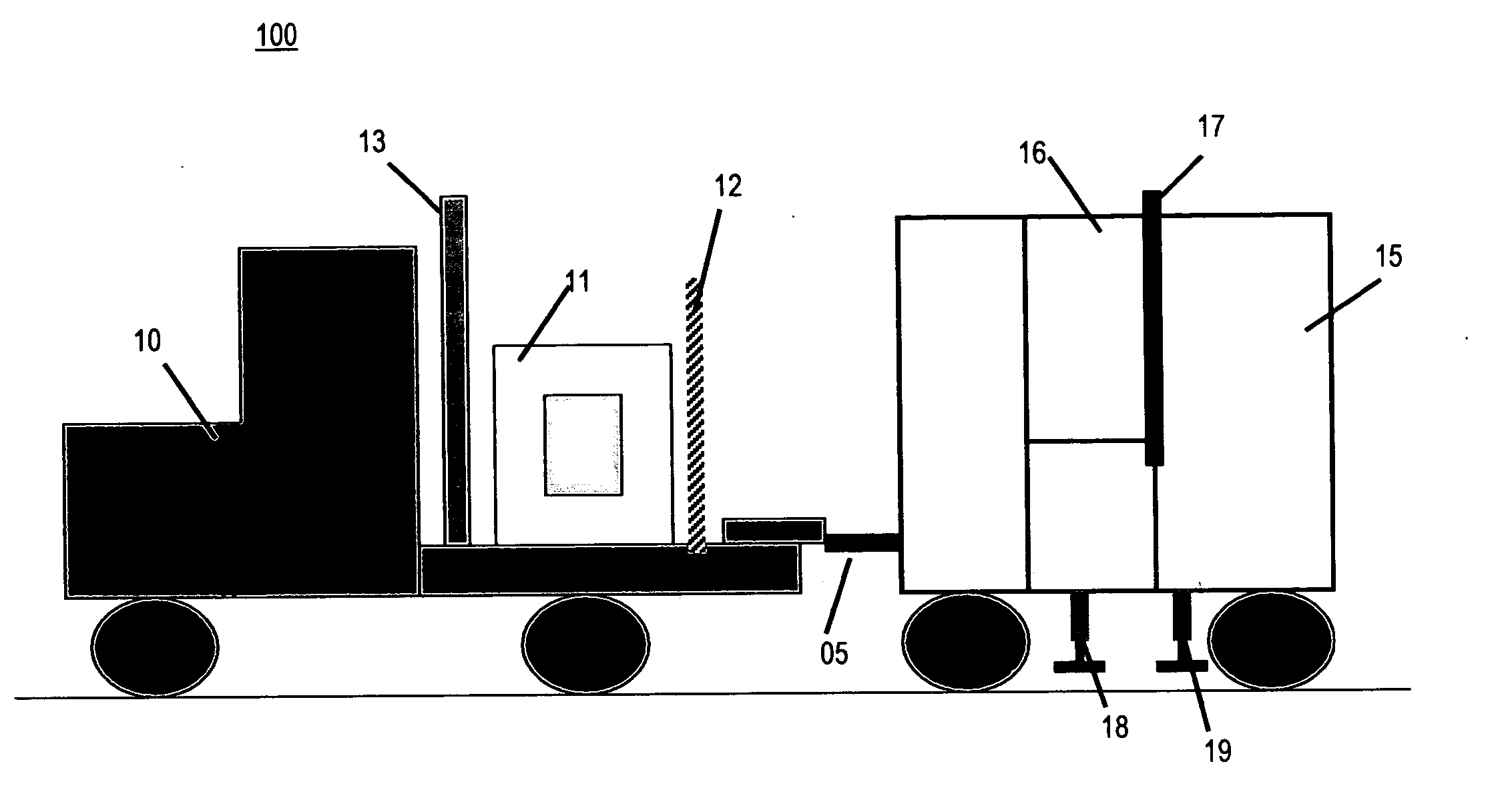

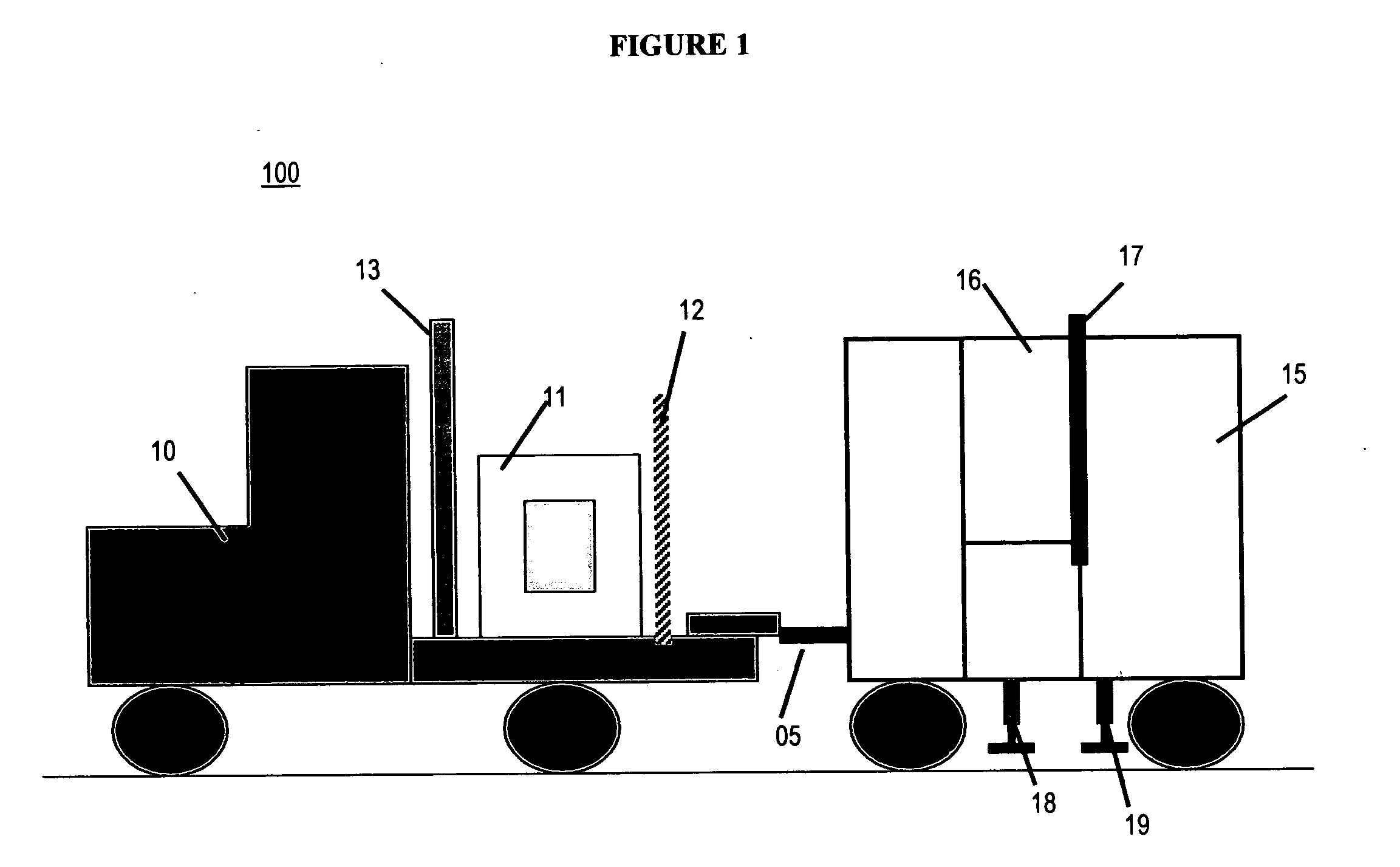

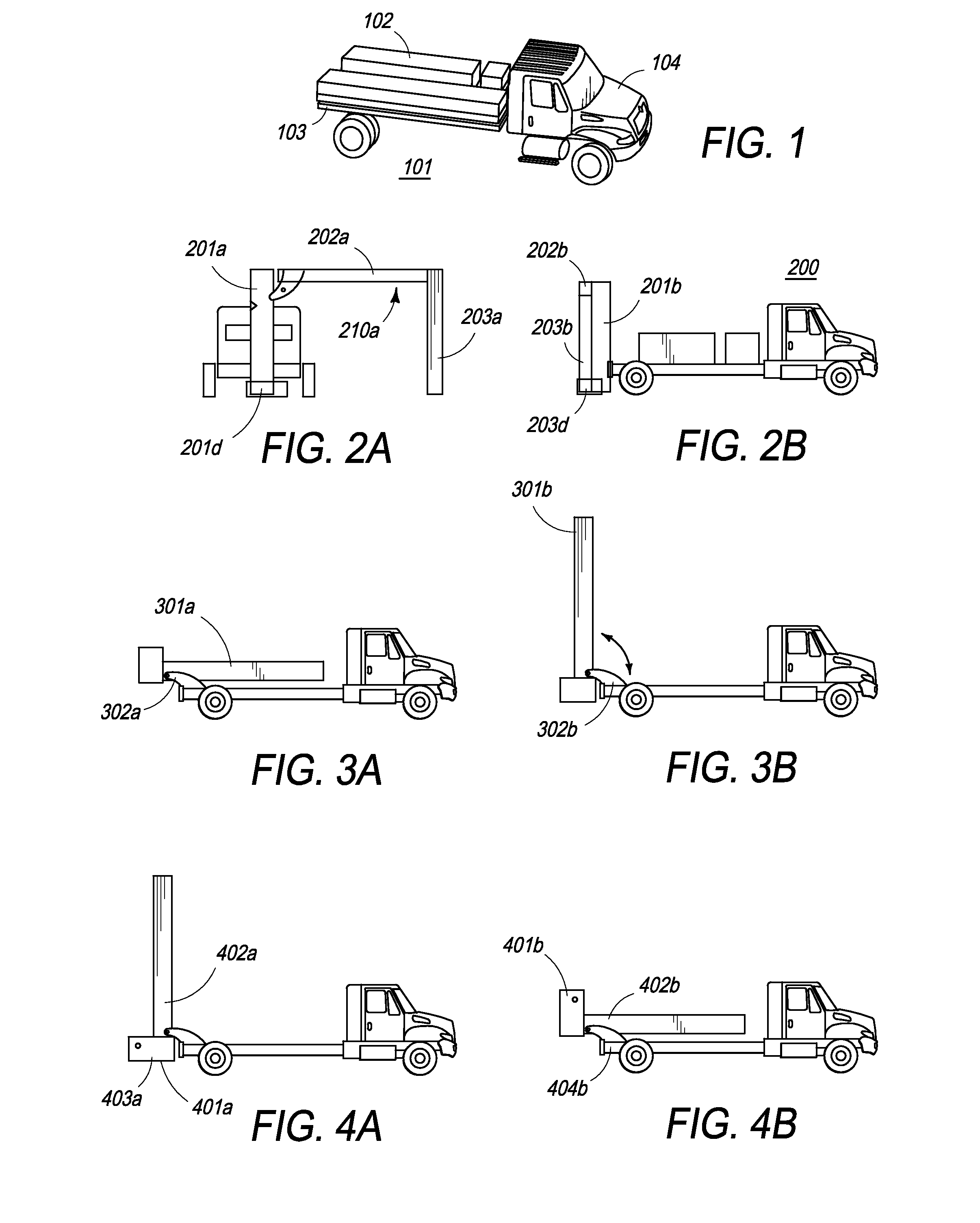

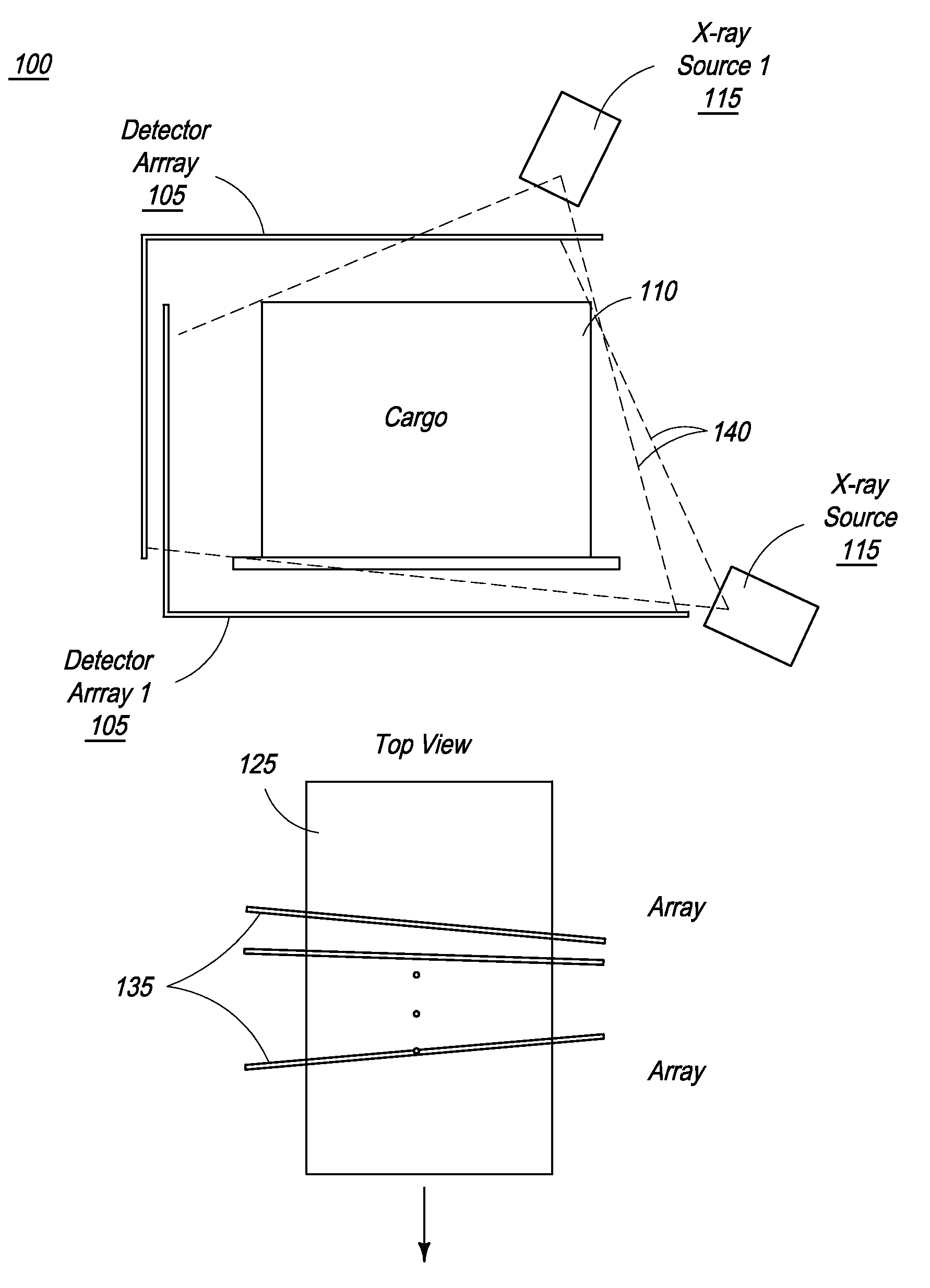

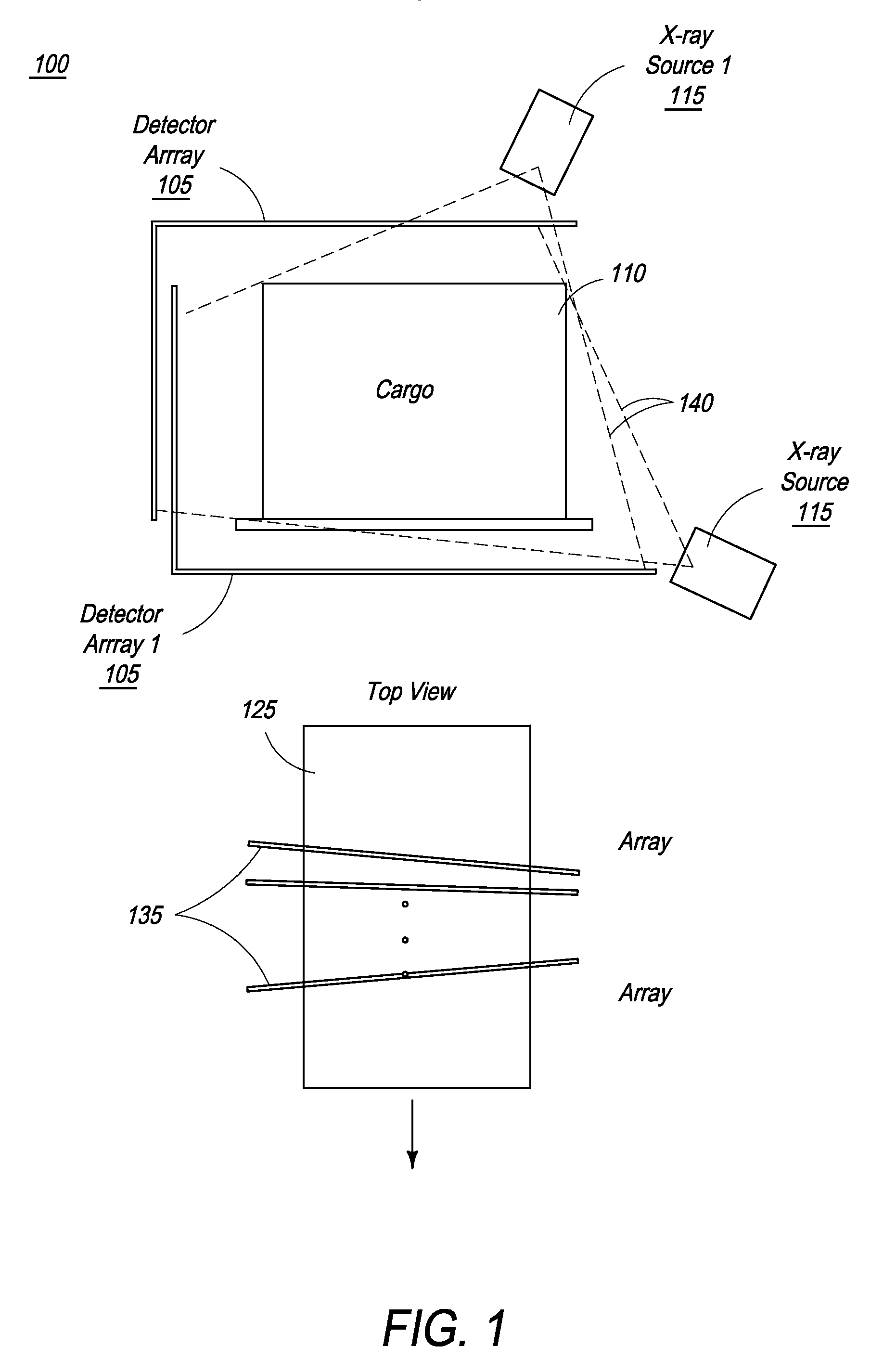

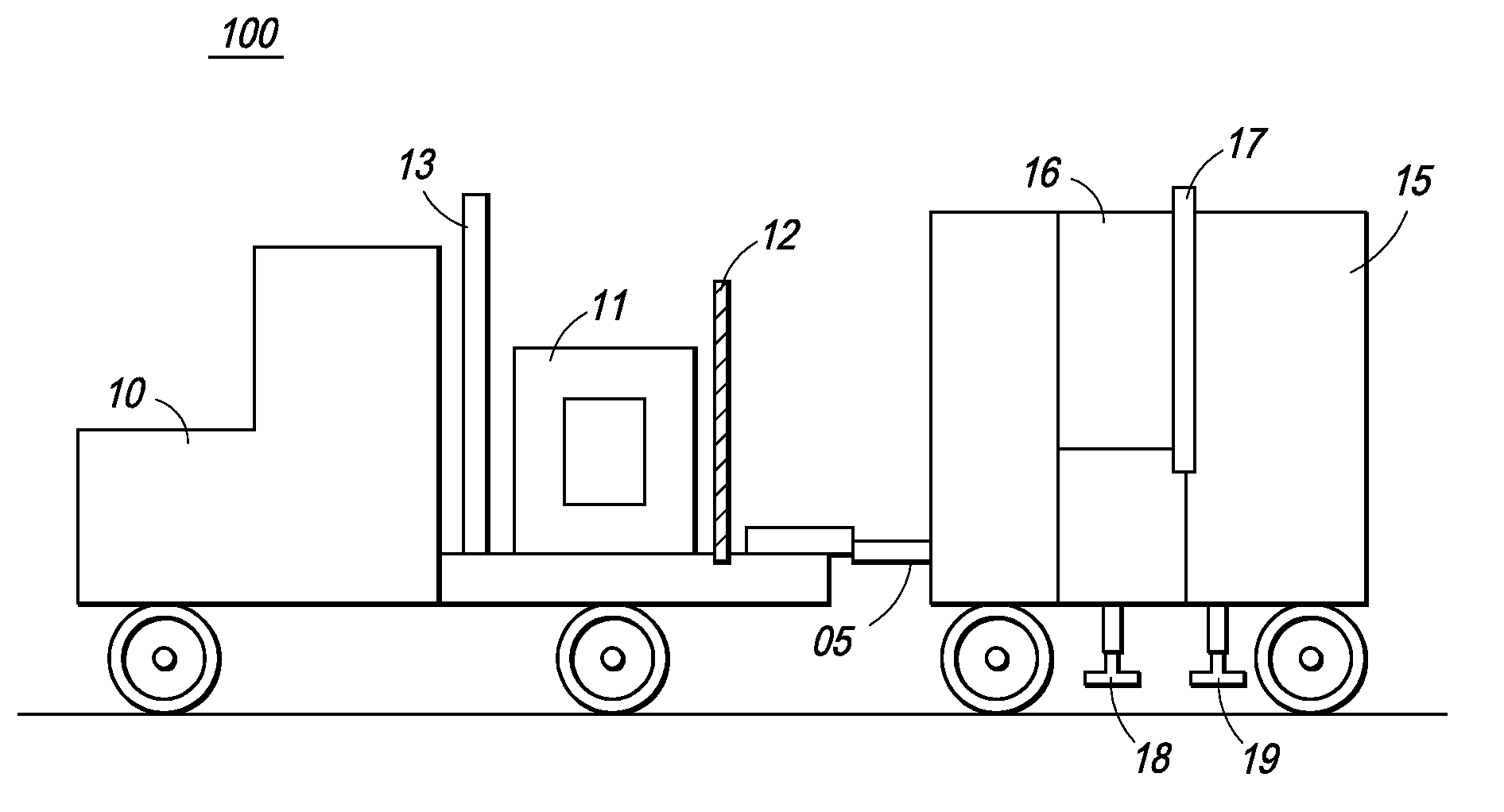

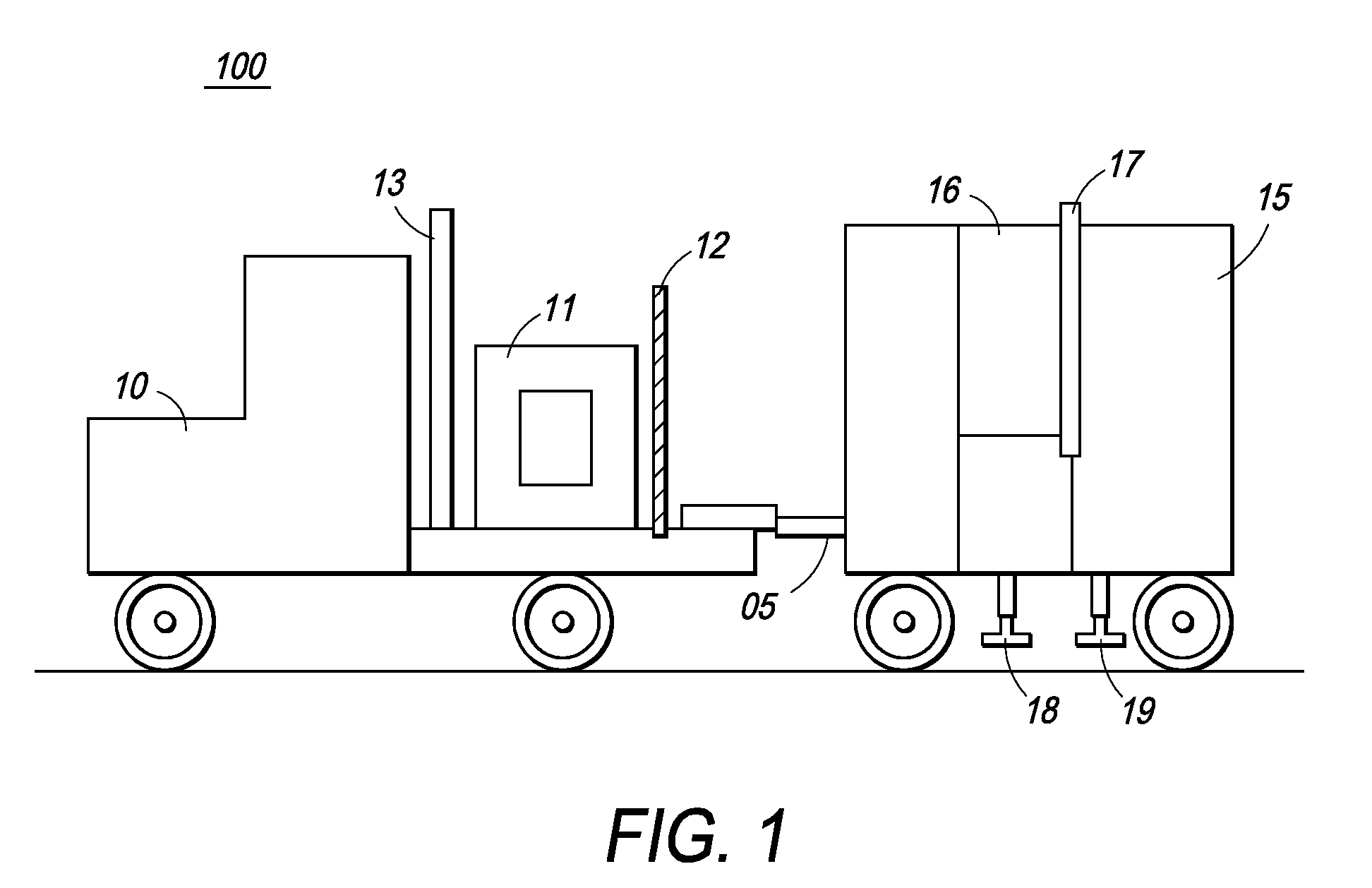

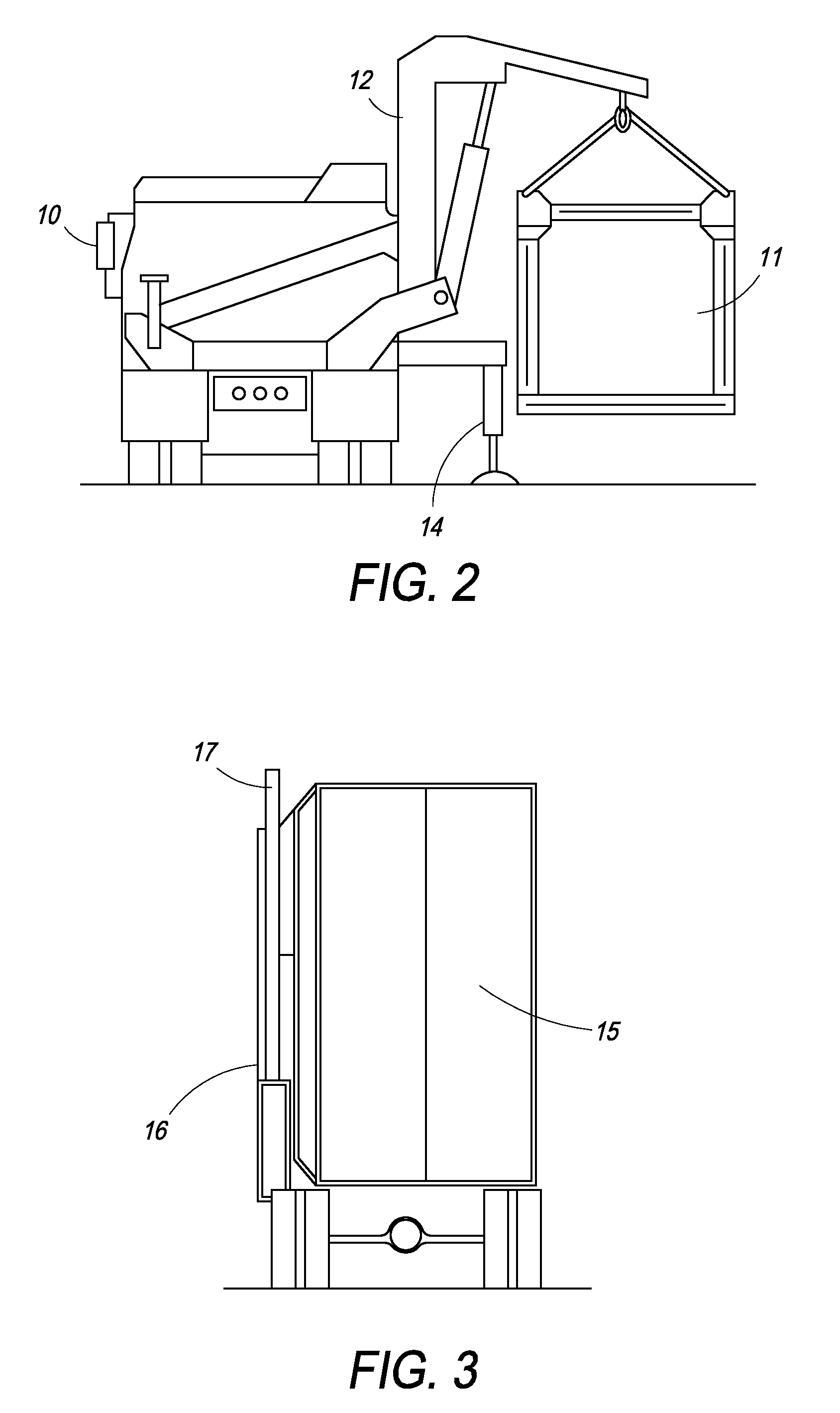

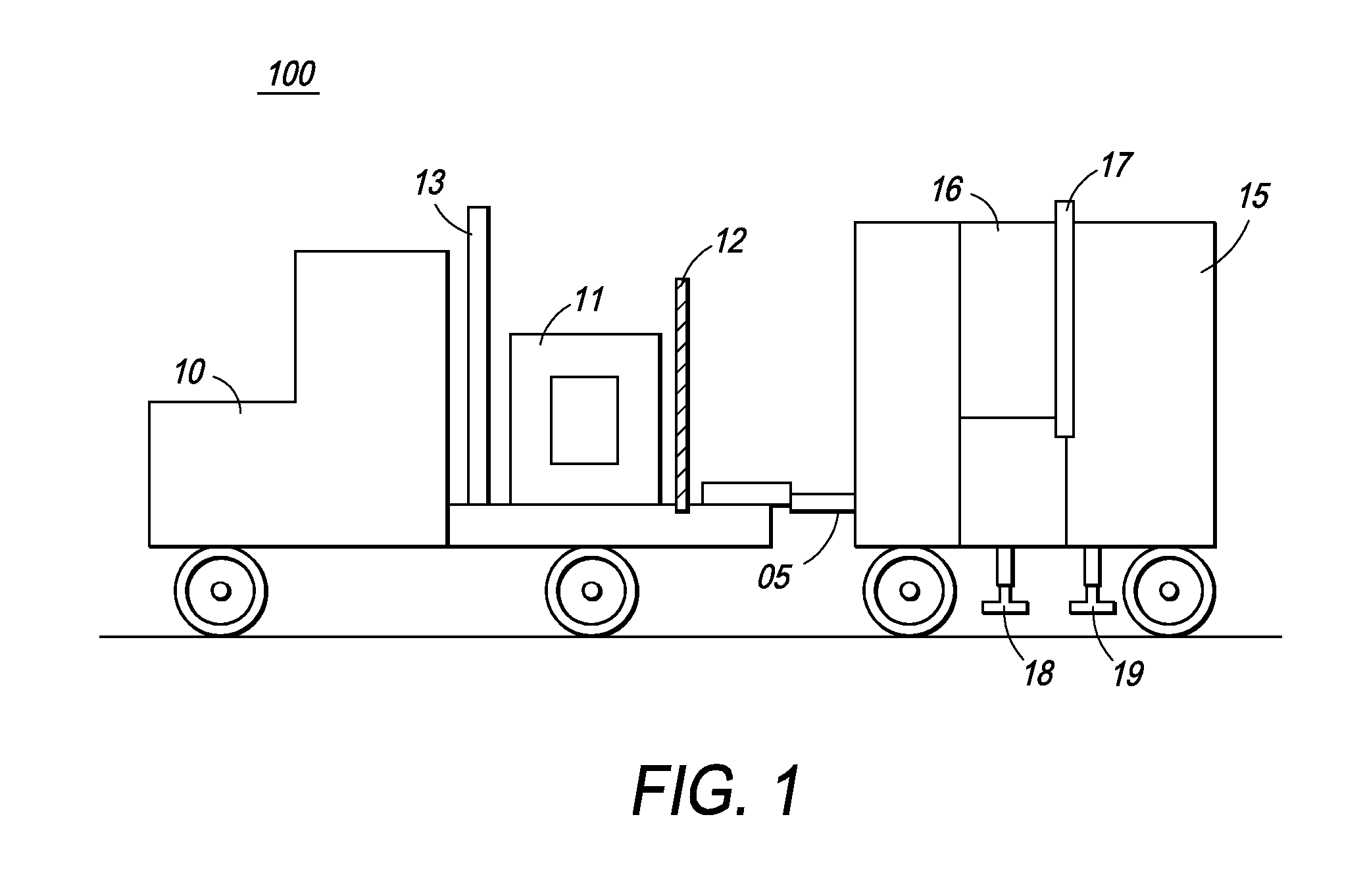

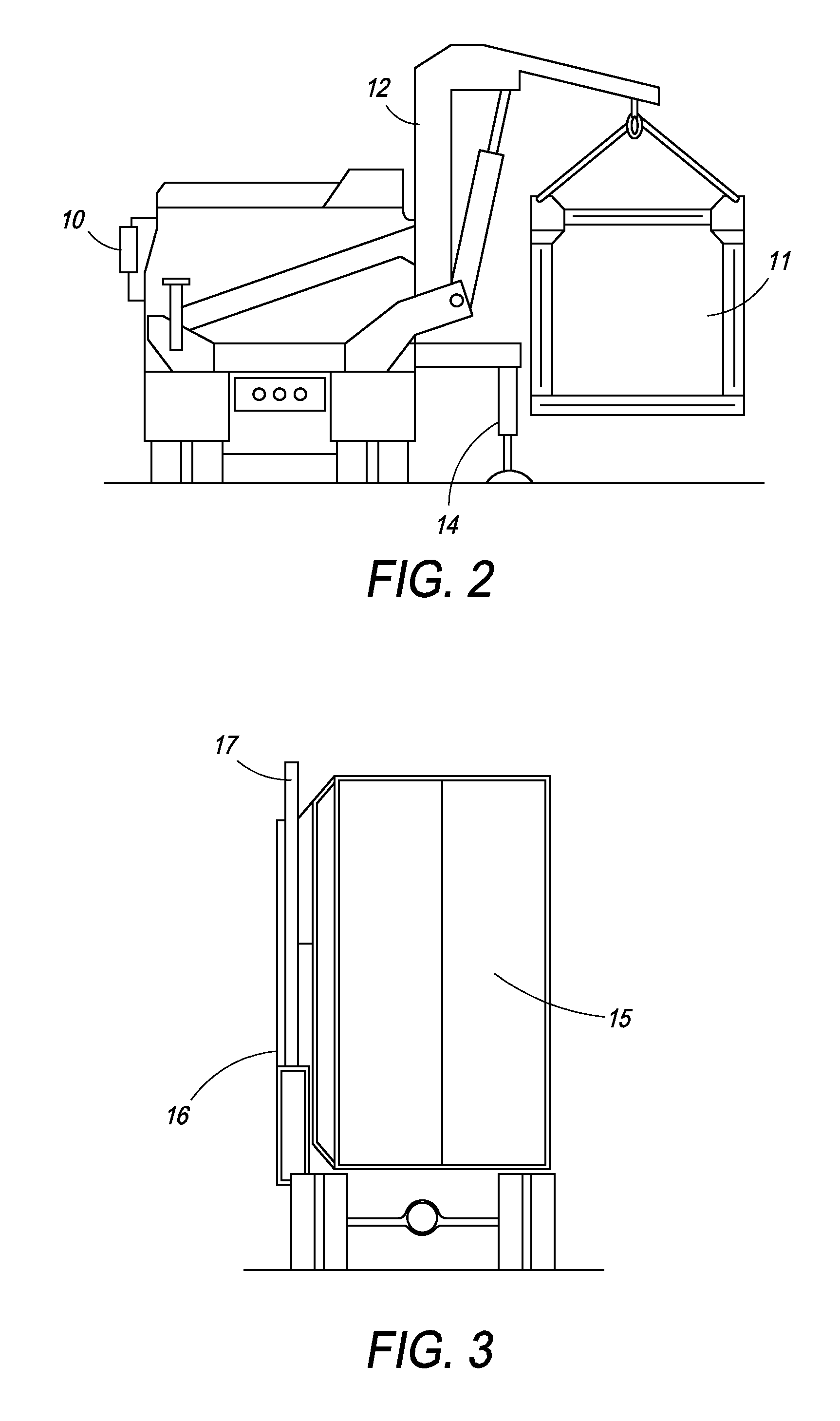

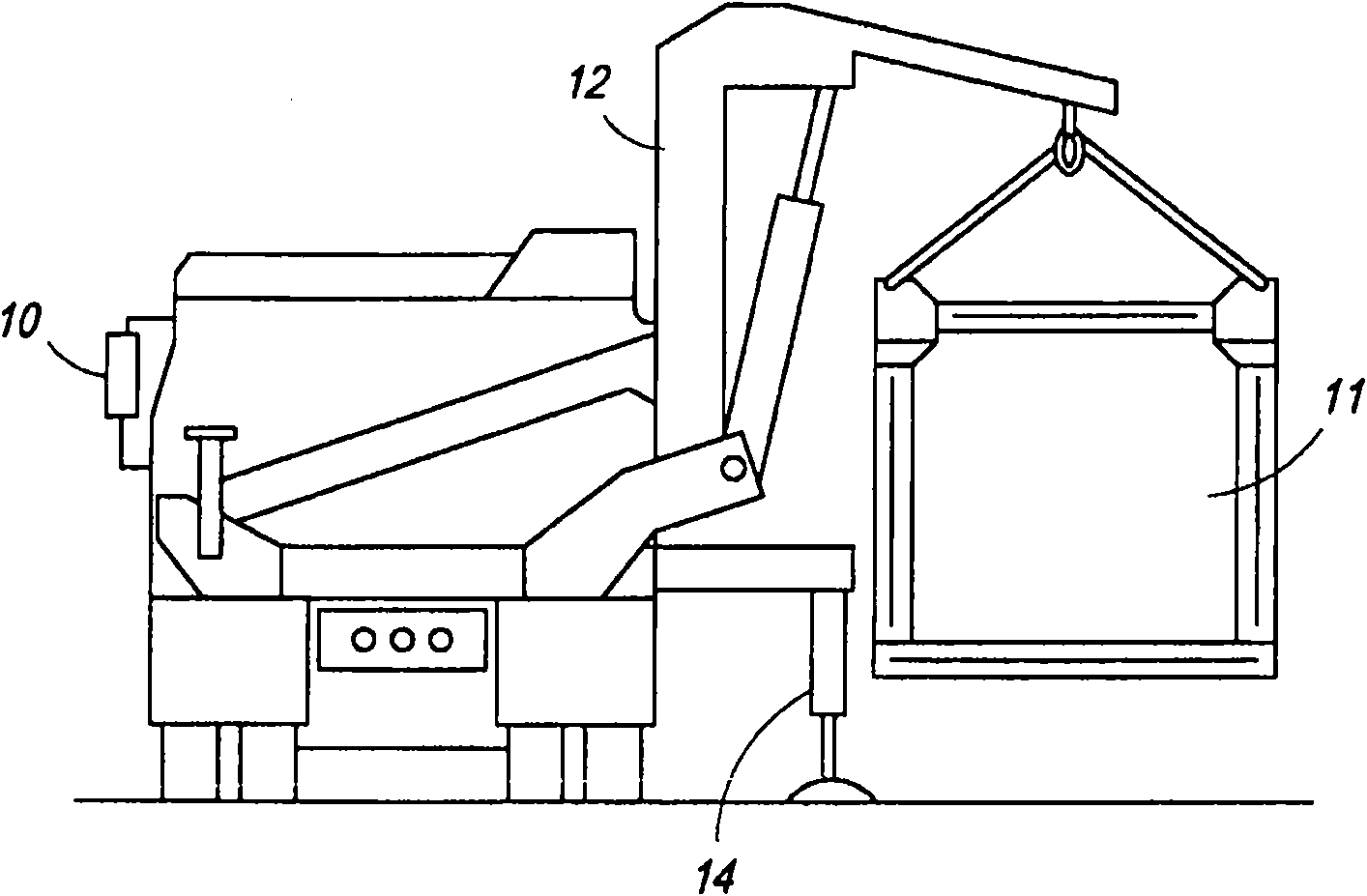

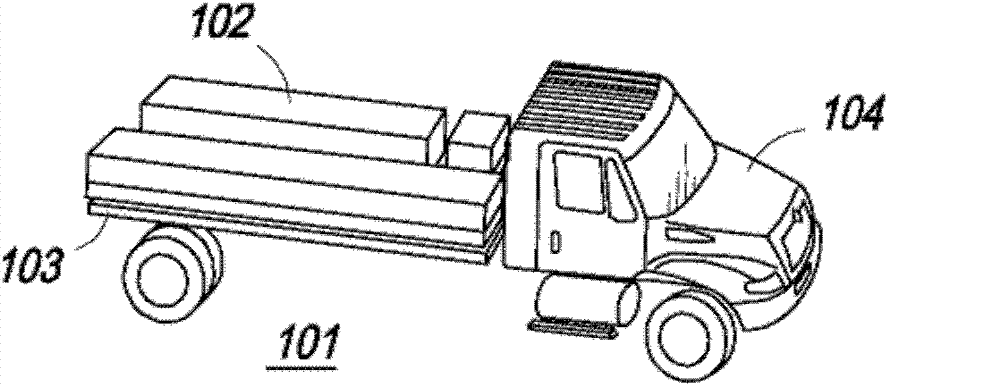

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

Single boom cargo scanning system

InactiveUS7369643B2Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

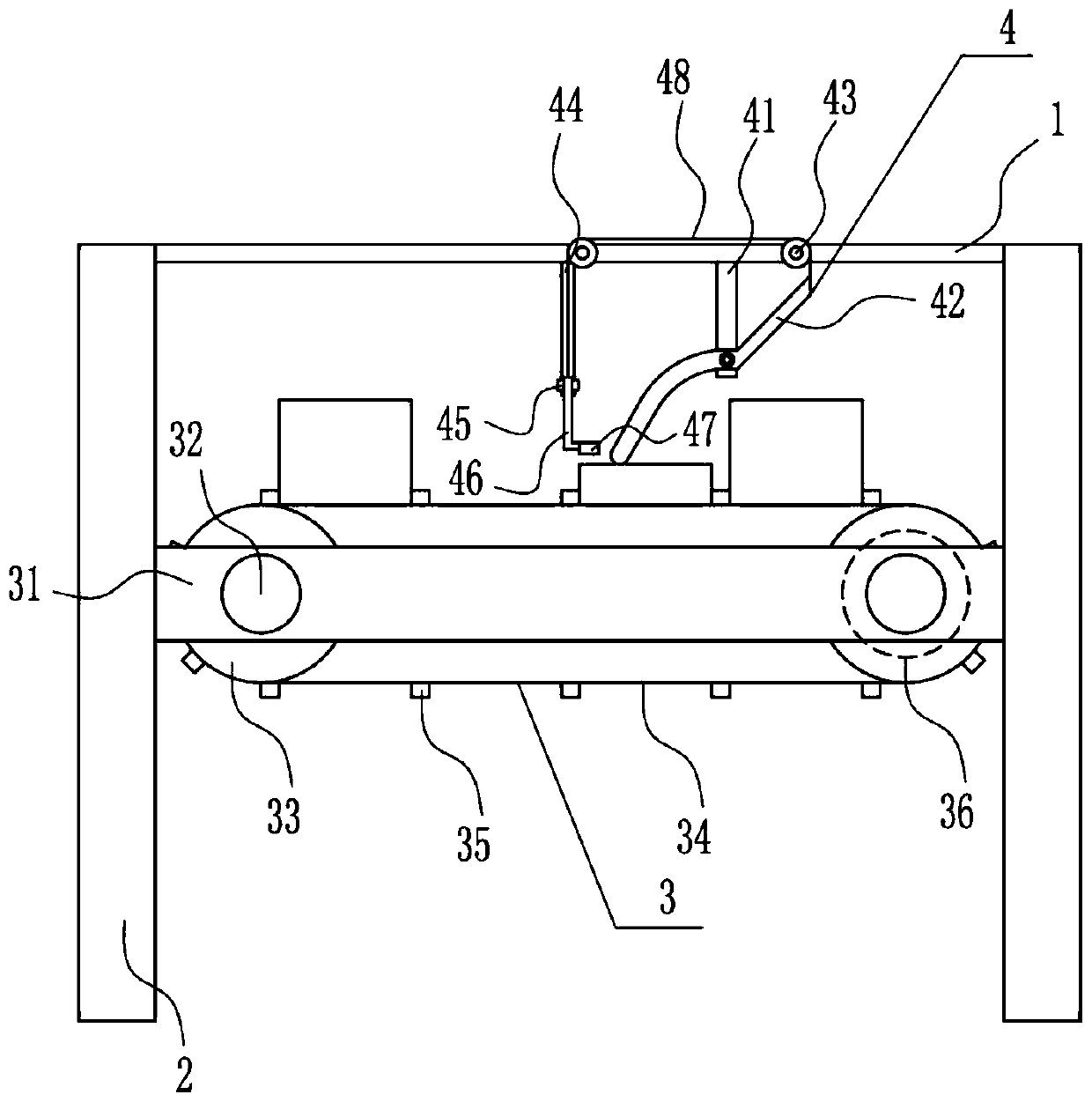

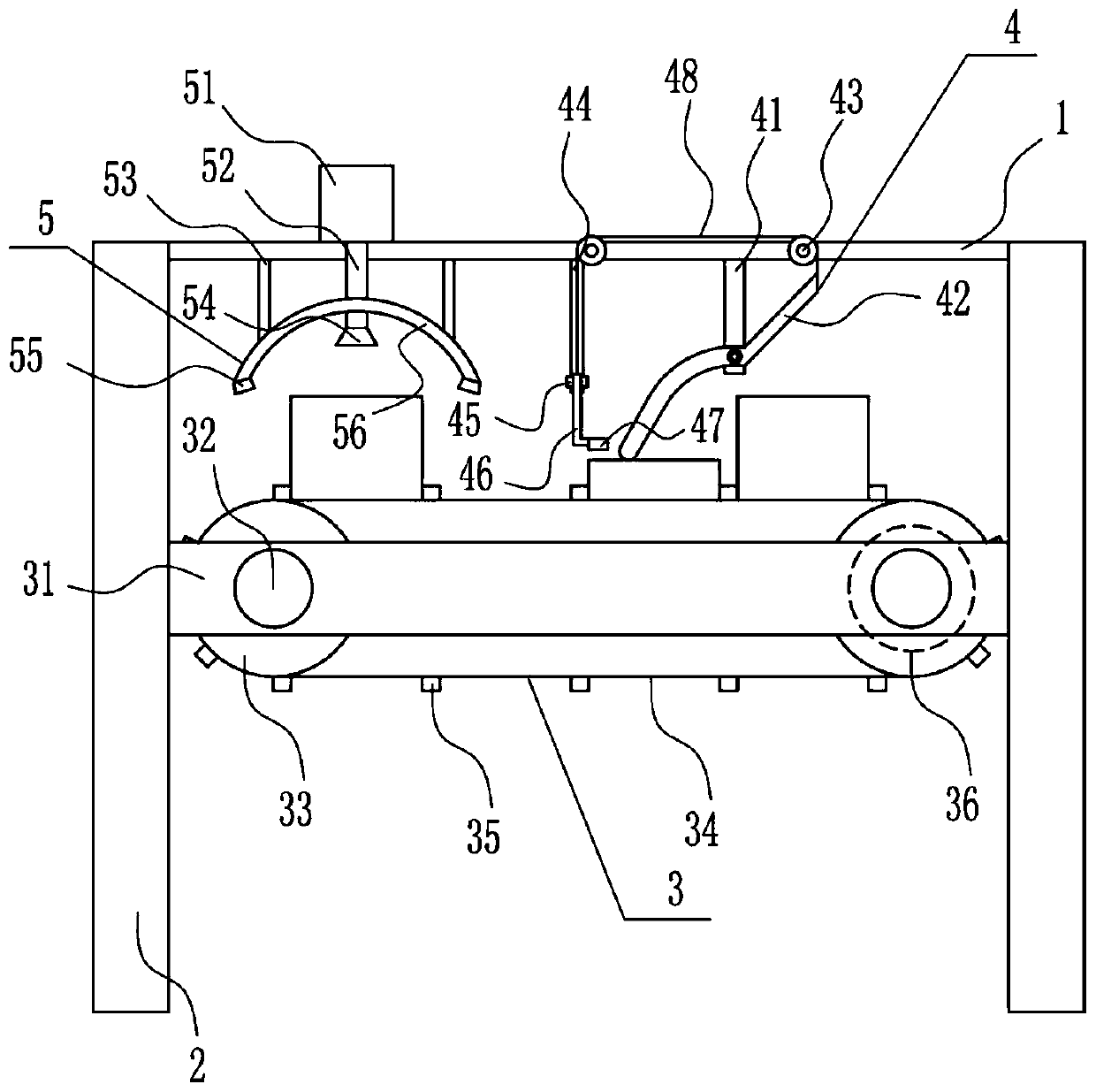

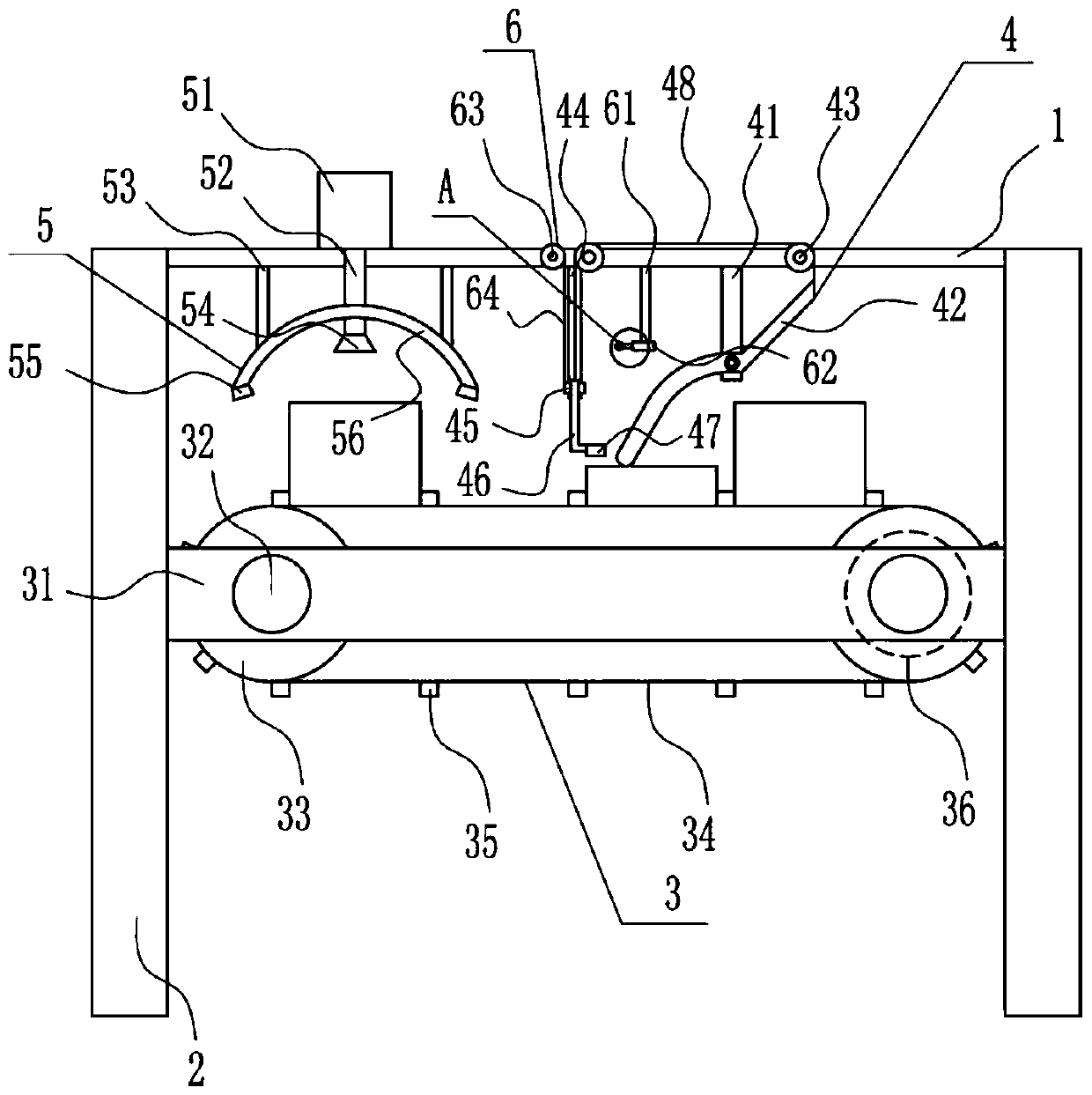

Compact Mobile Cargo Scanning System

InactiveUS20110038453A1X-ray apparatusMaterial analysis by transmitting radiationOperabilityEngineering

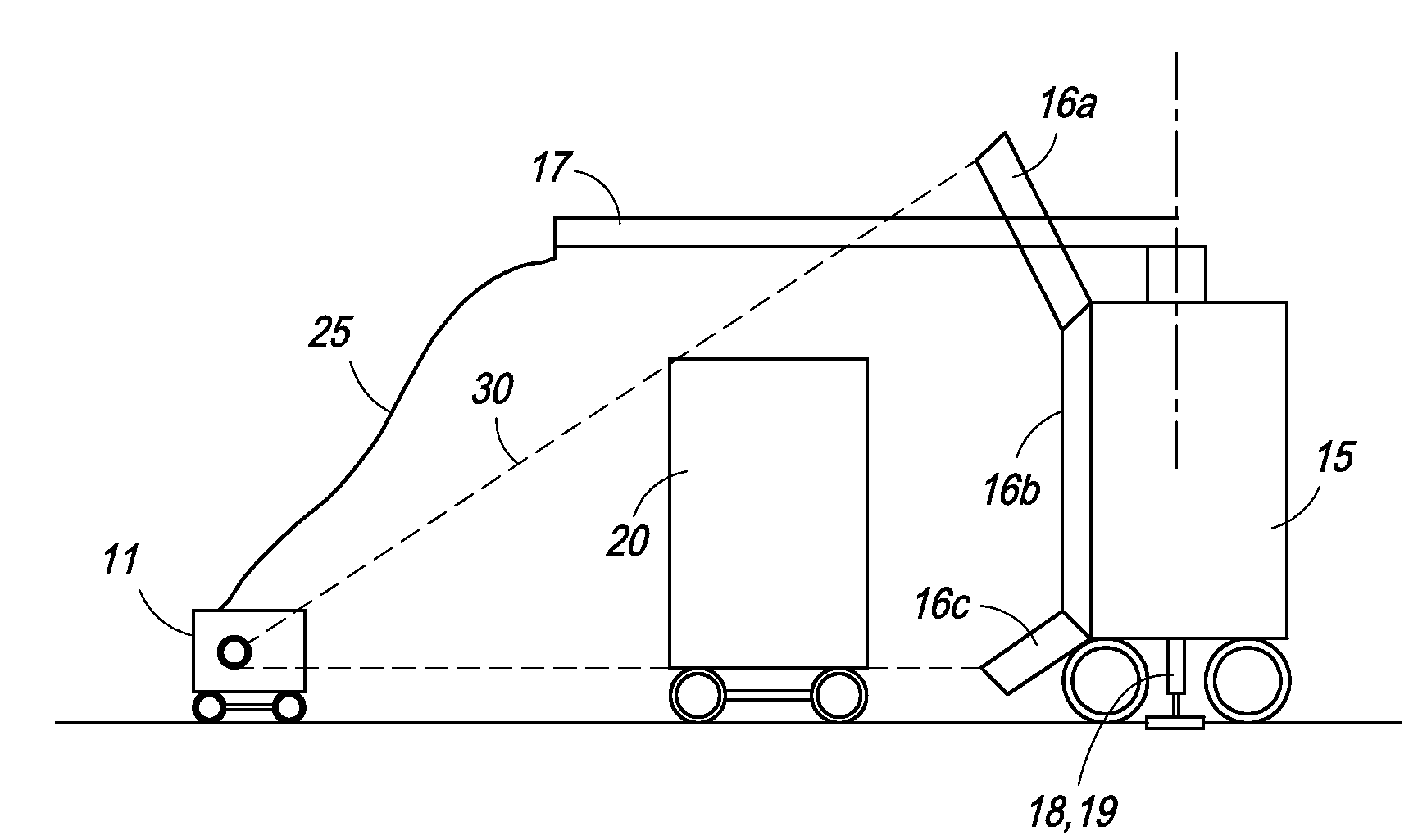

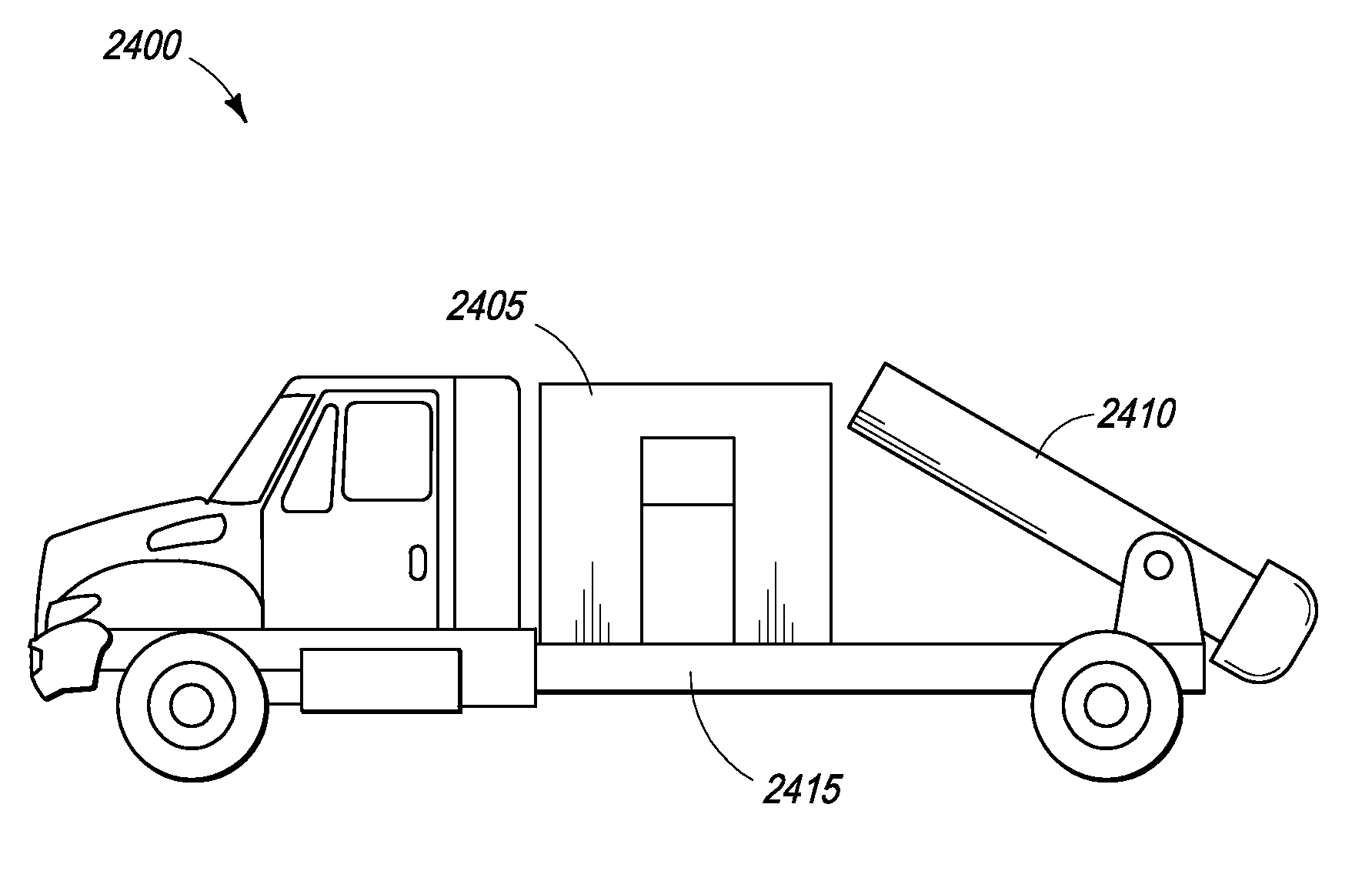

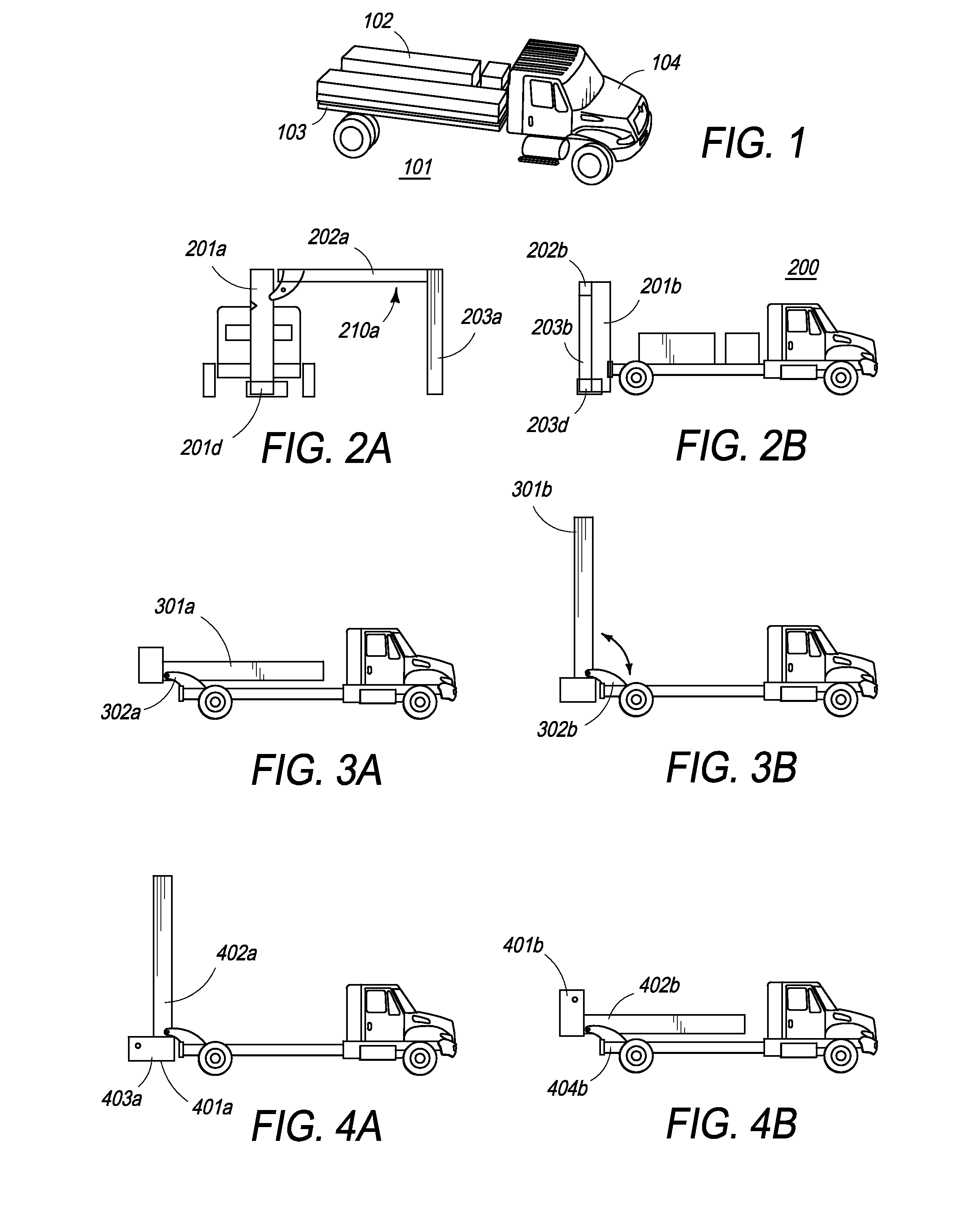

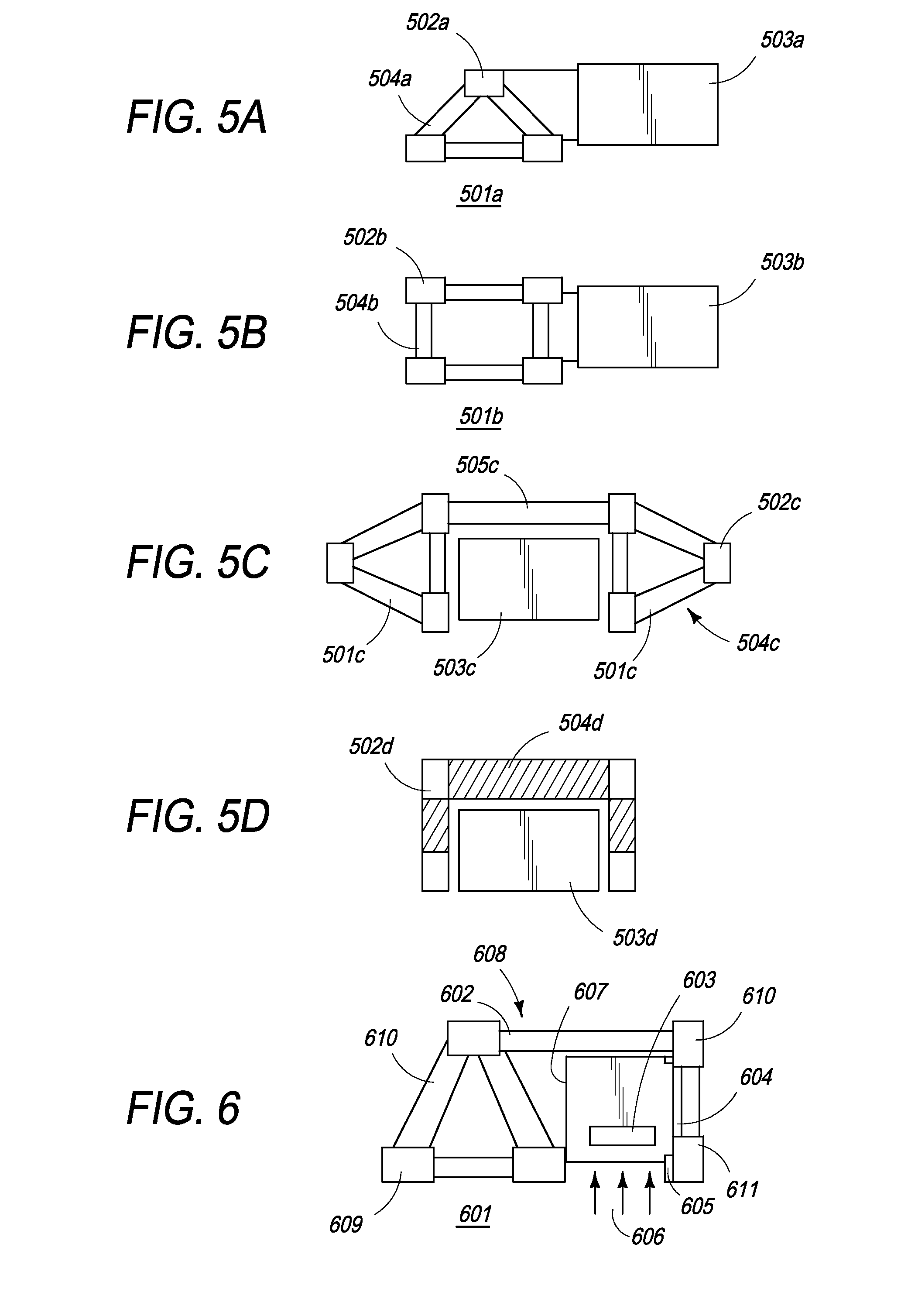

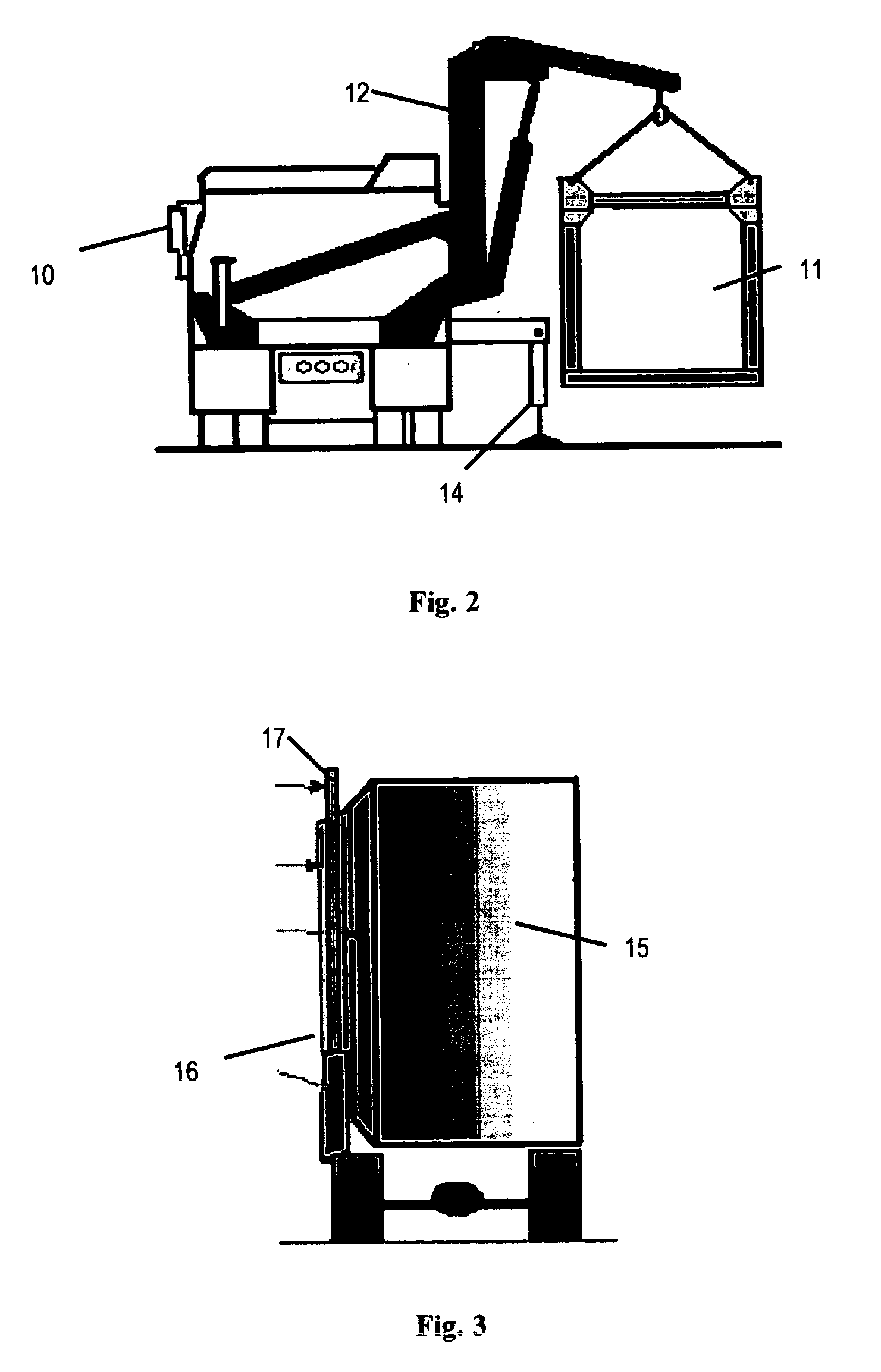

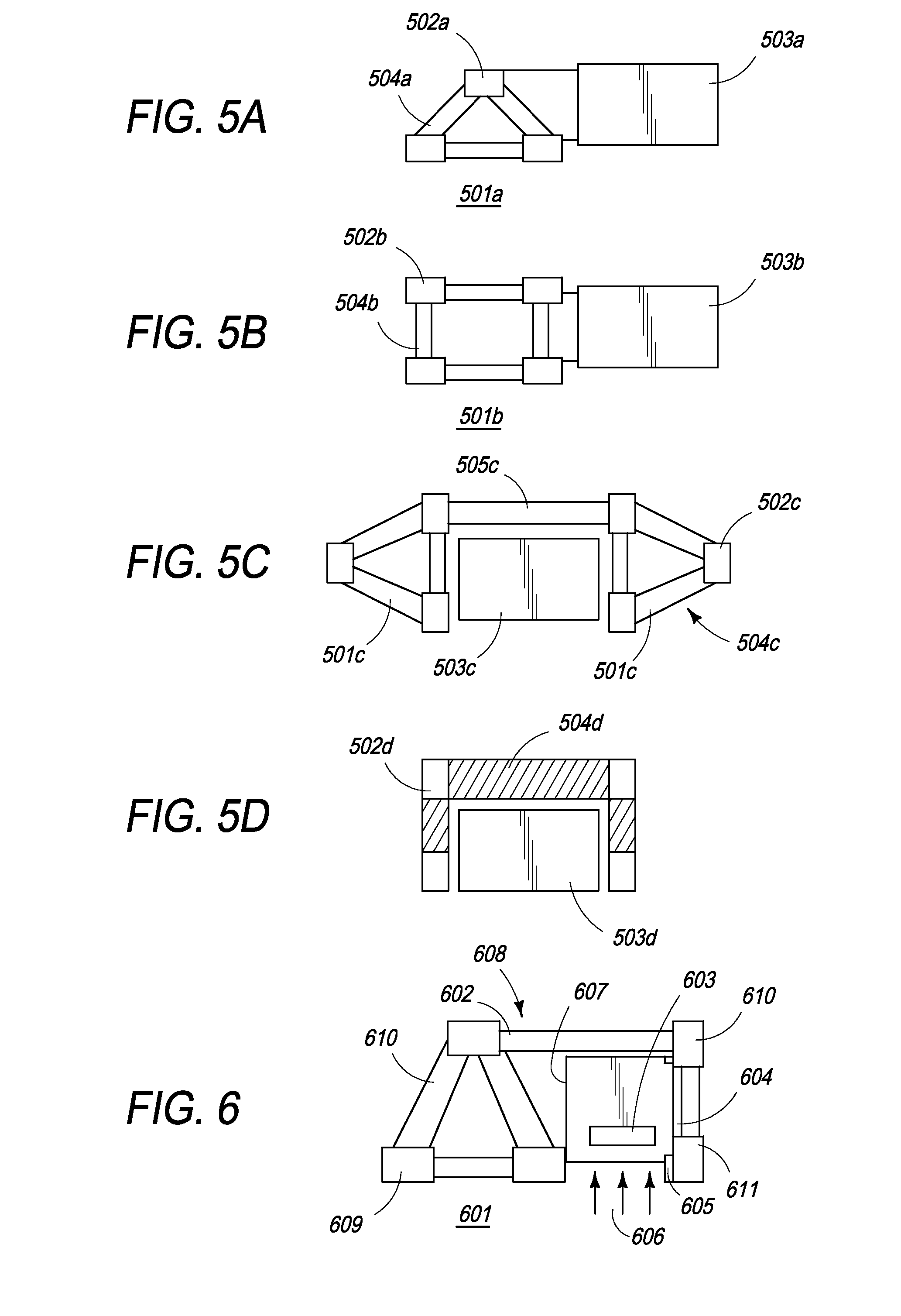

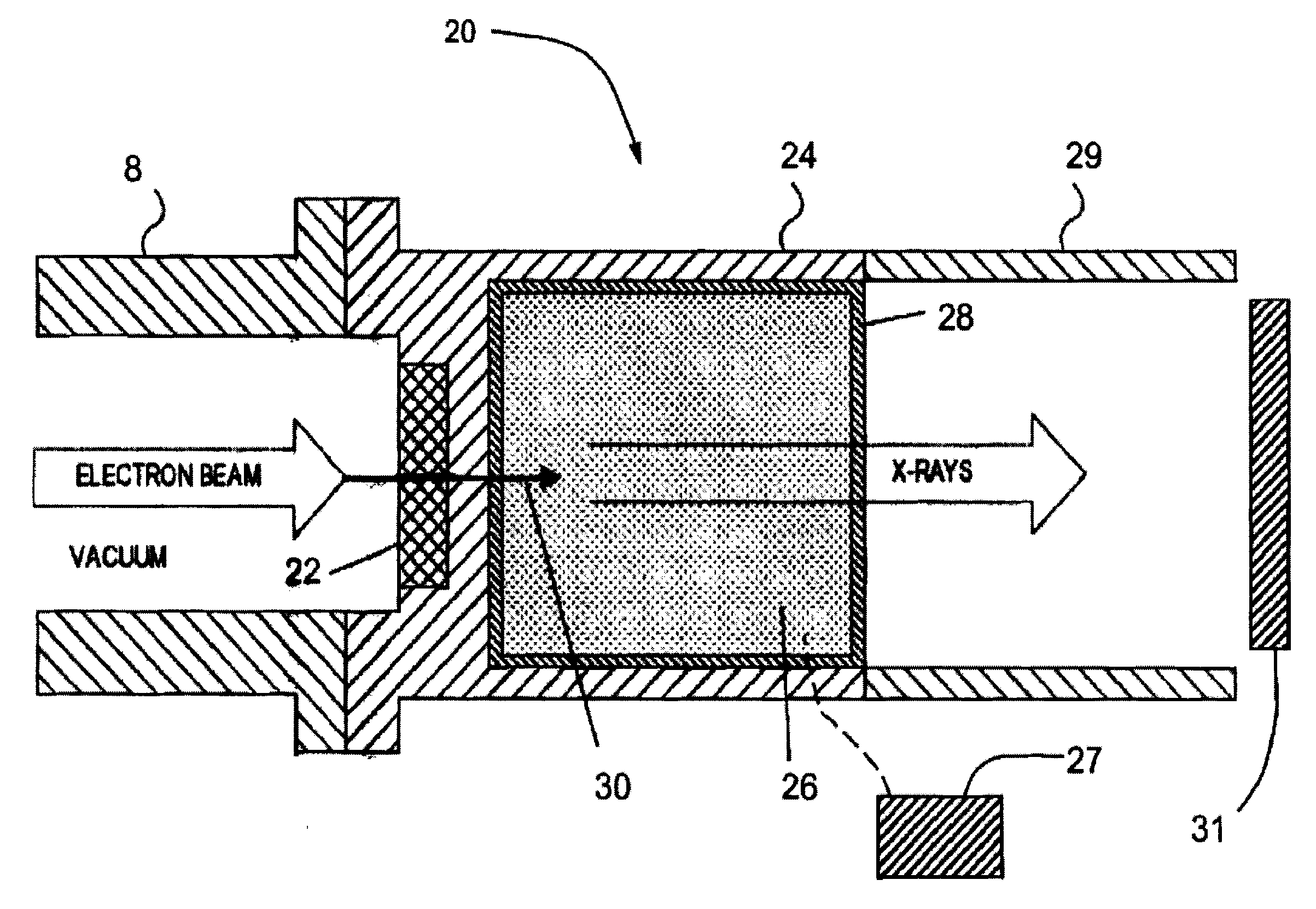

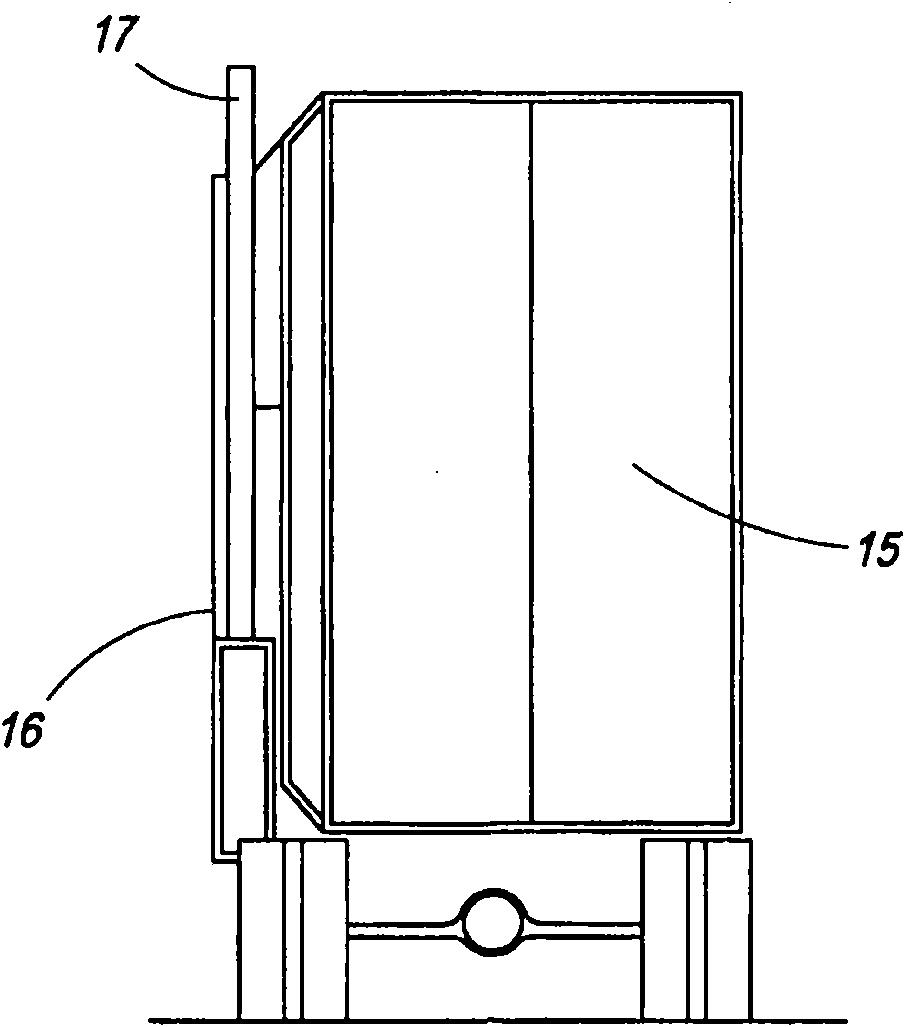

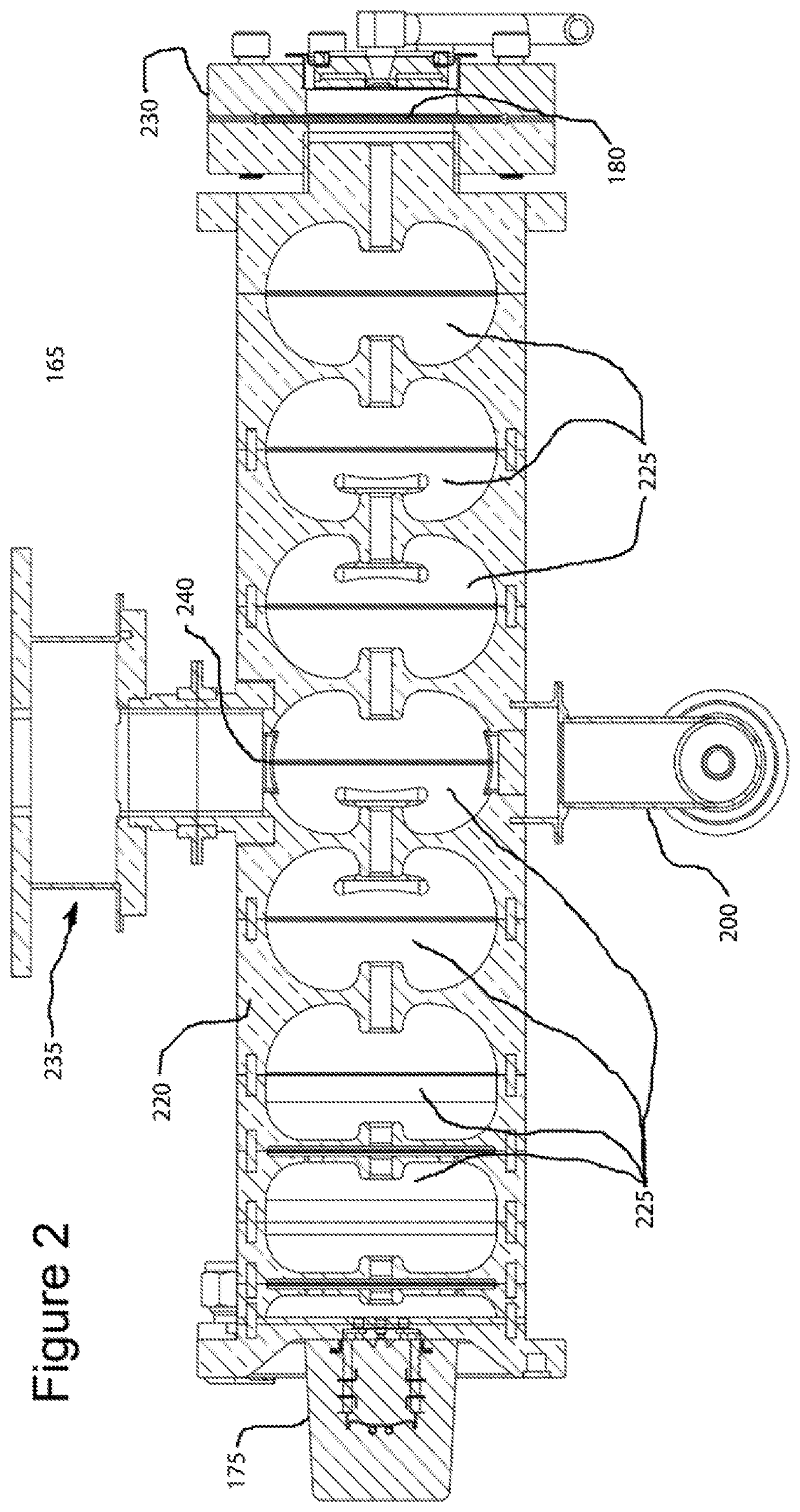

The present invention is a self-contained mobile inspection system and method and, more specifically, improved methods and systems for detecting materials concealed within a wide variety of receptacles and / or cargo containers. In particular, the present invention is an improved method and system with a novel boom structure that reduces the weight of the boom. The single, light-weight boom of the inspection system is relatively compact in a stowed configuration and has a low height and center of gravity lending to greater maneuverability.

Owner:RAPISCAN SYST INC (US)

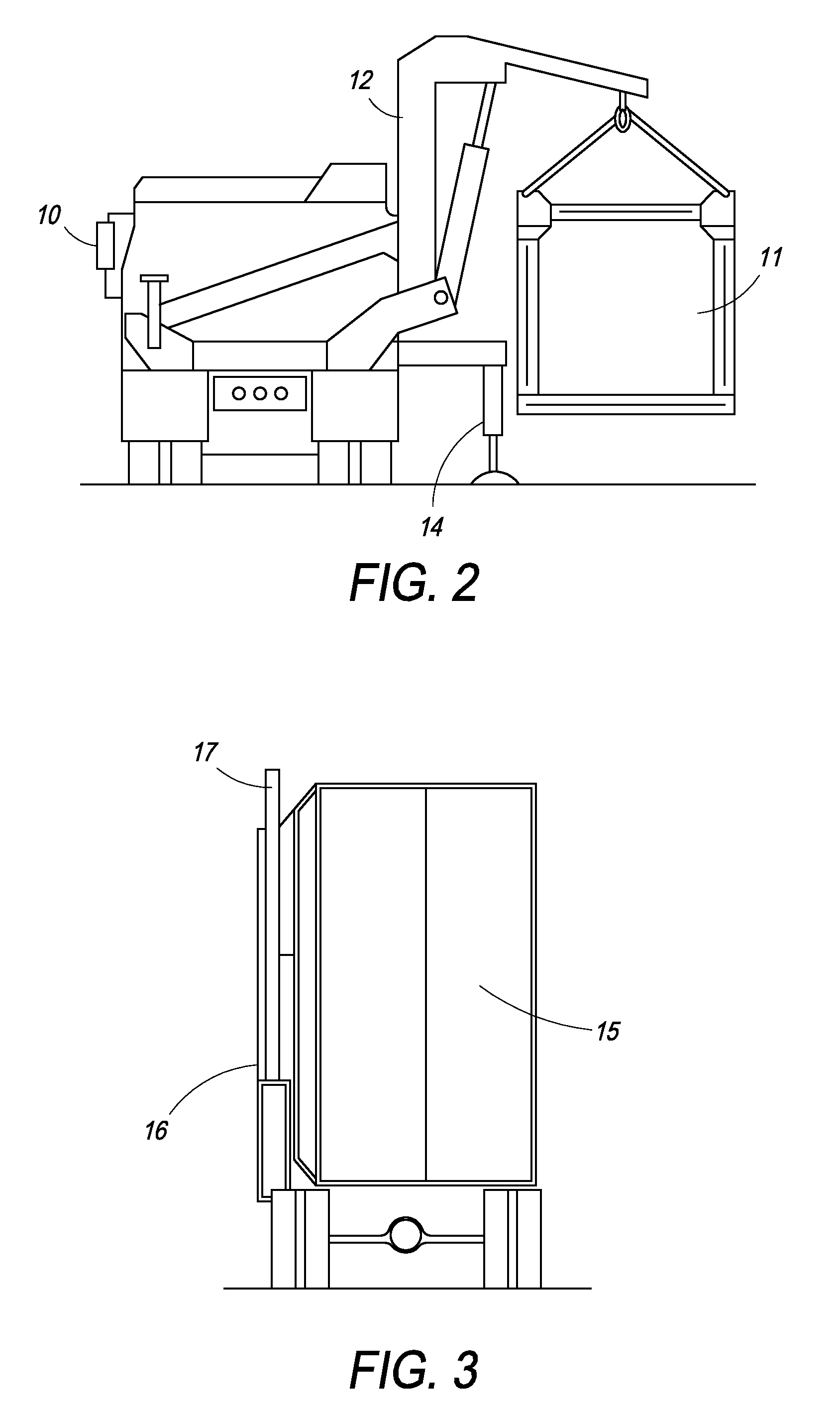

Cargo scanning system

InactiveUS7783004B2Cost-effectively and accurately on uneven surfaceRapidly deployableX-ray apparatusMaterial analysis by transmitting radiationDetector arrayTranslational energy

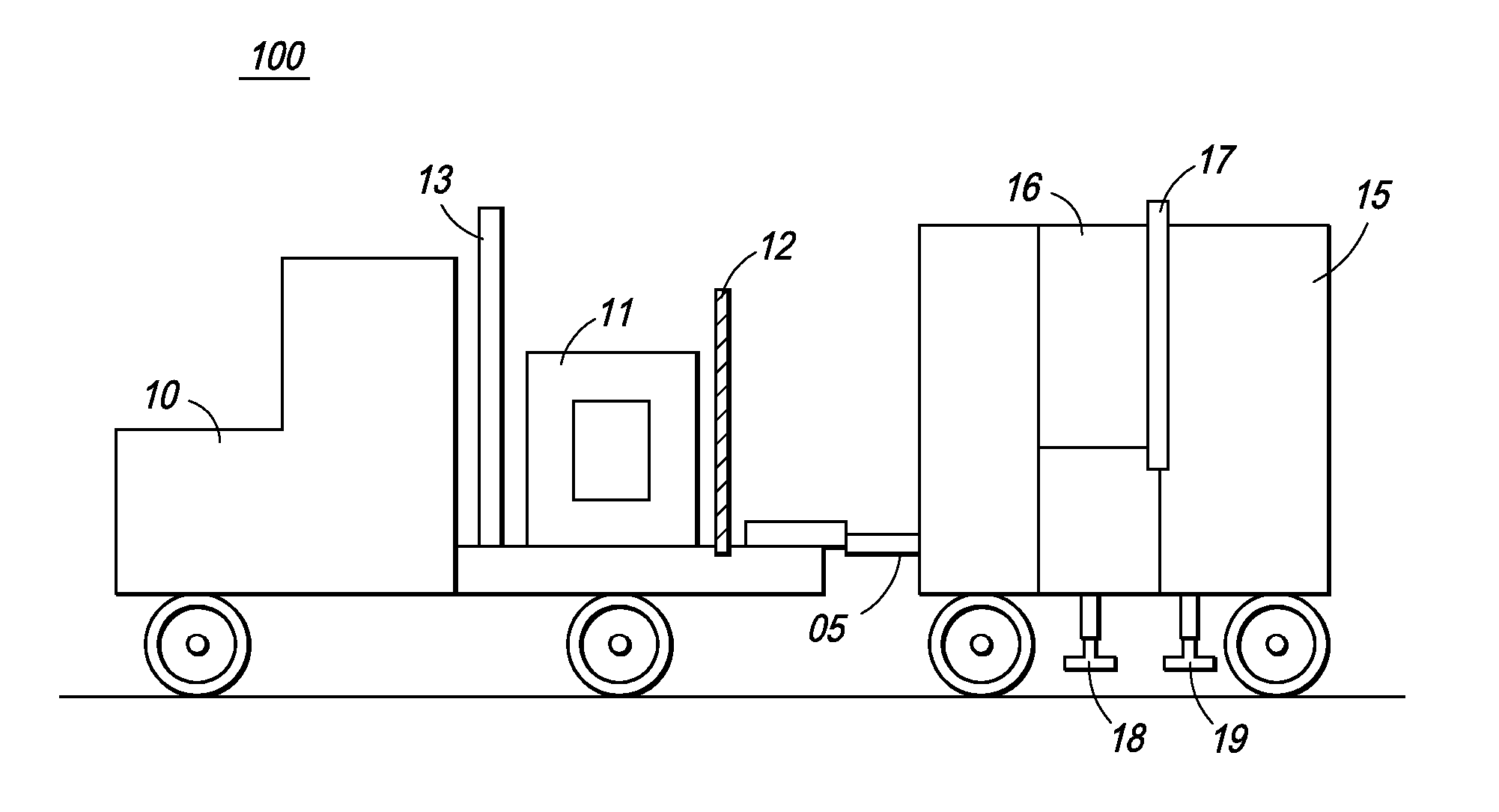

The present invention is directed to a portable inspection system for generating an image representation of target objects using a radiation source. A detector array having a first configuration and a second configuration is connected to a housing and at least one source of radiation. The radiation source is capable of being transported to a site by a vehicle and of being positioned separate from the housing. The radiation source is housed in a radiation source box and movable within the radiation source box using an actuator. The actuator is operably connected to the radiation source and provides a translational energy that moves the radiation source between an operational position and a stowed position.

Owner:RAPISCAN SYST INC (US)

Single boom cargo scanning system

InactiveUS20050157842A1Rapidly deployableCost-effectively and accurately on uneven surfaceRadiation/particle handlingX-ray apparatusMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

Compact mobile cargo scanning system

InactiveUS8275091B2X-ray apparatusMaterial analysis by transmitting radiationEngineeringImproved method

The present invention is a self-contained mobile inspection system and method and, more specifically, improved methods and systems for detecting materials concealed within a wide variety of receptacles and / or cargo containers. In particular, the present invention is an improved method and system with a novel boom structure that reduces the weight of the boom. The single, light-weight boom of the inspection system is relatively compact in a stowed configuration and has a low height and center of gravity lending to greater maneuverability.

Owner:RAPISCAN SYST INC (US)

Multi-View Cargo Scanner

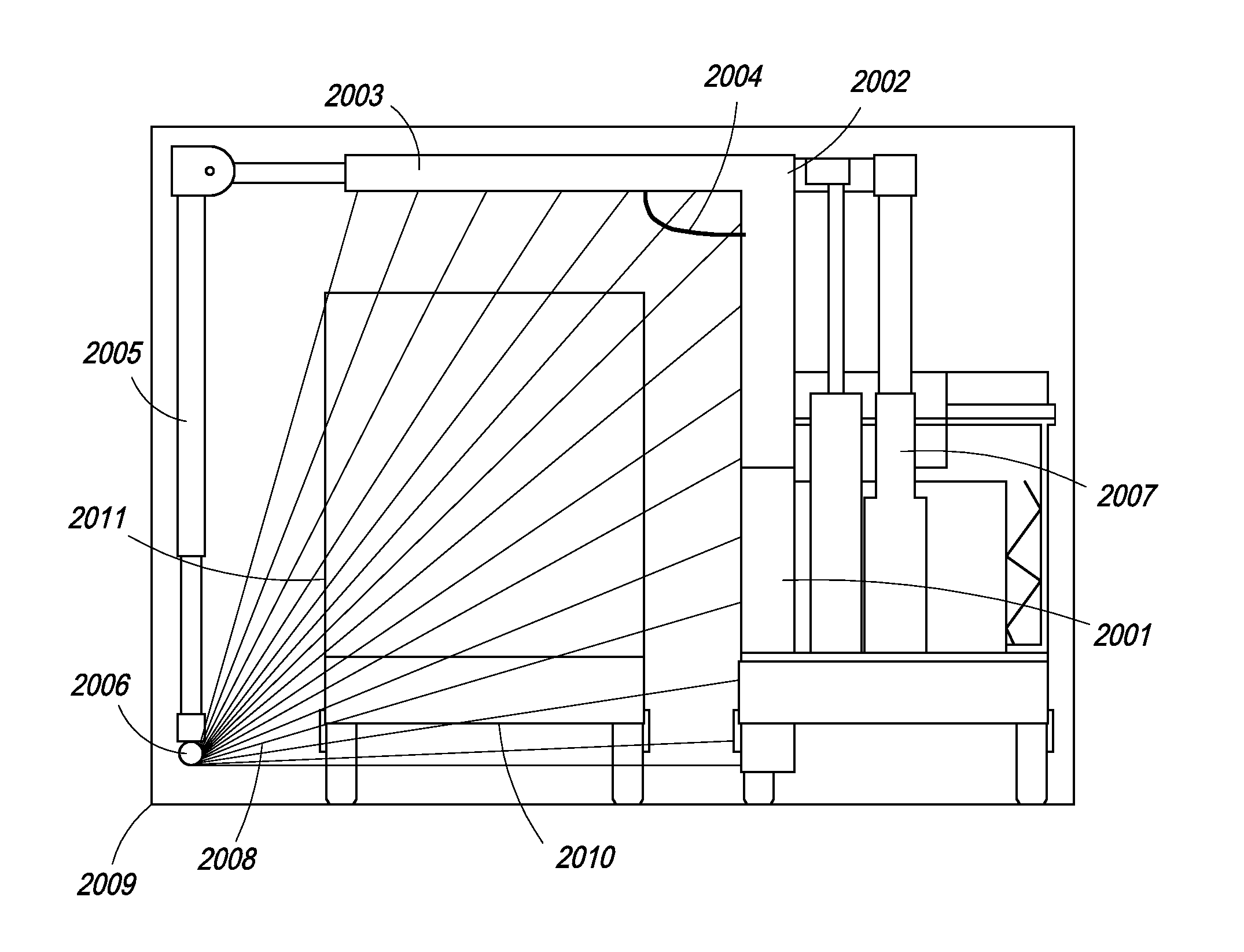

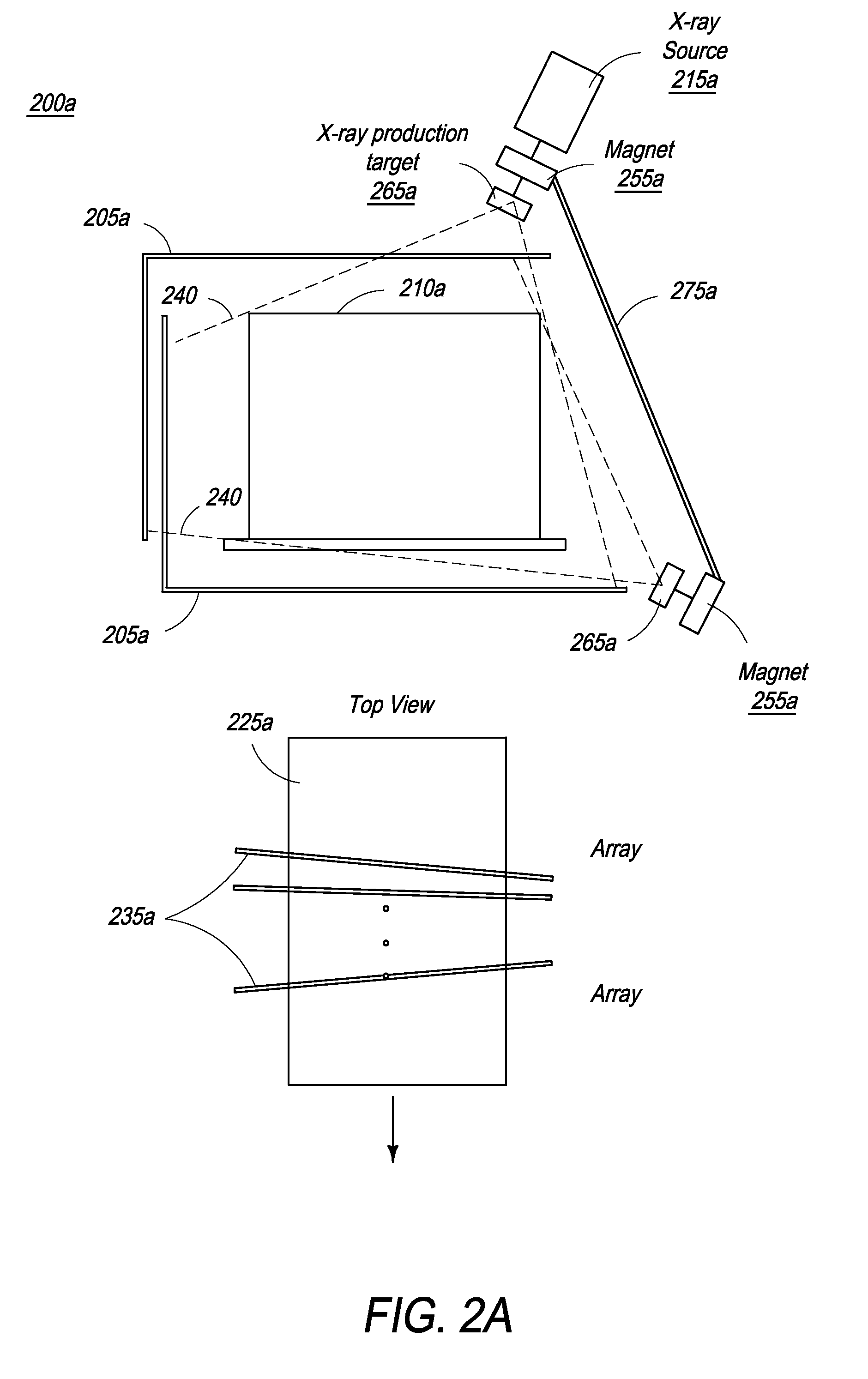

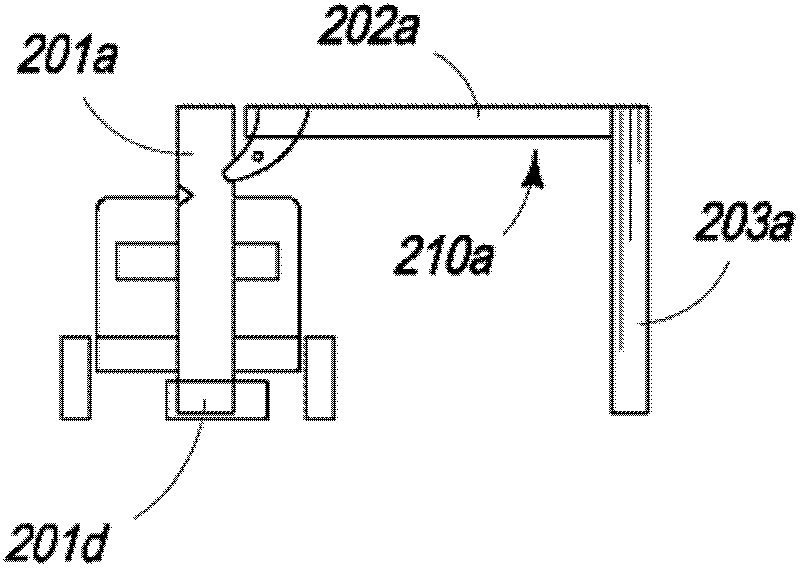

ActiveUS20110206179A1Increase the number ofRadiation/particle handlingComputerised tomographsLight beamX-ray

The present invention provides a multi-view X-ray inspection system. In one embodiment, a beam steering mechanism directs the electron beam from an X-ray source to multiple production targets which generate X-rays for scanning which are subsequently detected by a plurality of detectors to produce multiple image slices (views). The system is adapted for use in CT systems. In one embodiment of a CT system, the X-ray source and detectors rotate around the object covering an angle sufficient for reconstructing a CT image and then reverse to rotate around the object in the opposite direction. The inspection system, in any configuration, can be deployed inside a vehicle for use as a mobile detection system.

Owner:RAPISCAN SYST INC (US)

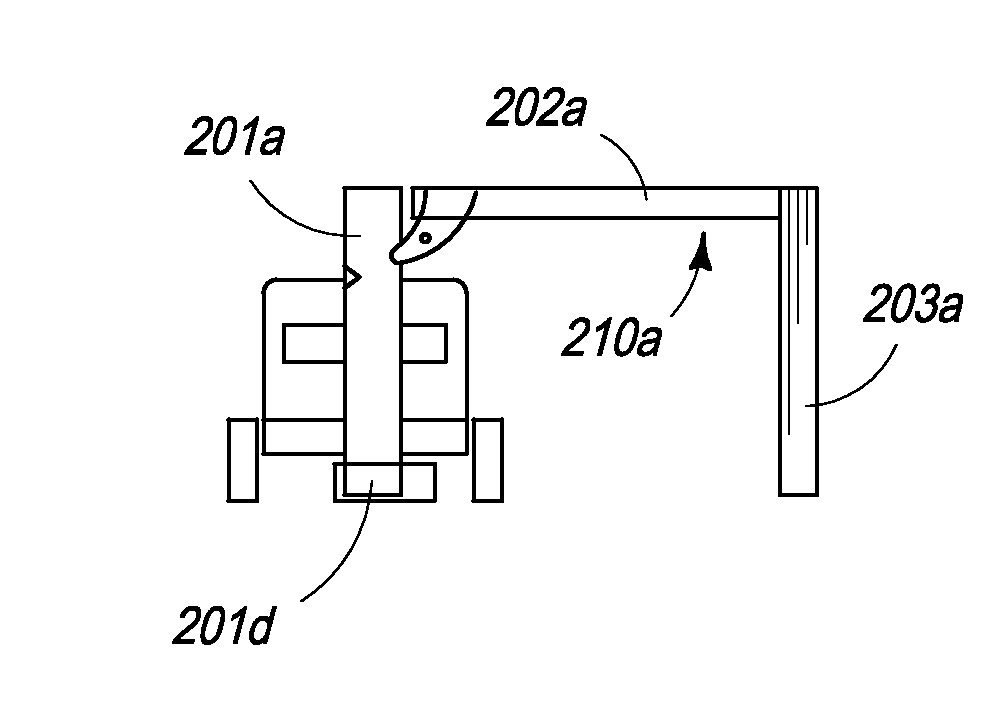

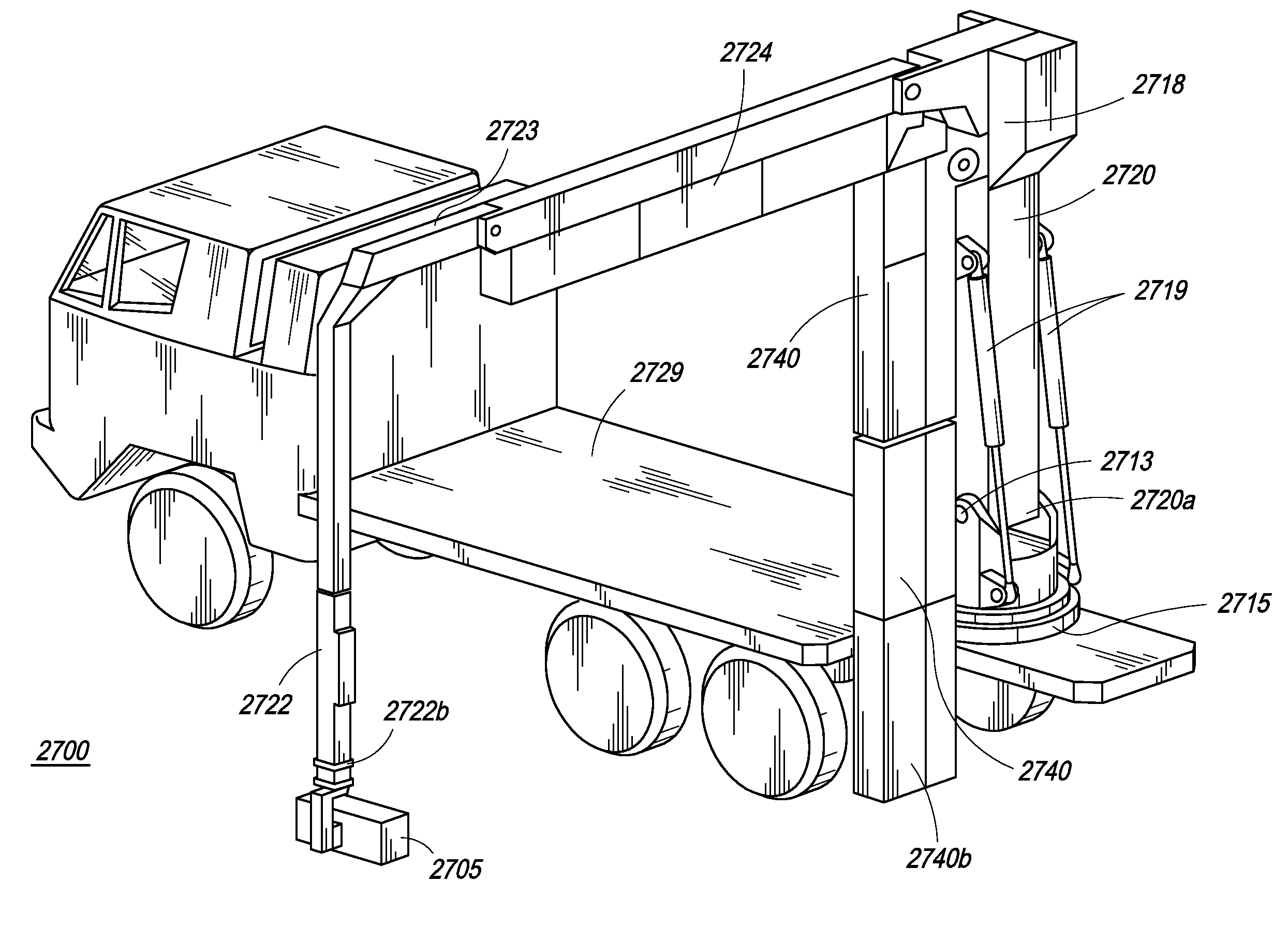

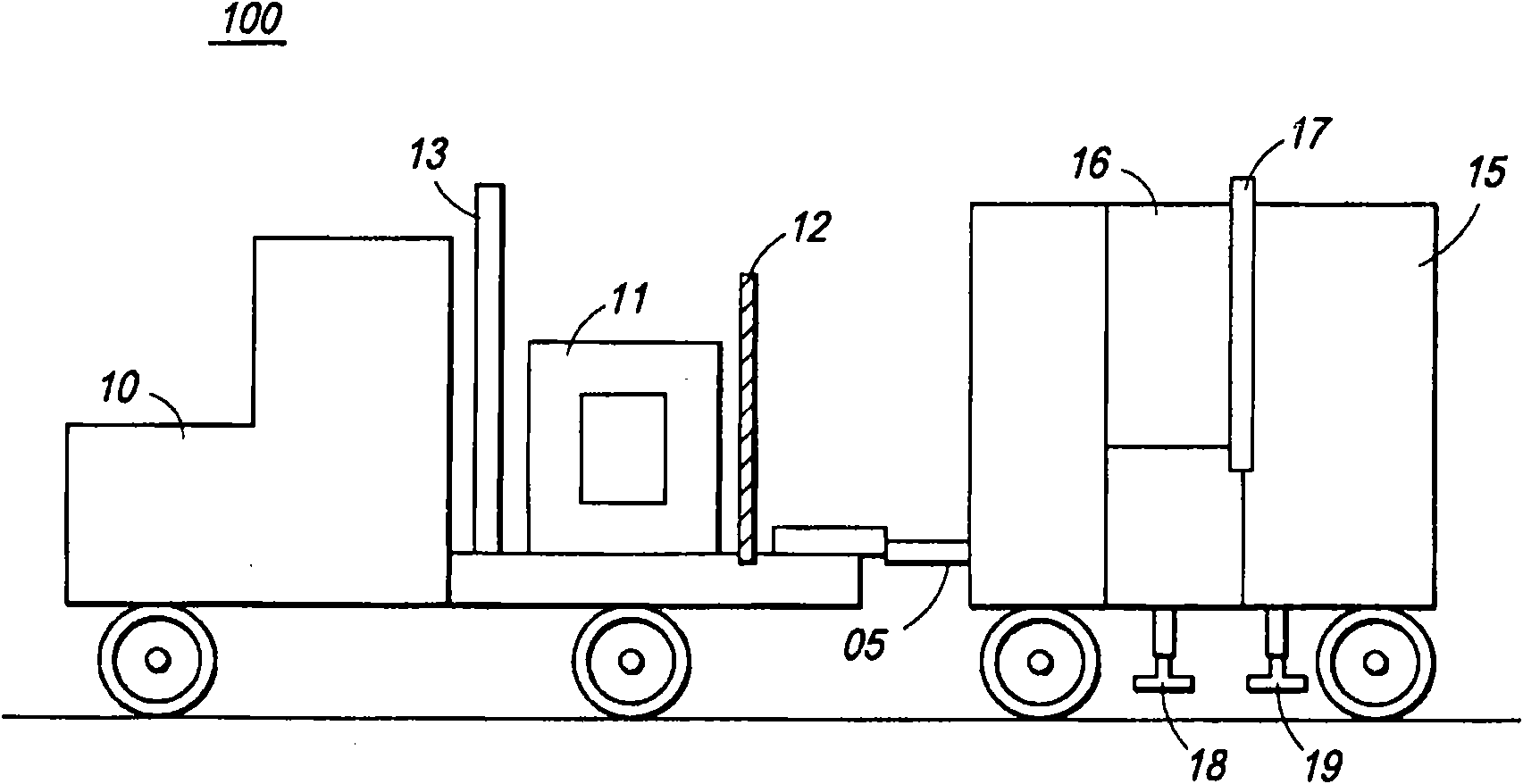

Rotatable boom cargo scanning system

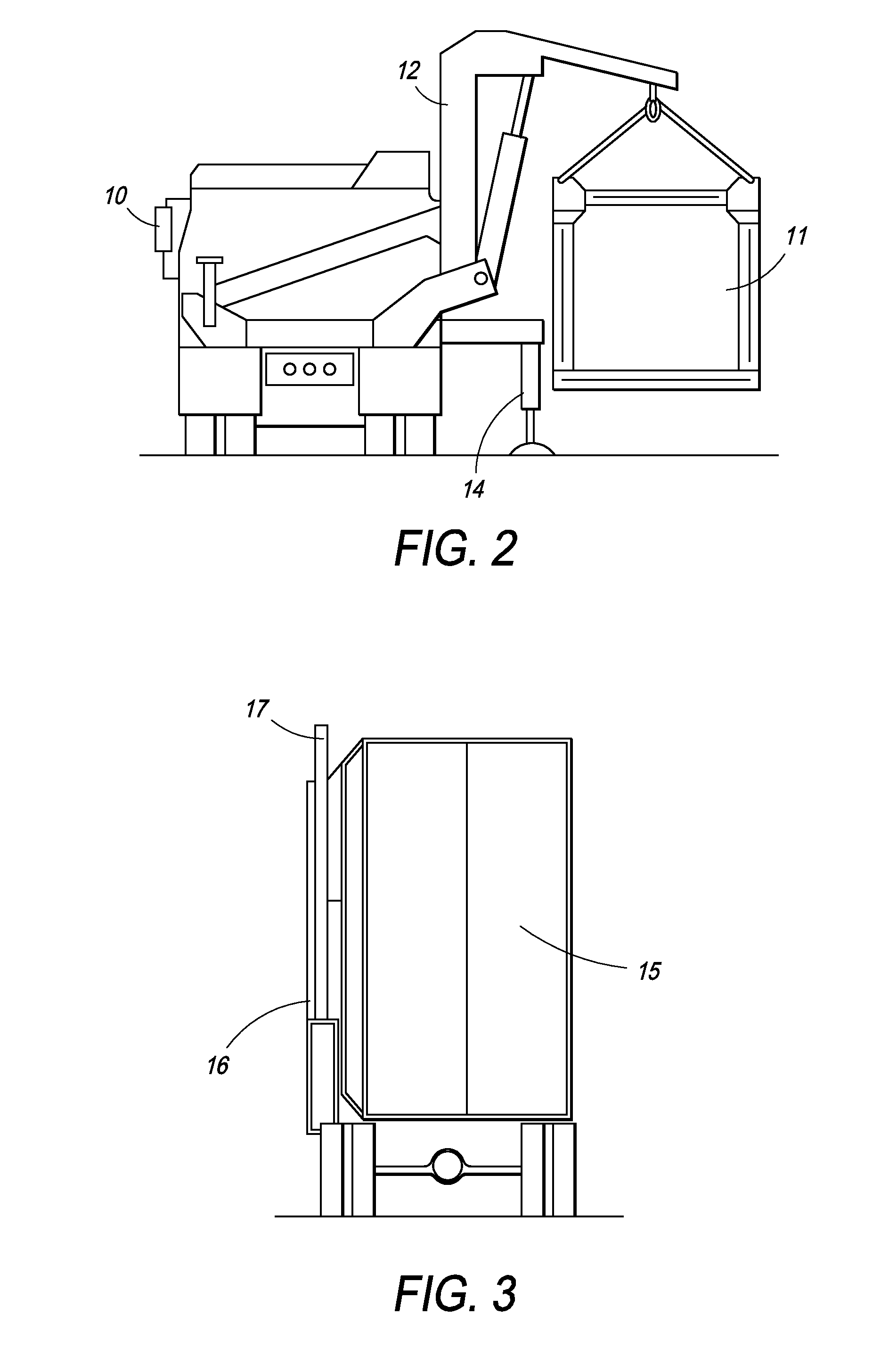

The present invention is a self-contained mobile inspection system and method and, more specifically, improved methods and systems for detecting materials concealed within a wide variety of receptacles and / or cargo containers. In particular, the present invention is an improved method and system for inspecting receptacles and / or cargo containers using a single boom placed on a turntable with pivot points to allow for folding and unfolding of the boom, such that the inspection system is relatively compact in a stowed configuration and has a low center of gravity lending to greater stability.

Owner:RAPISCAN SYST INC (US)

Rotatable boom cargo scanning system

InactiveUS20100189226A1Improve stabilityLower center of gravityRadiation measurementX-ray apparatusEngineeringImproved method

The present invention is a self-contained mobile inspection system and method and, more specifically, improved methods and systems for detecting materials concealed within a wide variety of receptacles and / or cargo containers. In particular, the present invention is an improved method and system for inspecting receptacles and / or cargo containers using a single boom placed on a turntable with pivot points to allow for folding and unfolding of the boom, such that the inspection system is relatively compact in a stowed configuration and has a low center of gravity lending to greater stability.

Owner:RAPISCAN SYST INC (US)

Single boom cargo scanning system

InactiveUS20070217572A1Rapidly deployableCost-effectively and accurately on uneven surfaceX-ray apparatusMaterial analysis by transmitting radiationMobile vehicleDetector array

The inspection methods and systems of the present invention are mobile, rapidly deployable, and capable of scanning a wide variety of receptacles cost-effectively and accurately on uneven surfaces. The present invention is directed toward a portable inspection system for generating an image representation of target objects using a radiation source, comprising a mobile vehicle, a detector array physically attached to a movable boom having a proximal end and a distal end. The proximal end is physically attached to the vehicle. The invention also comprises at least one source of radiation. The radiation source is fixedly attached to the distal end of the boom, wherein the image is generated by introducing the target objects in between the radiation source and the detector array, exposing the objects to radiation, and detecting radiation.

Owner:RAPISCAN SYST INC (US)

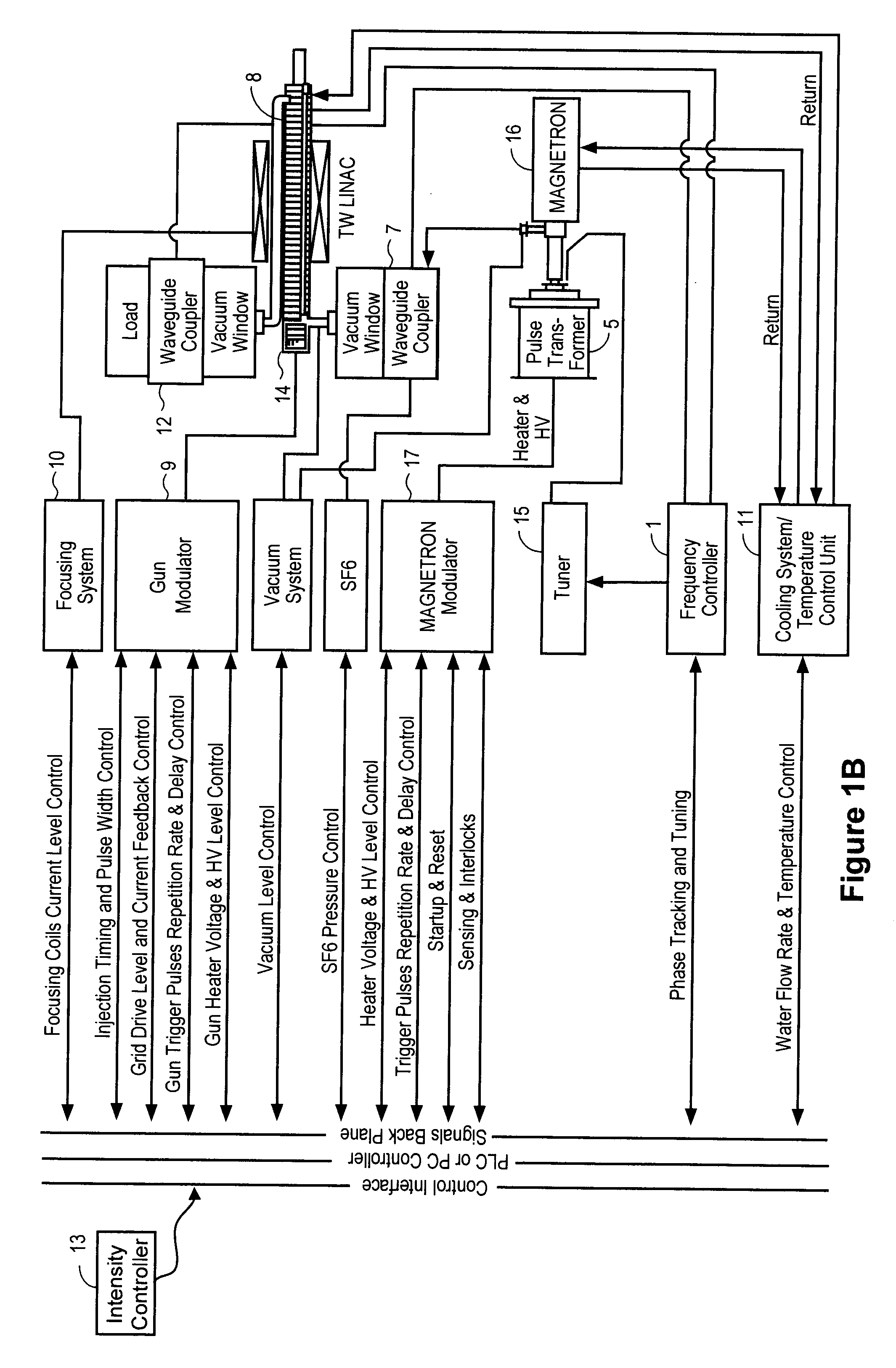

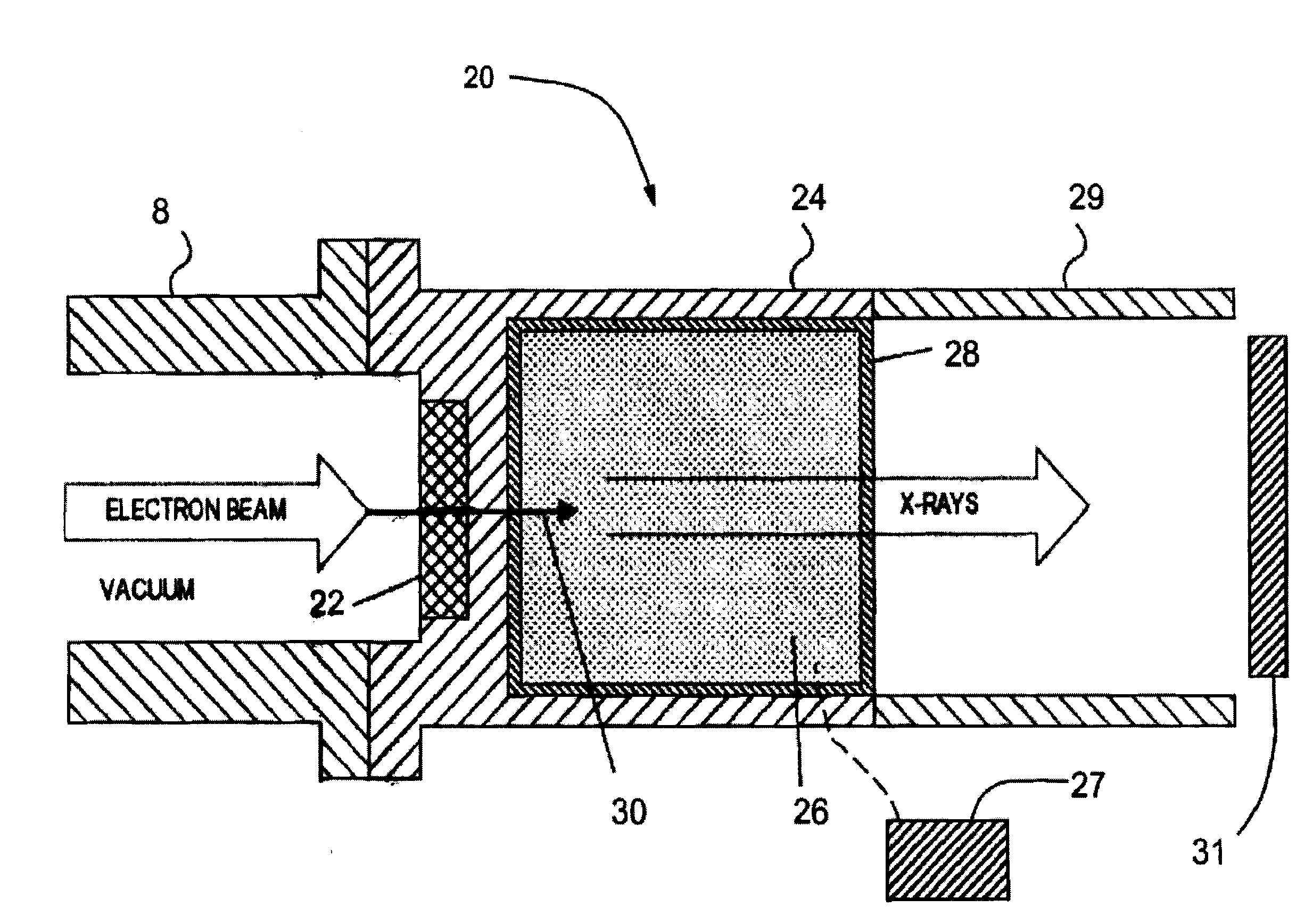

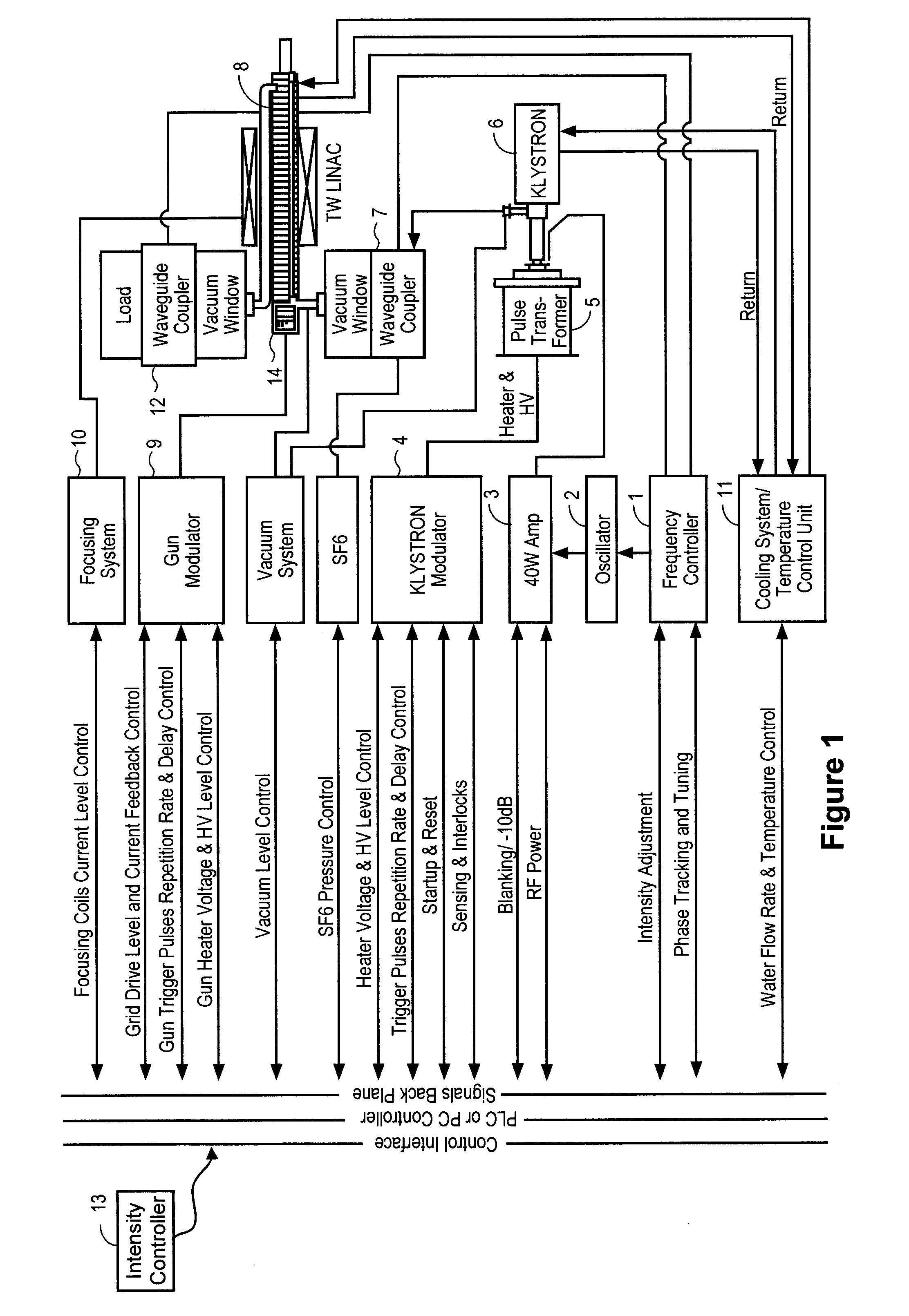

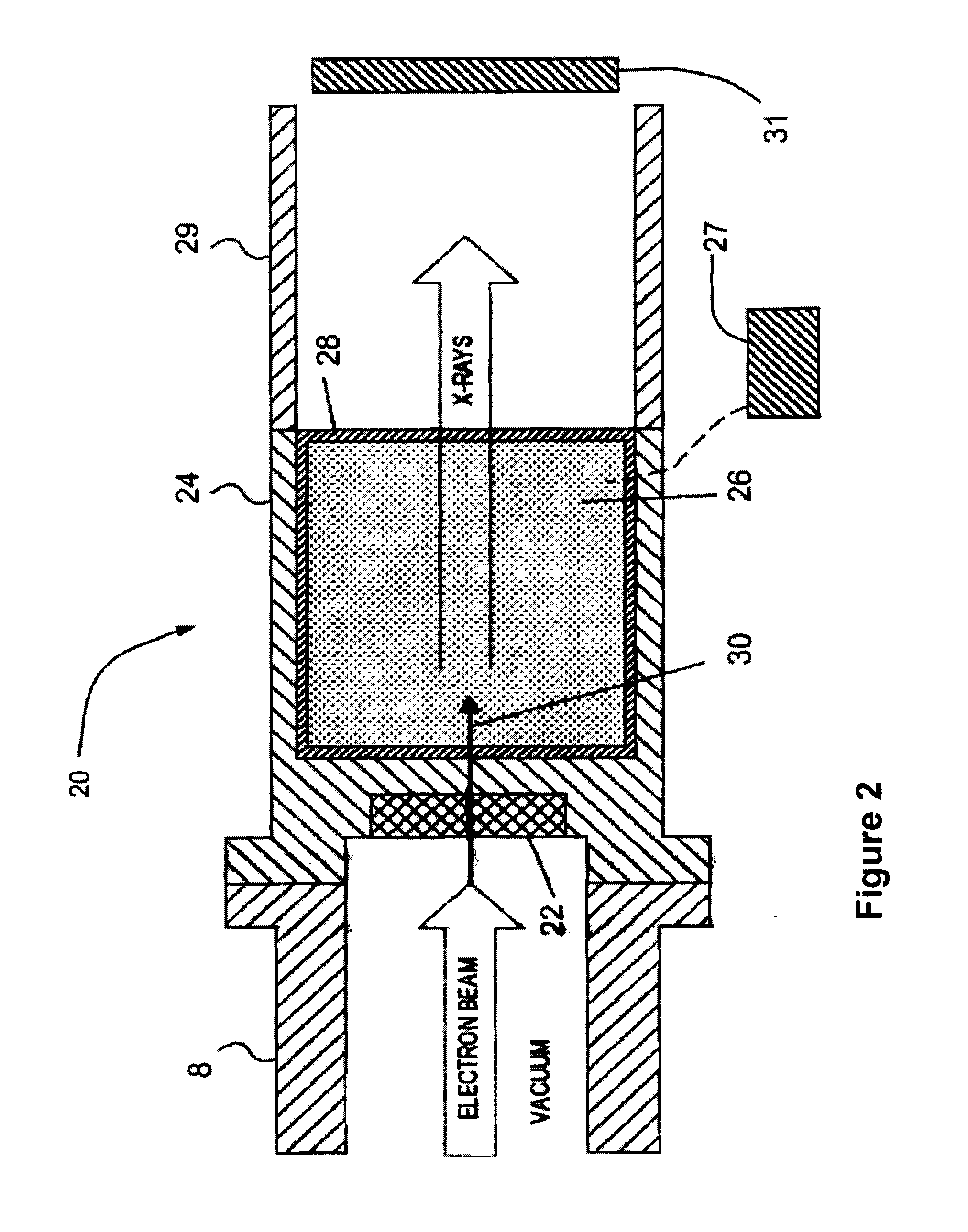

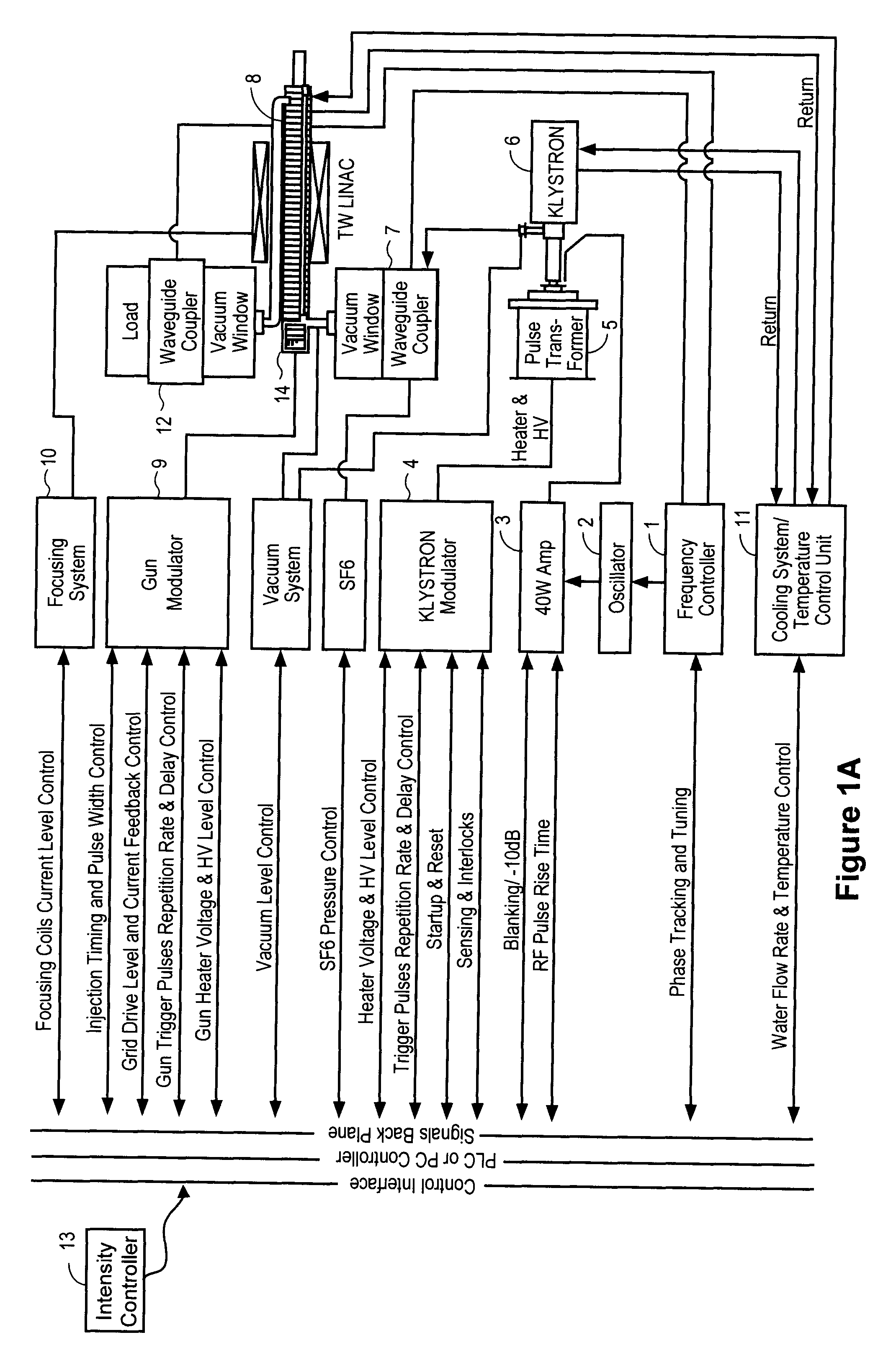

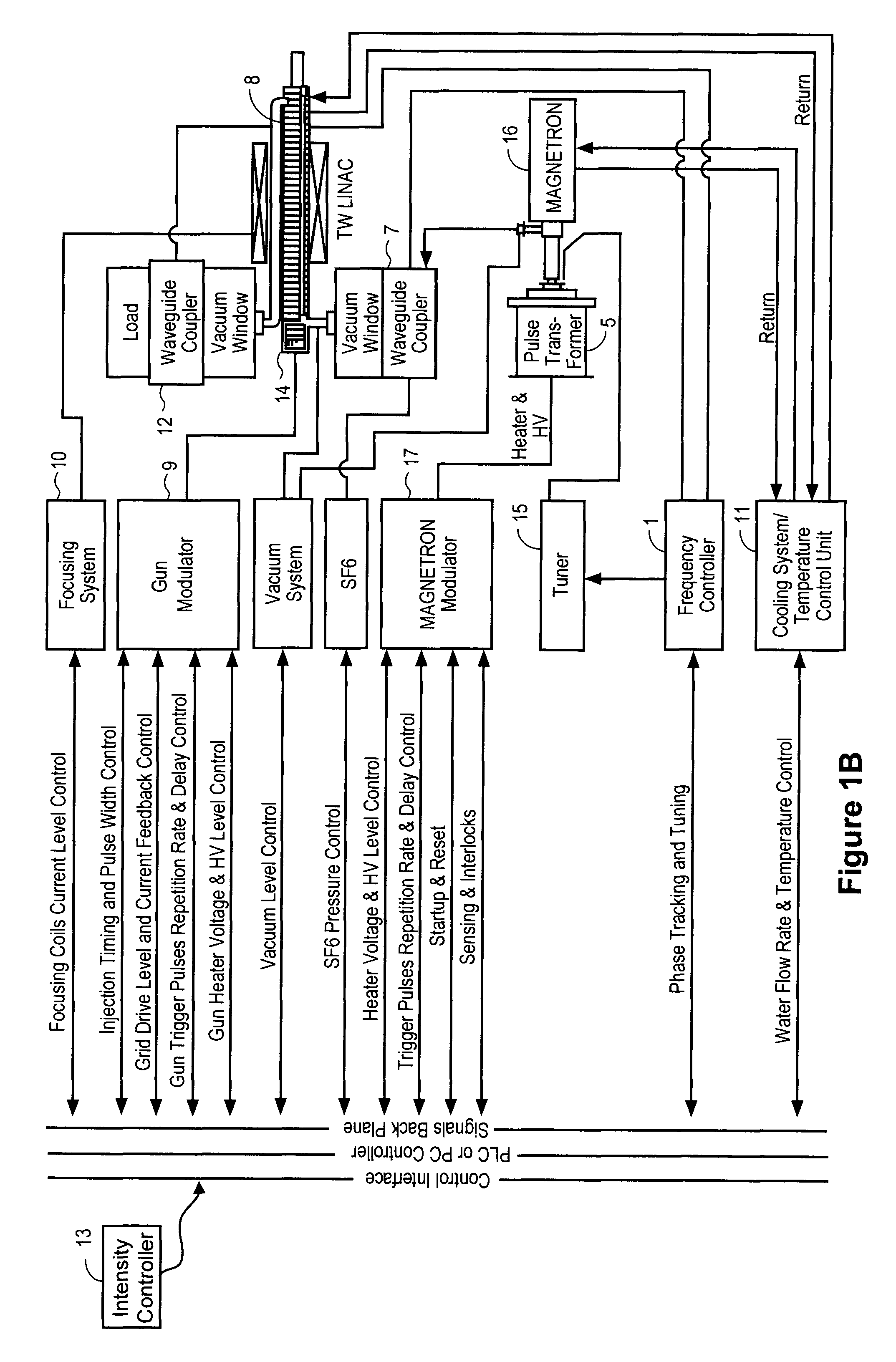

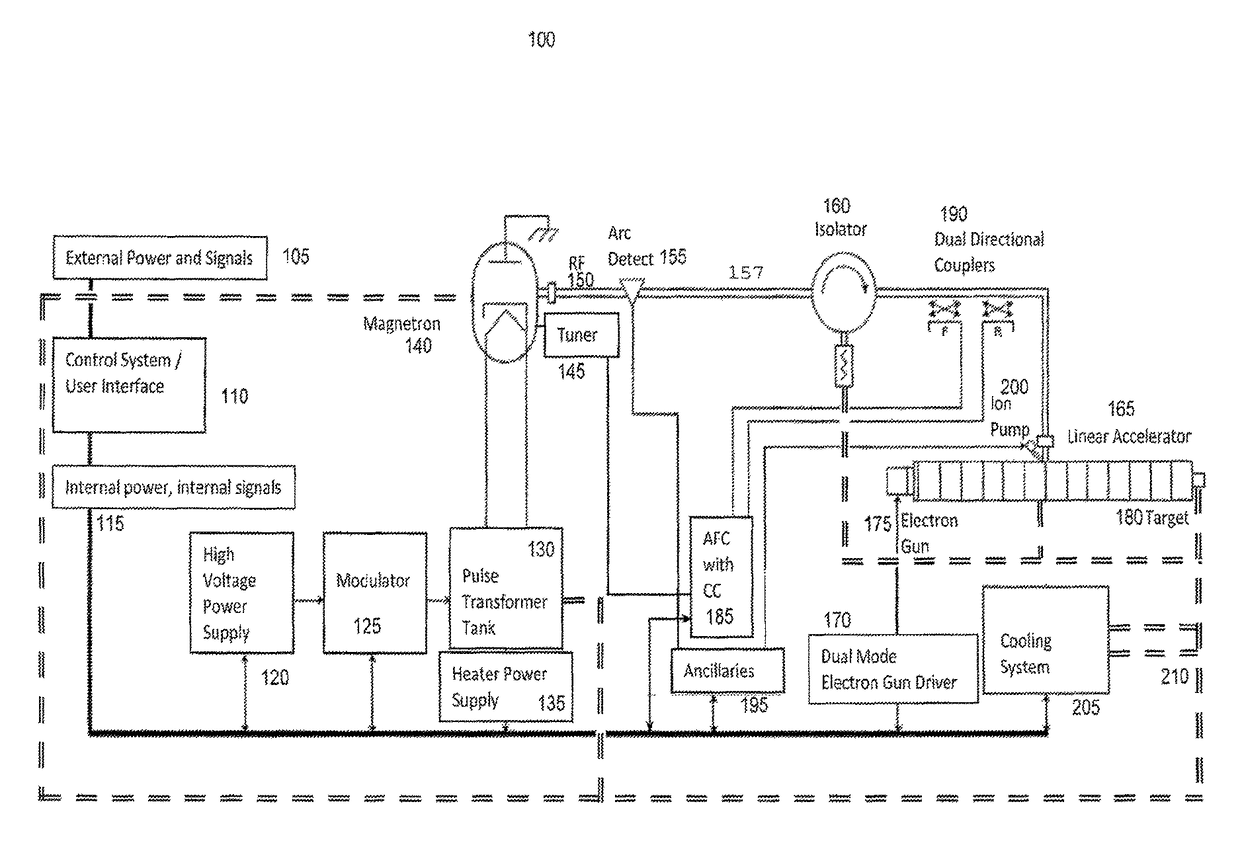

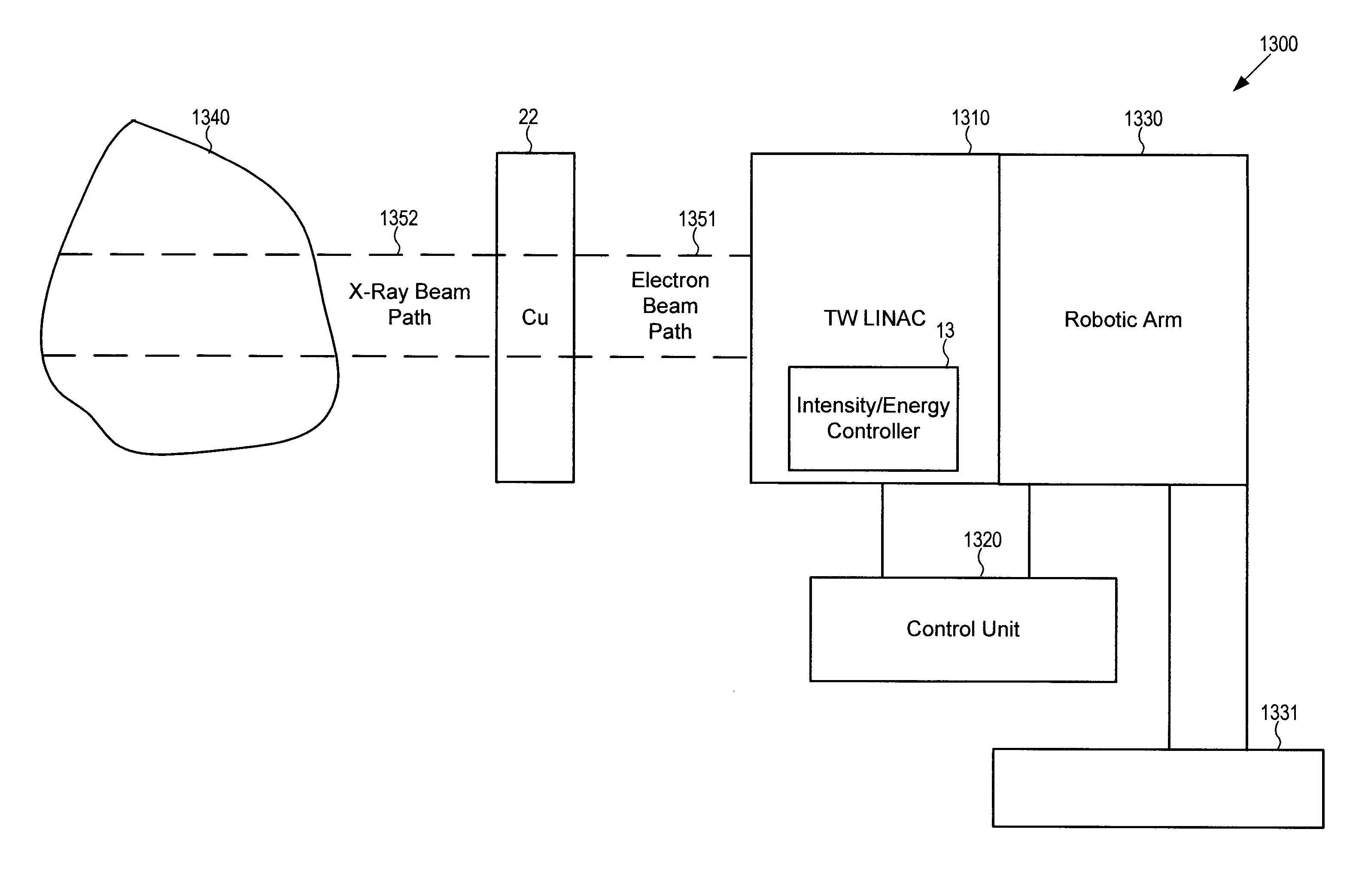

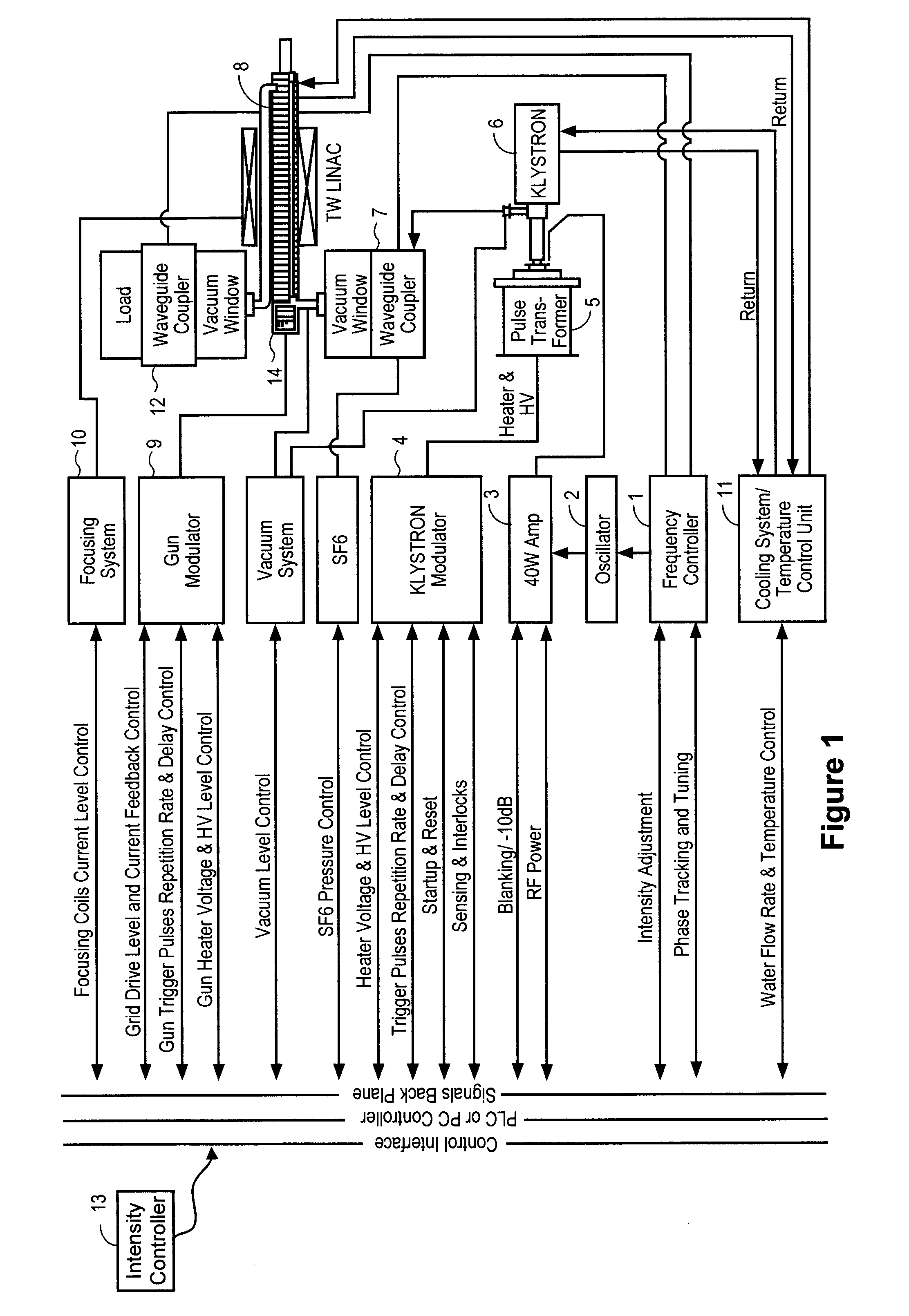

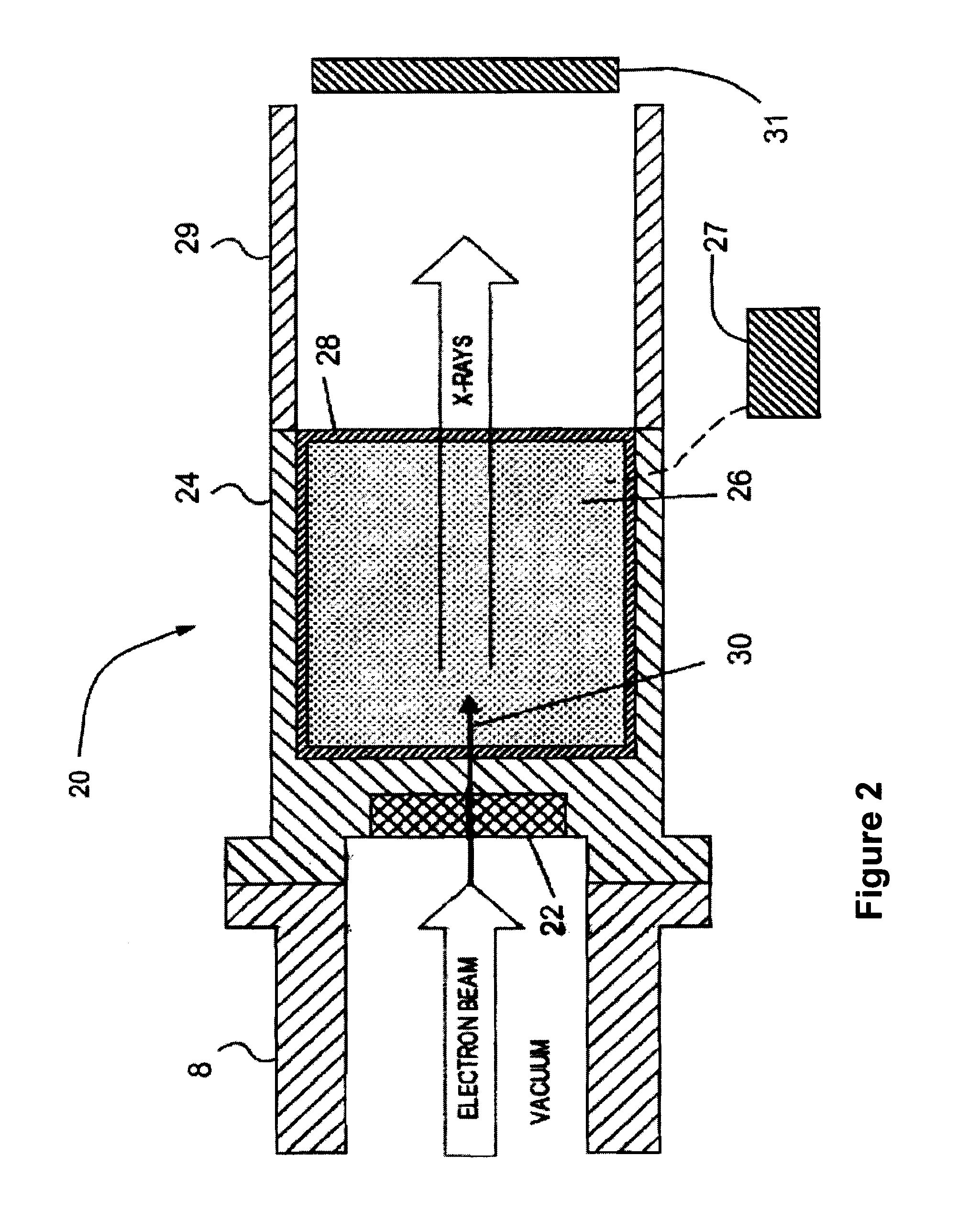

Systems and methods for cargo scanning and radiotherapy using a traveling wave linear accelerator based x-ray source using pulse width to modulate pulse-to-pulse dosage

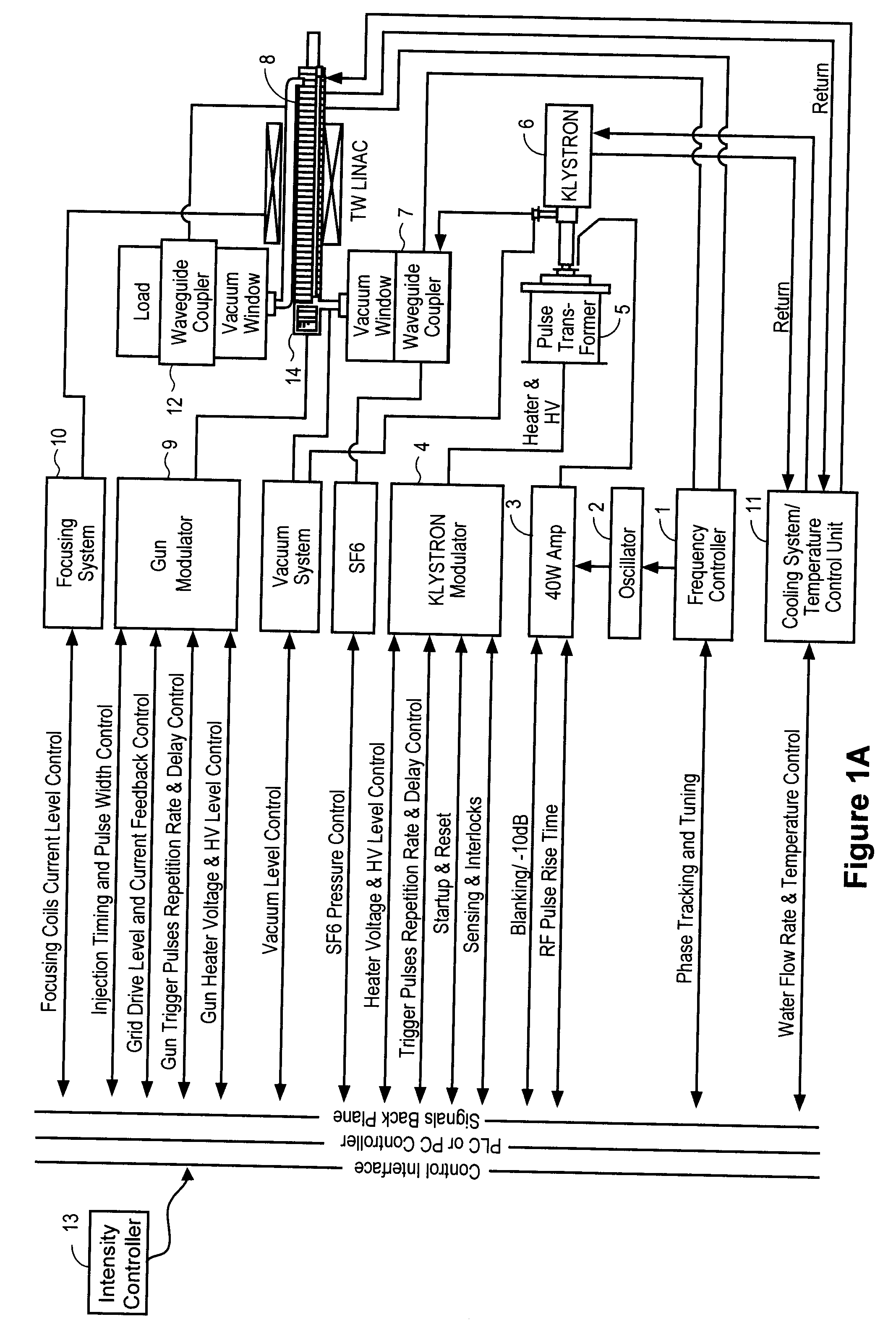

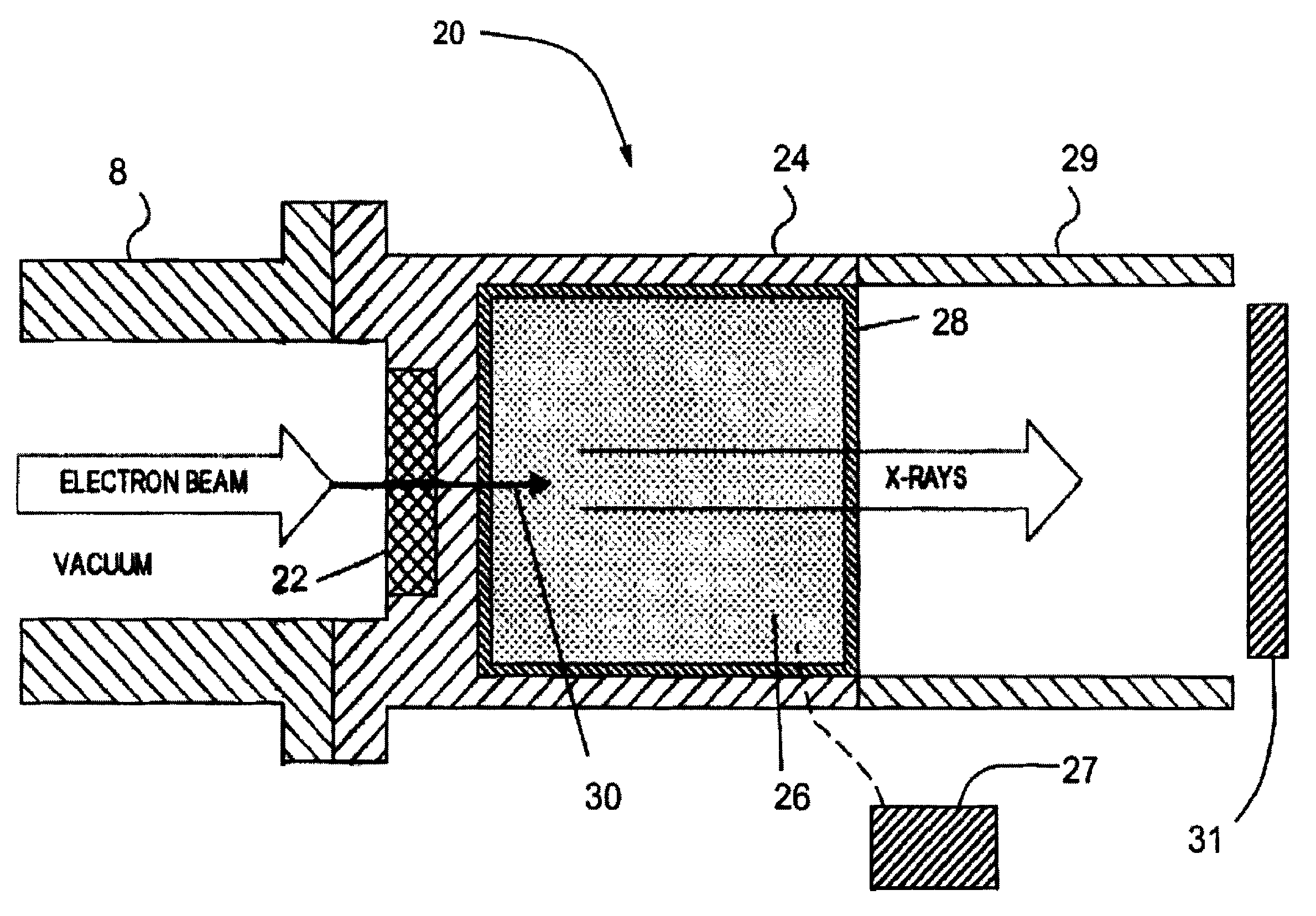

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the width of the beam pulse, i.e., pulse width. The electron beams may be used to generate x-rays having selected doses and energies, which may be used for cargo scanning or radiotherapy applications.

Owner:ACCURAY

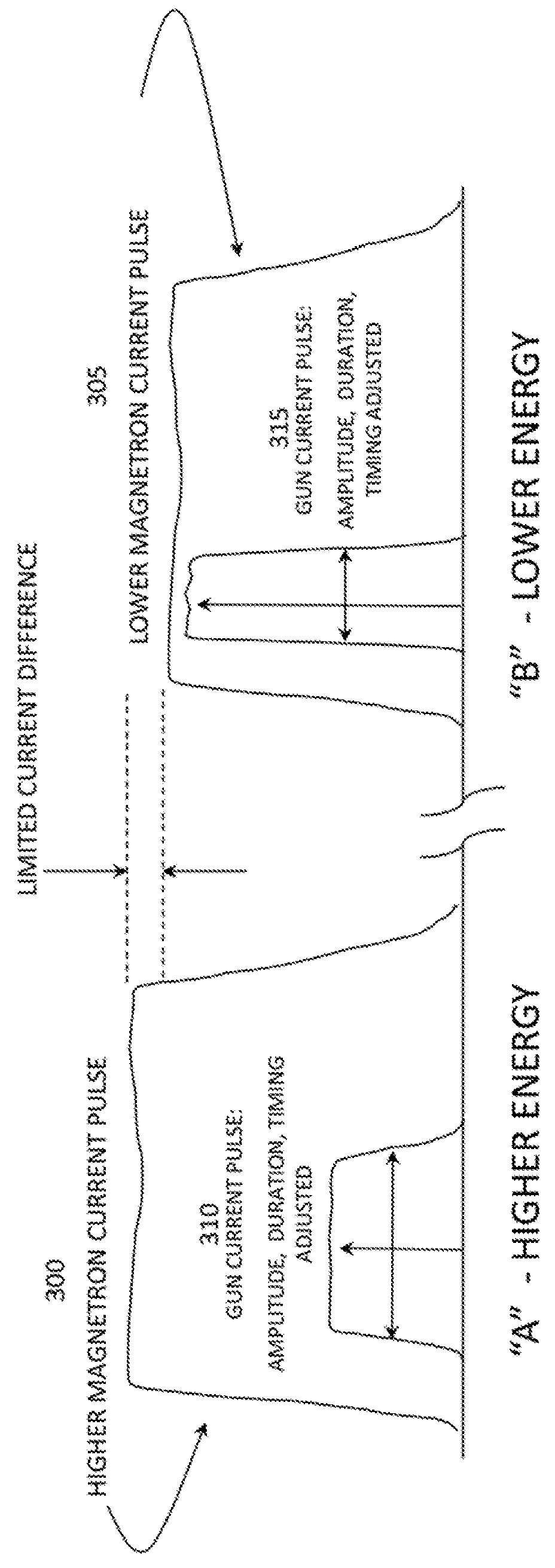

Systems and methods for cargo scanning and radiotherapy using a traveling wave linear accelerator based x-ray source using current to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the electron beam current applied to an electron gun. The electron beams may be used to generate x-rays having selected doses and energies, which may be used for cargo scanning or radiotherapy applications.

Owner:ACCURAY

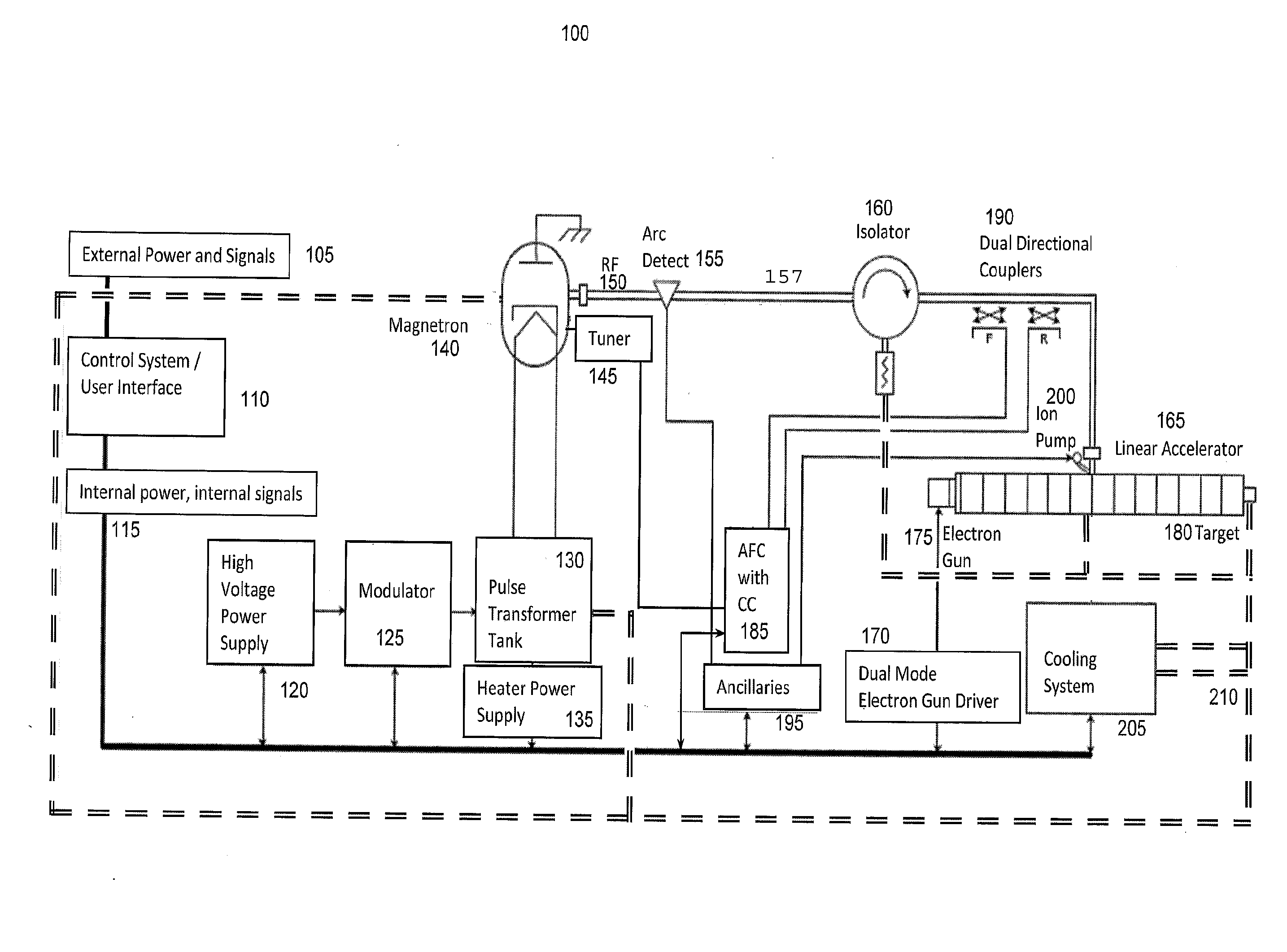

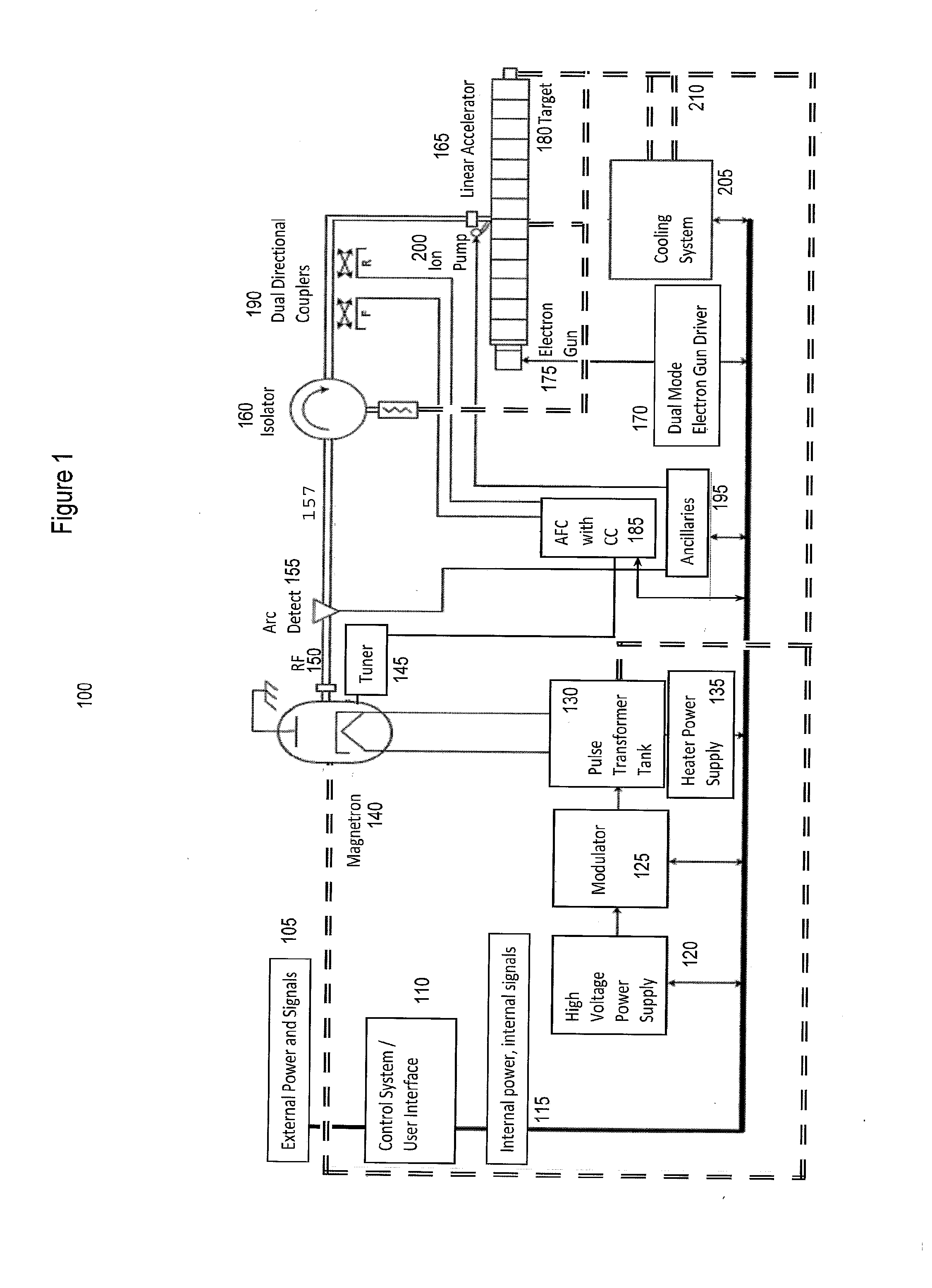

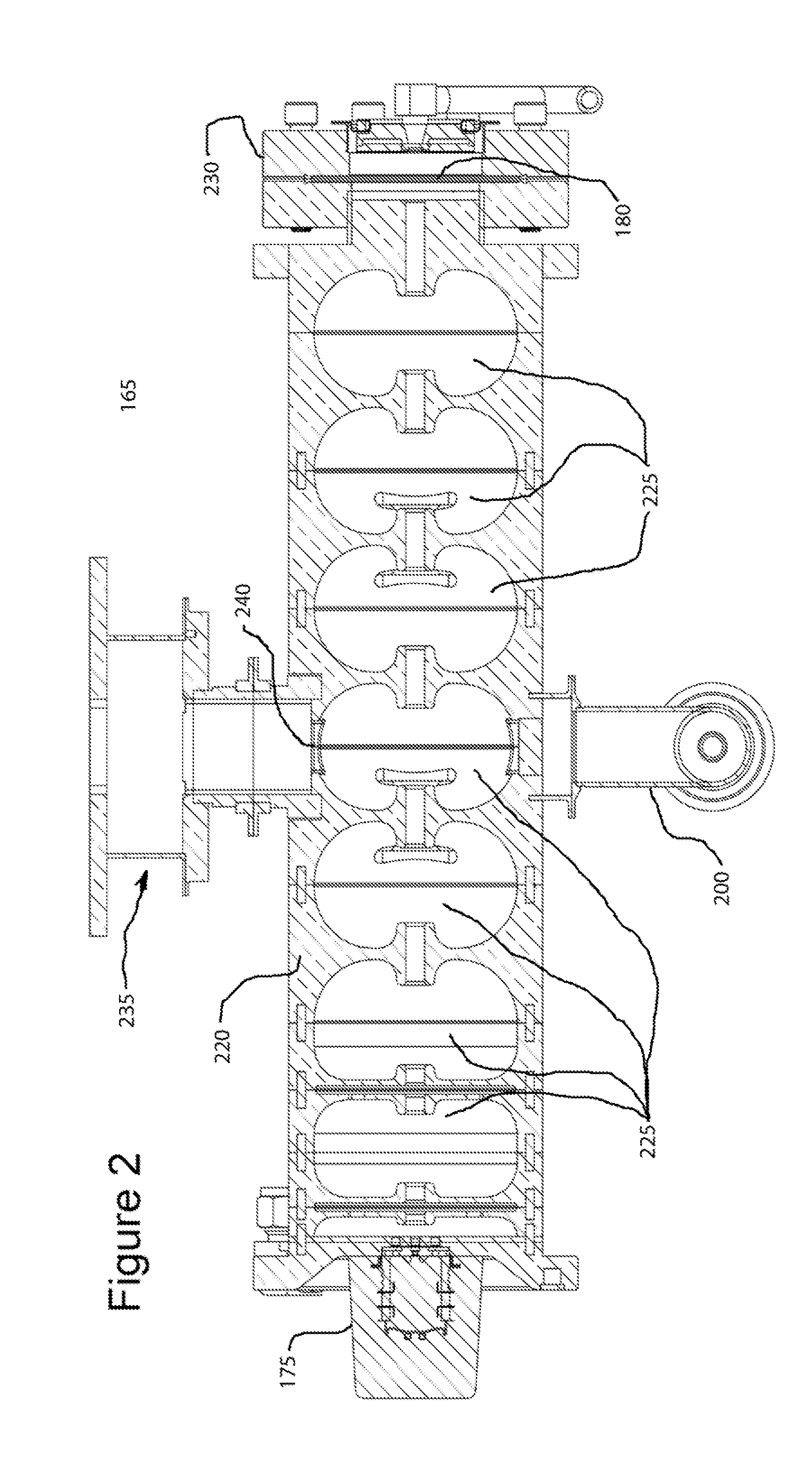

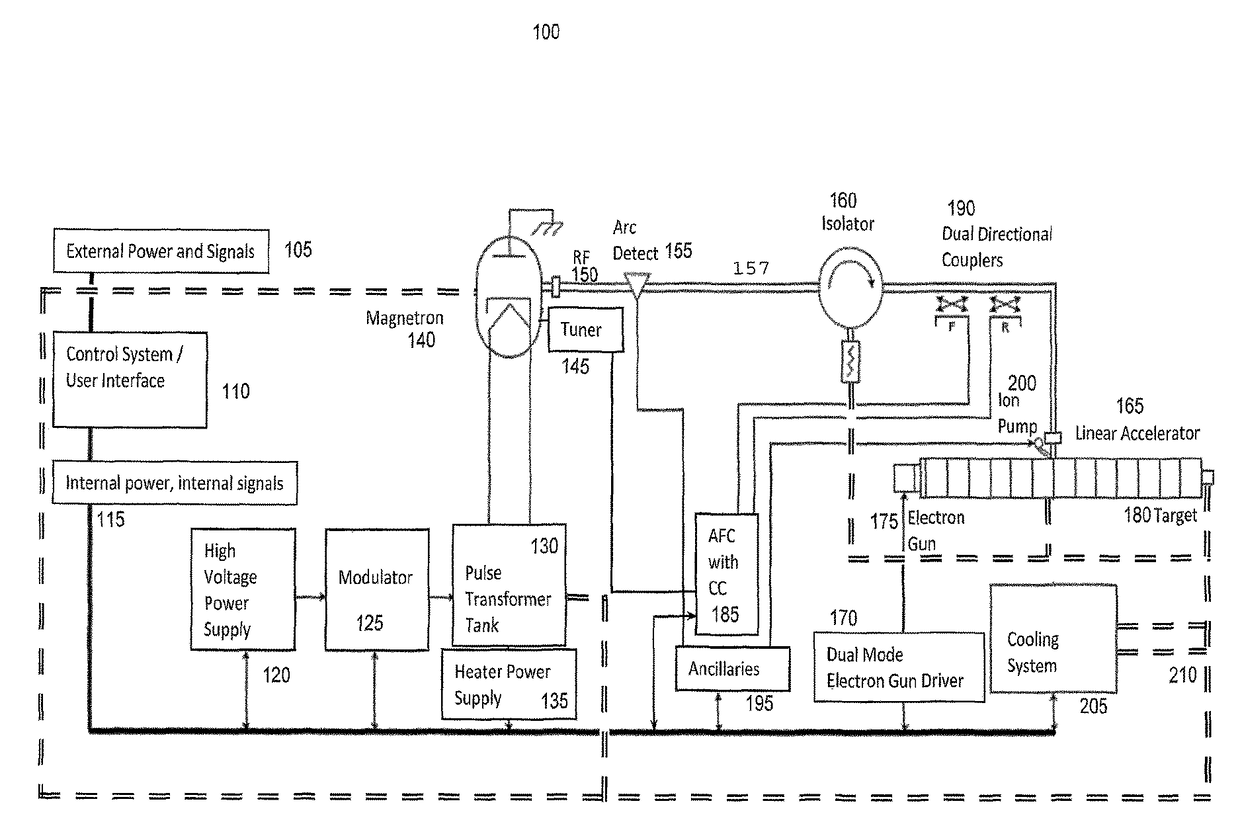

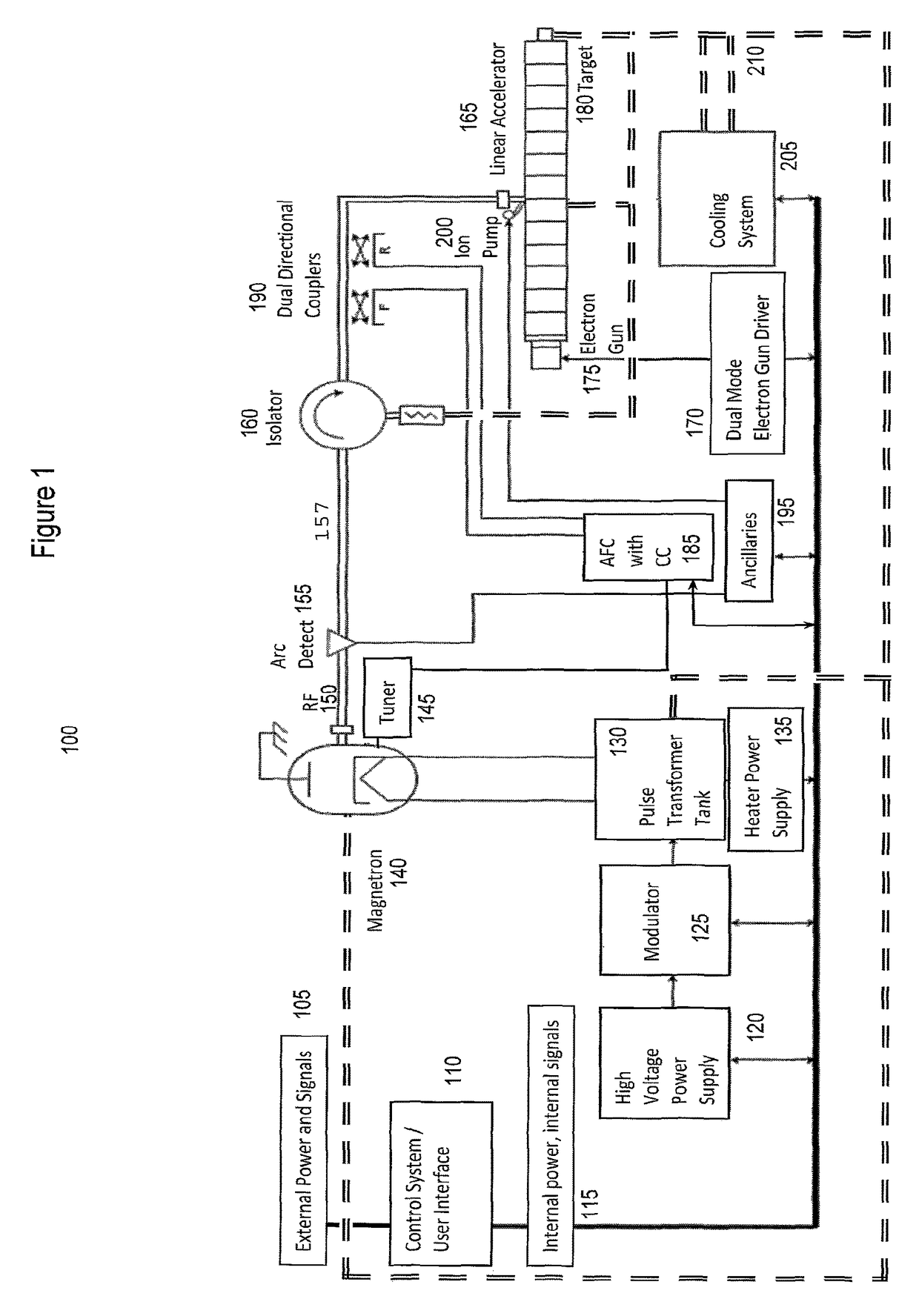

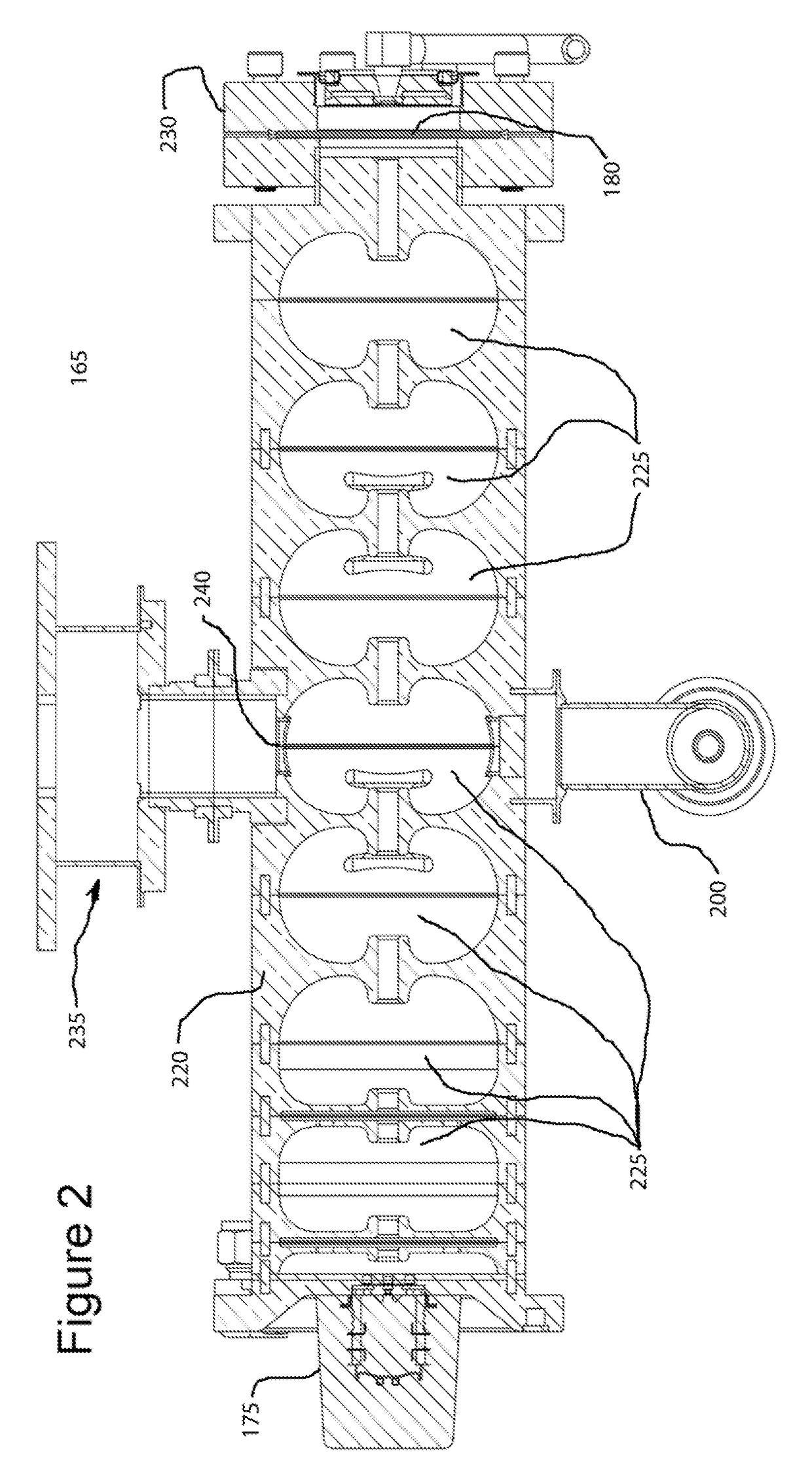

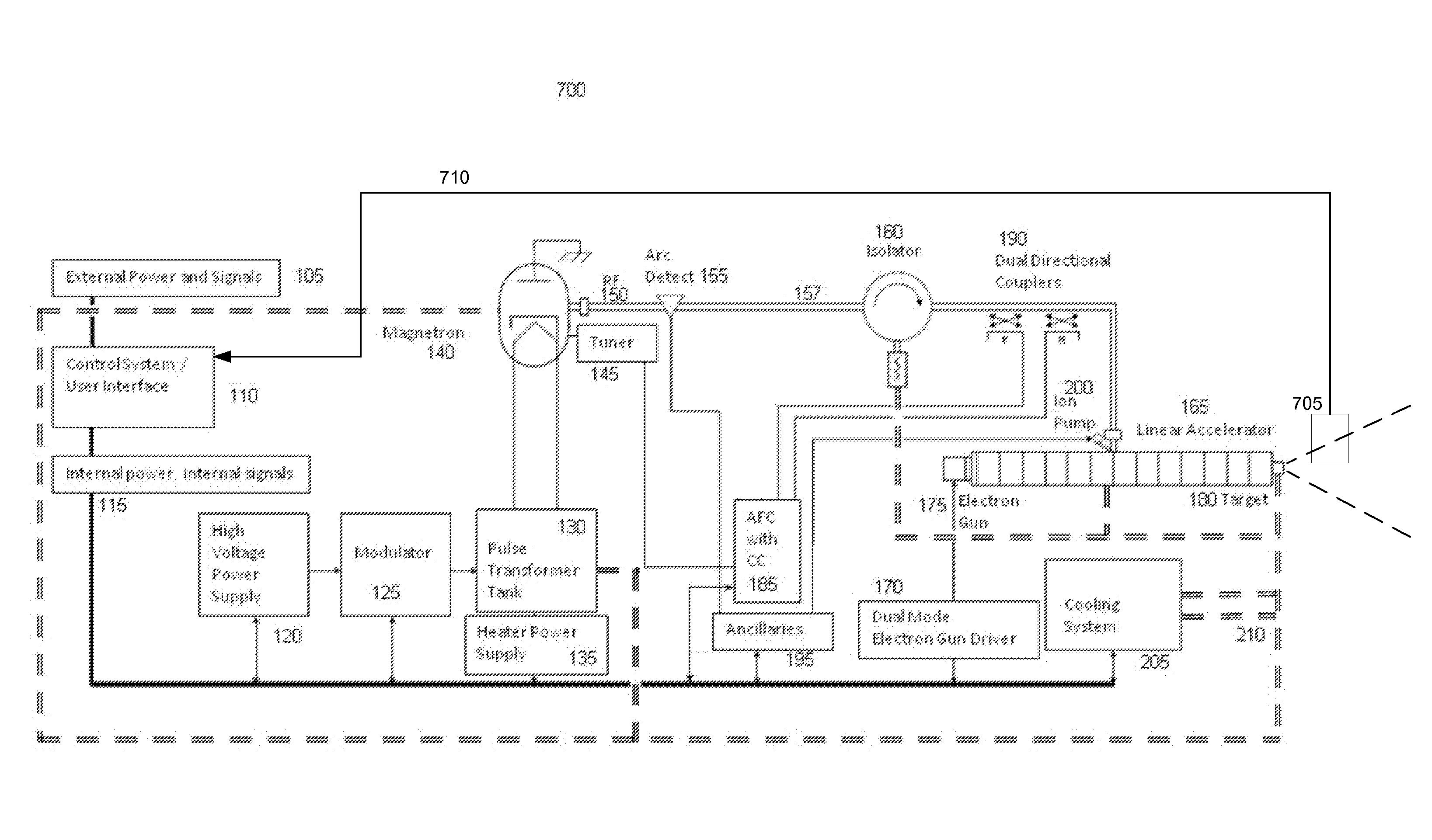

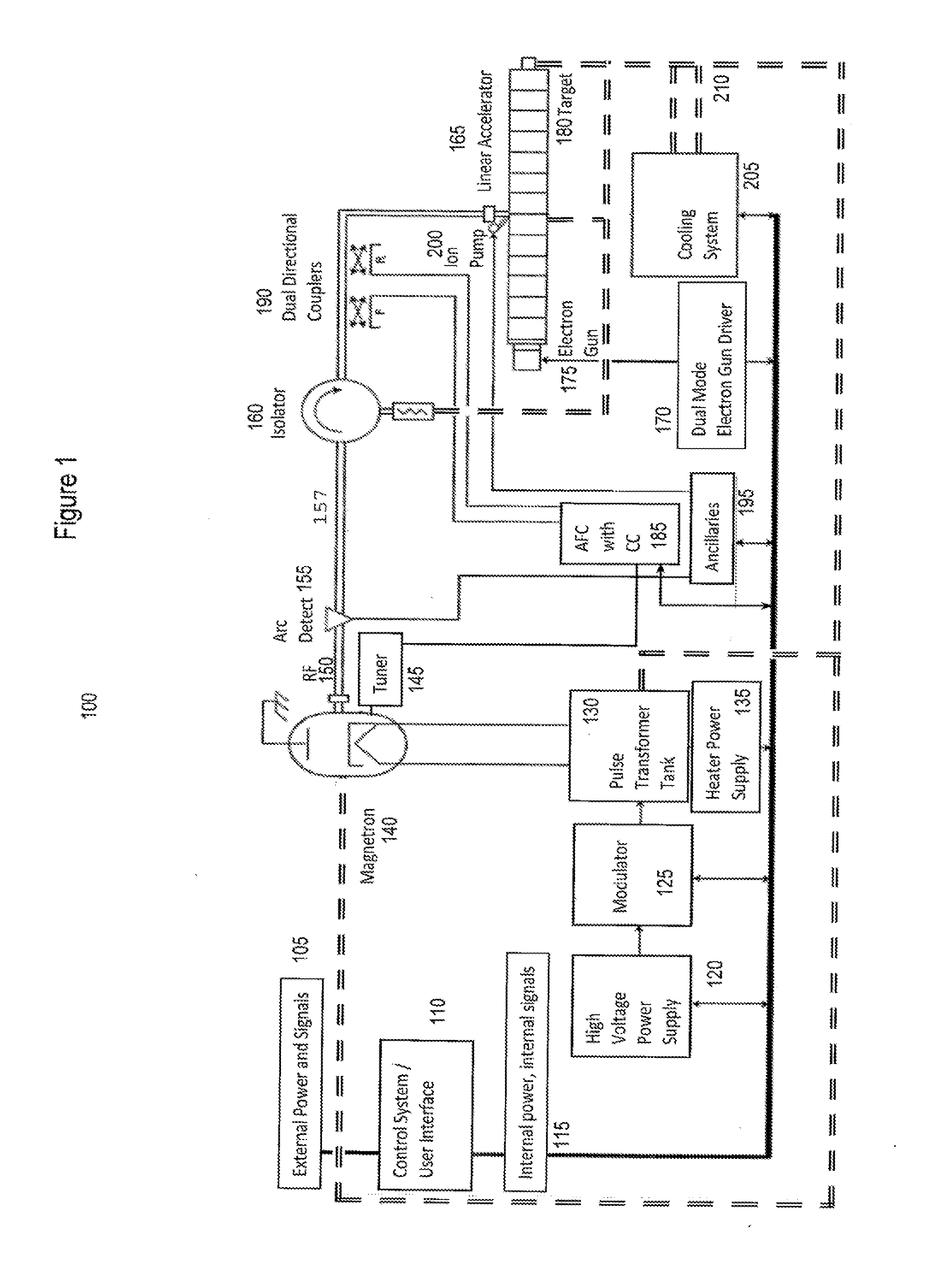

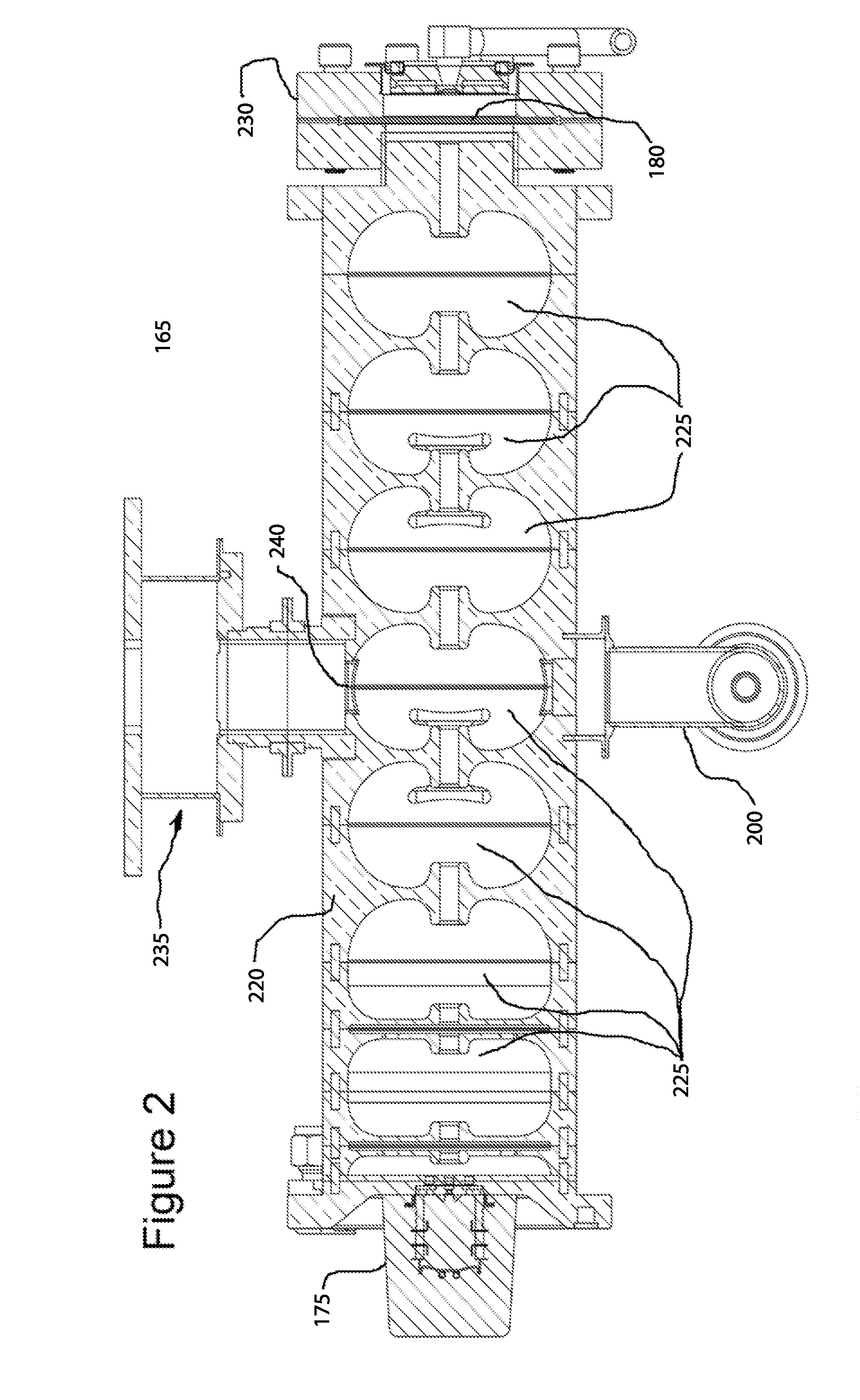

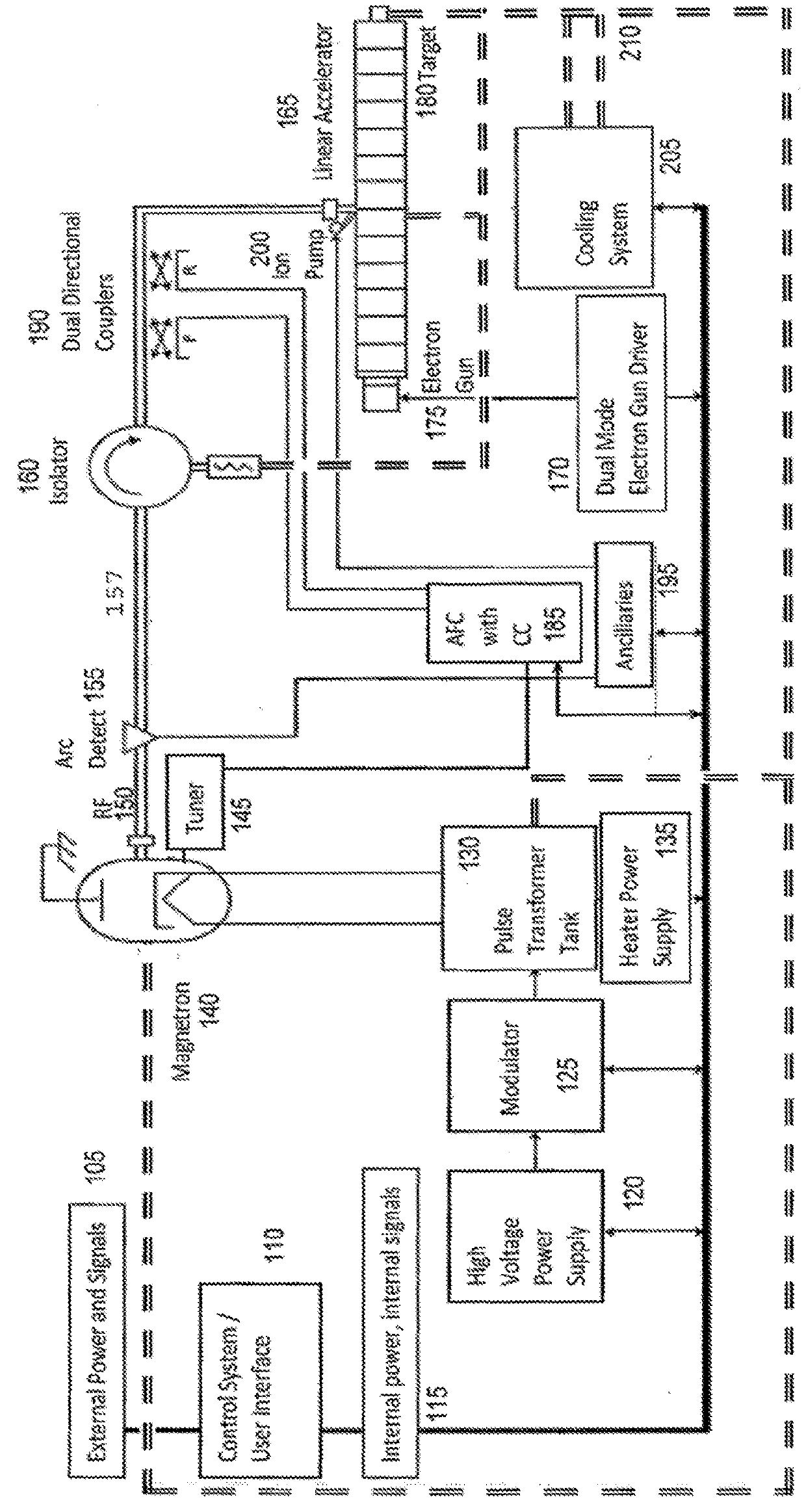

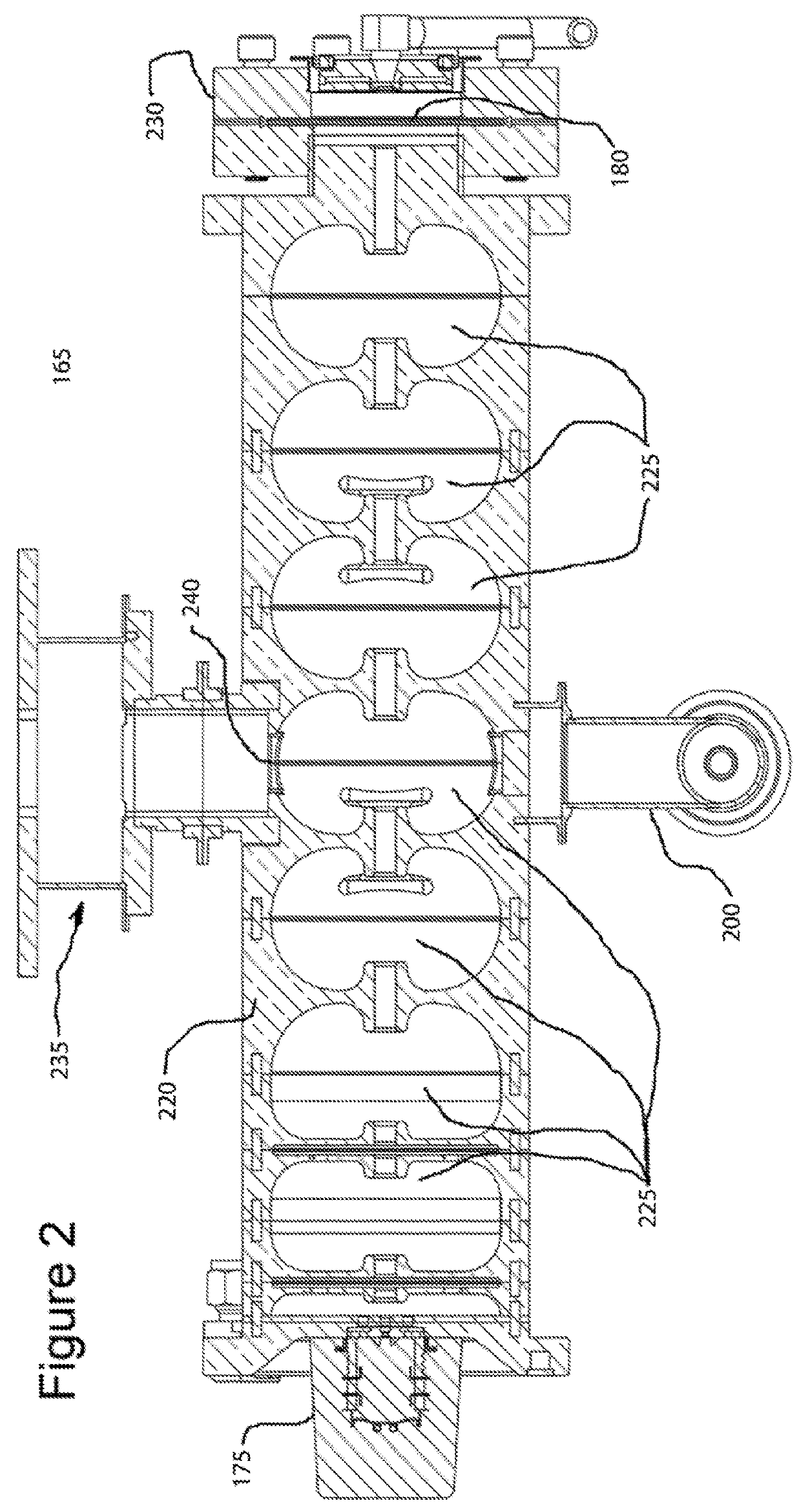

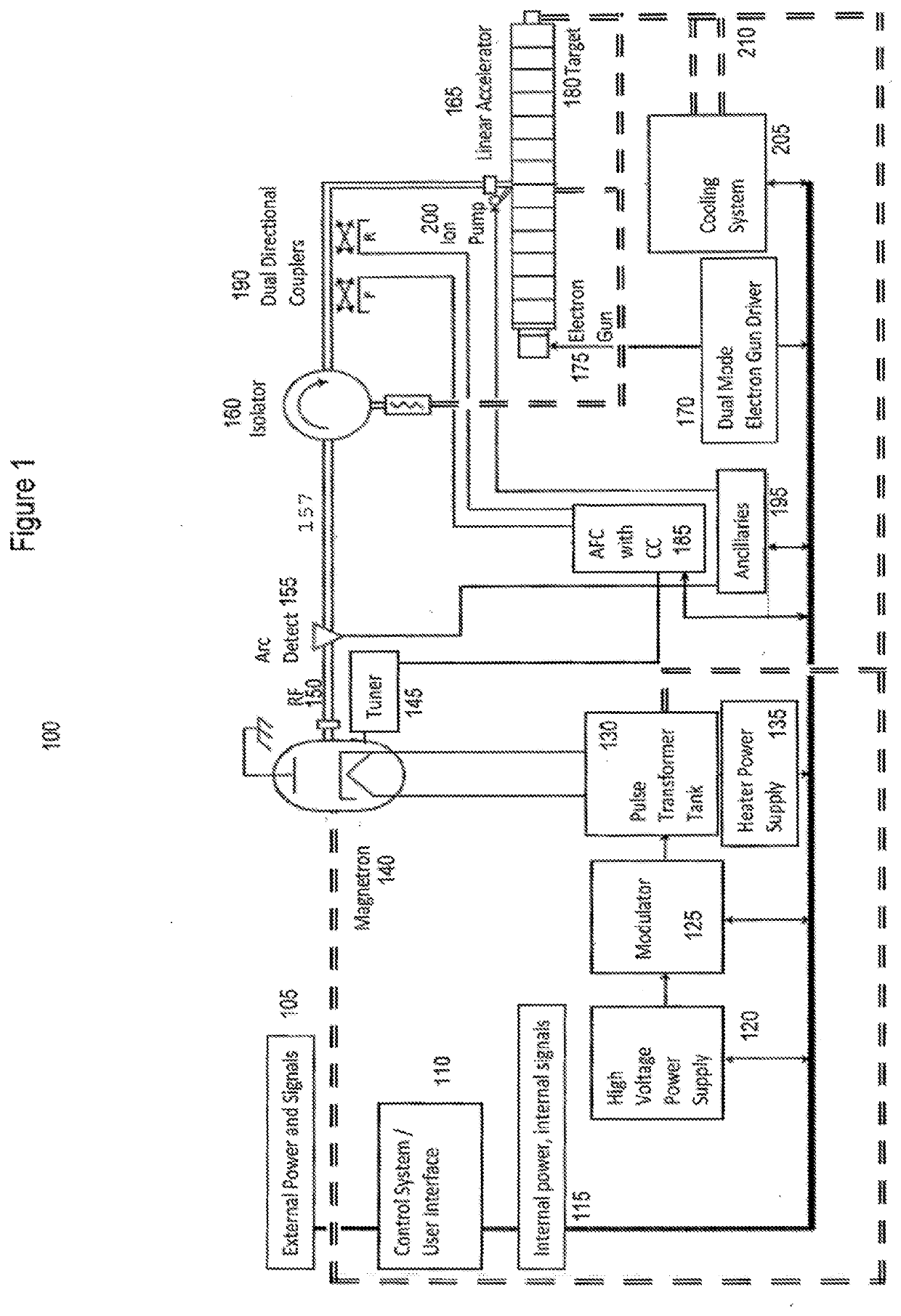

Linear accelerator system with stable interleaved and intermittent pulsing

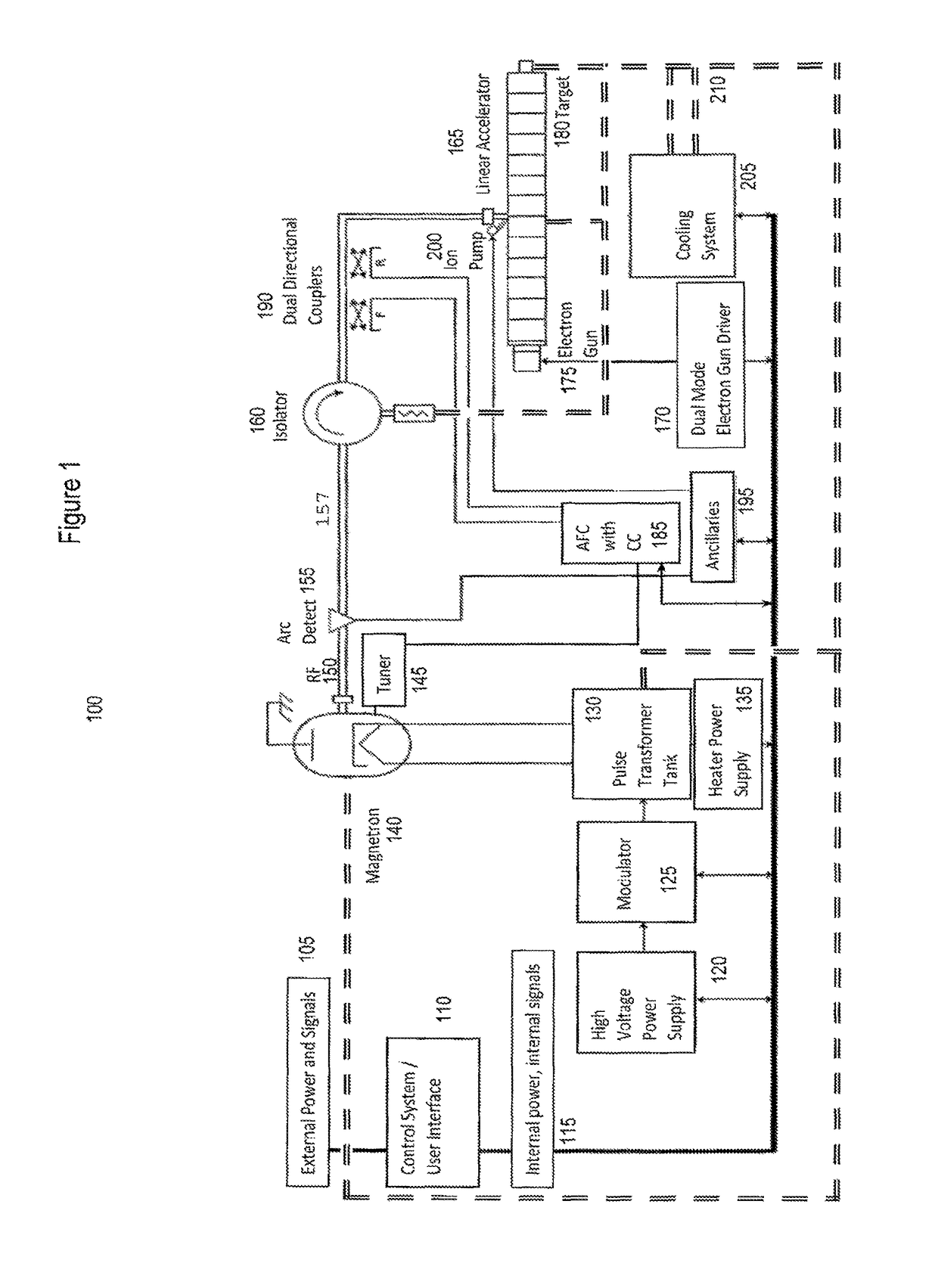

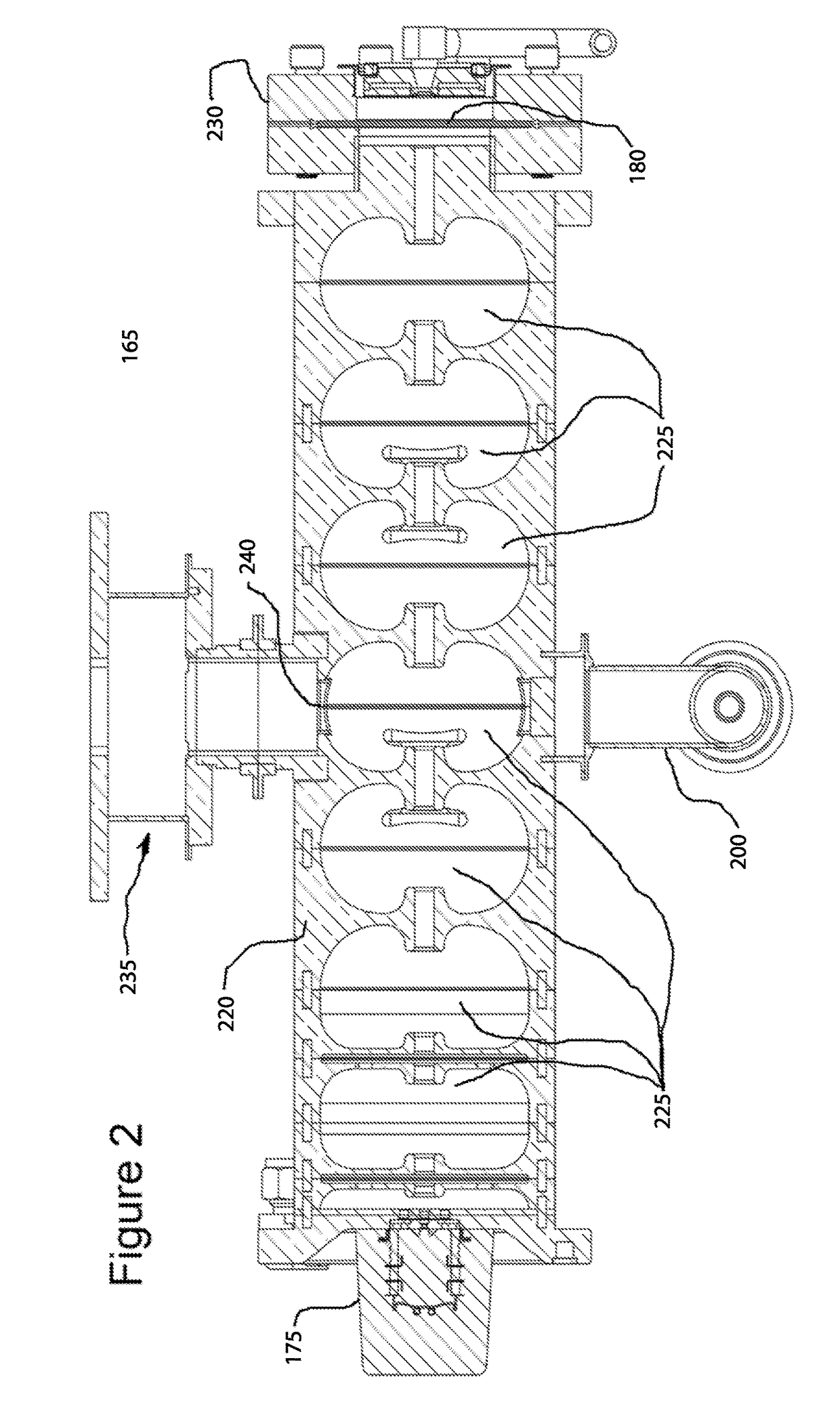

ActiveUS20150245463A1Linear acceleratorsRadiation diagnosticsNuclear engineeringAutomatic frequency control

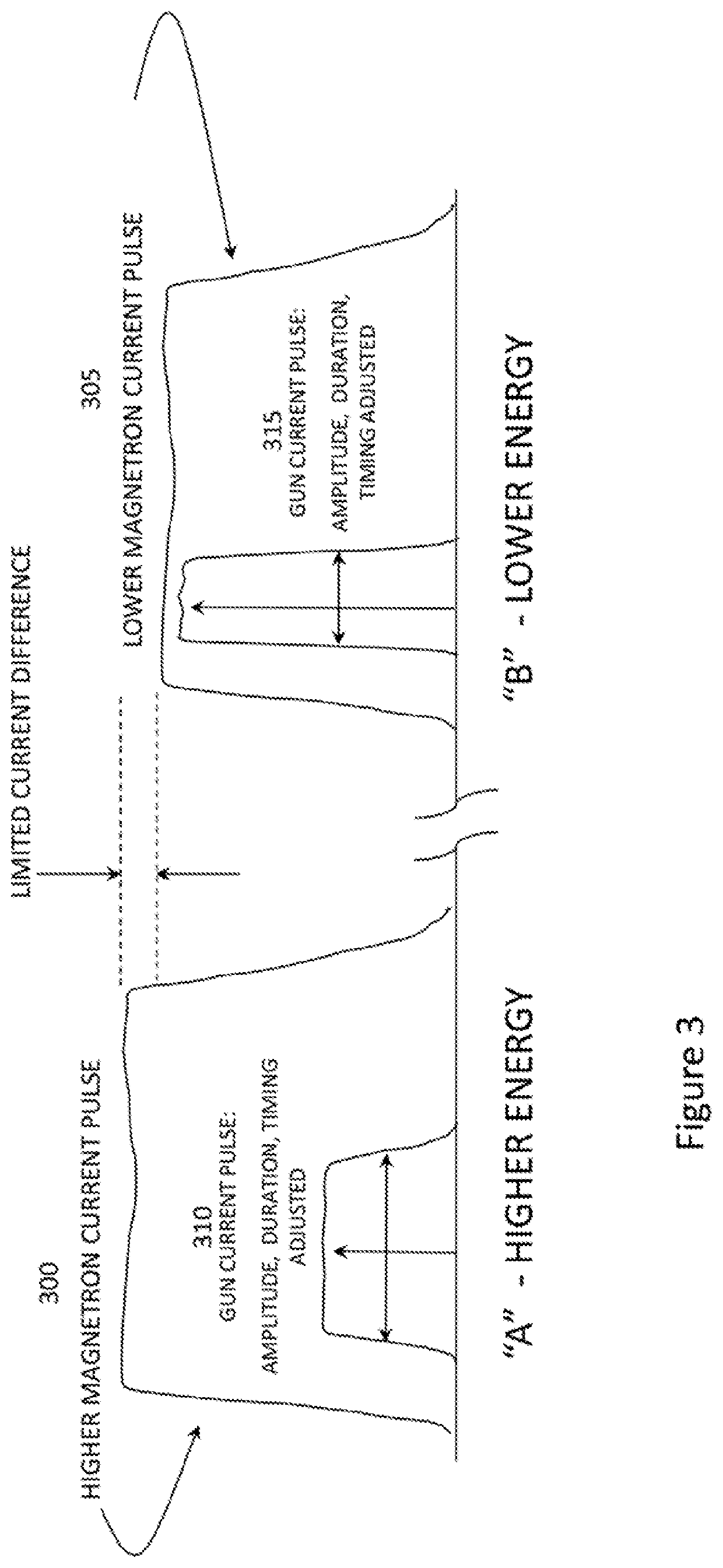

A linac-based X-ray system for cargo scanning and imaging applications uses linac design, RF power control, beam current control, and beam current pulse duration control to provide stable sequences of interleaved pulses having different energy levels, for example alternating 4 MeV and 6 MeV pulses or other energies where the difference in levels is at least approximately 1 MeV and less than approximately 5 MeV. The pulse repetition rate can be 100-400 pulses per second or more. In an embodiment, a cool down calculation is combined with automatic frequency control to provide stable energy and dose per pulse even upon restarting of pulsing after an “off” period of indeterminate duration.

Owner:ETM ELECTROMATIC

Linear accelerator system with stable interleaved and intermittent pulsing

A linac-based X-ray system for cargo scanning and imaging applications uses linac design, RF power control, beam current control, and beam current pulse duration control to provide stable sequences of interleaved pulses having different energy levels, for example alternating 4 MeV and 6 MeV pulses or other energies where the difference in levels is at least approximately 1 MeV and less than approximately 5 MeV. The pulse repetition rate can be 100-400 pulses per second or more. In an embodiment, a cool down calculation is combined with automatic frequency control to provide stable energy and dose per pulse even upon restarting of pulsing after an “off” period of indeterminate duration.

Owner:ETM ELECTROMATIC

Linear accelerator system with stable interleaved and intermittent pulsing

ActiveUS20150245462A1Cathode ray concentrating/focusing/directingLinear acceleratorsX-rayLinear particle accelerator

Owner:ETM ELECTROMATIC

Linear accelerator system for stable pulsing at multiple dose levels

A linac-based X-ray system for cargo scanning and imaging applications uses linac design, RF power control, beam current control, and beam current pulse duration control to provide stable sequences of pulses having different energy levels or different dose.

Owner:ETM ELECTROMATIC INC

Systems and methods for cargo scanning and radiotherapy using a traveling wave linear accelerator based X-ray source using pulse width to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the width of the beam pulse, i.e., pulse width. The electron beams may be used to generate x-rays having selected doses and energies, which may be used for cargo scanning or radiotherapy applications.

Owner:ACCURAY

Rotatable boom cargo scanning system

The present invention is a self-contained mobile inspection system and method and, more specifically, improved methods and systems for detecting materials concealed within a wide variety of receptacles and / or cargo containers. In particular, the present invention is an improved method and system for inspecting receptacles and / or cargo containers using a single boom placed on a turntable with pivot points to allow for folding and unfolding of the boom, such that the inspection system is relatively compact in a stowed configuration and has a low center of gravity lending to greater stability.

Owner:RAPISCAN SYST INC (US)

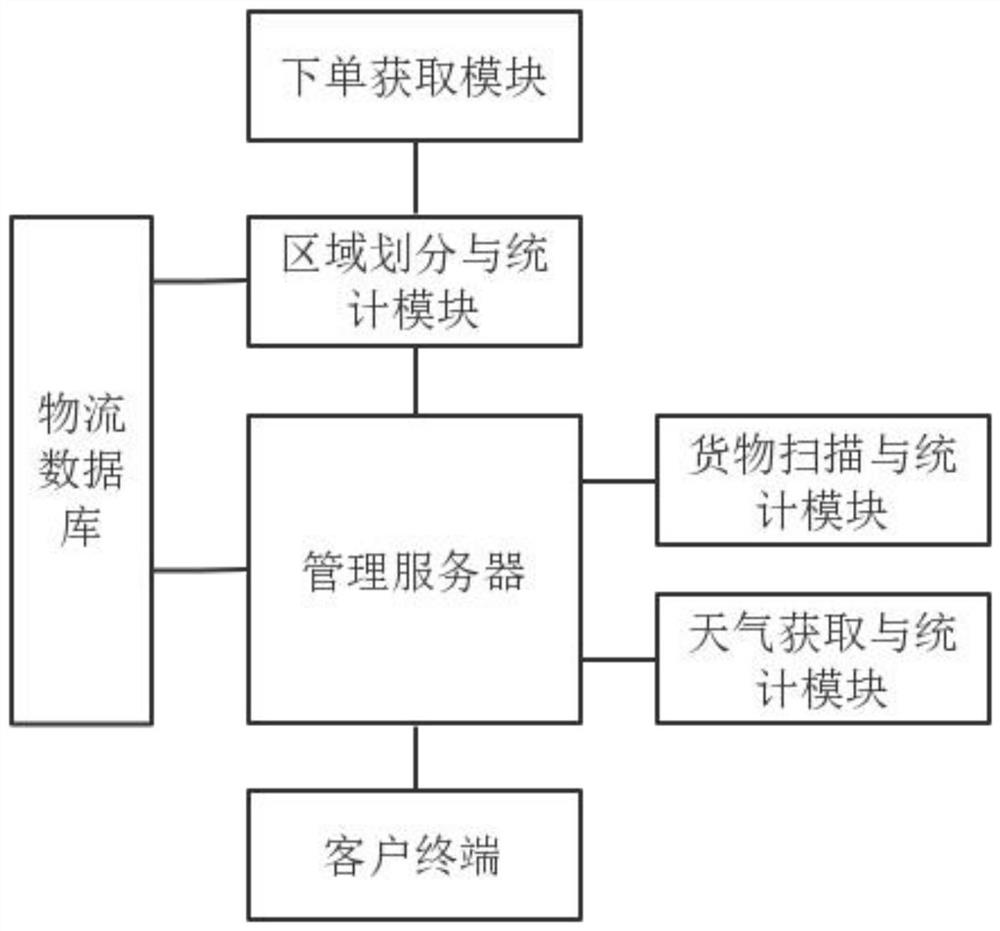

Logistics arrival time real-time monitoring and pre-estimating system based on big data

InactiveCN112418536AEfficient screeningImprove accuracyForecastingGeographical information databasesStreaming dataLogistics management

The invention provides a logistics arrival time real-time monitoring and pre-estimating system based on big data. The logistics arrival time real-time monitoring and pre-estimating system comprises aregion division and statistics module, an order placing acquisition module, a logistics database, a cargo scanning and statistics module, a weather acquisition and statistics module, a management server and a client terminal. According to the invention, through the cargo scanning statistics module and the order placing acquisition module and in combination with the management server, the path withthe shortest distribution distance is screened out, and the total time of the cargo from the current website to the distribution destination is counted; therefore, in the cargo transportation process, the problems that the transportation efficiency is poor and the current position and the estimated arrival time of goods cannot be mastered in real time can be solved; the transportation is performed according to the shortest path and the time from the current logistics website to the destination is displayed, so that purchasers can clearly know the current position and the transportation arrival time of the goods, the logistics transportation efficiency is improved, and the customer satisfaction degree is greatly improved.

Owner:南京鼓佳玺电子科技有限公司

Linear accelerator system with stable interleaved and intermittent pulsing

A linac-based X-ray system for cargo scanning and imaging applications uses linac design, RF power control, beam current control, and beam current pulse duration control to provide stable sequences of interleaved pulses having different energy levels, for example alternating 4 MeV and 6 MeV pulses or other energies where the difference in levels is at least approximately 1 MeV and less than approximately 5 MeV. The pulse repetition rate can be 100-400 pulses per second or more. In an embodiment, a cool down calculation is combined with automatic frequency control to provide stable energy and dose per pulse even upon restarting of pulsing after an “off” period of indeterminate duration.

Owner:ETM ELECTROMATIC

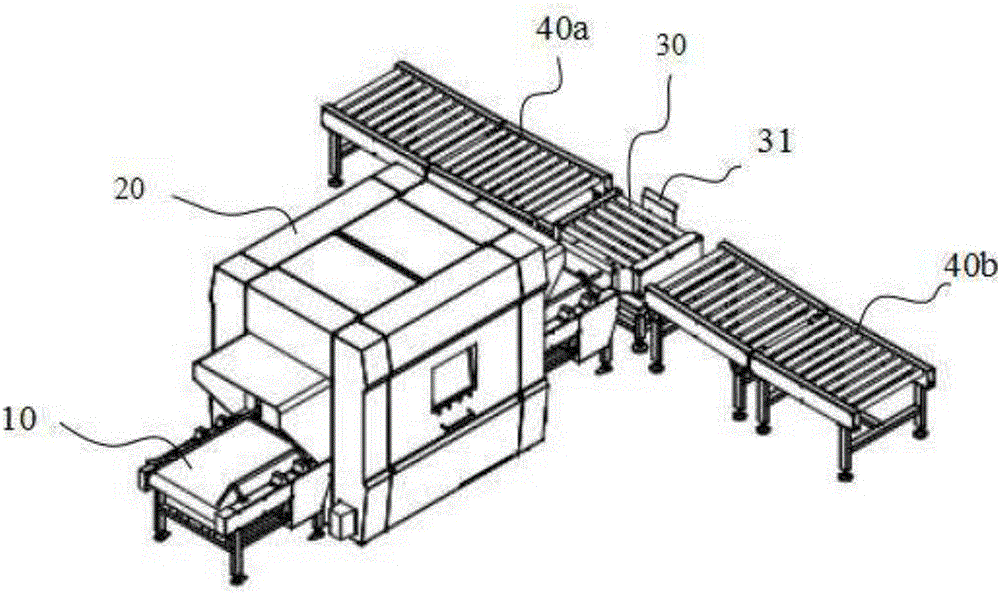

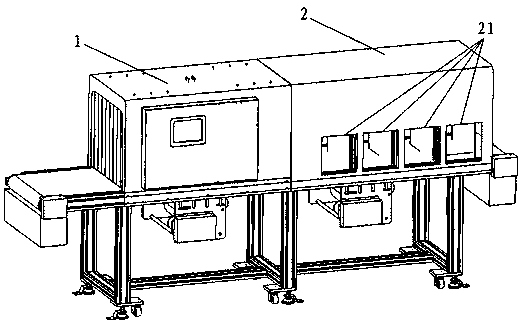

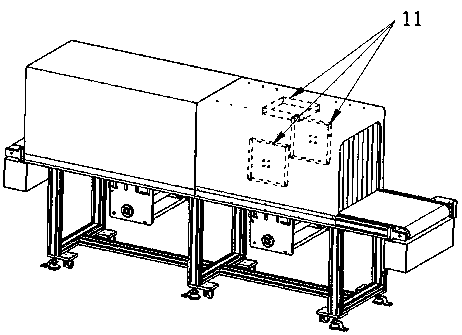

Scanning channel machine

InactiveCN105868809AAutomate operationImprove work efficiencyCo-operative working arrangementsInvoiceCargo scanning

The present invention relates to the technical field of scanning equipment, especially relating to a scanning channel machine which comprises transport equipment and a box body. The transport path of the transport equipment goes through the box body which is internally provided with a computer, a reading and writing device and an antenna. The computer is connected to the reading and writing device which is connected to the antenna. The display screen of the computer is exposed from one side outer wall of the box body. When the cargo scanning is carried out, firstly cargo is placed on the transport equipment, the transport equipment drives the cargo to move together to goes through the box body, the antenna scans the tag information on the cargo, the reading and writing device carries out reading and writing and uploads the information to the computer, the computer analyzes and processes the tag information and compares the cargo information on an invoice or purchase order, whether the cargo tag information is correct or not can be verified, through the setting of the transport equipment and the scanning equipment in the box body, the automatic operation of the scanning can be realized, and the working efficiency of the scanning is greatly improved.

Owner:WUXI PINGUANG IOT TECH CO LTD

Systems and methods for cargo scanning and radiotherapy using a traveling wave linear accelerator based x-ray source using current to modulate pulse-to-pulse dosage

Provided herein are systems and methods for operating a traveling wave linear accelerator to generate stable electron beams at two or more different intensities by varying the number of electrons injected into the accelerator structure during each pulse by varying the electron beam current applied to an electron gun. The electron beams may be used to generate x-rays having selected doses and energies, which may be used for cargo scanning or radiotherapy applications.

Owner:ACCURAY

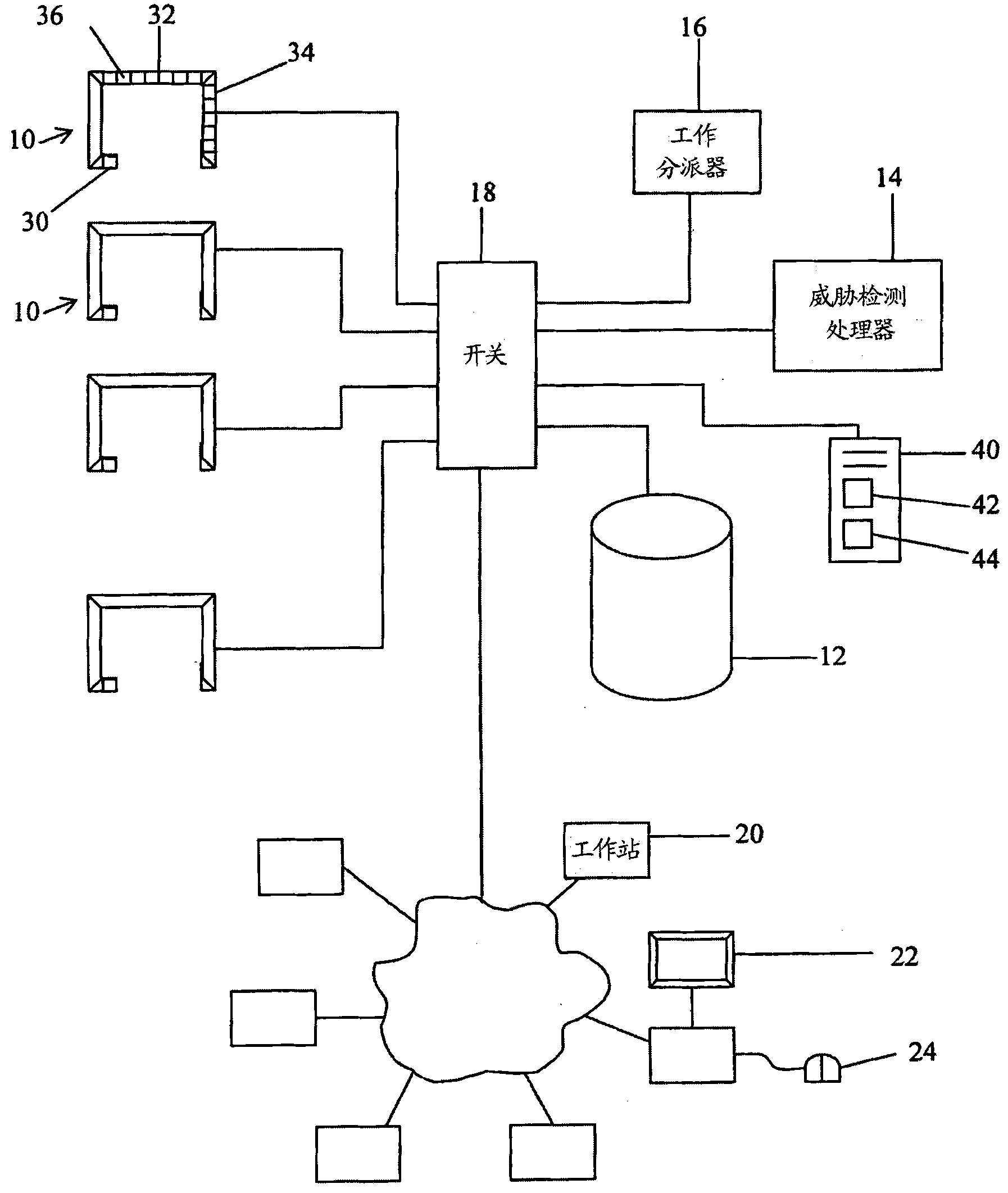

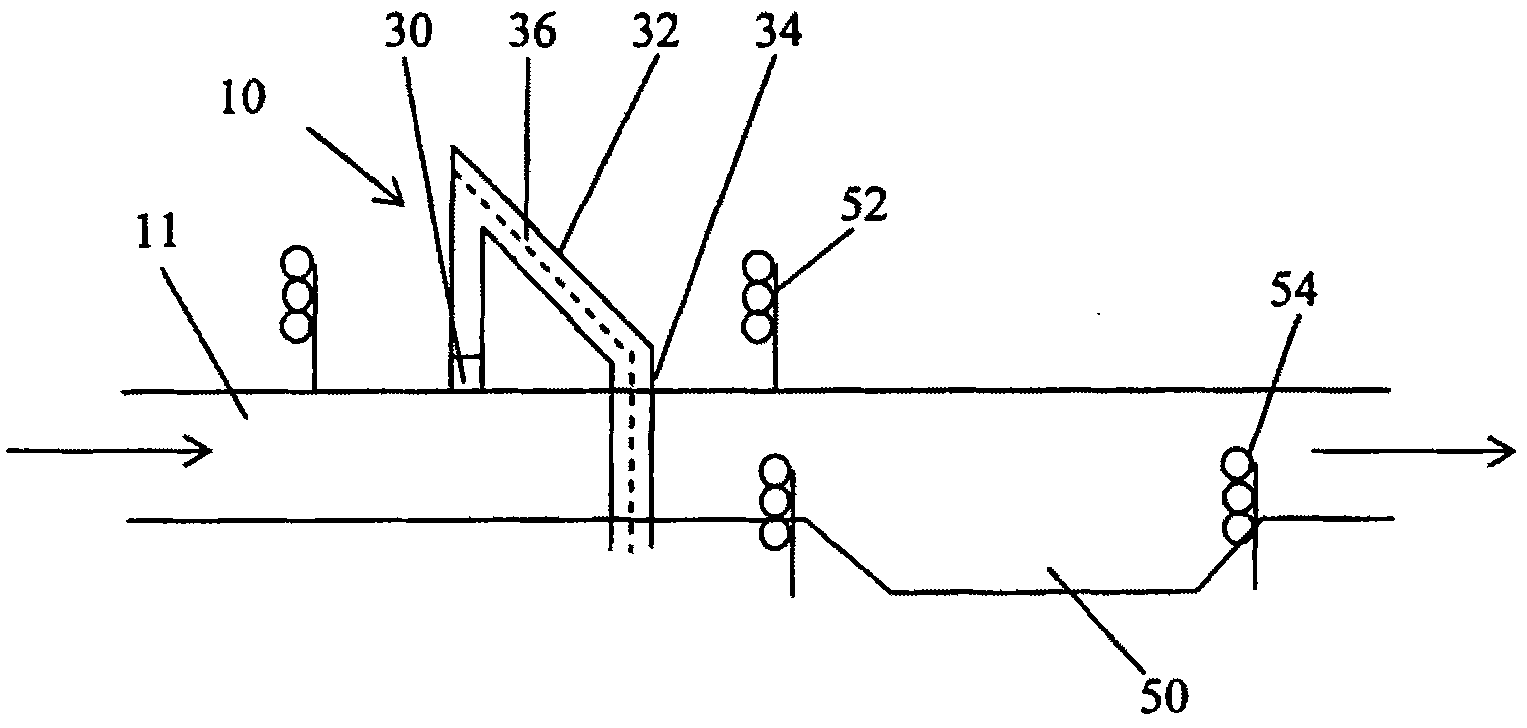

Scanning systems

ActiveCN102007432AImprove throughputReduce screening costsProgramme controlMaterial analysis using wave/particle radiationData managementWorkstation

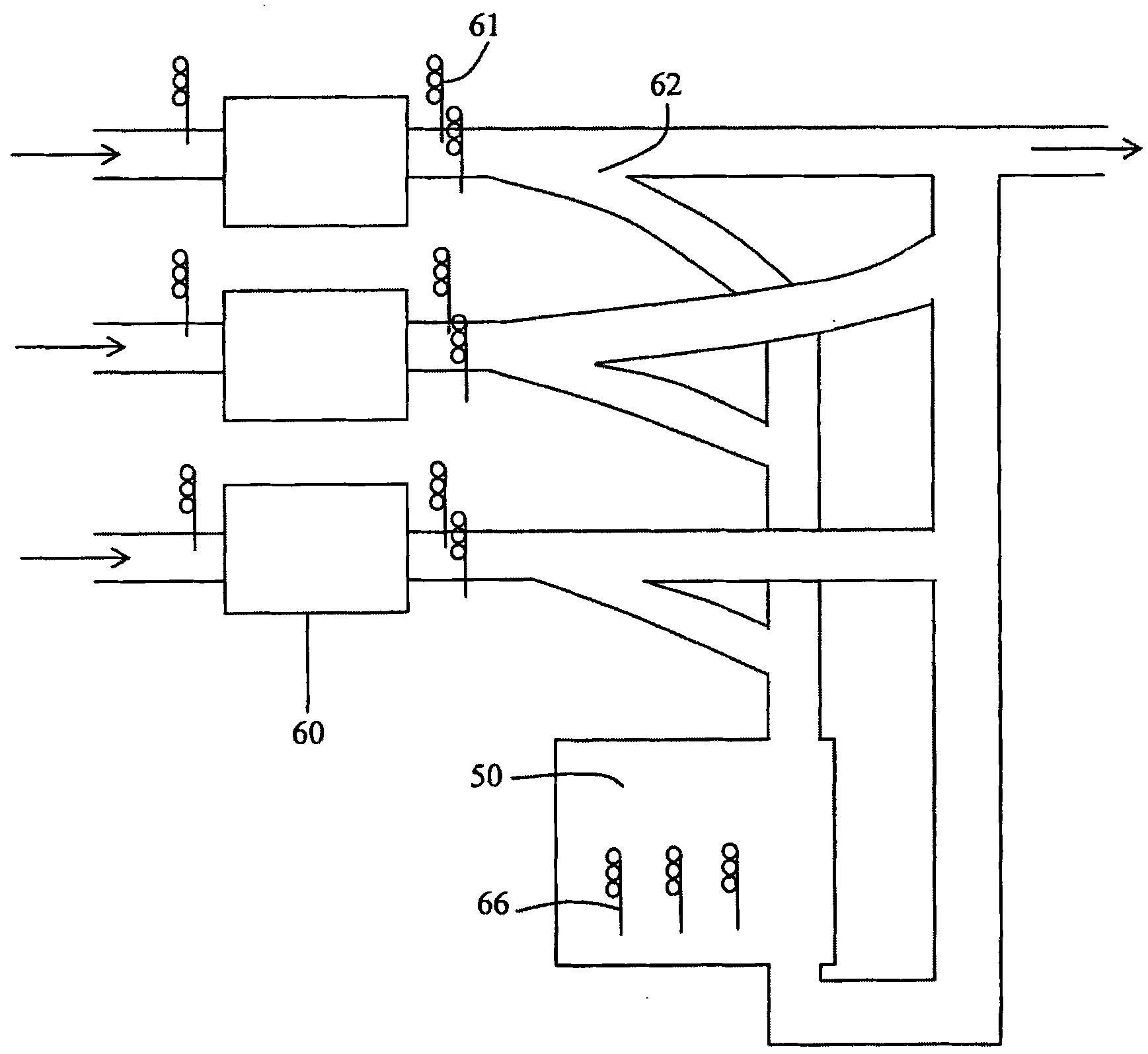

A cargo scanning system comprises a plurality of scanners each arranged to scan a respective object and generate a set of scan data, processing means arranged to process each set of scan data to determine whether it meets a predetermined threat condition, a plurality of workstations, and data management means arranged to direct data that meets the threat condition to one of the workstations for analysis.

Owner:RAPISCAN SYST INC (US)

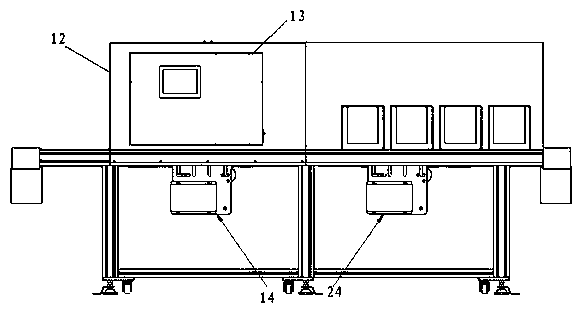

Intelligent RFID channel machine with automatic sorting and automatic sorting method

ActiveCN111229617AHigh degree of automationImprove scanning and sorting efficiencySortingComputer hardwareCargo scanning

The invention discloses an intelligent RFID channel machine with automatic sorting. The intelligent RFID channel machine comprises a detection cabinet and a sorting cabinet, wherein symmetrical openings are formed in the two ends, corresponding to a conveying mechanism, of the detection cabinet, the openings and an inner cavity of the detection cabinet form a detection channel, a conveyor belt ofthe conveying mechanism penetrates through the detection channel, and a plurality of RFID readers for reading cargo information are arranged in a detection cabinet body; and the sorting cabinet is infixed communication with the detection cabinet, and the sorting cabinet is parallel and level to the cargo conveying surface of the detection cabinet, and a sorting system is arranged in the sorting cabinet. According to the intelligent RFID channel machine, the RFID technology can be used for automatically scanning cargos, the sorting cabinet can automatically sort the cargos through a cargo sorting mechanism, manual participation is not required in the entire process of scanning and sorting the cargos, degree of automation of the device is high, and the scanning and sorting efficiency is greatly improved.

Owner:深圳市依时德科技有限公司

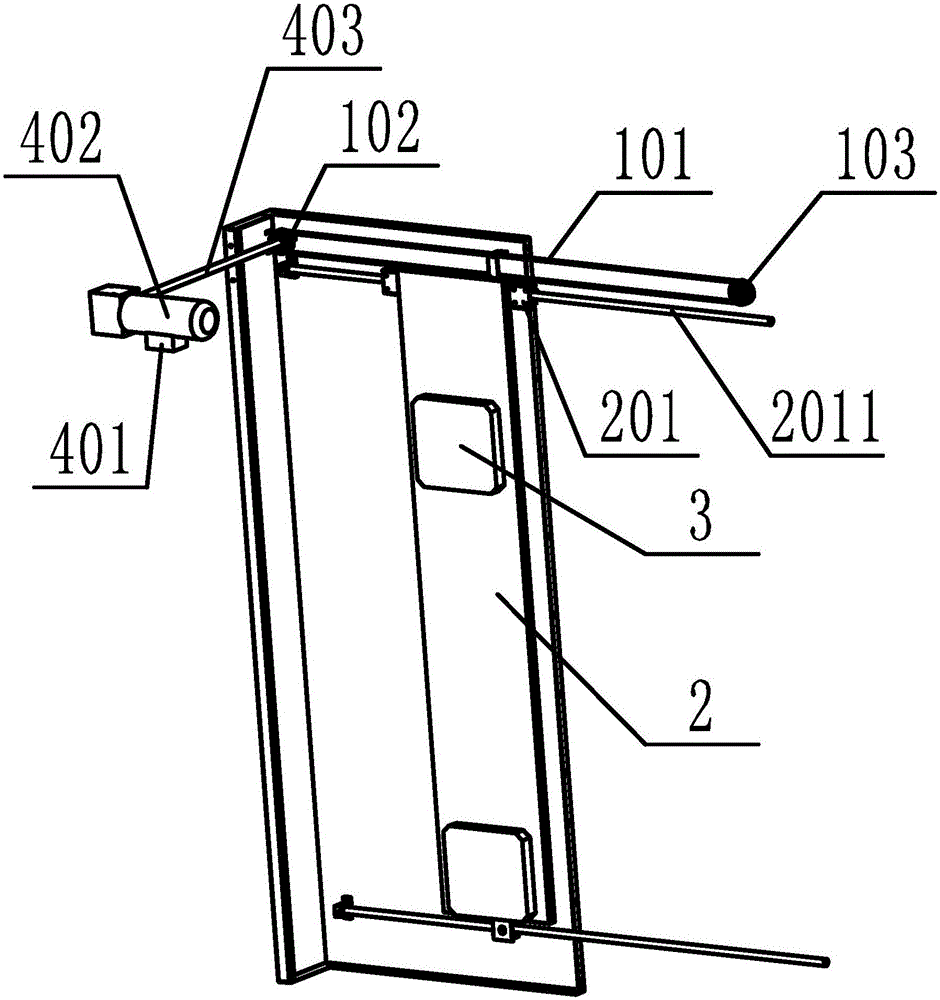

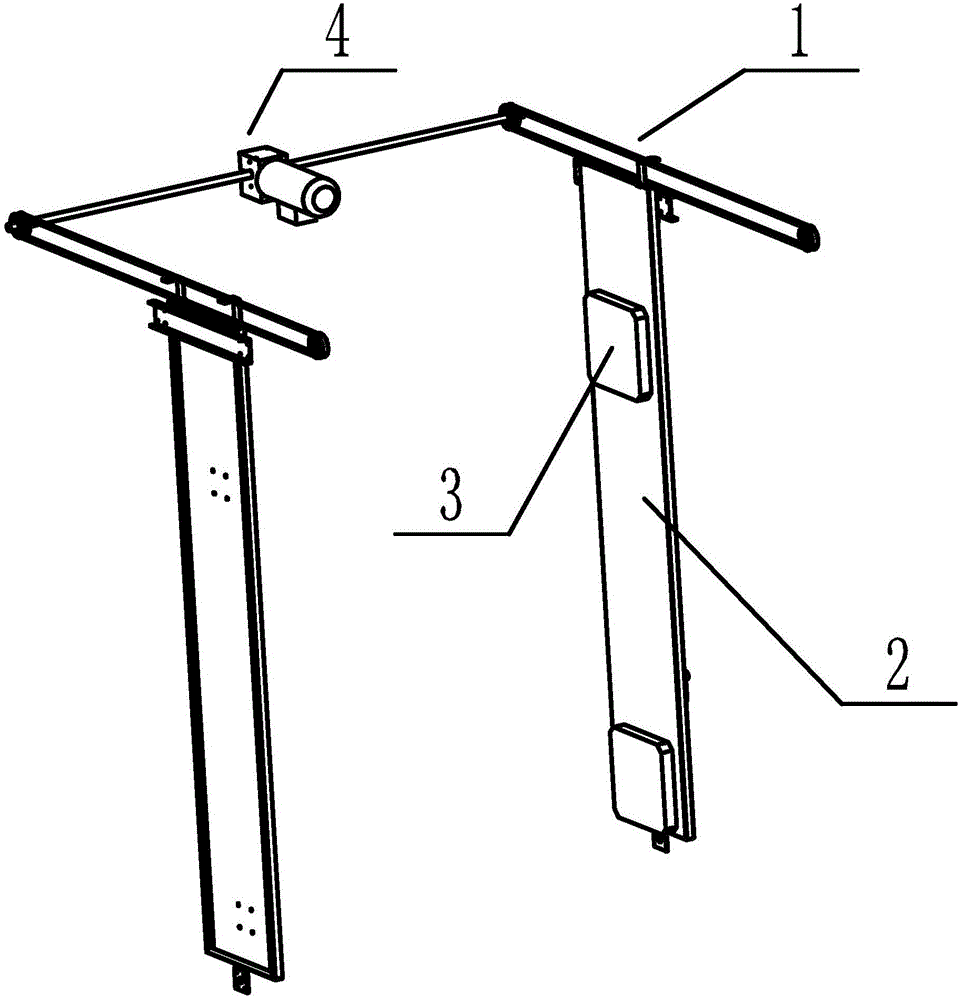

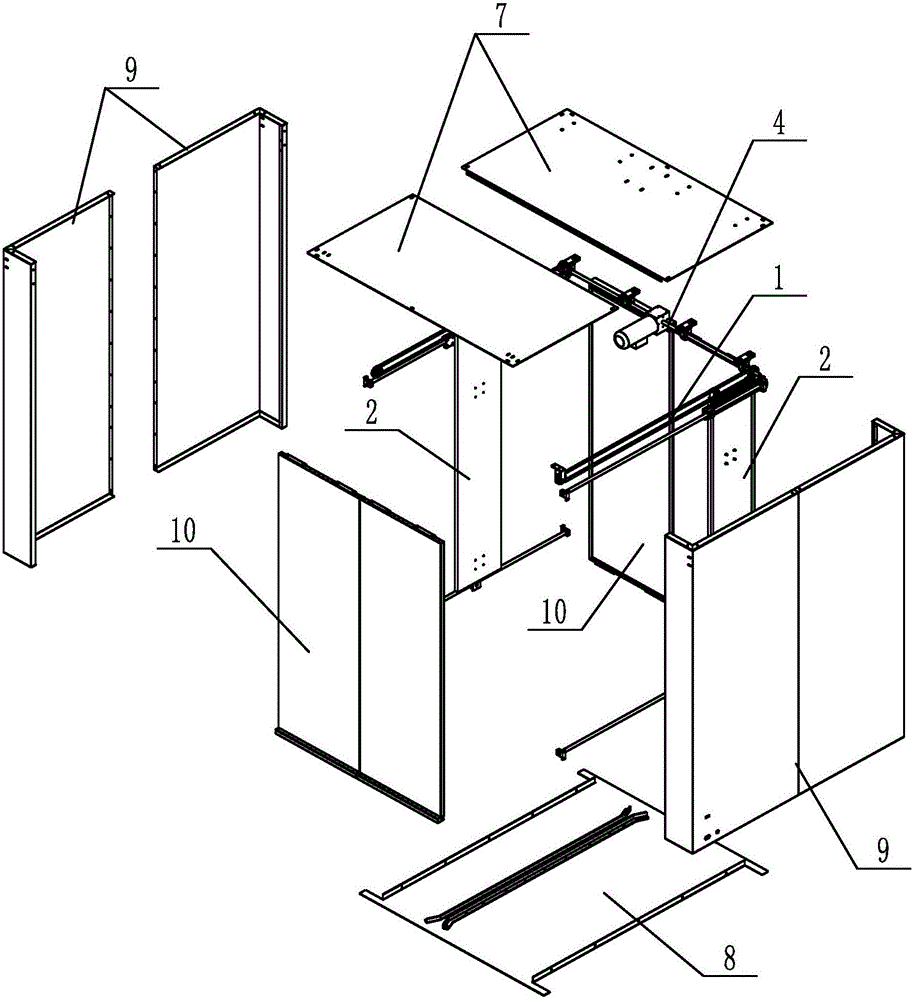

Automatic cargo scanning cabinet

InactiveCN106516544AWide coverageAvoid missed scansStorage devicesReciprocating motionRange of motion

The invention belongs to the technical field of radio frequency identification, and relates to an automatic cargo scanning cabinet, particularly to an automatic batch cargo scanning cabinet applying an RFID technology. The automatic cargo scanning cabinet comprises a cabinet body, and transmission devices, antenna supports, antennas, a driving device and limiting sensors are further arranged inside the cabinet body. According to the automatic cargo scanning cabinet, the antenna supports continuously perform front-and-back reciprocating motion under the driving of a deceleration motor and under the action of the limiting sensors, and the motion range is limited between a first limiting sensor and a second limiting sensor, so that the antennas can perform reciprocating motion along with the antenna supports, the coverage area of a radio-frequency signal emitted by the antennas inside the antenna supports is wider, scanning dead zones can be eliminated, and omissive scanning of labels is prevented.

Owner:北京蓝天清科控股有限公司

Linear accelerator system for stable pulsing at multiple dose levels

ActiveUS20200015346A1Simple designLinear acceleratorsNuclear radiation detectionNuclear engineeringPulse sequence

A linac-based X-ray system for cargo scanning and imaging applications uses linac design, RF power control, beam current control, and beam current pulse duration control to provide stable sequences of pulses having different energy levels or different dose.

Owner:ETM ELECTROMATIC INC

Compact mobile cargo scanning system

InactiveCN102460134BMaterial analysis by transmitting radiationNuclear radiation detectionEngineeringImproved method

The present invention is a self-contained mobile inspection system and method and, more specifically, improved methods and systems for detecting materials concealed within a wide variety of receptacles and / or cargo containers. In particular, the present invention is an improved method and system with a novel boom structure that reduces the weight of the boom. The single, light-weight boom of the inspection system is relatively compact in a stowed configuration and has a low height and center of gravity lending to greater maneuverability.

Owner:RAPISCAN SYST INC (US)

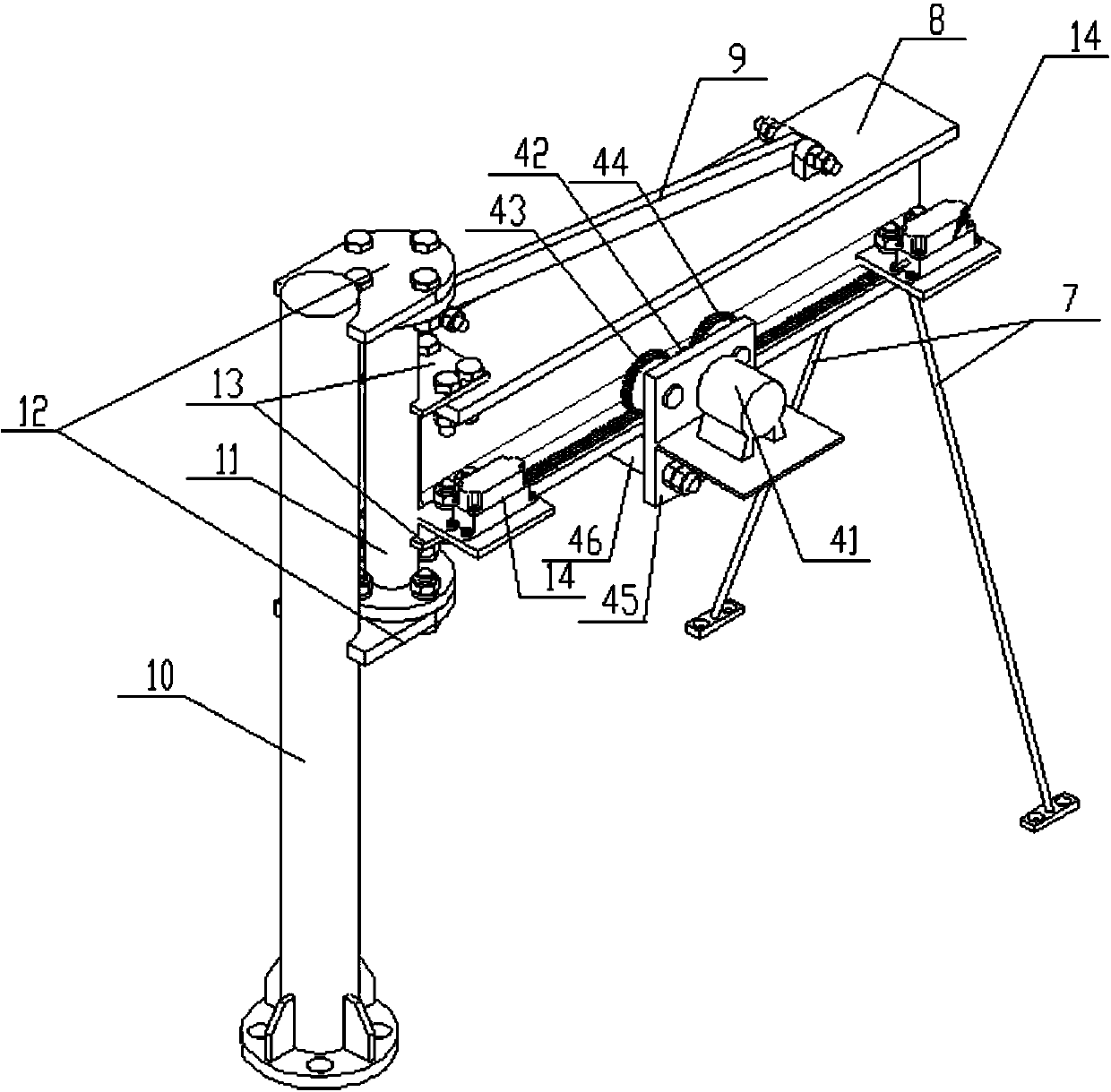

A liftable logistics cargo scanning device

ActiveCN107971251BQuick scanImprove work efficiencyConveyorsMemory record carrier reading problemsLogistics managementEngineering

Owner:唐山公路港物流有限公司

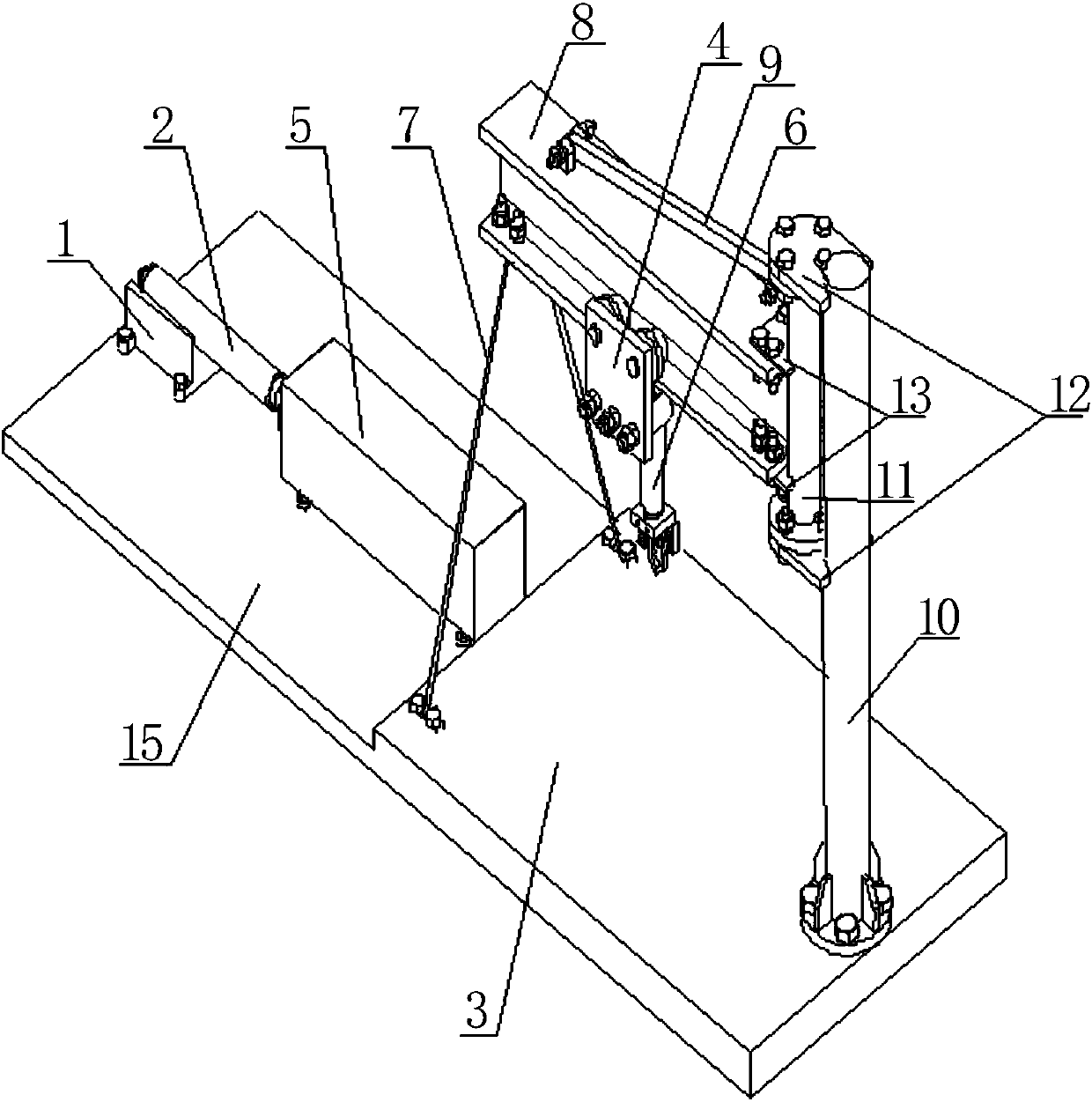

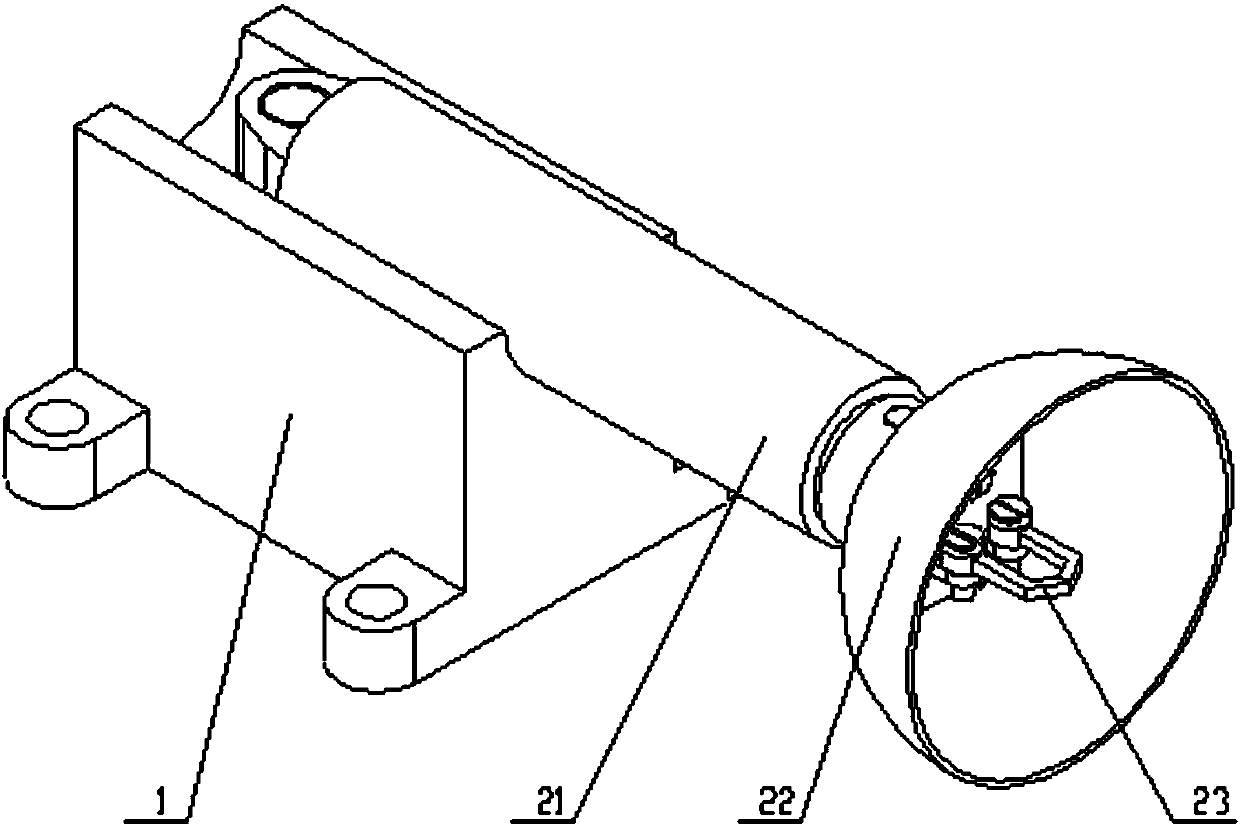

Express drone cargo automatic loading and unloading and counterweight platform

InactiveCN105127992BRealize the function of intelligent counterweightProgramme-controlled manipulatorFixed bearingNacelle

The invention discloses an automatic cargo loading and unloading and counterweight platform of an express delivery drone, which includes a platform base, a fixed support, a first manipulator, a bracket, a horizontal guide rail, a mobile slide, a second manipulator, a cargo information reader and a controller , the fixed support is set on the platform base to fix the manipulator one, and the manipulator one is under the control of the controller to load and unload the goods on the shelves in the unmanned aerial vehicle cabin; the horizontal guide rail is set on the bracket, and the mobile slide table is set On the horizontal guide rail, the manipulator 2 is set on the mobile slide table, and the cargo information reader is set on the manipulator 2. The cargo information reader transmits the scanned and read cargo information to the controller, and the controller controls the manipulator 2. Controls for counterweighting the unmanned cabin. Due to the adoption of the above-mentioned structural form, it has the functions of automatic loading and unloading of goods, reading of goods information and realizing the intelligent counterweight of goods according to the scanned data, so it is suitable for the automatic delivery platform of drones in the express delivery industry in the future.

Owner:GUANGDONG UNIV OF TECH

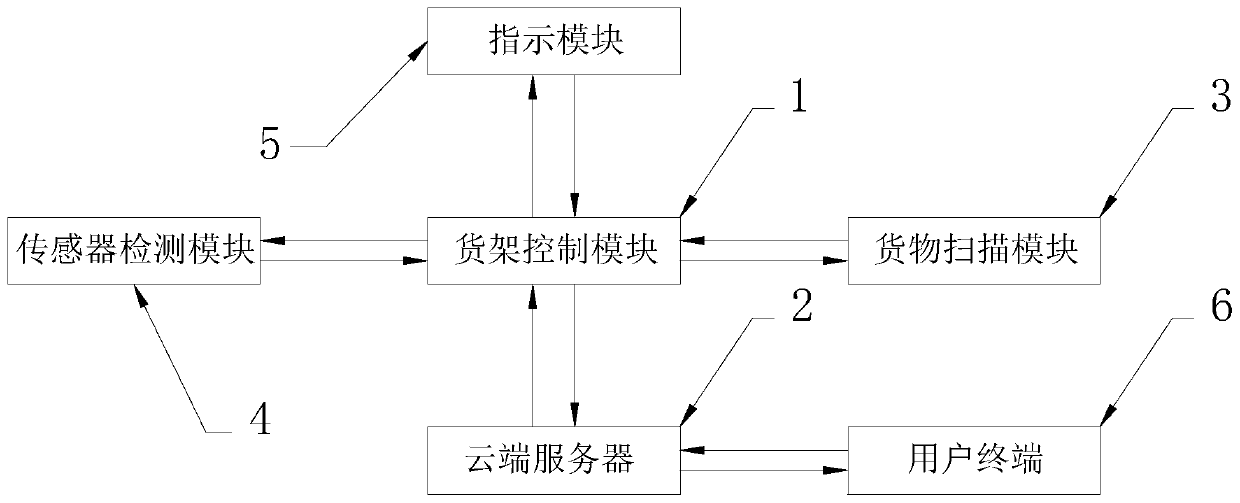

Novel intelligent shelf system for logistics picking operation

InactiveCN110775512AFind quicklyStorage impactLogisticsStorage devicesLogistics managementCargo scanning

The invention discloses a novel intelligent shelf system for logistics picking operation. The novel intelligent shelf system for logistics picking operation includes shelf control modules, a cloud server, cargo scanning modules, sensor detection modules, indication modules, and a user terminal, the shelf control modules and the cloud server are interconnected, and the cloud server is interconnected with the user terminal; the shelf control modules are arranged on shelves, the cargo scanning modules for scanning and distinguishing cargos, the sensor detection modules for detecting a shelf spaceenvironment, and the indication modules for prompting are fixedly arranged on the shelves, and the cargo scanning modules, the sensor detection modules, and the indication modules are all connected with the shelf control modules; the shelf control modules and the shelves are arranged in a pairing mode, the multiple shelves are arranged, the number of the cloud server is one, and the shelf controlmodules are in parallel relationship. The cargo scanning modules are arranged on the shelves, instructions are sent to the control modules through the server, and picking of the cargos is more convenient and faster.

Owner:合肥软致供应链管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com