Preparation method of nanocellulose and polymer composite aerogel

A technology of nanocellulose and composite airgel, which is applied in the field of preparation of nanocellulose/polymer composite airgel, can solve the problems of complex preparation process of composite airgel, limitation of polymer types, and high cost of industrial production. Achieve the effect of simple and fast preparation process, low density and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples, and the chemical reagents and raw materials used in the following examples are analytically pure.

[0018] Example:

[0019] (1) 0.8 milliliters of mass concentration is the water dispersion liquid of the sisal cellulose nanofiber of 0.4% and 0.2 milliliters of mass concentration is the dichloromethane solution of the polylactic acid of 1% to mix and make mixed solution, then mixed solution is in power Sonicate in a 400W ultrasonic emulsifier for 5 minutes to prepare a Pickering emulsion gel containing polylactic acid in the stable oil phase of the gelled sisal cellulose nanofibers.

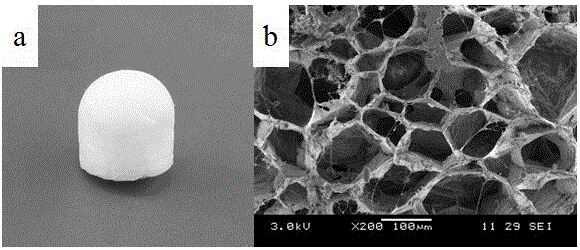

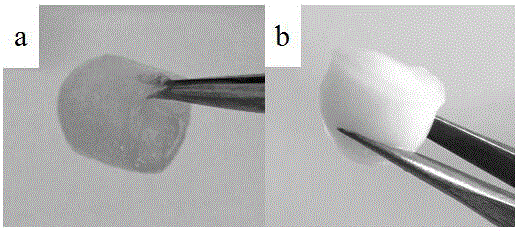

[0020] (2) Freeze the Pickering emulsion prepared in step (1) at -20°C for 24 hours, and then freeze it in a freeze dryer at -60°C with a vacuum of 10 Pa for 24 hours to obtain nanocellulose / Polylactic acid composite airgel (see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com