Cross-linked cellulose@molybdenum disulfide aerogel composite adsorbent as well as preparation method and application thereof

A technology of cellulose airgel and molybdenum disulfide, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., to achieve excellent adsorption capacity, excellent lead ion adsorption performance and adsorption selectivity, and solve the problem of water big damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A crosslinked cellulose @ disulfide molybdenum gel composite adsorbent is obtained by negative laminar molybdenum sulfide nanoparticles on the carrier; the carrier is a porous structure generated by cellulose crosslinked by epoxy chloropropane. The cellulose airgel, the inside of the carrier pore and the surface are uniformly distributed with a splitonal molybdenum nanoparticle; the innermost diameter of the carrier is 50-500 μm; the antlyptallidide nano particle size is 20-400 nm. The preparation method of the adsorbent includes the steps of:

[0033](1) The cellulose is added to a sodium hydroxide / urea mixture pre-cooled to -12 ° C, and the clear and transparent cellulose solution is obtained after high-speed stirring at 1000-2500 rpm; hydroxide in the sodium hydroxide / urea solution. The sodium mass fraction is 7-9 wt%, the urea mass fraction is 12-14 wt%; the ratio of the quality of the cellulose and the volume of sodium hydroxide / urea mixed solution is 30-50 μg / ...

Embodiment 1

[0037] Example 1: Crosslinked cellulose @ 二 二 molybdenum gel composite adsorbent

[0038] Step (1): Take 5 g of cellulose dissolved in 7 wt% / 9 wt% of 100 g of a 7 wt% / 9 wt% sodium hydroxide / urea mixed solution, stirring at high speed at 2000 rpm to give a clear and clear cellulose solution.

[0039] Step (2): Take 8G MOS 2 In the cellulose solution obtained from step (1), ultrasonic stirring was 30 min to obtain a uniformly dispersed diombite / cellulose suspension.

[0040] Step (3): Add 15 mL of epoxy chloropropane to step (2) to the mixing solution obtained using a peristaltic pump, followed by stirring at 300 rpm, and the resulting mixed solution is reacted at 60 ° C for 2 h.

[0041] Step (4): Use deionized water and anhydrous ethanol to remove the hydrogel obtained by step (3) to neutral, pre-freeze at -35 ° C for 12 h, then vacuum dried at -50 ° C to obtain a sulfide solution Floor cellulose airgel composite adsorbent.

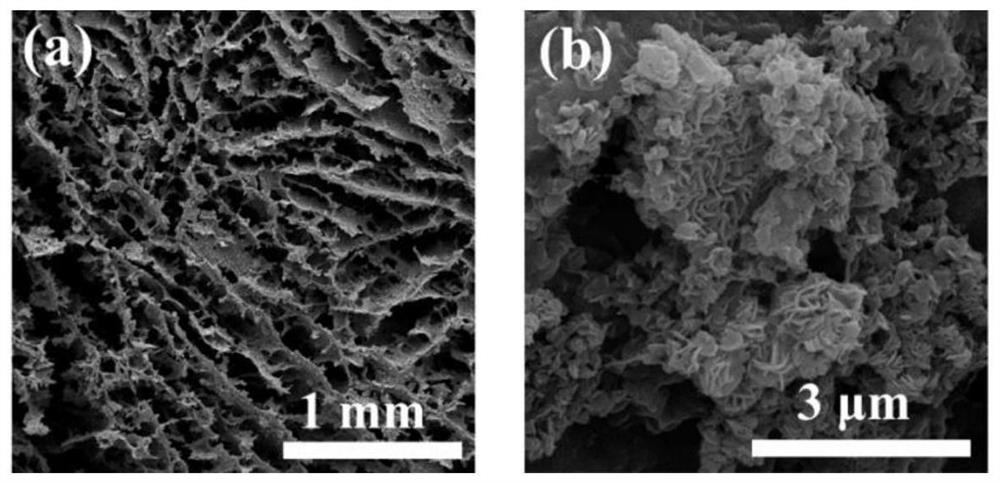

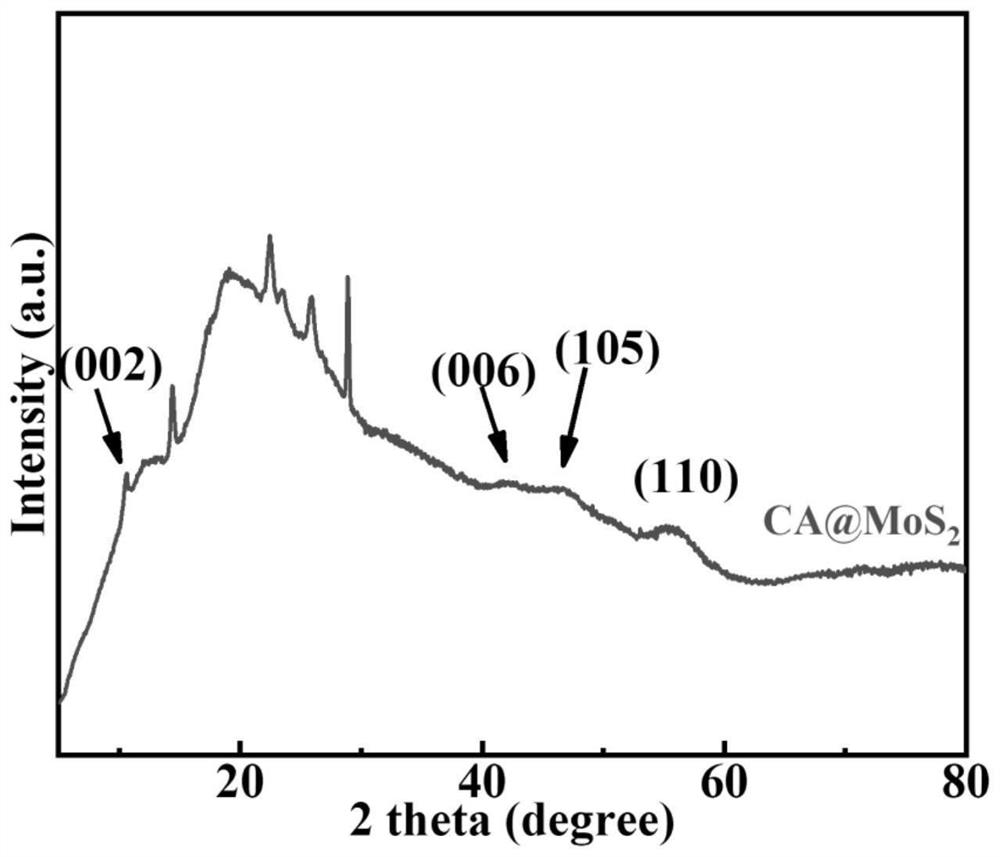

[0042] like figure 1 As shown, the scanning ele...

Embodiment 2

[0043] Example 2: Crosslinked cellulose @ 二 钼 钼 复 吸 吸 吸 吸 应用 子 吸 附

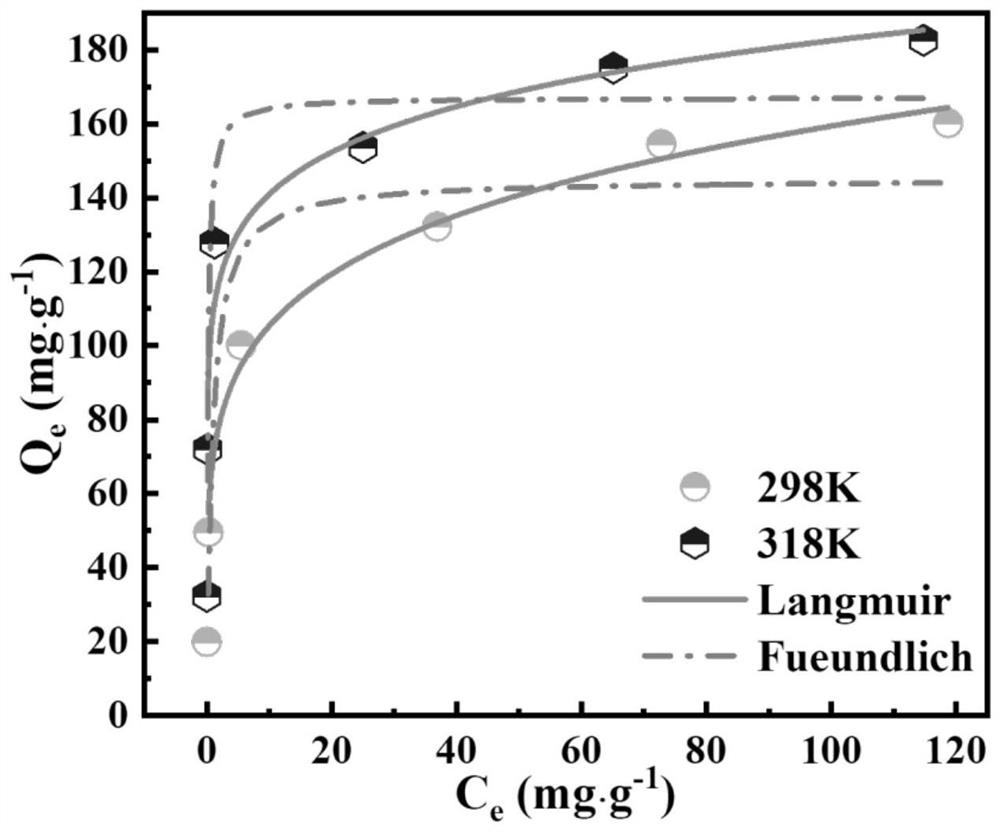

[0044] 25mg Ca @ MOS 2 The composite adsorbents were added to 50 ml of different concentrations of lead ion solution, and the solution concentration ranged from 5 to 500 mg / g, and the temperature of 25 ° C and 45 ° C, pH were controlled at 4.5 ± 0.3. Elever 24 hours to ensure adsorption balance. Take the supernatant to measure the residual lead ion concentration of the solution, resulting in a balanced adsorption amount at different initial lead ion concentrations, and the maximum adsorption amount at 25 ° C is 160 mg / g, 45 ° C is sucking up to 180 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com