Graphene oxide/cellulose compound material as well as preparation method and application of same

A composite material and cellulose technology, applied in the field of material science, can solve problems such as no literature and patent reports, and achieve the effects of no pollution in the water system, simple equipment, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 2g of dry graphite oxide and dissolve it in 400mL of deionized water, and peel off the graphite oxide by ultrasonication for 0.5h in an ultrasonic device with a power of 400W to obtain a 5mg / mL graphite oxide solution. Cellulose solvent sodium hydroxide / urea / thiourea / deionized water according to the weight ratio of 7:7:10:76 to configure 200g solution, freeze at -5°C for 6h in a low temperature cooling device, add 1g of absorbent cotton, at 0 Stirring at ℃ for 12h, slowly rising to room temperature under stirring conditions to obtain a cellulose solution with a mass fraction of 0.5%. Take 50g of the above-mentioned cellulose solution and slowly add 25mL of graphite oxide solution, and stir for 0.5h to obtain a uniform slurry. The slurry was filtered with a polytetrafluoroethylene membrane, washed with deionized water until neutral to obtain a graphene oxide / cellulose composite membrane.

Embodiment 2

[0037] Weigh 0.5 g of dry graphite oxide and dissolve it in 200 mL of deionized water, and peel off the graphite oxide by ultrasonication for 2 h in an ultrasonic device with a power of 600 W to obtain a 2.5 mg / mL graphite oxide solution. Cellulose solvent Potassium hydroxide / urea / thiourea / deionized water is prepared in a weight ratio of 10:6:9:75 to prepare 200g solution, freeze at 0°C for 6 hours in a low-temperature cooling device, add 100g of absorbent cotton, and freeze at -5 Stir at ℃ for 12 h, and slowly rise to room temperature under stirring conditions to obtain a cellulose solution with a mass fraction of 50%. Take 50g of the above-mentioned cellulose solution and slowly add 100mL of graphite oxide solution, and stir for 0.5h to obtain a uniform slurry. The slurry was filtered with a polytetrafluoroethylene membrane, washed with deionized water until neutral, and dried in vacuum at 80°C to obtain a light gray graphene / cellulose material. Put the above-mentioned comp...

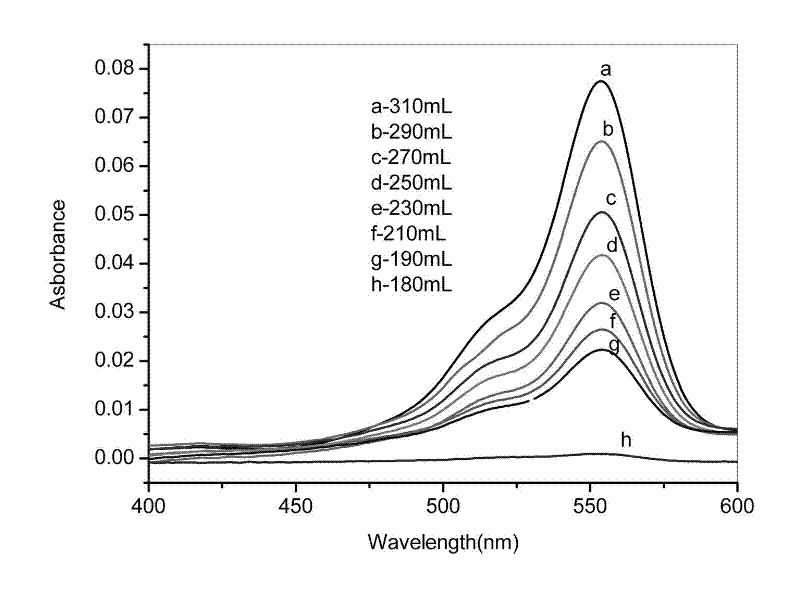

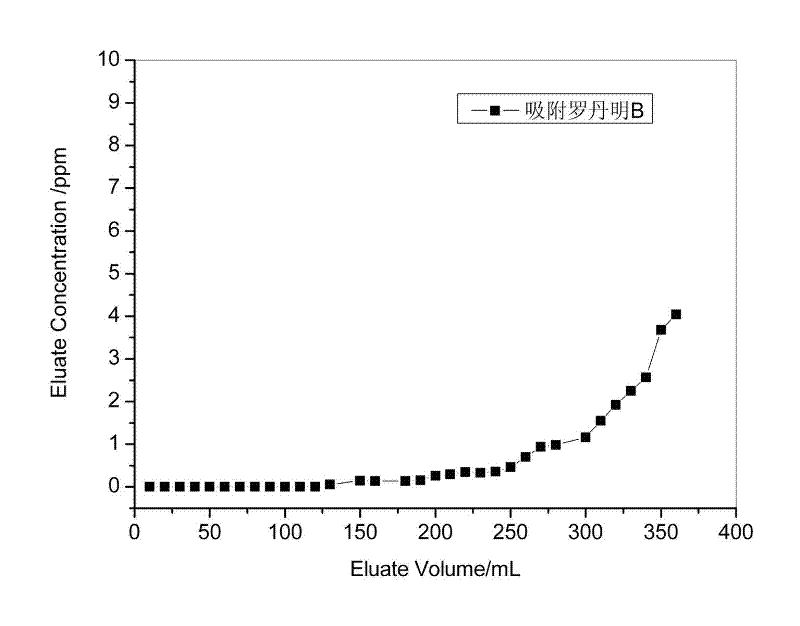

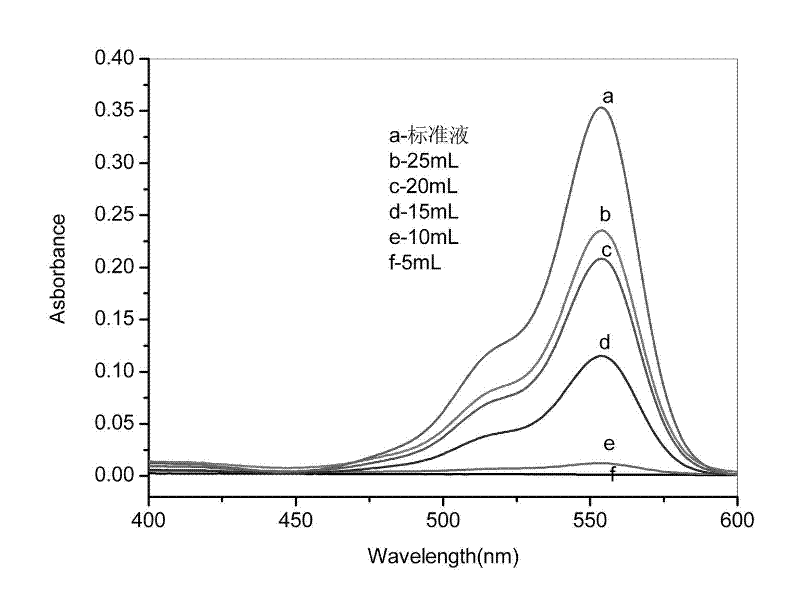

Embodiment 3

[0039] Weigh 2g of dry graphite oxide and dissolve it in 300mL of deionized water, shear it in a shearing device at 10000rpm for 0.5h to peel off the graphite oxide, and then centrifuge to remove the unstripped graphite oxide to obtain a graphite oxide solution with a concentration of 5mg / mL. Prepare 200g solution of sodium hydroxide / urea / thiourea / deionized water in a ratio of 10:5:8:77 by weight, freeze at -5°C for 3 hours in a low-temperature cooling device, add 10g of qualitative filter paper, and freeze at -10 Stir at ℃ for 12h. Slowly rise to room temperature with stirring to obtain a cellulose solution with a mass fraction of about 2%. Take 25g of the above-mentioned cellulose solution, slowly add 100mL of graphite oxide solution, and cut in a shearing device for 0.5h to obtain a uniform slurry. The slurry was filtered with a 4# sand core funnel, washed with deionized water until neutral, and vacuum-dried at 100°C for 12 hours to obtain a graphene oxide / cellulose compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com