Cellulose-heteropoly acid proton exchange membrane for electrochemical sensor and preparation method therefor

A proton exchange membrane and cellulose technology, applied in the field of cellulose-heteropolyacid proton exchange membranes for electrochemical sensors, can solve the problems of increasing the complexity of the system, reducing the sensitivity and reliability of the catalytic layer, and achieving simple processing and molding , low cost, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

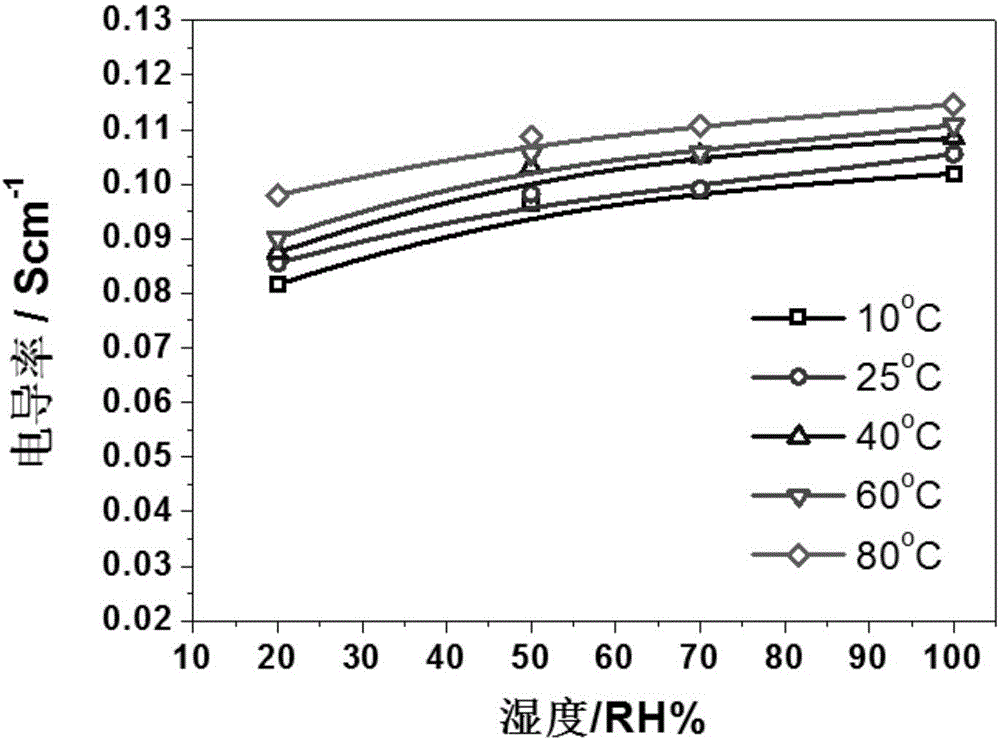

Embodiment 1

[0029] A preparation method of cellulose-heteropolyacid proton exchange membrane for electrochemical sensor, comprising the following steps:

[0030] (1) Mix wood pulp cellulose with a polymerization degree of 600, sodium hydroxide, urea, and water in a mass ratio of 1:0.3:0.2:5, and stir in an ice bath for 4 hours to obtain a cellulose carbamate solution;

[0031] (2) Add phosphotungstic acid with a mass ratio of 0.3 (relative to cellulose) into the cellulose carbamate solution prepared in step (1), and stir at room temperature for 2 hours to obtain a phosphotungstic acid-cellulose carbamate solution;

[0032] (3) Scrape-coat the phosphotungstic acid-cellulose carbamate solution prepared in step (2) into a liquid film, and after volatilizing the solvent at 95°C, soak it in 0.5 mol / liter sulfuric acid for 10 minutes to make the cellulose carbamate The acid ester is regenerated into cellulose, then washed with deionized water for 1-3 times, and dried at 80-100°C to obtain a cel...

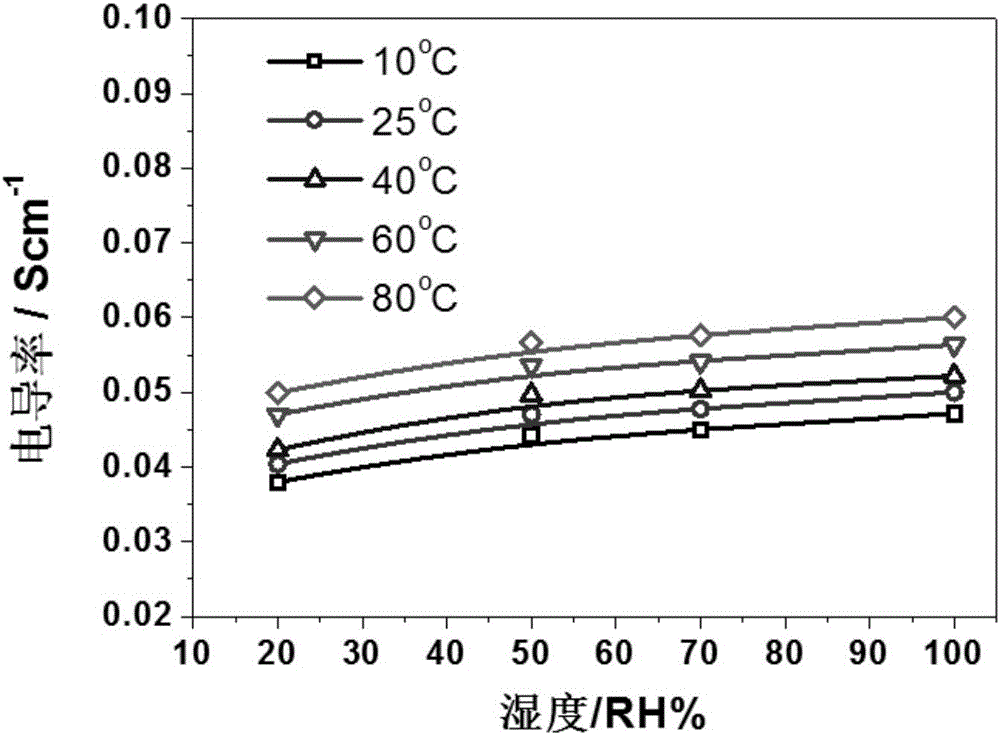

Embodiment 2

[0037] A preparation method of cellulose-heteropolyacid proton exchange membrane for electrochemical sensor, comprising the following steps:

[0038] (1) Mix cotton pulp cellulose with a polymerization degree of 300, sodium hydroxide, urea, and water in a mass ratio of 1:0.05:0.1:20, and stir in an ice bath for 1 hour to obtain a cellulose carbamate solution;

[0039] (2) Add silicotungstic acid with a mass ratio of 0.1 (relative to cellulose) into the cellulose carbamate solution prepared in step (1), and stir at room temperature for 0.5h to obtain a silicotungstic acid-cellulose carbamate solution ;

[0040] (3) Scrape-coat the silicotungstic acid-cellulose carbamate solution prepared in step (2) into a liquid film, and after volatilizing the solvent at 60°C, soak it in 0.1 mol / liter sulfuric acid for 5 minutes to make the cellulose carbamate The acid ester was regenerated into cellulose, then washed once with deionized water, and dried at 100°C to obtain a cellulose-silico...

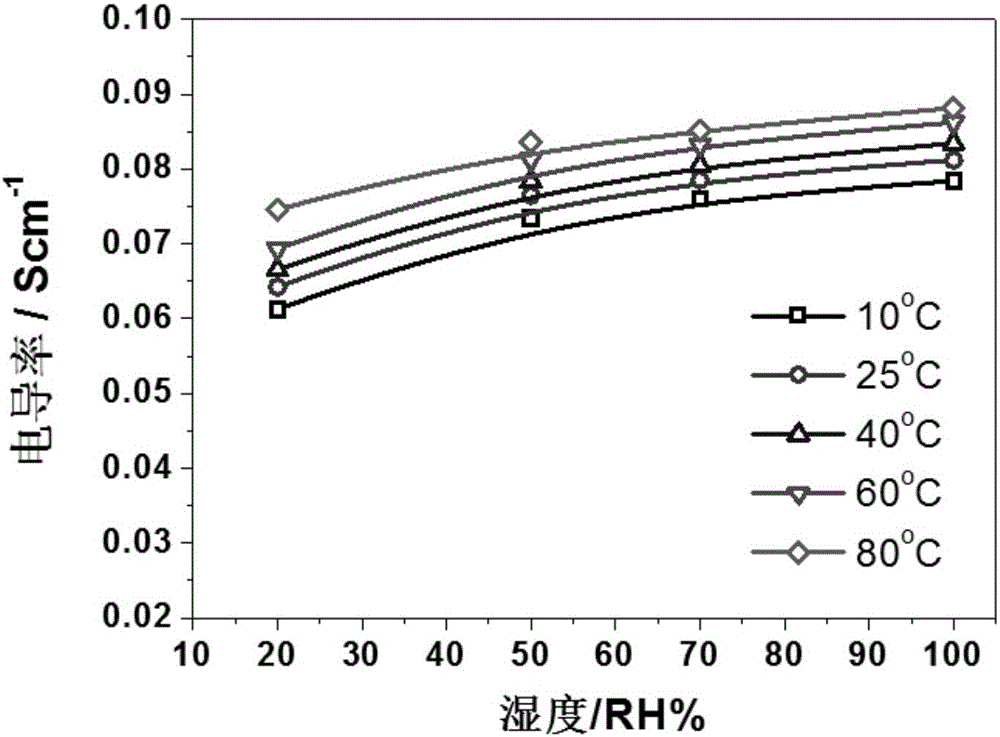

Embodiment 3

[0044] A preparation method of cellulose-heteropolyacid proton exchange membrane for electrochemical sensor, comprising the following steps:

[0045] (1) Mix wood pulp cellulose with a degree of polymerization of 400, sodium hydroxide, urea, and water in a mass ratio of 1:0.4:0.14:12, and stir in an ice bath for 3 hours to obtain a cellulose carbamate solution;

[0046] (2) Add phosphomolybdic acid with a mass ratio of 0.24 (relative to cellulose) into the cellulose carbamate solution prepared in step (1), and stir at room temperature for 1 h to obtain a phosphomolybdic acid-cellulose carbamate solution;

[0047] (3) Scrape-coat the phosphomolybdic acid-cellulose carbamate solution prepared in step (2) into a liquid film, and after volatilizing the solvent at 75°C, soak it in 1 mol / liter of sulfuric acid for 30 minutes to make the cellulose carbamate The ester was regenerated into cellulose, then washed twice with deionized water, and dried at 80°C to obtain a cellulose-phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com