Preparation method of antibacterial hydrogel

A hydrogel and hemicellulose technology, which is applied in the field of antibacterial hydrogel preparation, can solve the problem that it is difficult to apply antibacterial hydrogel to hemicellulose raw materials, and achieve excellent antibacterial effect, low energy consumption, and low reaction temperature conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

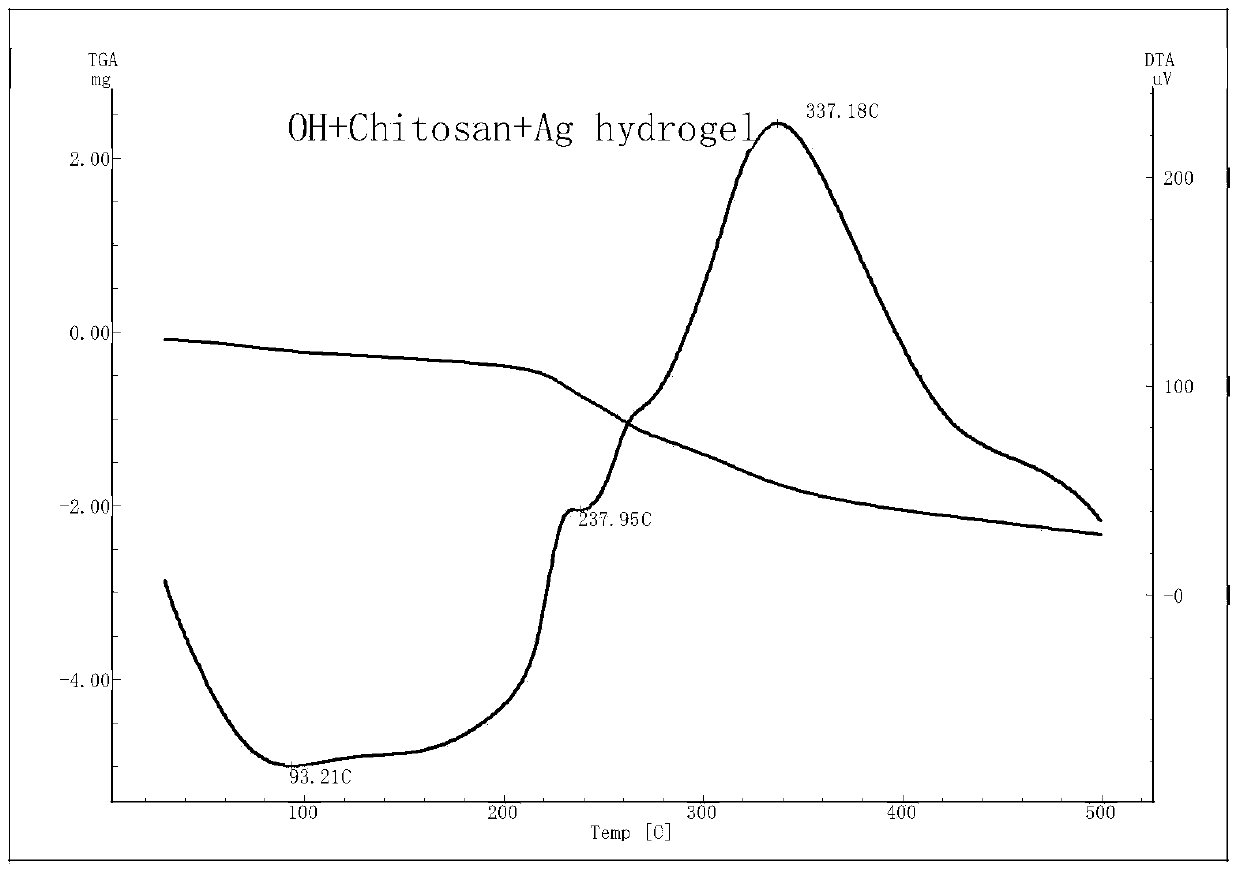

Image

Examples

Embodiment 1

[0025] In the first step, add 1g of sodium periodate and 2g of hemicellulose into 10ml of water, stir until completely dissolved, add NaOH solution to adjust the pH value to neutral, and stir in a 37°C water bath for 12h. After the reaction is completed, the mixed solution is centrifuged, washed with water for 3 times, and dried to obtain dialdehyde hemicellulose;

[0026] Second step, 1g chitosan is dissolved in the acetic acid solution of 2v / v%, stirs until dissolving completely, obtains the chitosan solution of 5wt%;

[0027] In the third step, 1 g of dialdehyde hemicellulose is dissolved in water, stirred and centrifuged to obtain a suspension of 5 wt % dialdehyde hemicellulose;

[0028] The fourth step is to mix the dialdehyde hemicellulose solution with the chitosan solution, adjust the pH value to neutral, place the mixed solution in a 45°C water bath and stir for 10 hours, then continue to heat up to 90°C for 60 minutes, and obtain water after cooling A mixture of gel...

Embodiment 2

[0034] In the first step, add 1g of sodium periodate and 2g of hemicellulose into 10ml of water, stir until completely dissolved, add NaOH solution to adjust the pH value to neutral, and stir in a 37°C water bath for 12h. After the reaction is completed, the mixed solution is centrifuged, washed with water for 3 times, and dried to obtain dialdehyde hemicellulose;

[0035] Second step, 0.5g chitosan is dissolved in the acetic acid solution of 1v / v%, stirs until dissolving completely, obtains the chitosan solution of 2wt%;

[0036] In the third step, 2g of dialdehyde hemicellulose is dissolved in water, stirred and centrifuged to obtain a 10wt% suspension of dialdehyde hemicellulose;

[0037] The fourth step is to mix the dialdehyde hemicellulose solution with the chitosan solution, adjust the pH value to neutral, place the mixed solution in a 45°C water bath and stir for 10 hours, then continue to heat up to 90°C for 60 minutes, and obtain water after cooling A mixture of gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com