Recyclable anti-collapse type polymer mud and preparation method thereof

A polymer and anti-slump technology, applied in the direction of drilling compositions, chemical instruments and methods, chemical/physical/physicochemical fixed reactors, etc., can solve the inconvenience of conveying components, the inability to clean mud, and the adjustment of conveying tracks and other issues, to achieve the effect of saving costs, improving construction safety and construction quality, and preventing expansion and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

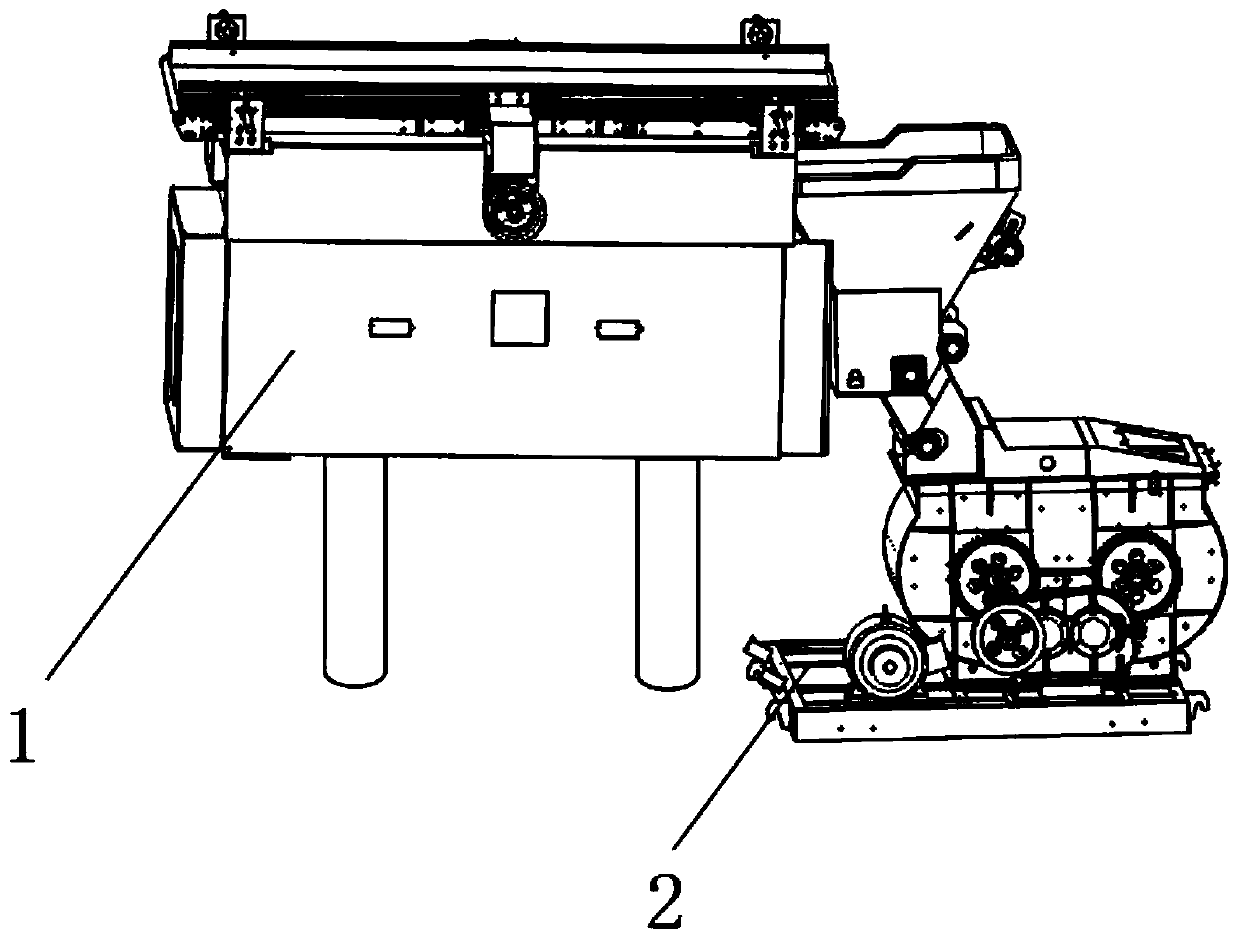

[0039] see Figure 1-7 Shown, a kind of recyclable anti-slump type polymer mud, this anti-slump type polymer mud is prepared by following raw materials by weight: 2.5 parts of vegetable gums, 4 parts of sulfonate copolymers, 70 parts of wood fiber powders , 2000.05 parts of polyethylene glycol, 0.1 part of polyacrylamide, 30 parts of soda ash, 70 parts of water;

[0040] The anti-collapse type polymer mud is prepared through the following steps:

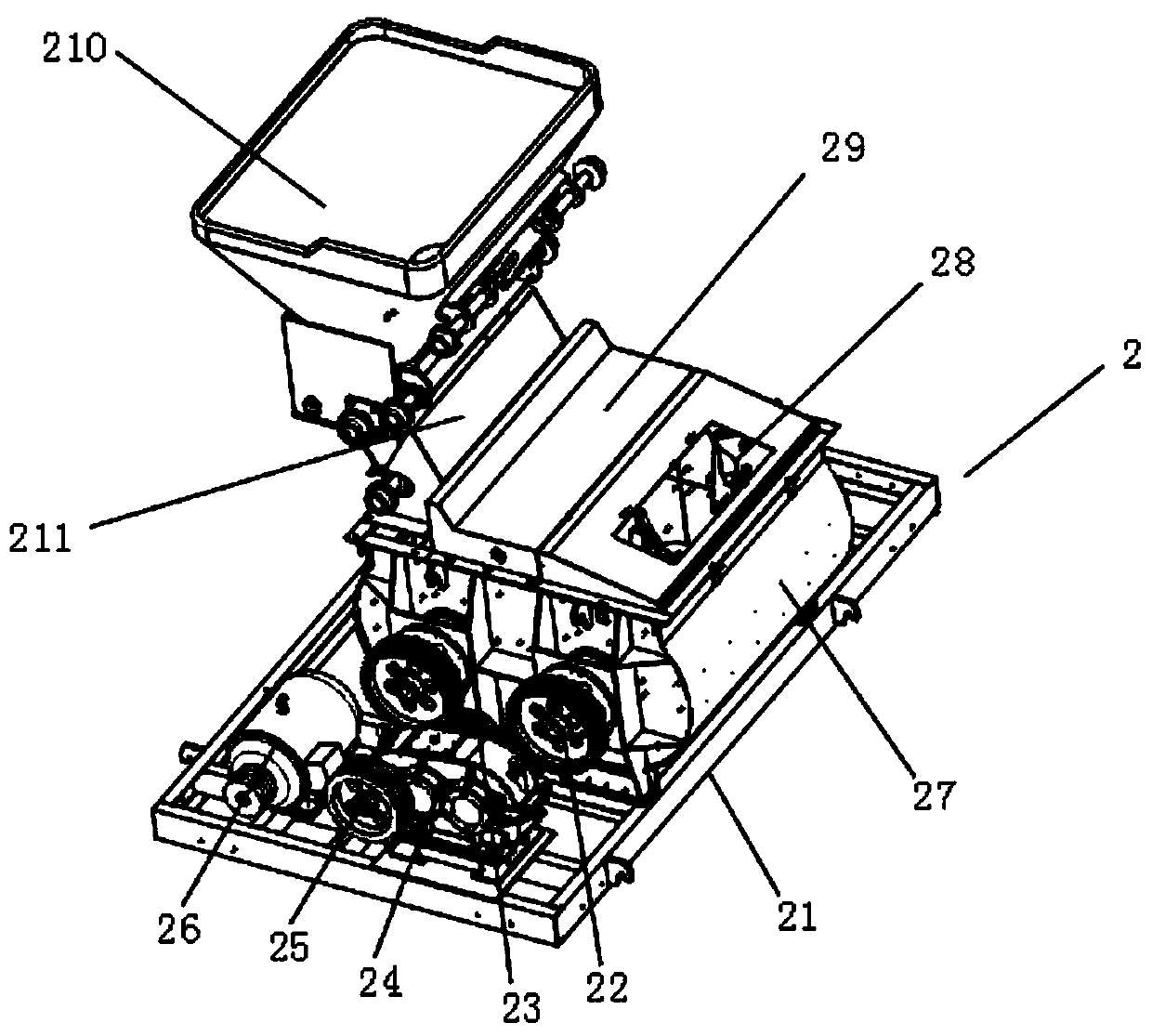

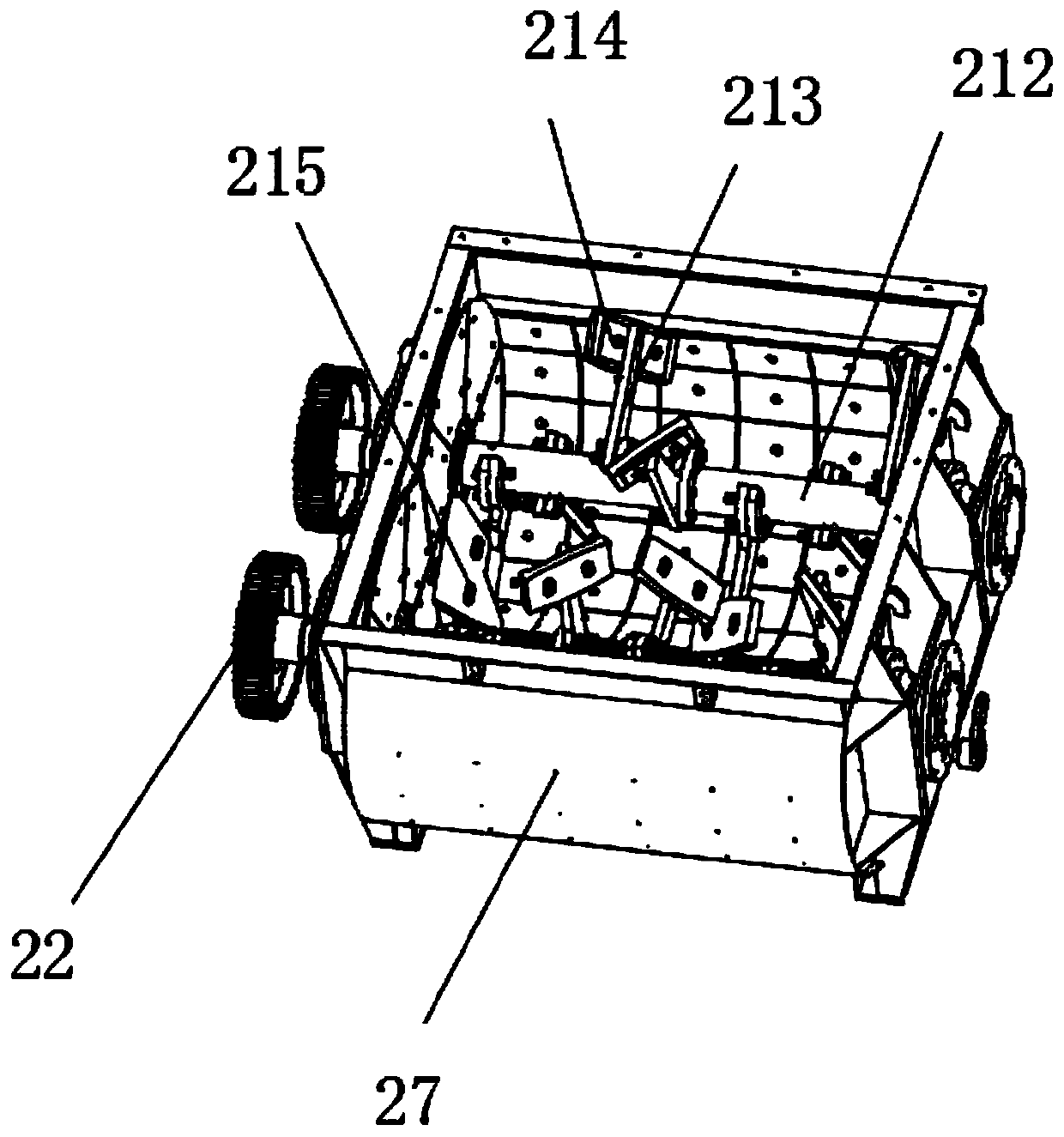

[0041] Step 1. Weigh the above raw materials in various parts by weight, then add water into the polymerization cylinder 27 of the polymerization equipment, drive the rotating motor 26, drive the synchronous pulley 25 to rotate through the belt, and after the synchronous pulley 25 is decelerated by the gear box 24, Drive the second gear 23 to rotate, the second gear 23 drives the first gear 22 to rotate, the first gear 22 drives the rotating shaft 212 to rotate, the rotating speed is 400r / min, the rotating shaft 212 drives the first...

Embodiment 2

[0046] see Figure 1-7 Shown, a kind of recyclable anti-slump type polymer mud, this anti-slump type polymer mud is prepared by following raw materials by weight: 5 parts of vegetable gums, 11 parts of sulfonate copolymers, 80 parts of wood fiber powders , 2000.1 parts of polyethylene glycol, 0.2 parts of polyacrylamide, 60 parts of soda ash, and 110 parts of water;

[0047] The anti-slump polymer slurry is prepared through the following steps: the preparation method is the same as in Example 1.

Embodiment 3

[0049] see Figure 1-7 Shown, a kind of recyclable anti-slump type polymer mud, this anti-slump type polymer mud is prepared by following raw materials by weight: 3 parts of plant gums, 8 parts of sulfonate copolymers, 75 parts of wood fiber powders , 2000.1 parts of polyethylene glycol, 0.1 part of polyacrylamide, 50 parts of soda ash, and 100 parts of water;

[0050] The anti-slump polymer slurry is prepared through the following steps: the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com