Preparation method of anti-shrink silk-linen fabric

An anti-shrinkage and fabric technology, applied in physical treatment, plant fibers, animal fibers, etc., can solve the problems of high shrinkage rate of silk and linen fabrics, anti-shrinkage technology can not meet the relevant standards, affecting the performance and dimensional stability of fabrics, etc. To achieve the effect of simple and easy operation, improved performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

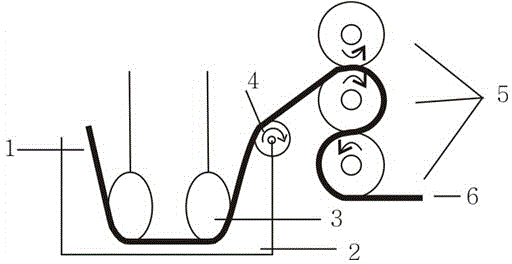

[0035] Such as figure 1 Shown is the padding tank that needs to be used in chemical finishing. The unimpregnated fabric 1 first passes through the impregnation tank 2 filled with impregnation liquid, and is impregnated for 30 minutes under the action of the impregnation roller 3, and then the impregnated fabric is introduced into the pressure roller 5 through the cloth guide roller 4, and the excess finishing liquid in the fabric is impregnated. The fabric that is rolled out by the roller is the fabric that is padded, and finally the padding process is repeated.

[0036] Concrete preparation process is as follows:

[0037] (1) Physical shrinkage

[0038] Soak the silk and linen fabric in a constant temperature water bath at 65°C for 60 minutes, then move it into an electric blast oven, and dry it at 65°C for 5 minutes to obtain a preshrunk silk and linen fabric;

[0039] (2) chemical finishing

[0040] ① Preparation of finishing solution: finishing solution includes ci...

Embodiment 2

[0062] use figure 1 The padding tank shown. Concrete preparation process is as follows:

[0063](1) Physical shrinkage

[0064] Soak the silk and linen fabric in a constant temperature water bath at 30°C for 90 minutes, then move it into an electric blast oven, and dry it at 95°C for 25 minutes to obtain a preshrunk silk and linen fabric;

[0065] (2) chemical finishing

[0066] ① Preparation of finishing solution: finishing solution includes citric acid, polymaleic acid, sodium hypophosphite, triethanolamine, boric acid, fatty alcohol polyoxyethylene ether;

[0067] The composition of described finishing solution is:

[0068] Citric acid 40g / L

[0069] Polymaleic acid 20g / L

[0070] Sodium hypophosphite 40g / L

[0071] Triethanolamine 20g / L

[0072] Boric acid 4g / L

[0073] Fatty alcohol polyoxyethylene ether 3g / L

[0074] Weigh the above amount of chemical finishing agent, and then add deionized water to prepare 1000mL finishing s...

Embodiment 3

[0088] use figure 1 The padding tank shown. Concrete preparation process is as follows:

[0089] (1) Physical shrinkage

[0090] Soak the silk and linen fabric in a constant temperature water bath at 80°C for 120 minutes, then move it into an electric blast oven, and dry it at 80°C for 10 minutes to obtain a preshrunk silk and linen fabric;

[0091] (2) chemical finishing

[0092] ① Preparation of finishing solution: finishing solution includes citric acid, polymaleic acid, sodium hypophosphite, triethanolamine, boric acid, fatty alcohol polyoxyethylene ether;

[0093] The composition of described finishing solution is:

[0094] Citric acid 50g / L

[0095] Polymaleic acid 16.67g / L

[0096] Sodium hypophosphite 50g / L

[0097] Triethanolamine 25g / L

[0098] Boric acid 6g / L

[0099] Fatty alcohol polyoxyethylene ether 4g / L

[0100] Weigh the above amount of chemical finishing agent, and then add deionized water to prepare 1000mL fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com