Patents

Literature

33 results about "Wellbore instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

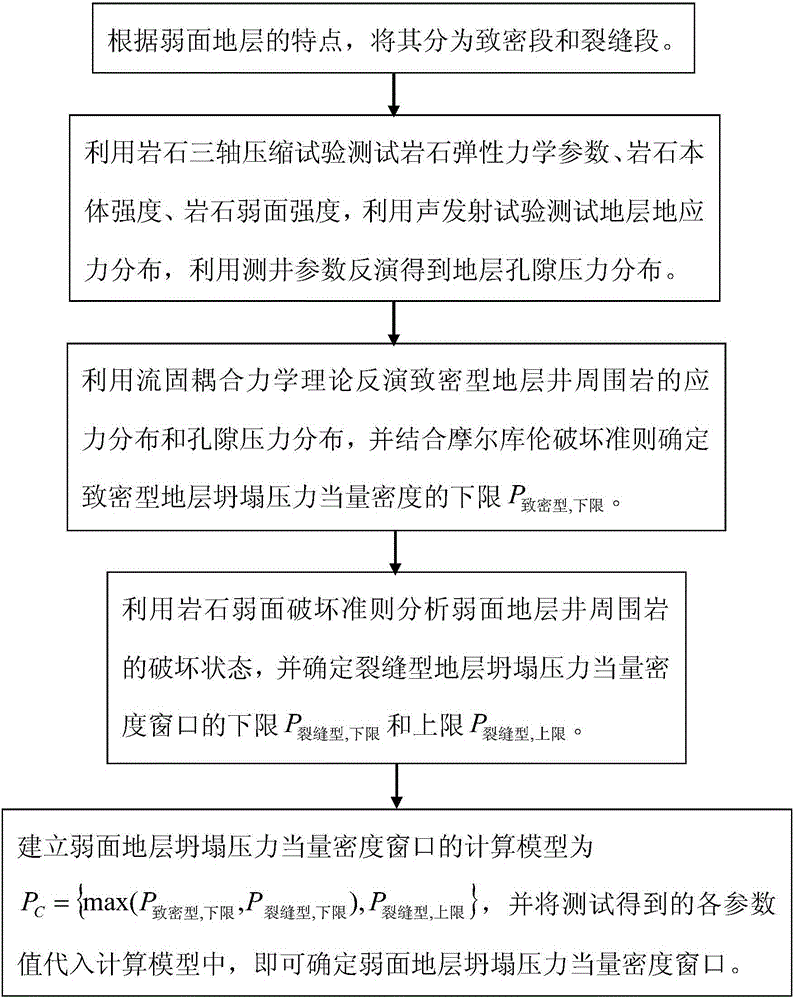

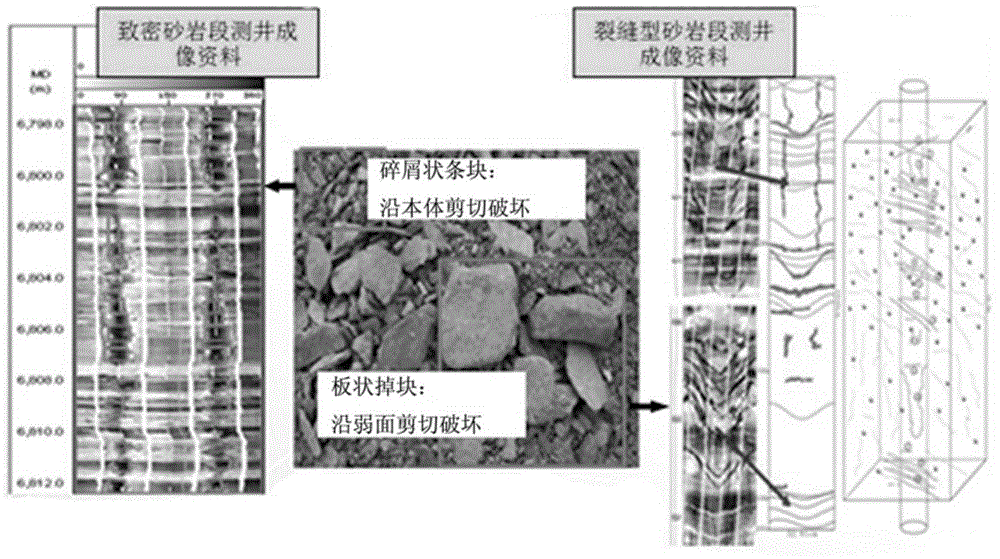

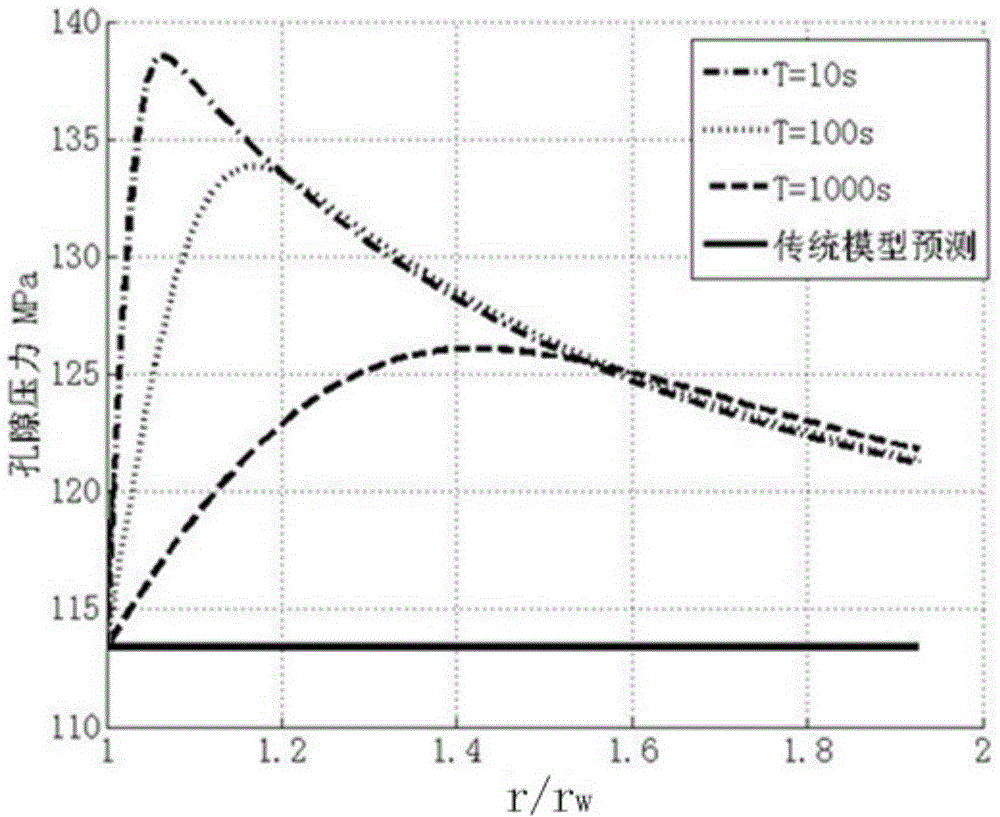

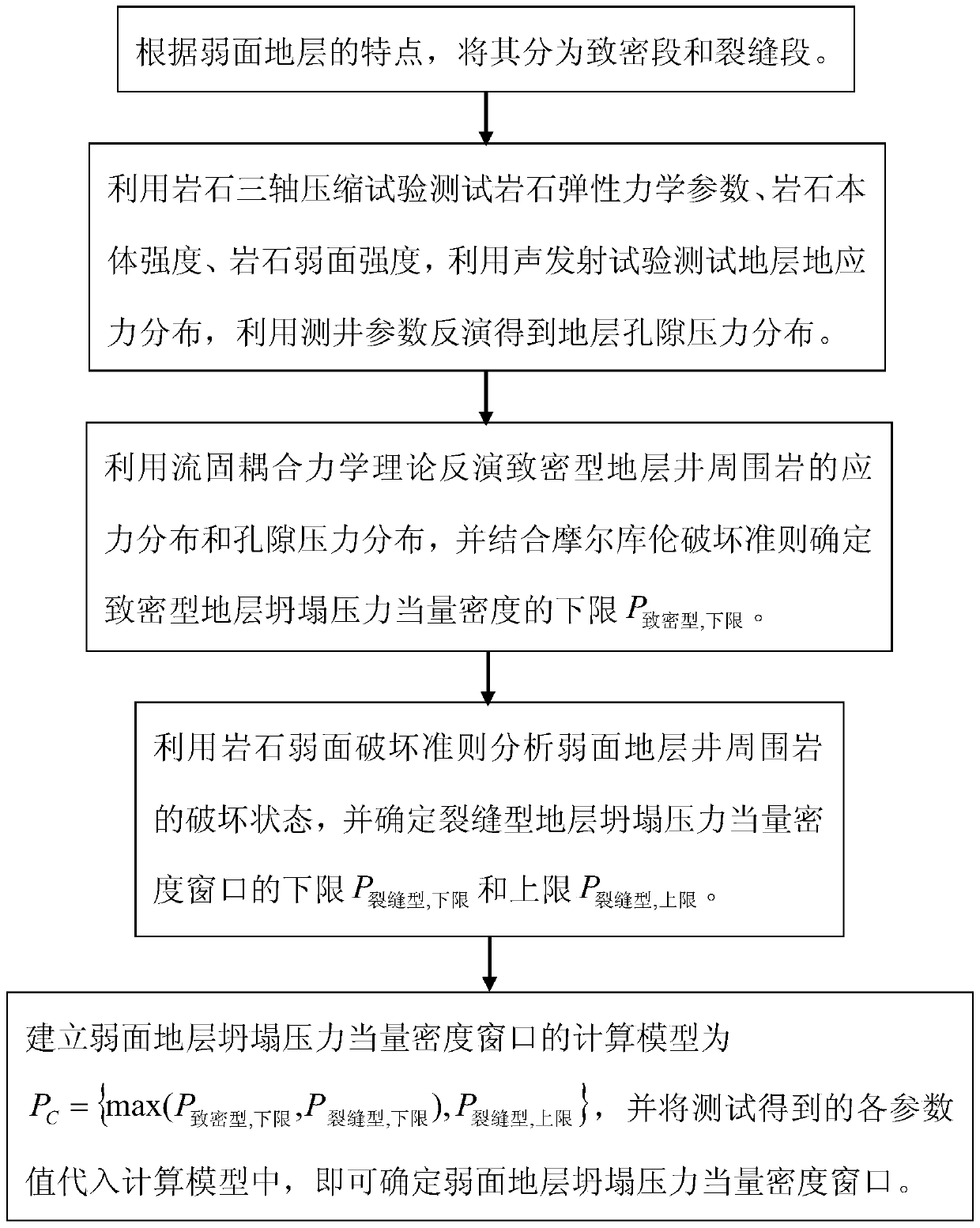

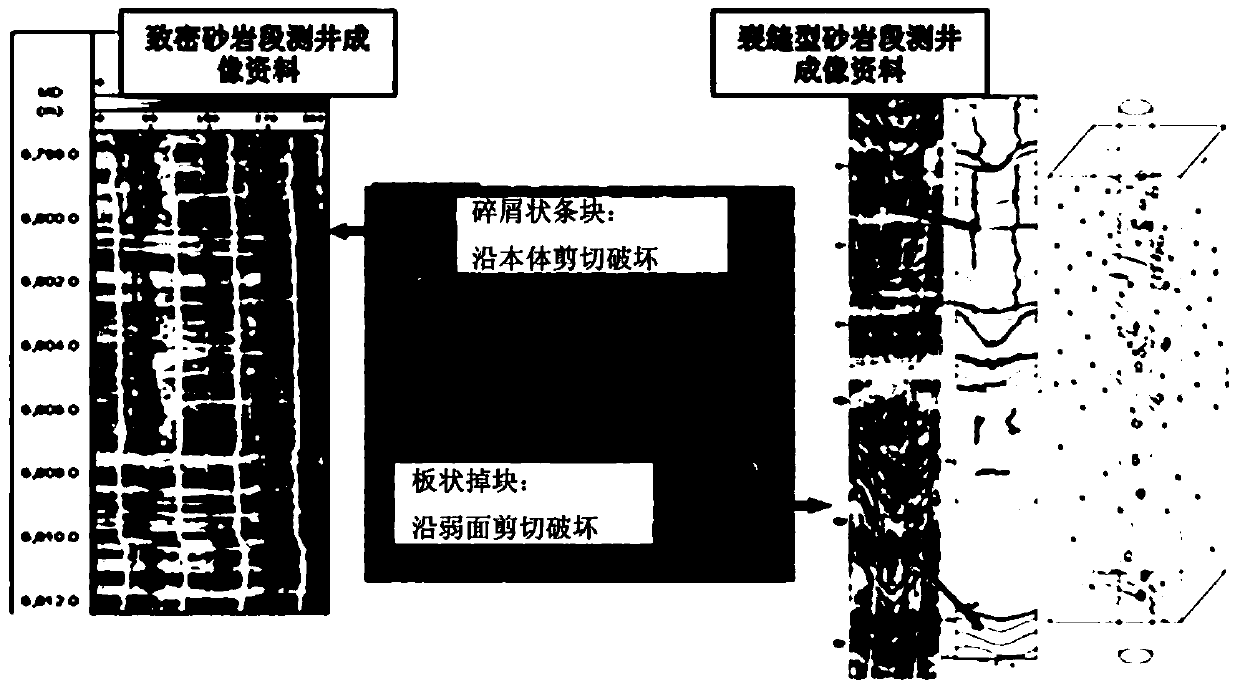

Method for forecasting weak plane formation collapse pressure equal yield density window

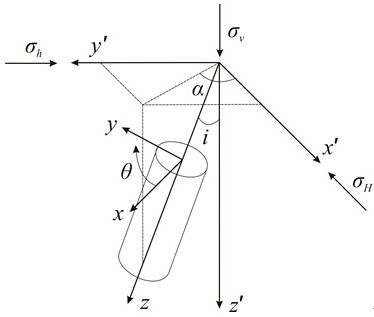

ActiveCN104806233AAvoid instabilityPrevent downhole complicationsBorehole/well accessoriesLower limitStress distribution

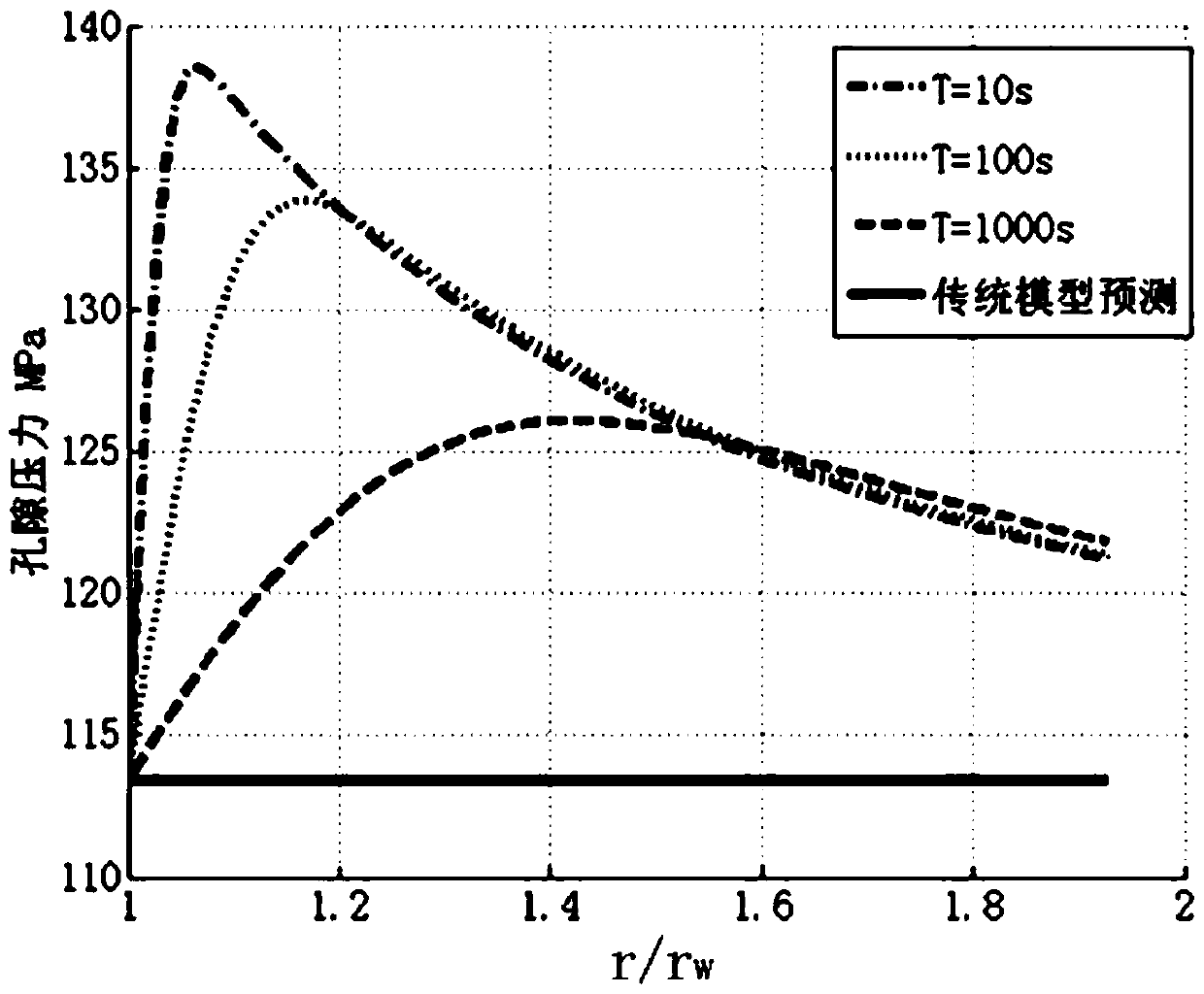

The invention discloses a method for forecasting a weak plane formation collapse pressure equal yield density window. The method sequentially includes the steps: dividing a weak plane formation into a compact section and a crack section according to characteristics of the weak plane formation; testing the strength of a rock body and the strength of a weak plane of a rock by the aid of the triaxial compression test of the rock; inverting stress distribution and pore pressure distribution of surrounding rocks of a compact formation well by the aid of a fluid-solid coupling model, and determining the lower limit of the collapse pressure equal yield density of a compact formation according to Mohr-coulomb failure criteria; analyzing the failure state of the surrounding rocks of the weak plane formation well according to the rock weak plane failure criteria, and determining the lower limit and the upper limit of the collapse pressure equal yield density window of a crack formation; building a weak plane formation collapse pressure equal yield density window calculation model, substituting parameter values into the model and then determining the weak plane formation collapse pressure equal yield density window. The weak plane formation collapse pressure equal yield density window can be forecasted before drilling, so that drilling fluid density is reasonably selected, and wellbore instability is effectively stopped.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

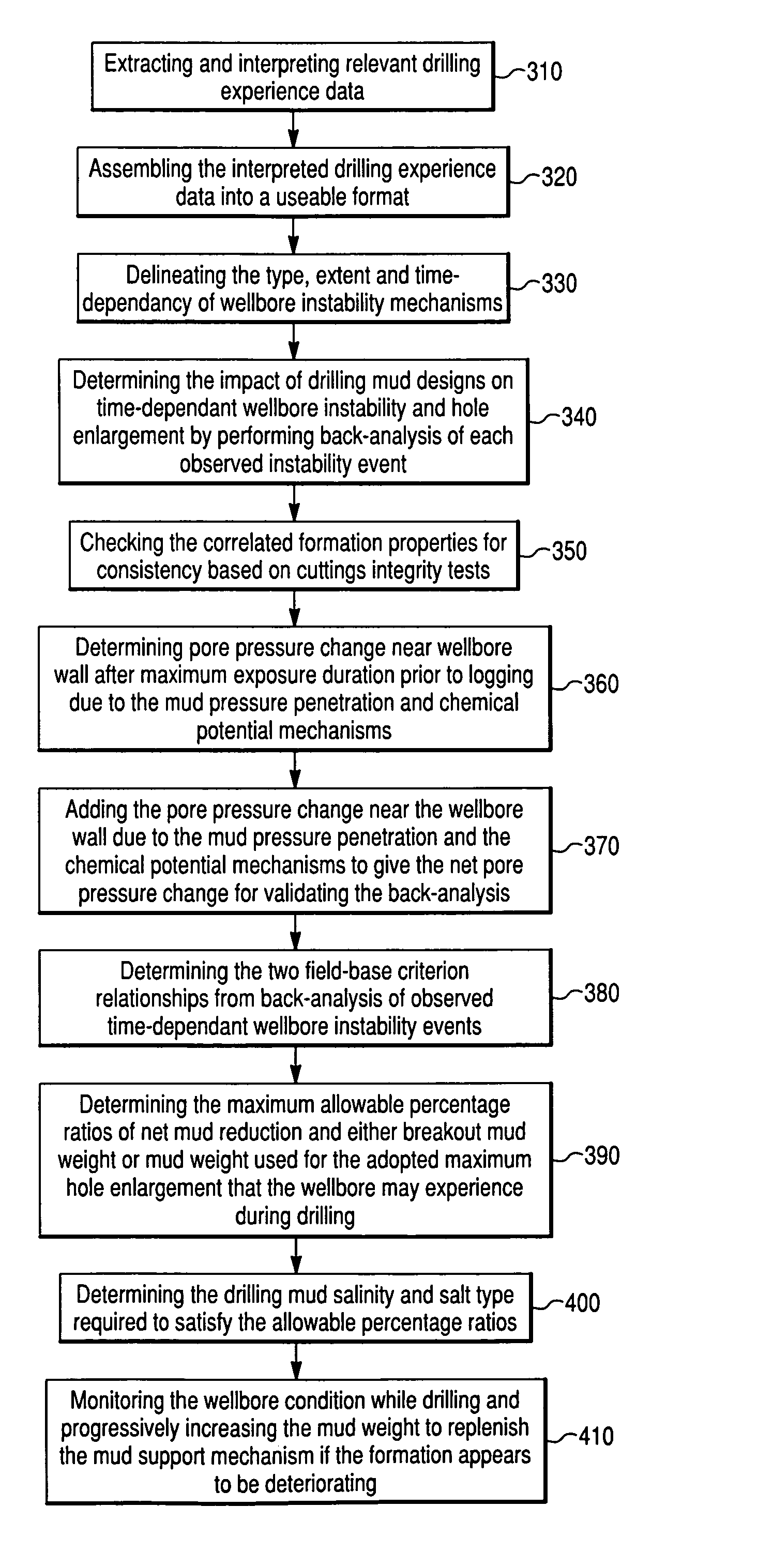

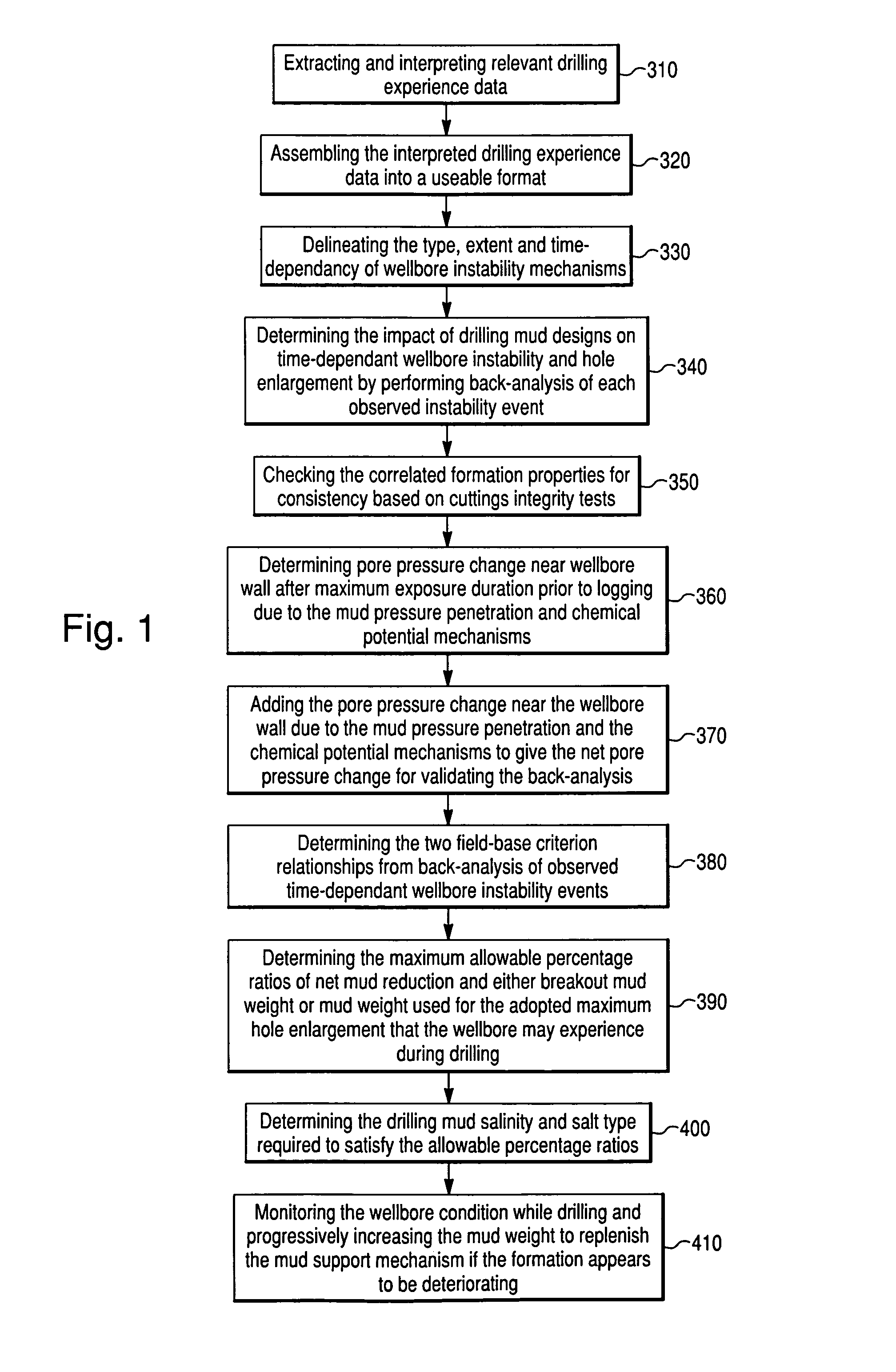

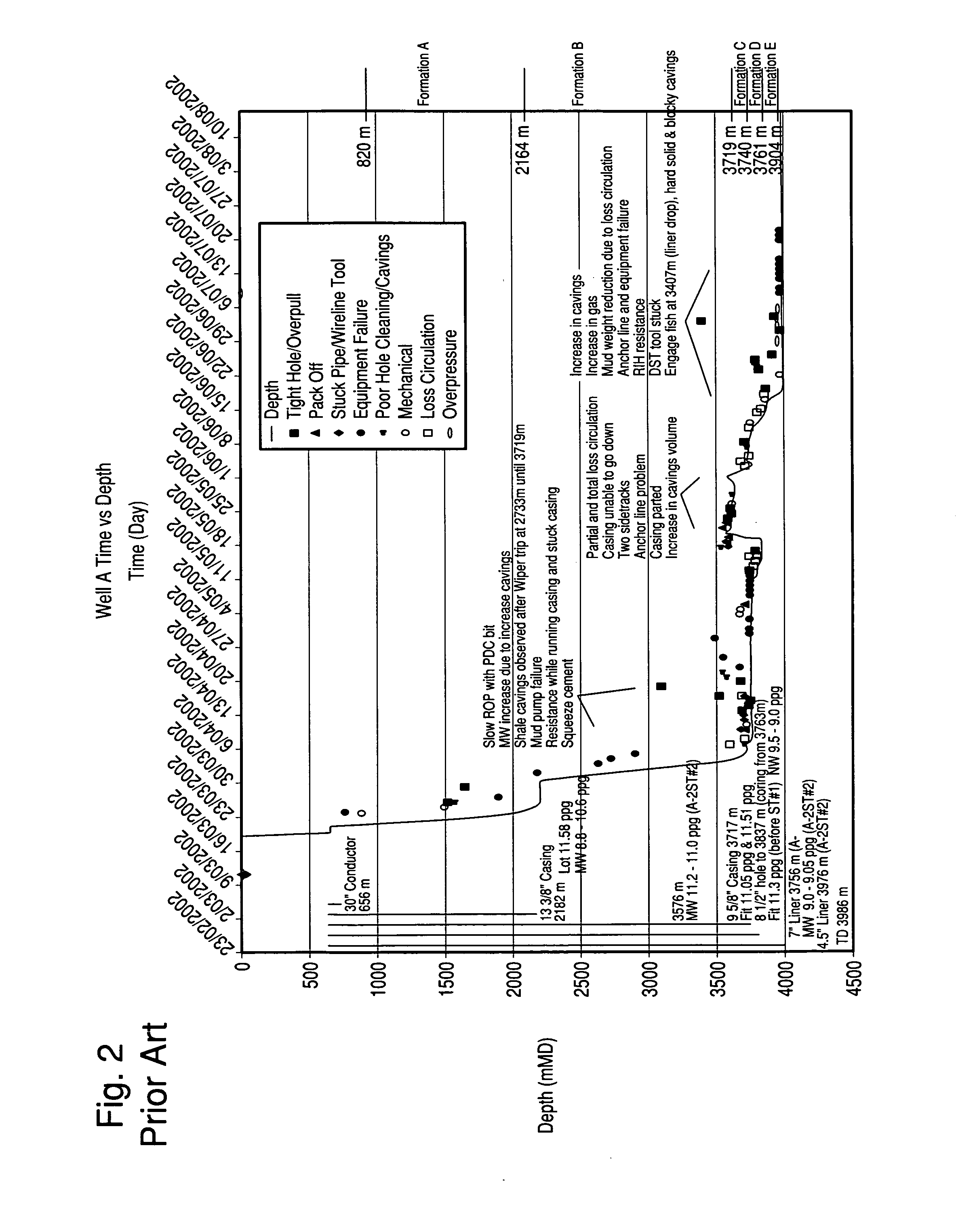

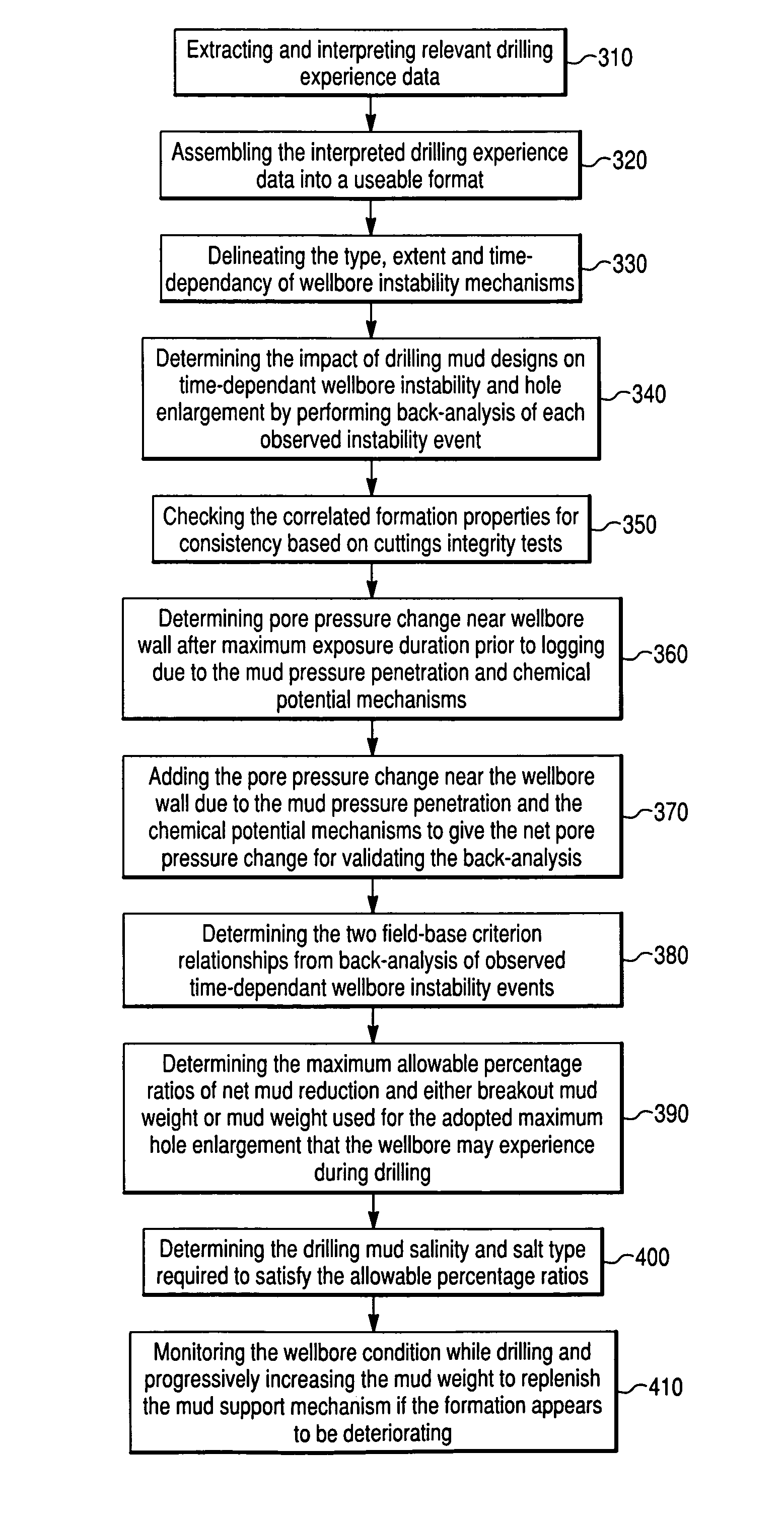

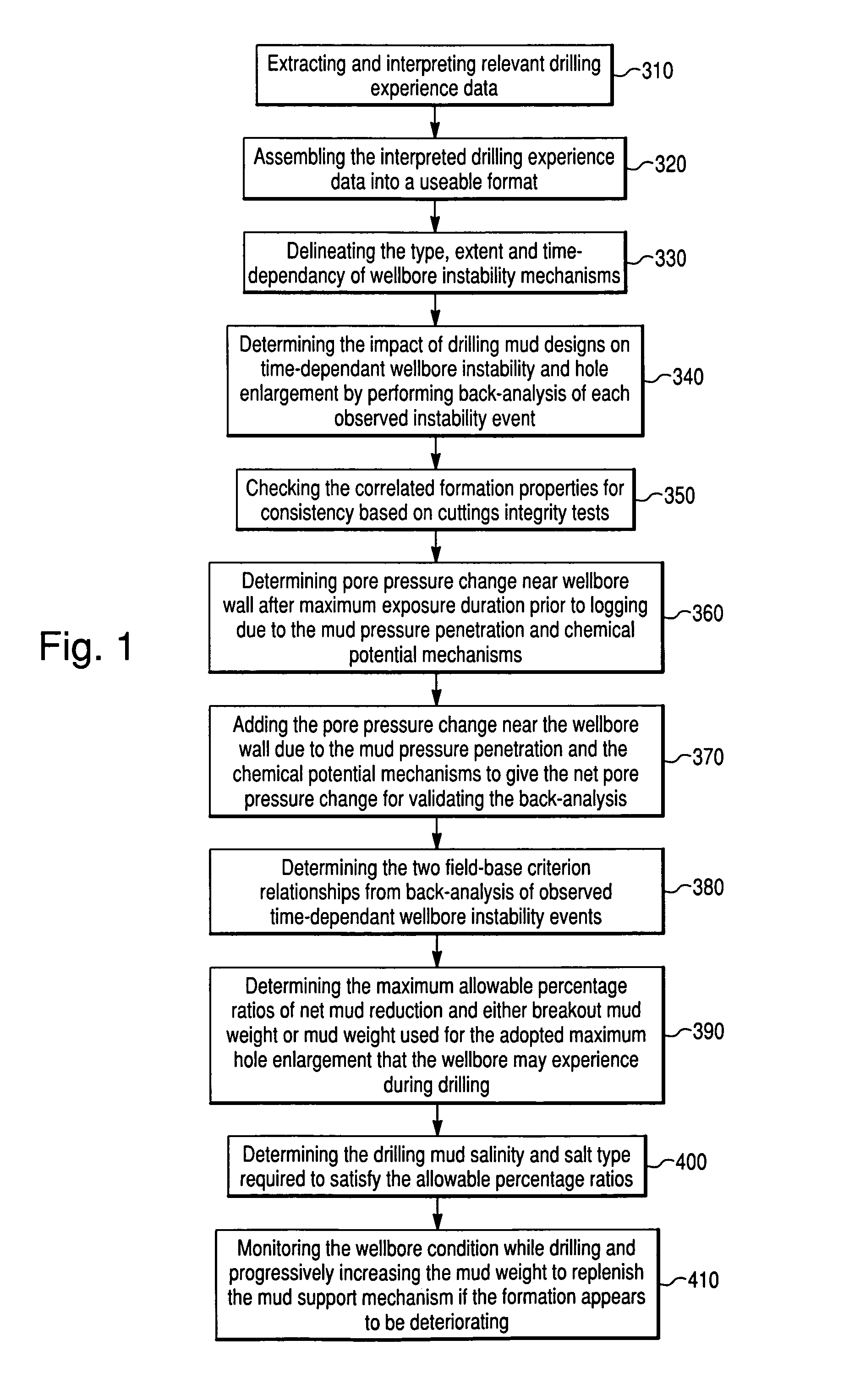

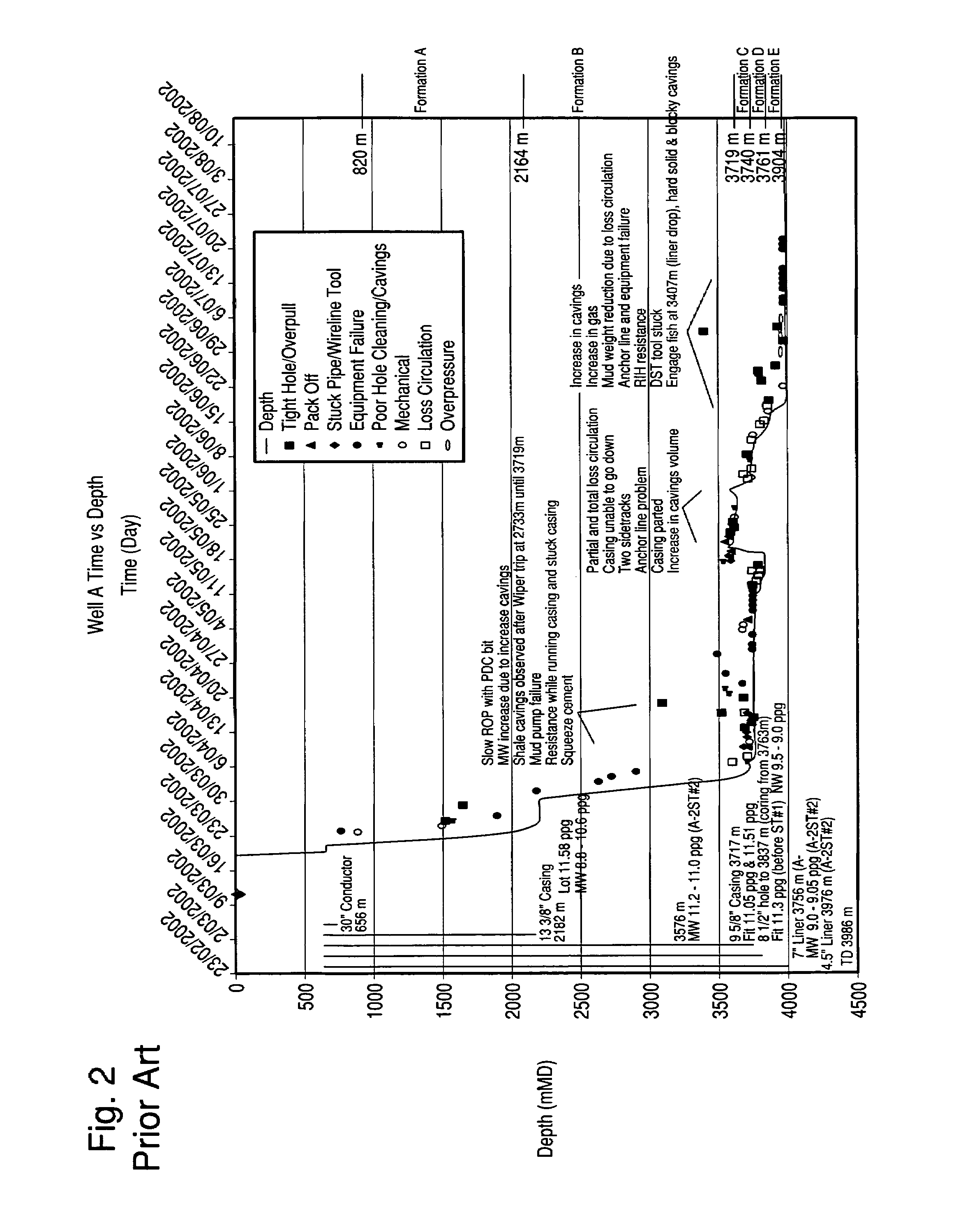

Method and computer program product for drilling mud design optimization to maintain time-dependent stability of argillaceous formations

InactiveUS20080190190A1Increase pressureElectric/magnetic detection for well-loggingSurveyWell drillingInstability

A method and computer program product of either preventing or minimizing pore pressure increase near the wellbore wall within argillaceous formations through which a borehole has been drilled. By interpreting relevant drilling experience data, the type, extent and time-dependency of wellbore instability mechanisms are determined. The impact of drilling mud designs on the time-dependent wellbore instability and hole enlargement is determined by back-analyzing observed drilling events. At least one field-based criterion relationship between net mud weight reduction percentage ratio and hole enlargement is determined. A maximum allowable percentage ratio(s) of net mud weight reduction and either breakout mud weight or mud weight used for the adopted maximum hole enlargement that the wellbore may experience during drilling is determined. Drilling mud salinity value and salt type to satisfy maximum allowable percentage ratio(s) is then determined.

Owner:SCHLUMBERGER TECH CORP

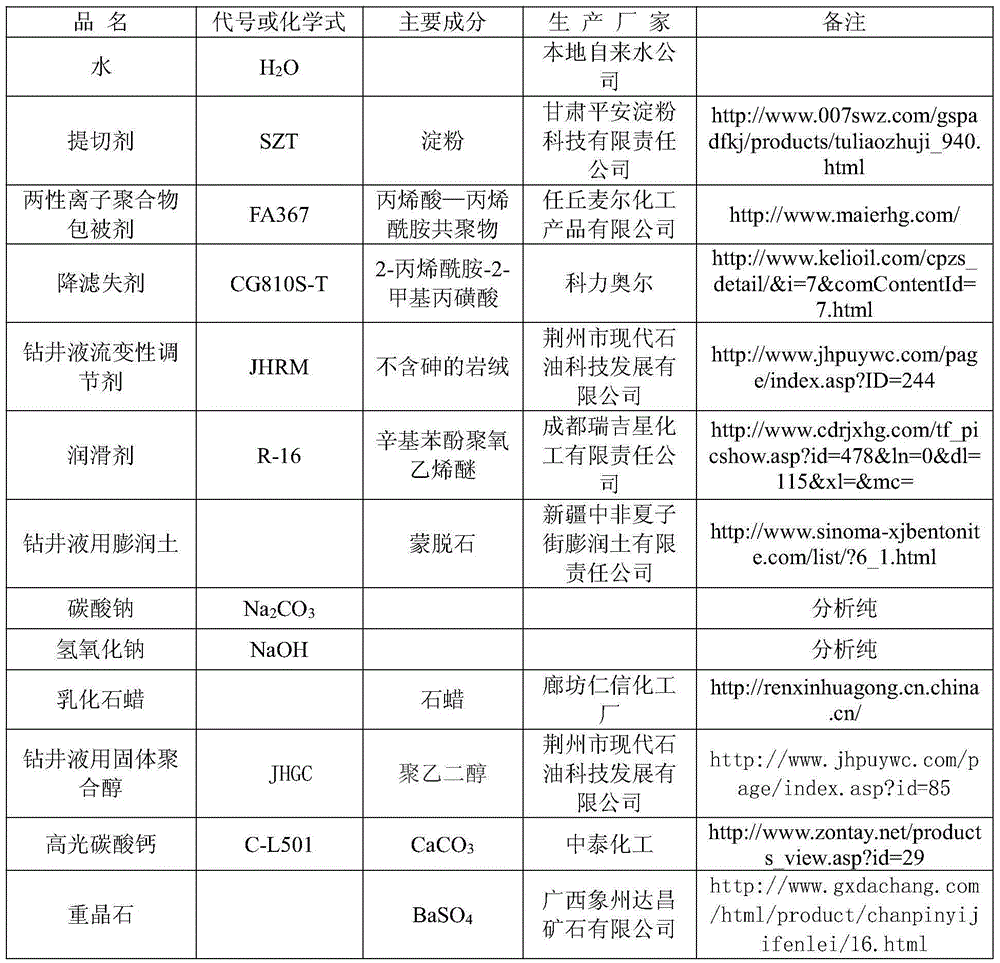

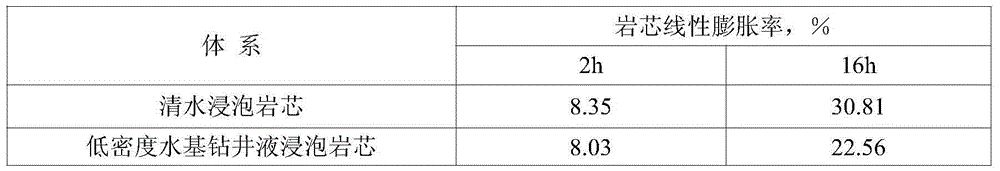

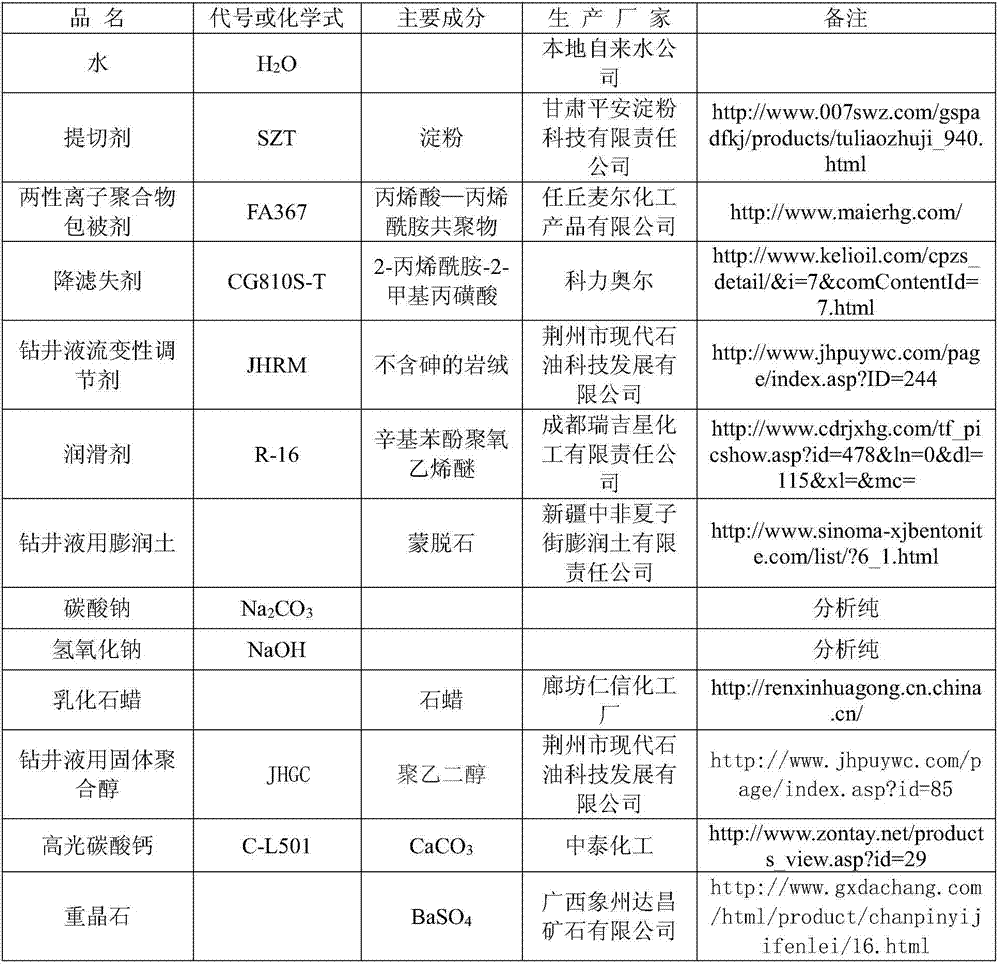

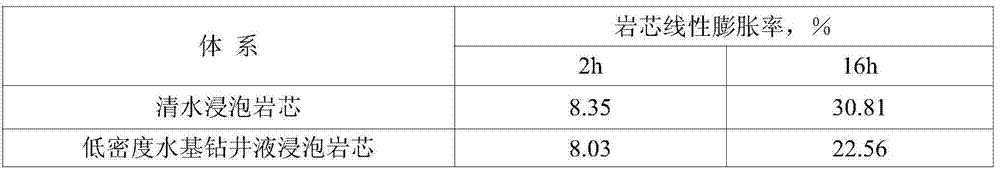

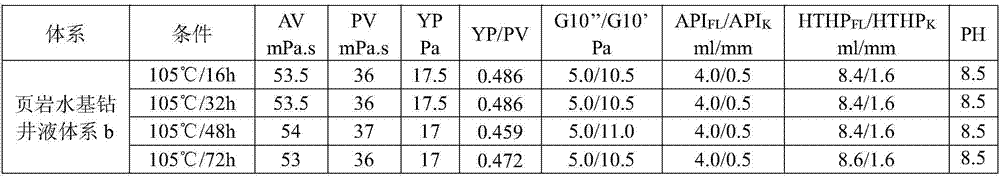

Low density water-based drilling fluid for drilling into shale

The invention relates to low density water-based drilling fluid for drilling into shale. The fluid overcomes the problem of wellbore instability when the water-based drilling fluid is used. The drilling fluid adopts the technical scheme that the drilling fluid comprises the following raw materials: 30-50g bentonite for the drilling fluid, 1.5-2.5g sodium carbonate, 5-10g sodium hydroxide, 15-20g shear strength improving agent SZT, 2-5g zwitterionic polymer coating agent FA367, 10-15g fluid loss agent CG810S-T, 0.2-1g drilling fluid rheological regulator JHRM, 40-60g highlight calcium carbonate C-L501, 10-30g lubricant R-16, 25-35g emulsified paraffin, 40-60g solid polymerization alcohol JHGC for the drilling fluid and 1000g tap water. The tap water, the bentonite for the drilling fluid and soda are added for prehydration for 24h first, the shear strength improving agent SZT is added under the mixing condition at 8000r / min, then the treatment agents are sequentially added under the mixing condition at 500r / min, pH (potential of hydrogen) of a system is regulated to 8.5, and barite is added finally. The drilling fluid system has good rejection capability and blocking performance and is used for drilling of a long horizontal section of a shale bed.

Owner:SOUTHWEST PETROLEUM UNIV

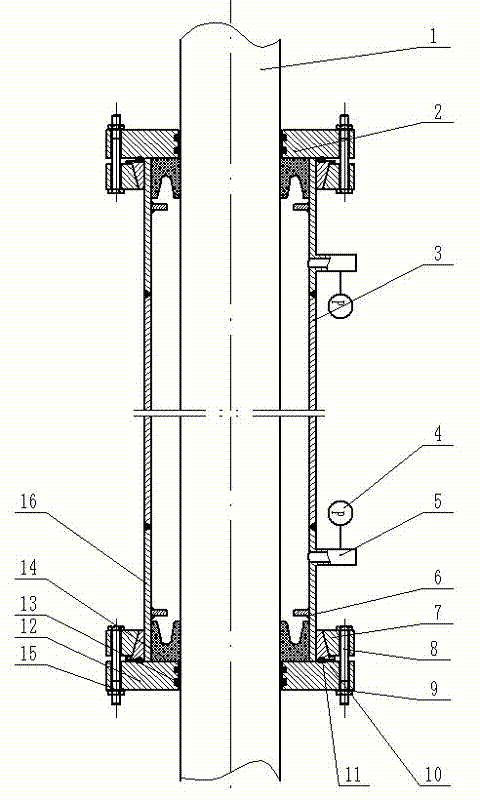

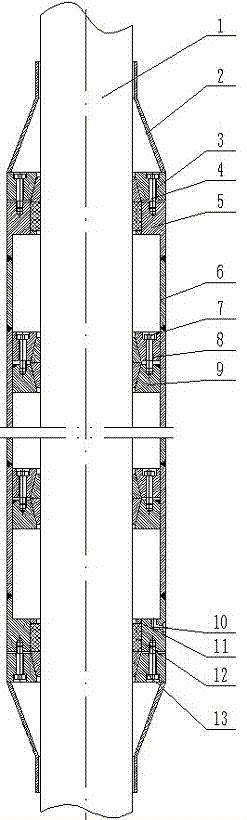

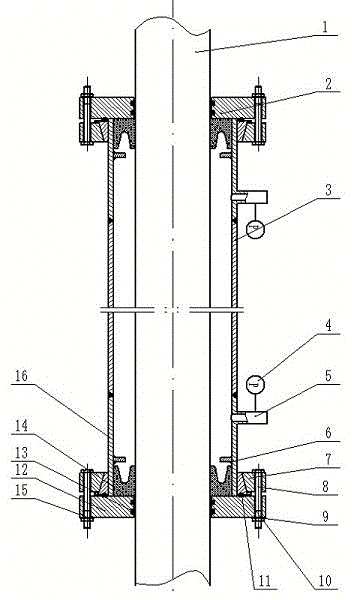

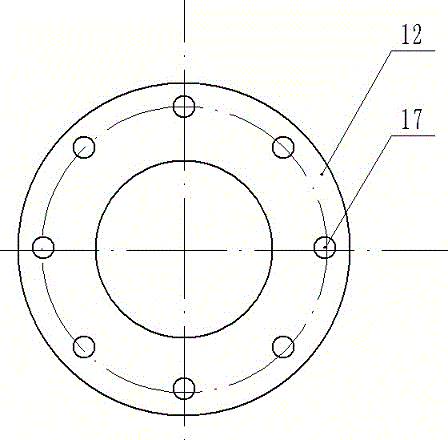

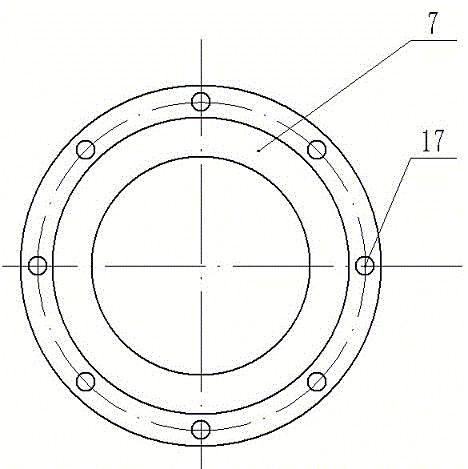

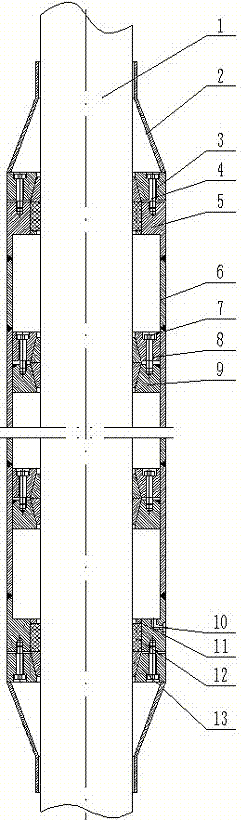

Non-excavation sunken pipe protecting device

InactiveCN103672297AGuarantee long-term normal deliveryAvoid uneven forcePipe supportsPipe protection against damage/wearEngineeringWellbore instability

The invention relates to a non-excavation sunken pipe protecting device which can prevent the accidents that sunken pipes are squashed, crushed and partially deformed due to wellbore instability, and the process that the sunken pipes are repaired and replaced or a new pipe is rearranged is omitted. The protecting device is composed of a sunken pipe, blocking devices and a protecting pipe, wherein the sunken pipe penetrates into the protecting pipe, the length of the protecting pipe is equal to the length of the sunken pipe needing protection, the blocking devices are mounted at the two ends of the protecting pipe, the annular space between the protecting pipe and the sunken pipe is filled with fluid, and the pressure of the fluid is smaller than or equal to the pressure of media in the sunken pipe; each blocking device is composed of a slips structure or a flange structure, a Y-shaped sealing ring, a pressure gage, a fluid inlet pipe and an O-shaped sealing ring, so that the fluid in the annular space is sealed, and pressure detection and fluid supplement are achieved. The non-excavation sunken pipe protecting device is simple in structure, convenient to operate and suitable for protecting pipes which penetrate through railways, roads, buildings, soft soil sections and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Well wall film formation anti-sloughing drilling fluid

InactiveCN105860942APrevent collapseReduce pollutionDrilling compositionSodium BentoniteWell drilling

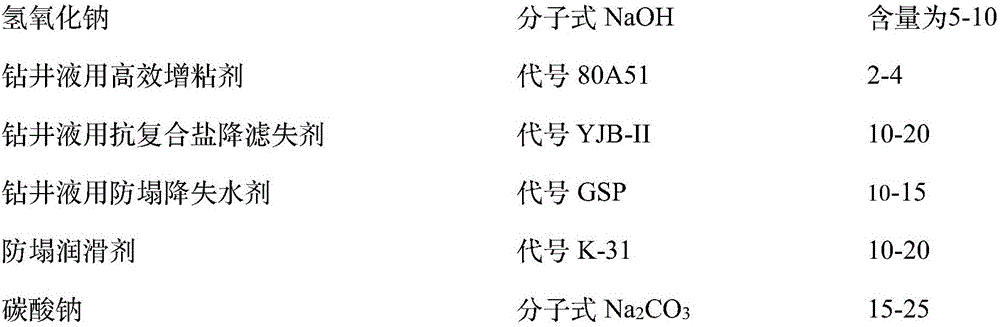

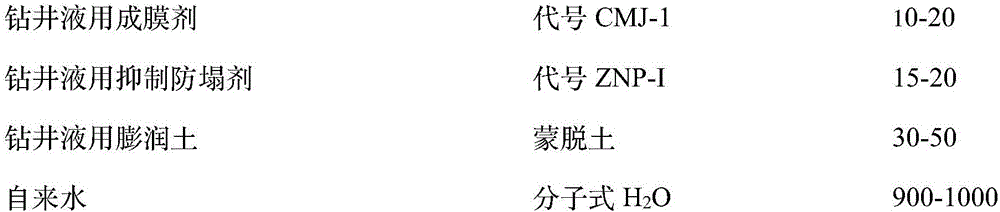

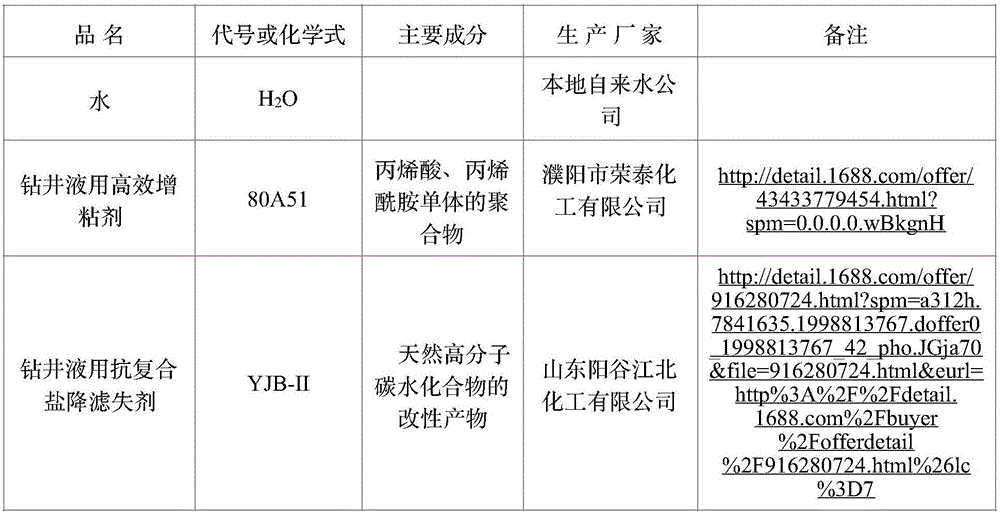

The invention relates to well wall film formation anti-sloughing drilling fluid applied to shale gas exploitation and shale drilling. The well wall film formation anti-sloughing drilling fluid solves the problem of wellbore instability, restrains hydrated collapse of a shale stratum and effectively plugs micro-nanometer holes of shale. The well wall film formation anti-sloughing drilling fluid is characterized by being prepared from raw materials of the content by mass unit of gram: 900-1000 of tap water, 30-60 of bentonite for drilling fluid, 1.5-2.5 of Na2CO3, 2-4 of high-efficiency thickening agent 80A51 for the drilling fluid, 10-20 of anti-compound salt filtrate reducer YJB-II for the drilling fluid, 10-15 of anti-sloughing filtrate reducer GSP for the drilling fluid, 10-20 of anti-sloughing lubricant K-31, 10-20 of film forming agent CMJ-1 for the drilling fluid and 15-20 of restraining anti-sloughing agent ZNP-I for the drilling agent. NaOH and water are prepared into alkali liquor with a mass percentage concentration as 40%, a system pH is adjusted as 8.5, the raw materials are stirred for 30 minutes, and a system density is aggravated to 1.20g / cm<3> through weighting agent barite for the drilling fluid, and the drilling fluid can be obtained. The drilling fluid system is small in environmental pollution, good in rheological property, strong in restraining and plugging capacity and applied to shale drilling.

Owner:SOUTHWEST PETROLEUM UNIV

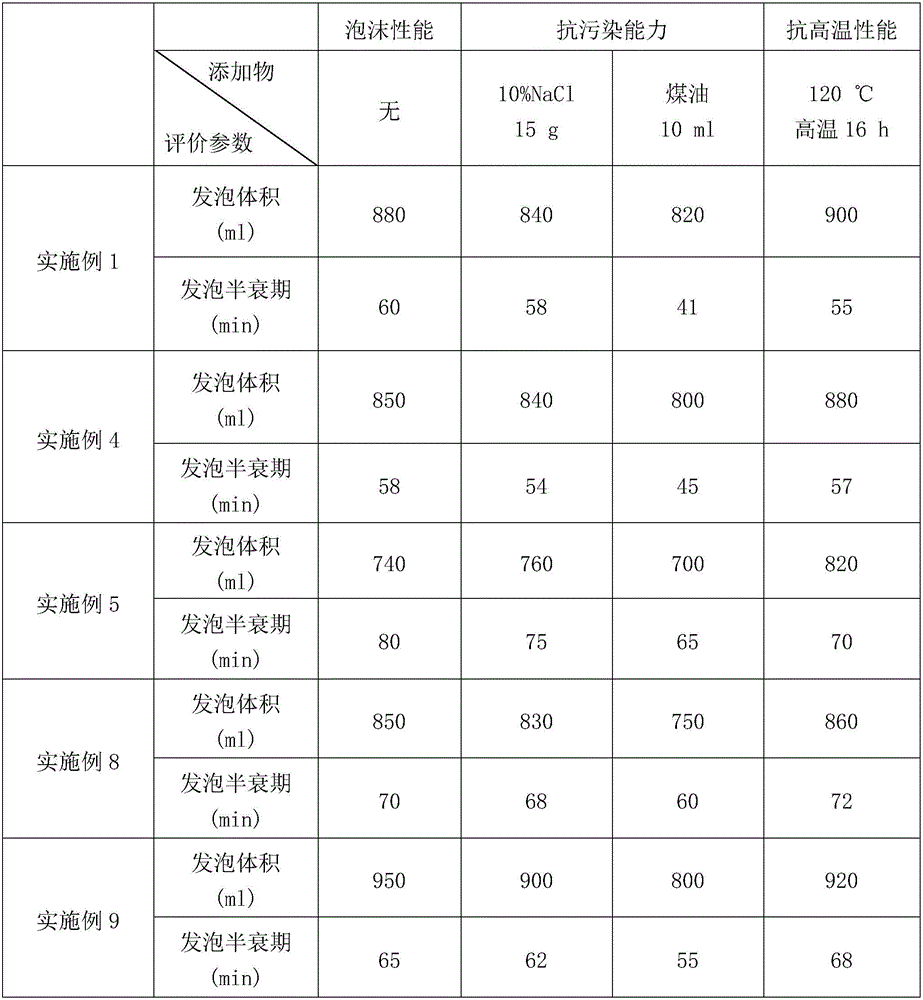

Foam drilling fluid and preparation method thereof

InactiveCN106433583APromote foam volumeEnhanced inhibitory effectDrilling compositionFiberCarrying capacity

A foam drilling fluid is prepared from, in percentage by mass, 2%-4% of a first foaming agent, 1%-2% of a second foaming agent, 1%-3% of inorganic fibers and the balance of water, wherein dosage of the first foaming agent is the double of that of the second foaming agent. Under the normal-temperature and normal-pressure conditions, the inorganic fibers are dispersed in deionized water for prehydration treatment for 8-12 h, then the first foaming agent and the second foaming agent are added and evenly stirred at 60-80 DEG C, the mixture is foamed at the rotating speed of 5,000-8,000 rpm for 3-5 min, and the foam drilling fluid is prepared. The foam drilling fluid has good foaming capacity, high high-temperature-resistant and anti-pollution capacity, good dynamic yield point, good yield point and plastic viscosity ratio, good suspension property, higher inhibitive ability and proper water loss, can maintain the higher rate of penetration and water and rock carrying capacity in the drilling process and effectively solves the complex problems of wellbore instability, tool sticking, reservoir pollution and the like.

Owner:SHANDONG UNIV

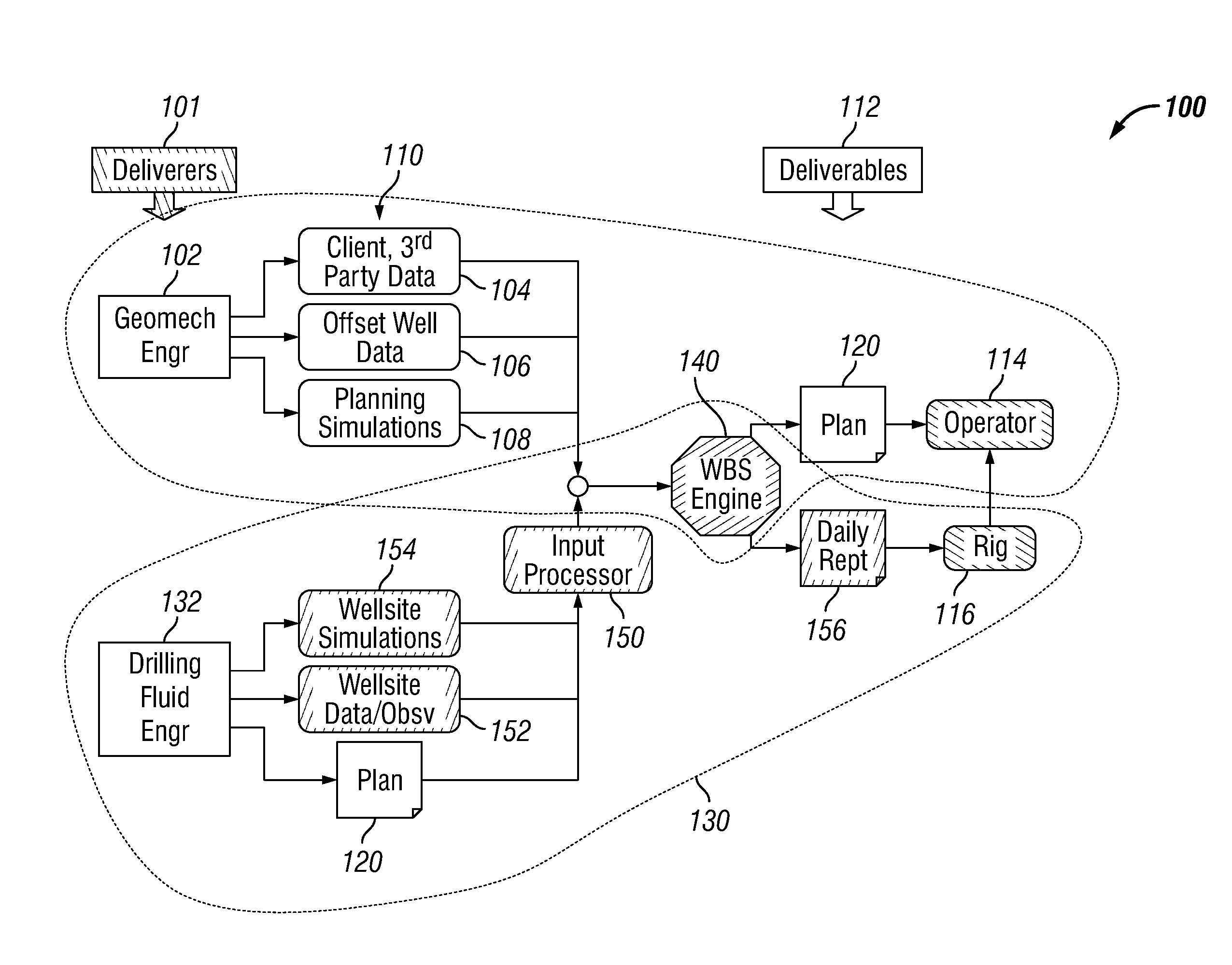

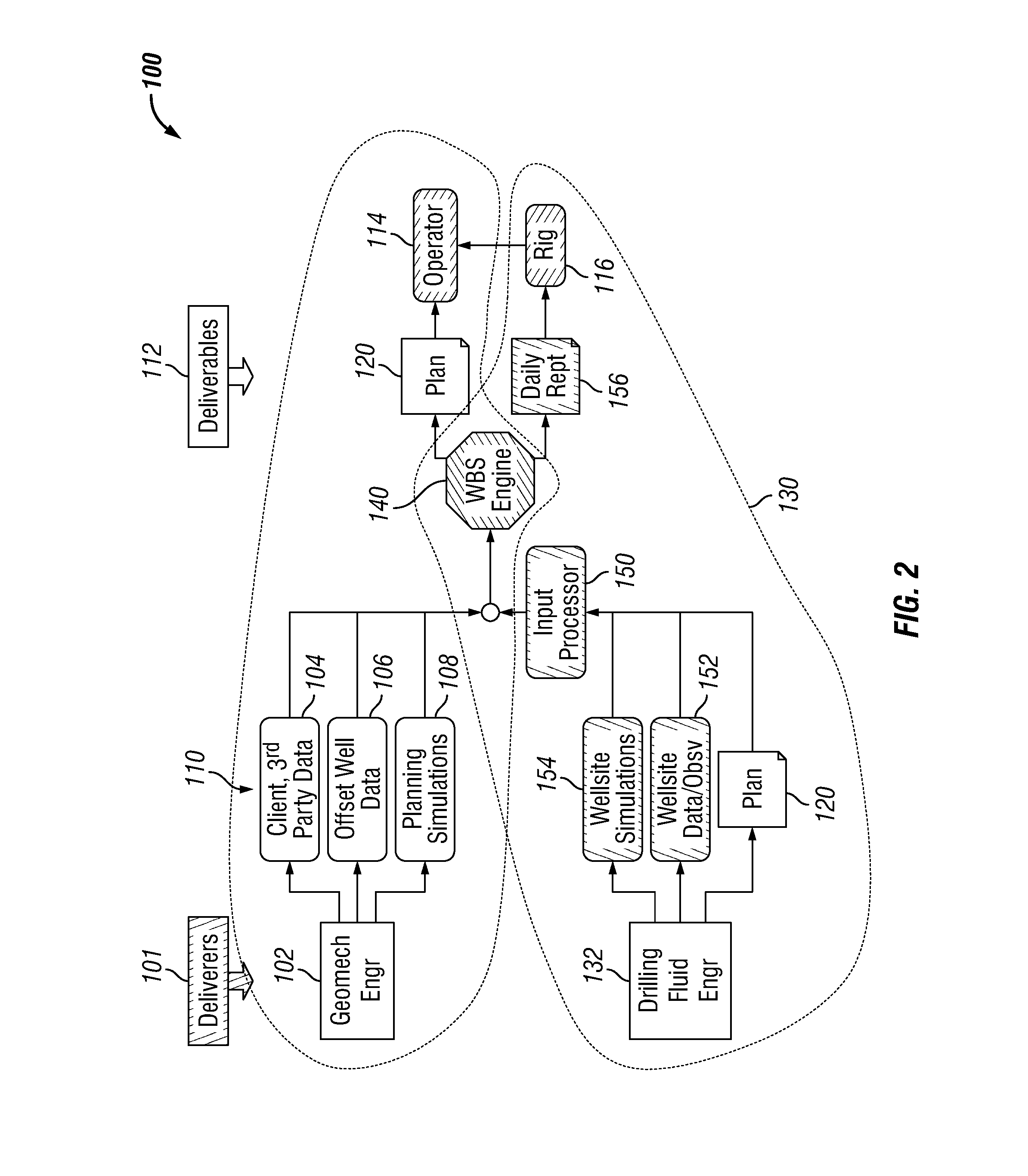

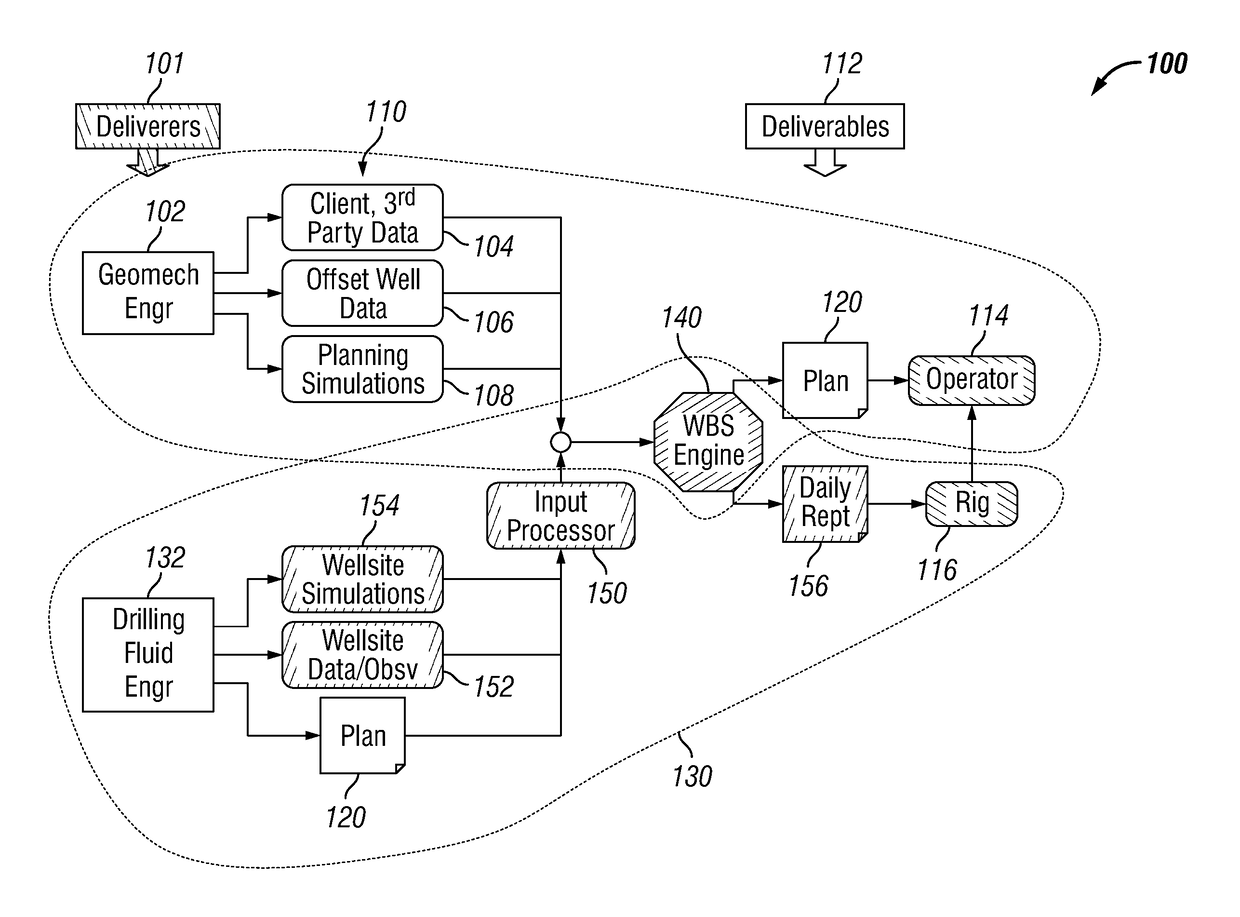

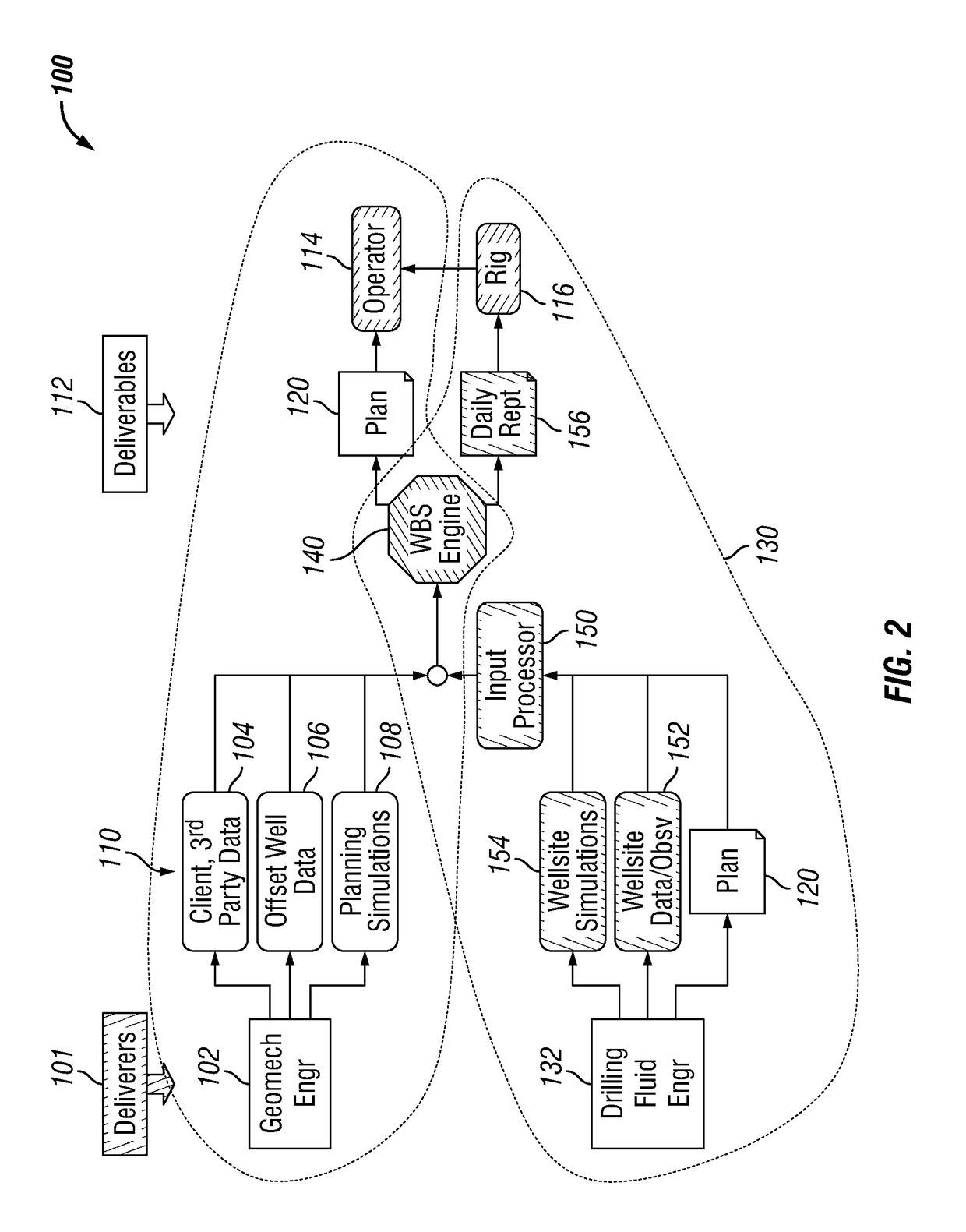

Method Of Minimizing Wellbore Instability

ActiveUS20140032192A1Reducing wellbore instabilityReduce instabilityFluid removalAnalogue processes for specific applicationsInstabilityWellbore instability

A process for reducing wellbore instability includes inputting pre-drilling assessment information into an hydraulics analysis and wellbore stability application, inputting a well plan into the hydraulics and wellbore analysis application, inputting a parameter measured at the wellsite into the hydraulics and wellbore stability analysis application, inputting an observation made at the wellsite into the hydraulics and wellbore stability analysis application, integrating the pre-drilling assessment information, the measured parameter, and the observation into the wellbore strengthening analysis application, and adjusting a drilling fluid parameter in response to the integrated pre-drilling assessment information, the measured parameter, and the observation.

Owner:MI

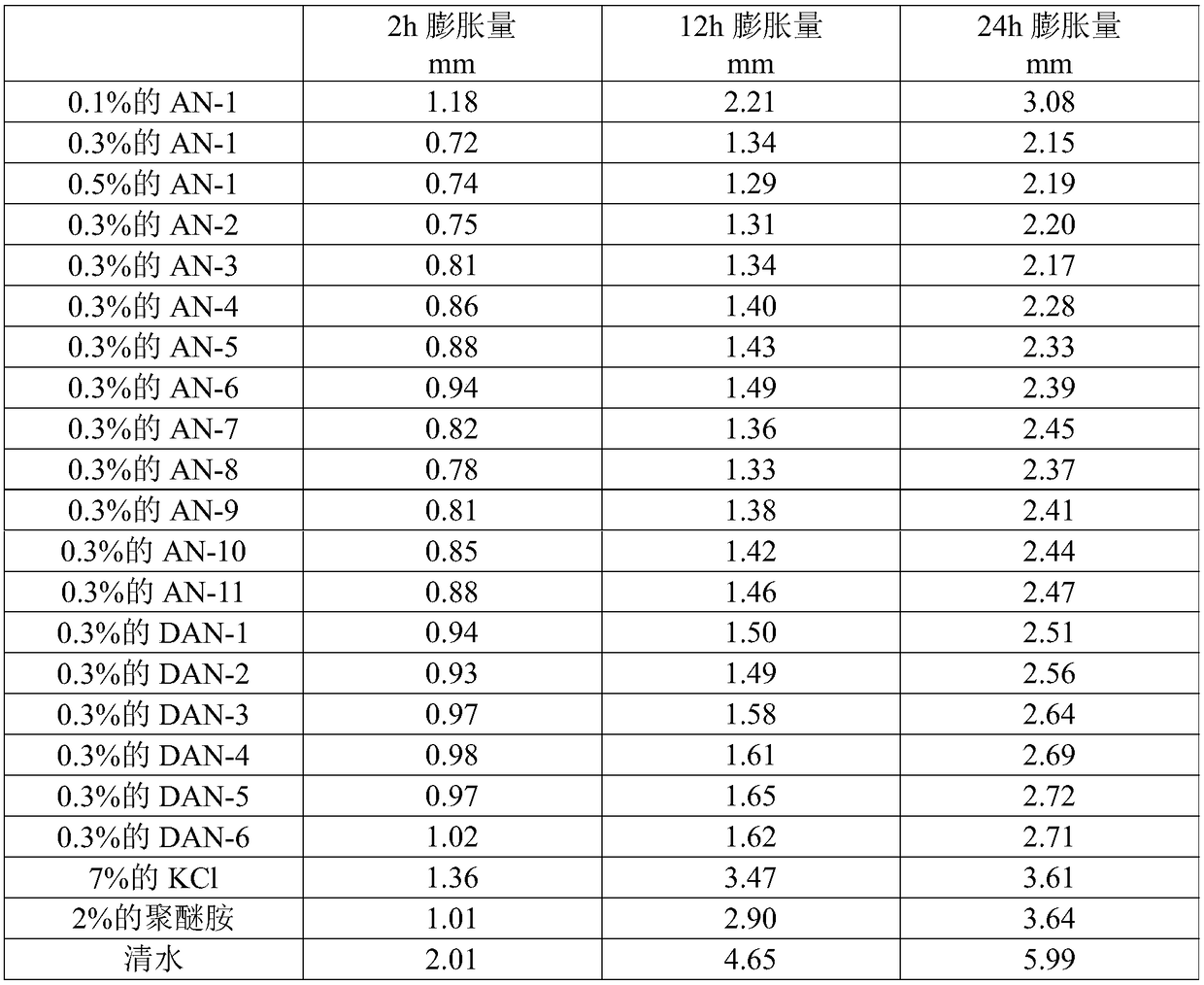

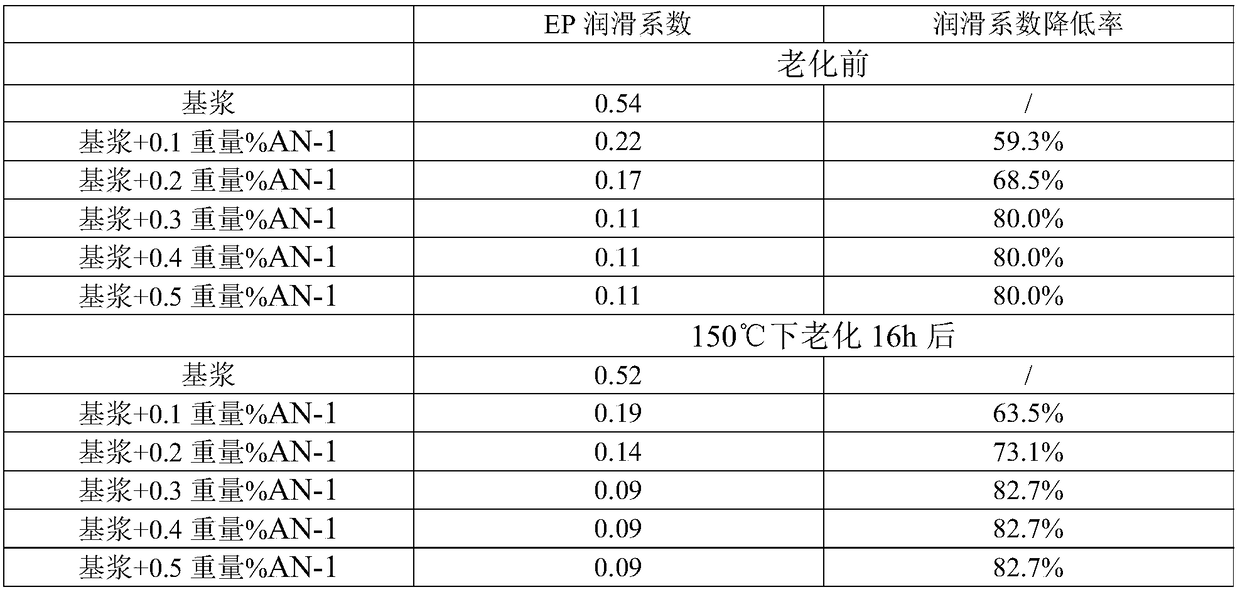

Drilling fluid, preparation method and application

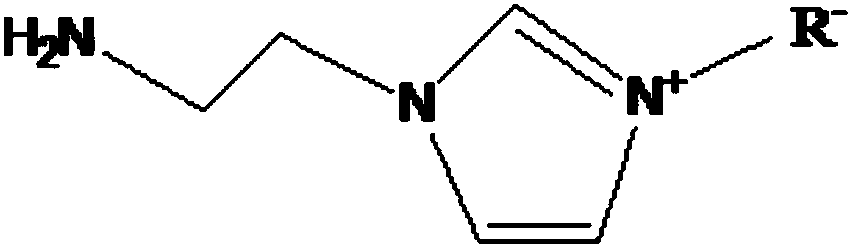

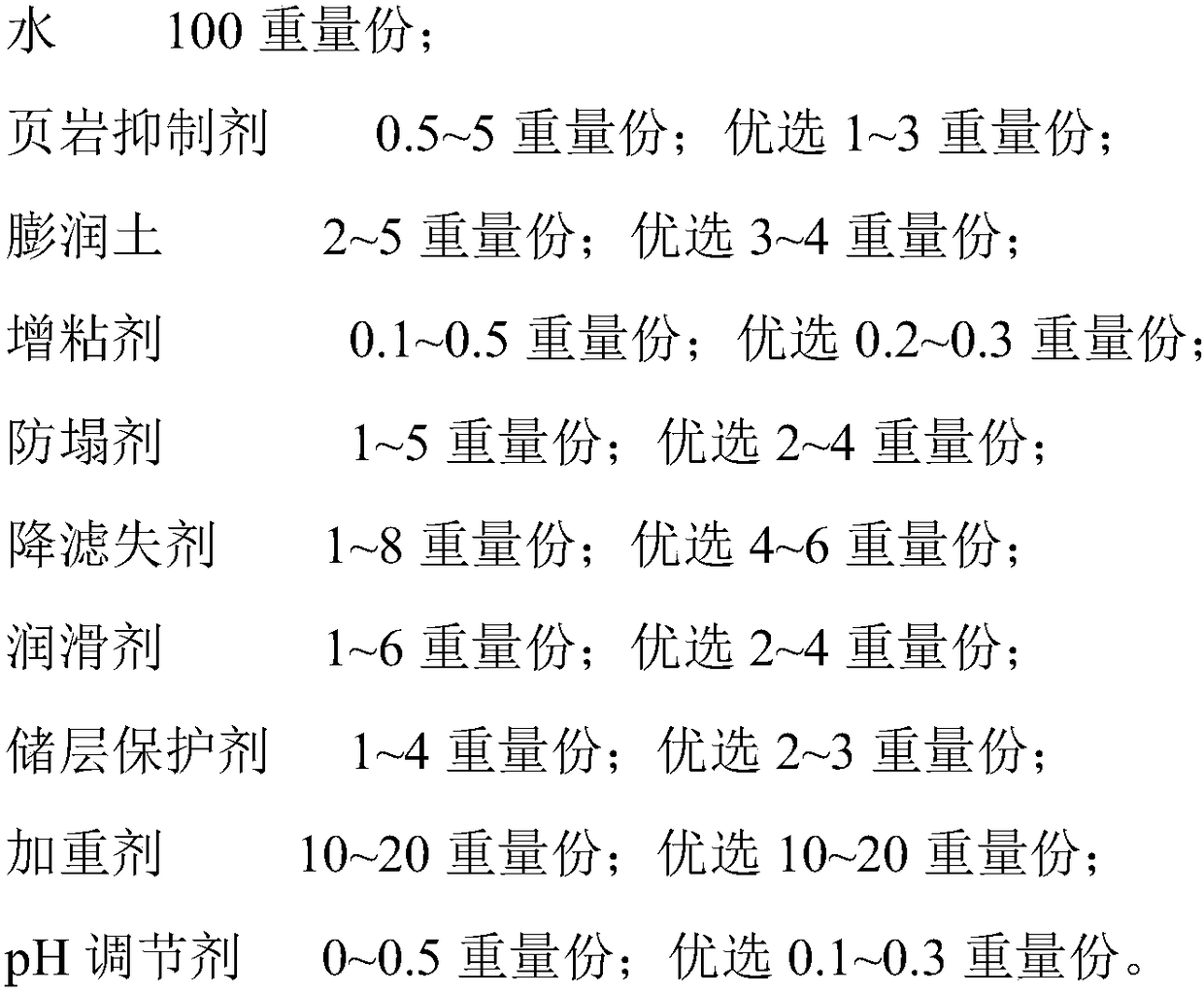

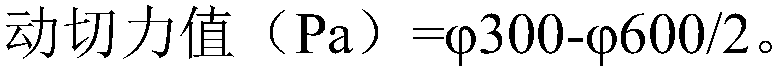

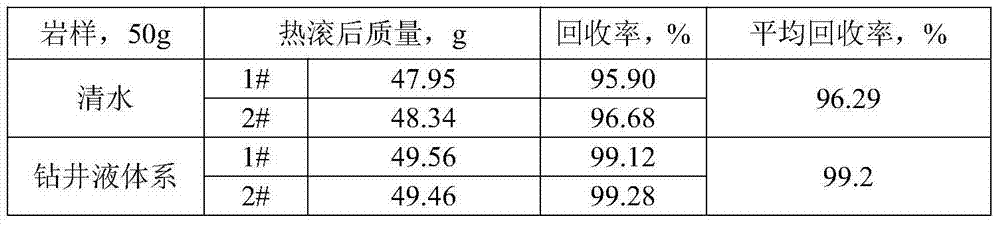

ActiveCN109233762AReduce intensityEnsure stabilityOrganic chemistryDrilling compositionSwelling pressureWell drilling

The invention discloses a drilling fluid, a preparation method and an application. The drilling fluid is prepared from the following components in parts by weight: 100 parts of water and 0.5-5 parts of a shale inhibitor, wherein the shale inhibitor is 1-aminoethyl-3-methylimidazolium salt with structural formula shown in the description, R is R is Br, NO3, PF6 or BF4. The drilling fluid contains the shale inhibitor capable of effectively inhibiting shale hydration dispersion, and can effectively prevent surface hydration of montmorillonite in shale when being used for drilling large sections of shale formations prone to wellbore instability, so that shale swelling pressure is reduced, and wellbore stability is maintained.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-density water-based drilling fluid for drilling shale

The invention relates to a high-density water-based drilling fluid for drilling shale and solves the problem of wellbore instability during shale stratum drilling of a water-based drilling fluid. The technical scheme is that the high-density water-based drilling fluid is prepared from the following raw materials: 900-1,000 g of tap water, 30-60 g of bentonite, 2-4 g of Na2CO3, 1-3 g of a drilling-fluid polymer salt-resistant tackifying inhibitor CP-1, 3-5 g of drilling-fluid carboxymethyl starch GMS-1, 10-30 g of high-temperature-resistant special resin SPNH-III, 15-25 g of a high-temperature-resistant viscosity reducer JNT-1, 10-30 g of a lubricative nano emulsion NL-III, 10-20 g of a fluorescence-free white asphalt anti-collapse agent WBF-II and 10-30 g of water-dispersing cationic emulsified asphalt power SFT-I; an alkali solution with the mass percentage concentration of 40% is prepared from NaOH to adjust the pH of the system to 9; a hydrocarbon reservoir protection weighting agent YB-I is adopted to increase the density of the system to 1.8-2.0 g / cm<3>. The high-density water-based drilling fluid is low in cost and high in inhibition performance, causes little reservoir damage and is used for drilling a deep shale stratum.

Owner:SOUTHWEST PETROLEUM UNIV

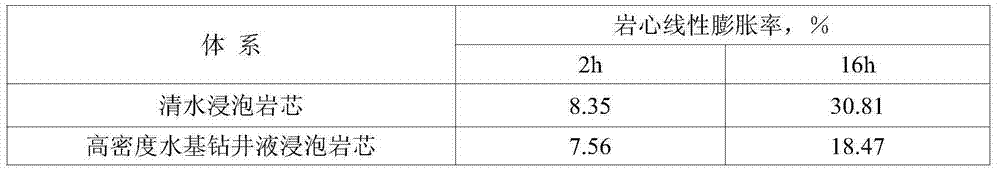

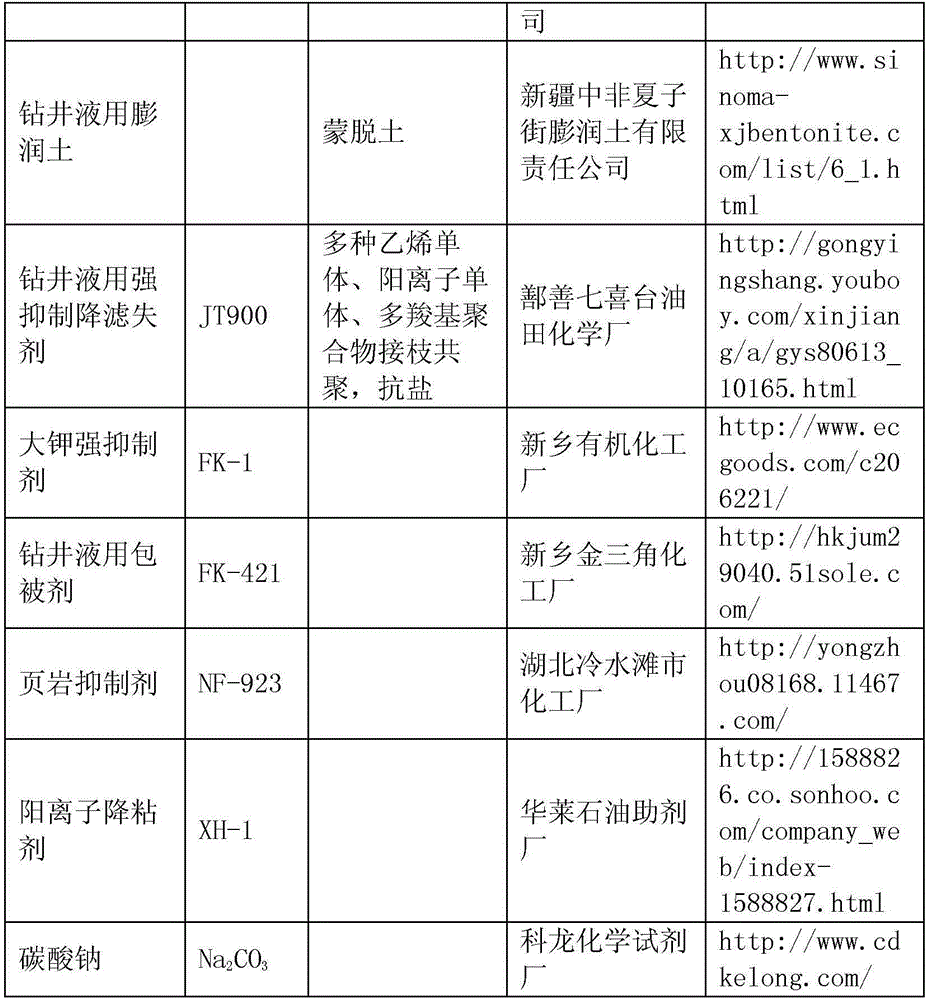

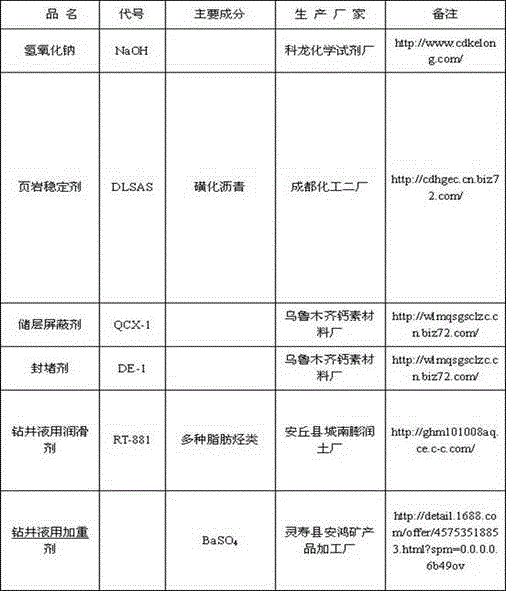

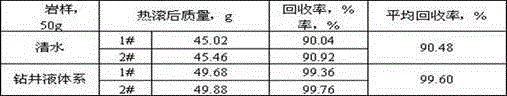

Strong inhibitive drilling fluid for drilling shale

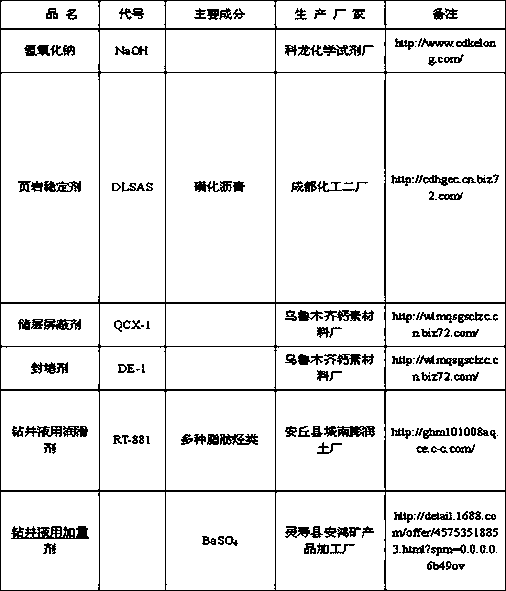

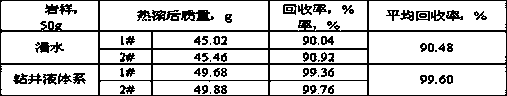

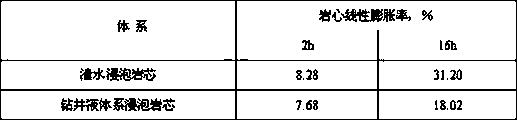

The invention relates to a strong inhibitive drilling fluid for drilling shale for shale gas development and solves the problem of wellbore instability, and hydration collapse of the shale stratum is inhibited. The technical scheme of the strong inhibitive drilling fluid is that the the drilling fluid is prepared from the compositions of, by mass unit, 900-1,000 g of tap water, 30-60 g of bentonite for drilling fluid, 2-4 g of Na2CO3, 0.3-1 g of strong inhibitive filtrate reducer JT900 for drilling fluid, 0.5-1 g of potassium strong inhibitor FK-1, 2-5 g of coating agent FK-421 for drilling fluid, 1-1.5 g of shale inhibitor NF-923, 1-2 g of positive ion viscosity reducer XH-1, 2-3 g of shale stabilizer DLSAS, 4-6 g of reservoir shielding agent QCX-1, 2-4 g of blocking agent DE-1 and 0.5-1 g of lubricant RT-881 for drilling fluid; finally, the alkali liquor with the mass percentage concentration of 40% is prepared by adding water to NaOH, the system PH is adjusted to be 8.5, the drilling fluid weighting agent baryte is used for weighting the the system density to be 1.8-2.0 g / cm<3>, and the drilling liquid is prepared. The drilling fluid system has small environment pollution, and the drilling liquid has excellent rheological property and high sealing capacity and is used for drilling the shale.

Owner:SOUTHWEST PETROLEUM UNIV

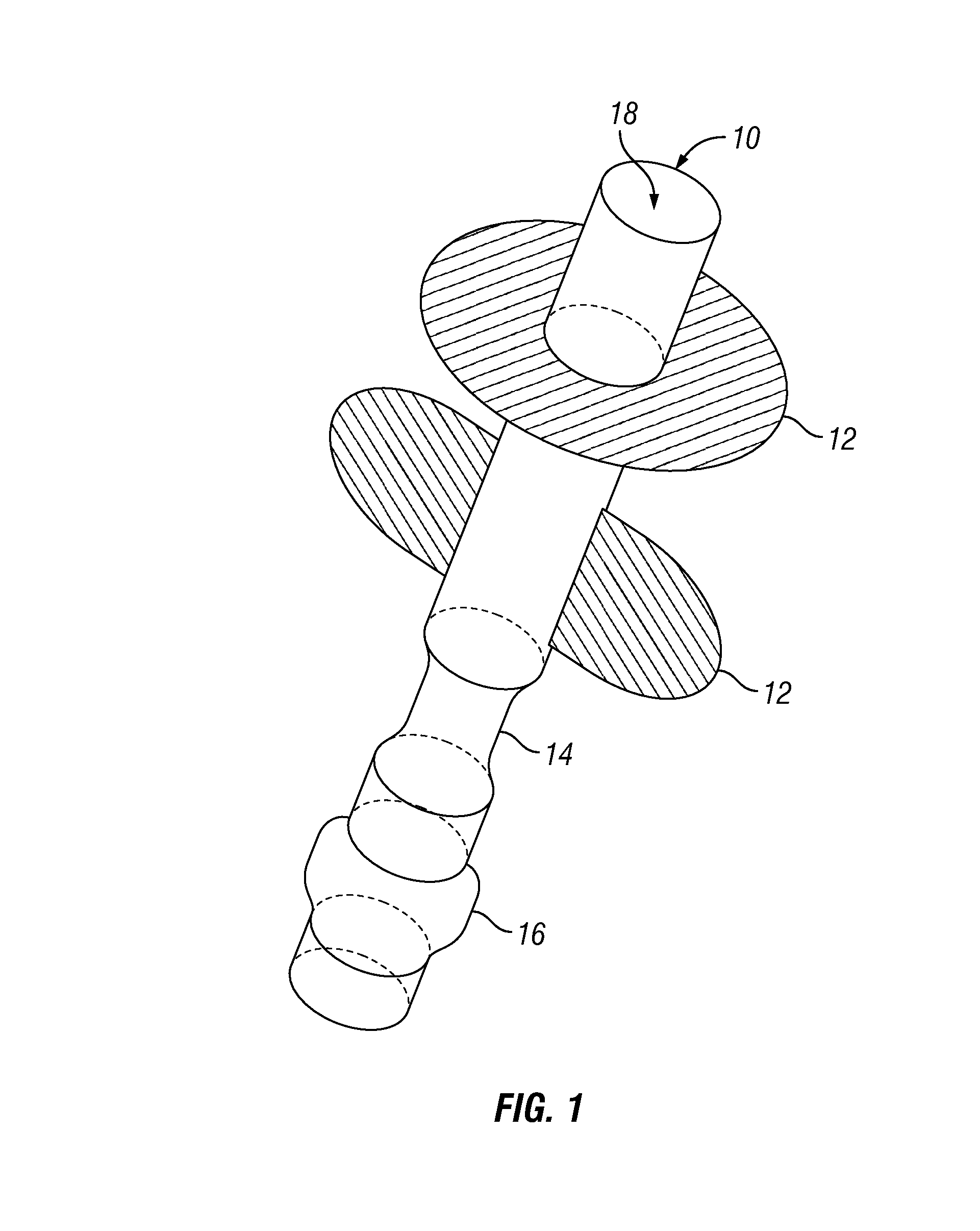

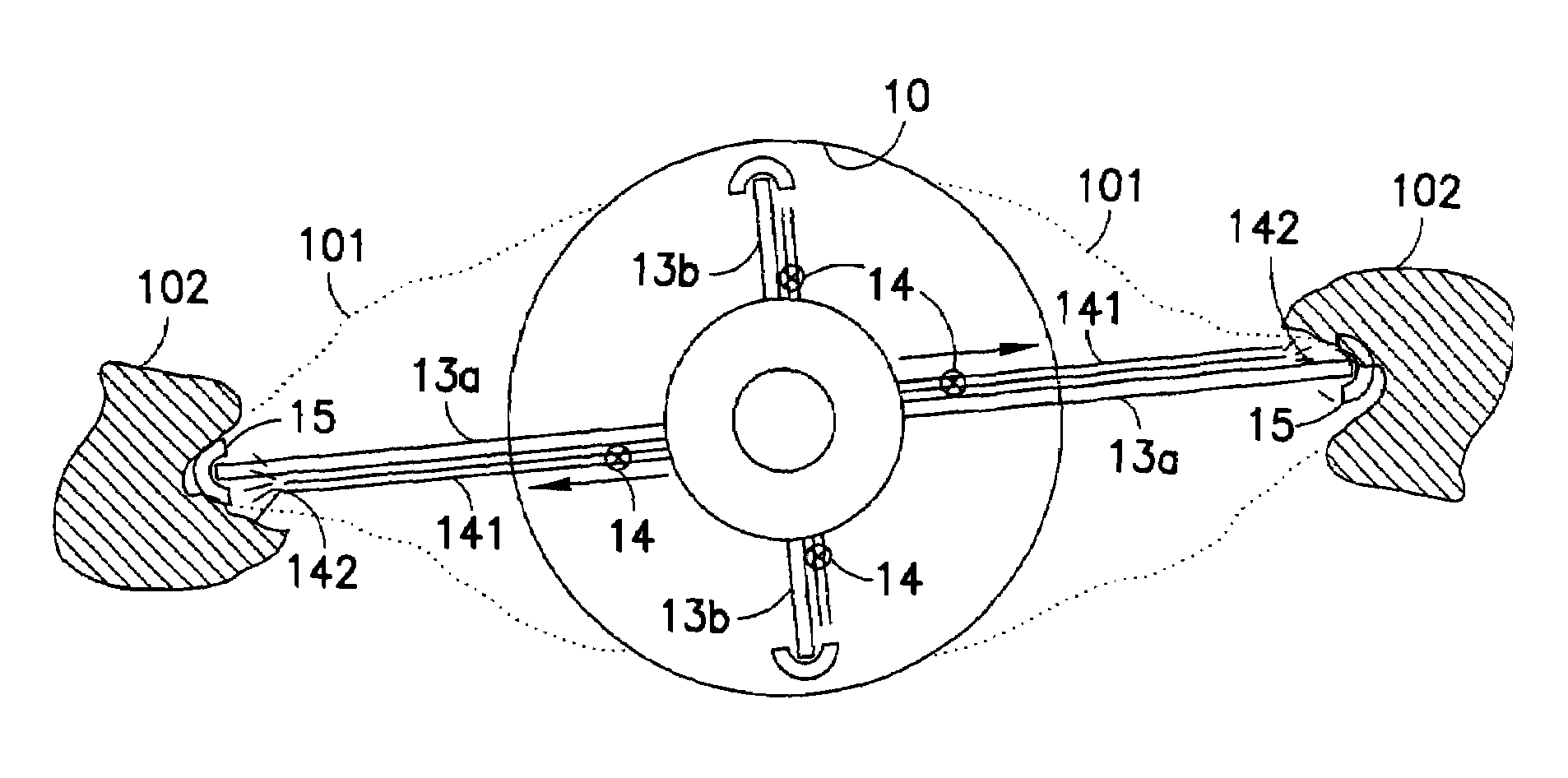

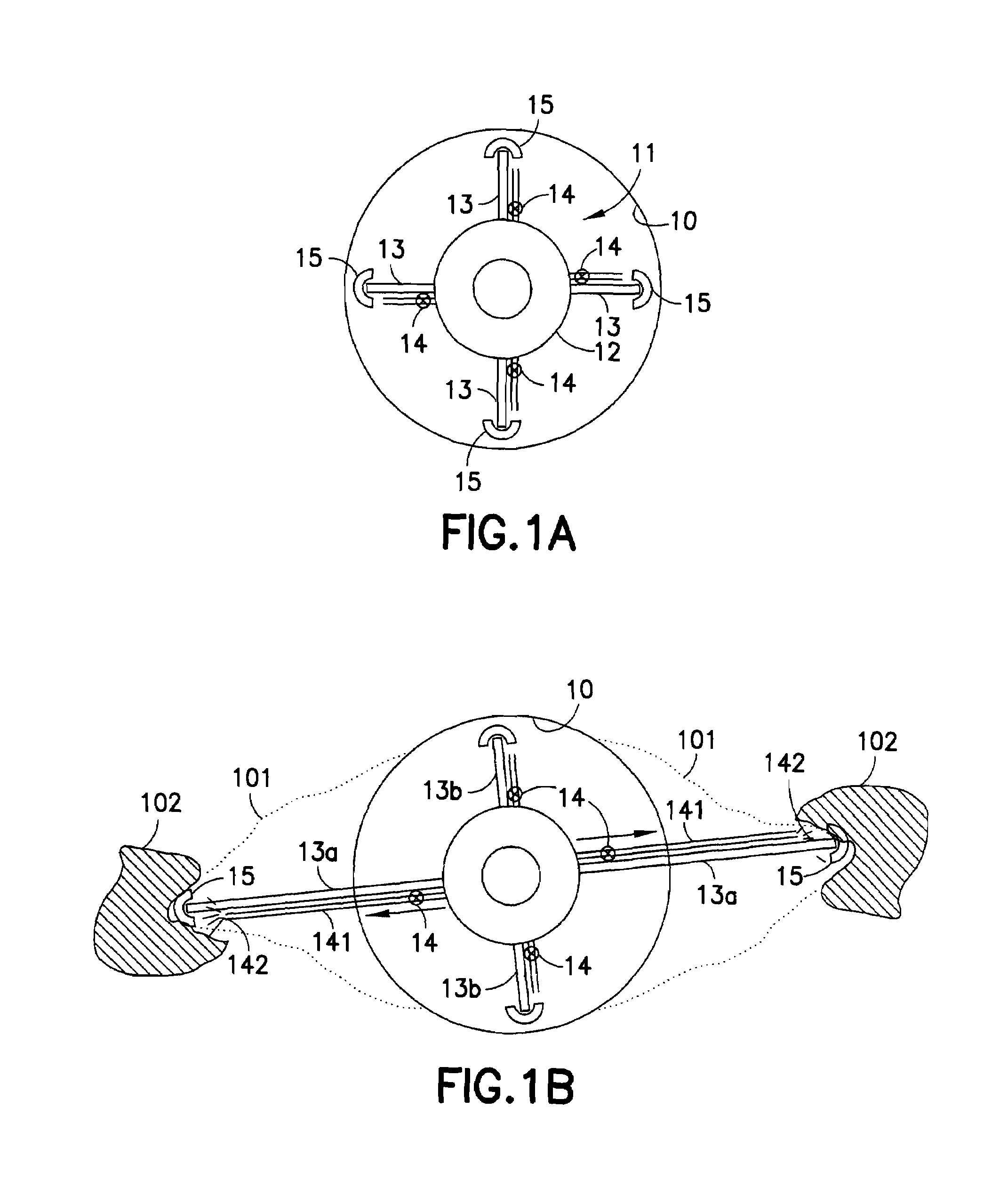

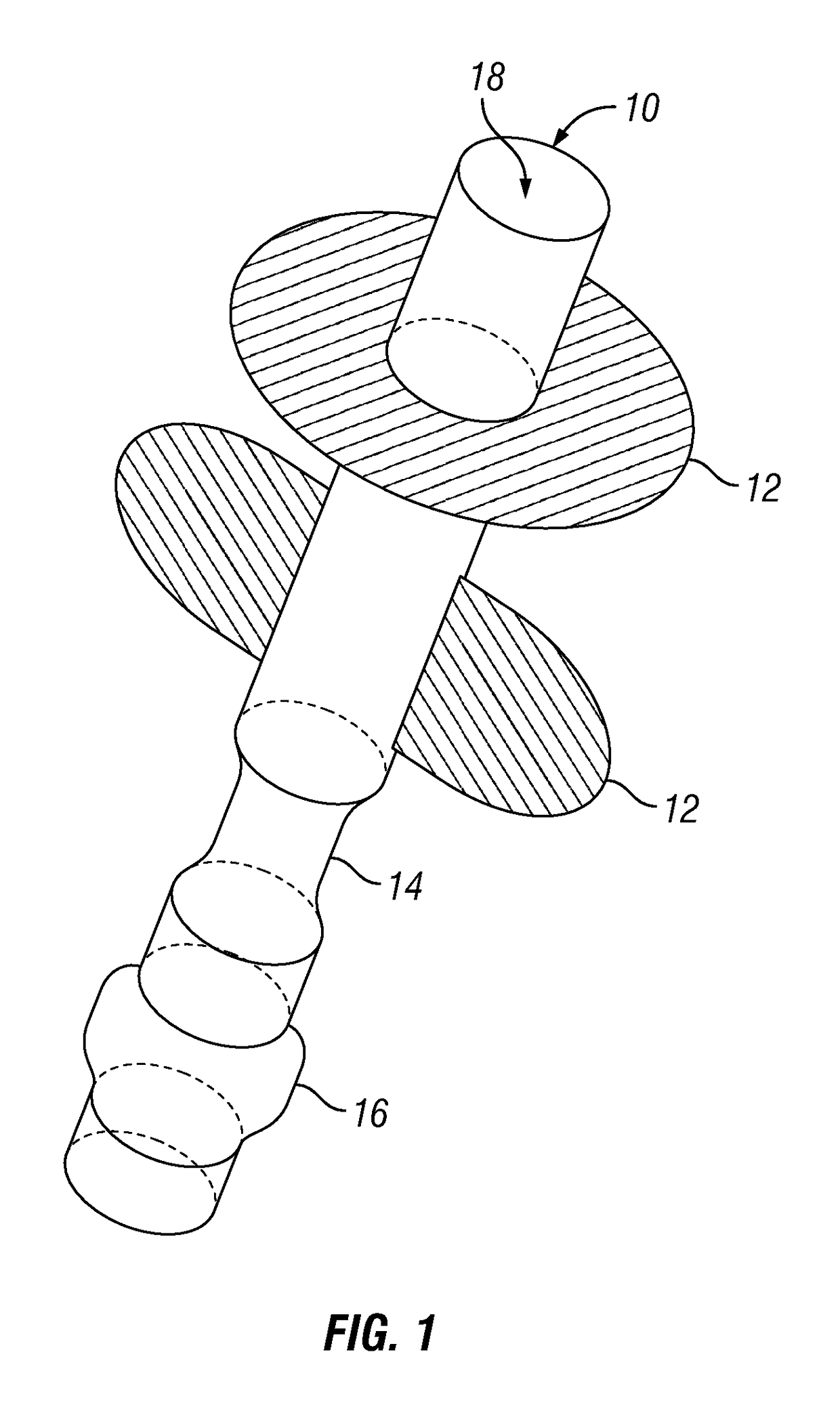

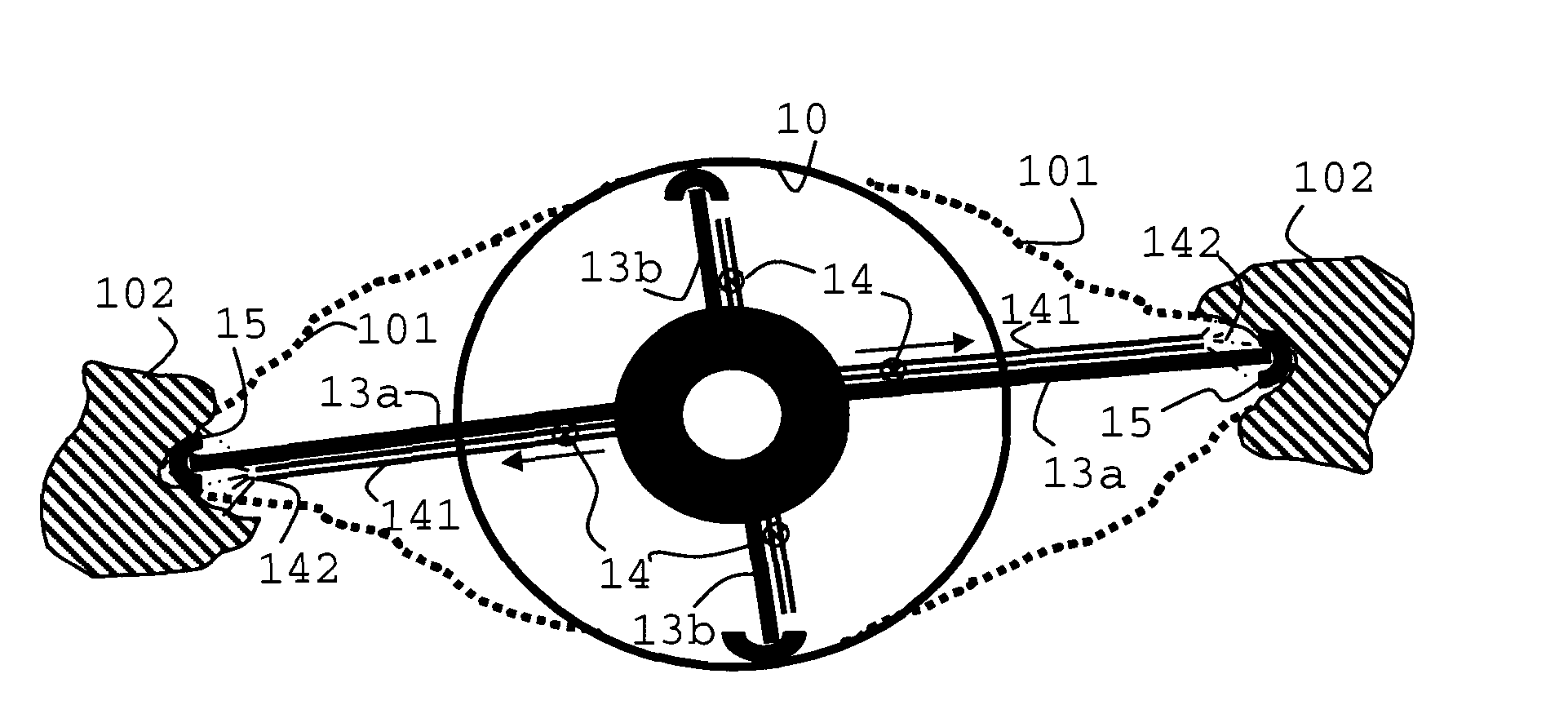

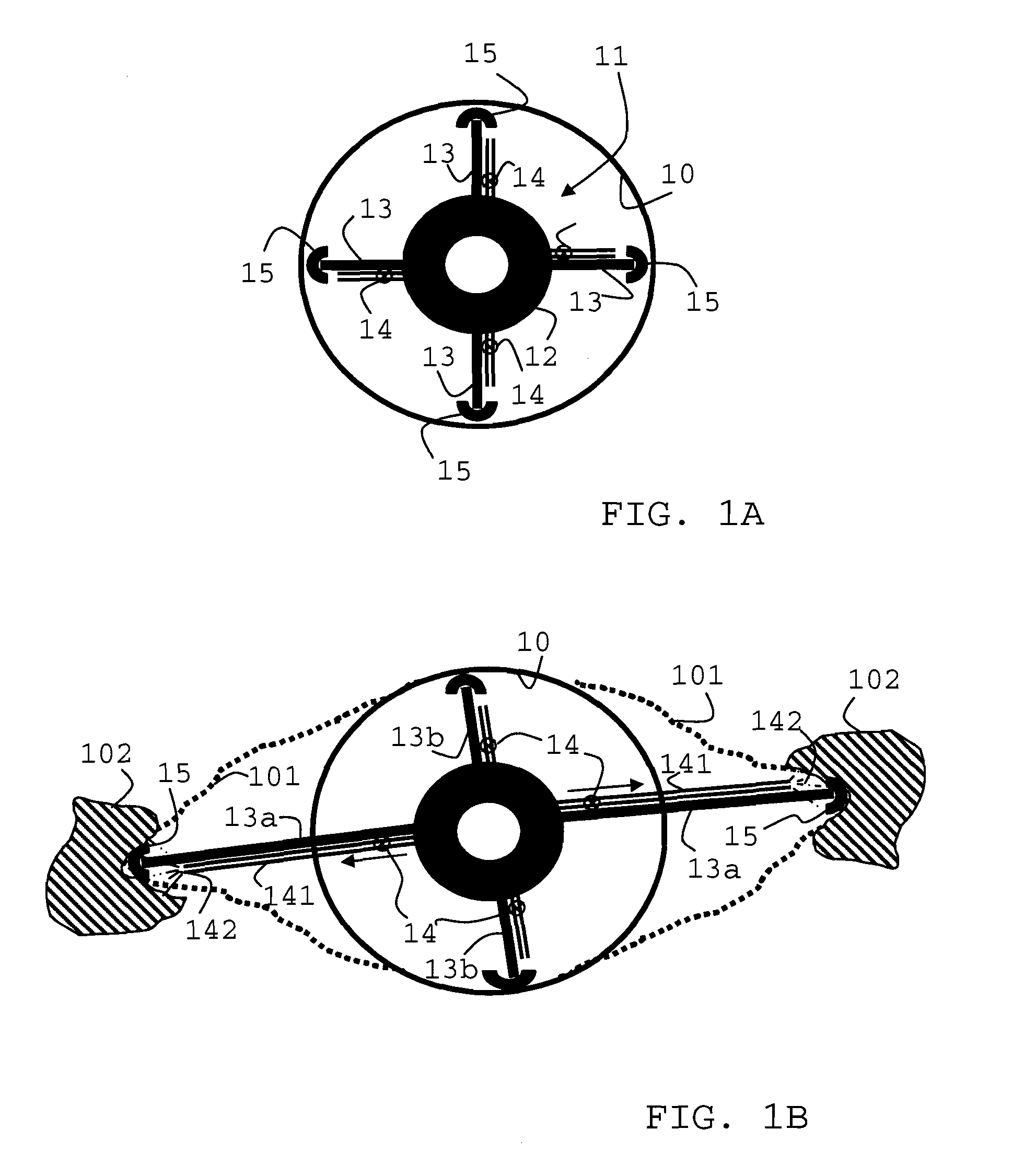

Wellbore treatment apparatus and method

A treatment apparatus and method for wellbore instability is described including a caliper with one or more radially extending arms which are capable of extending and retracting movement in a radial direction and a fluid supply facility to deliver treatment fluid from the ends of the arms to the wellbore wall, with a sensing and valve mechanism such that in use fluid is being delivered from the end of any extended arm to a breakout region of the wellbore where there is instability.

Owner:SCHLUMBERGER TECH CORP

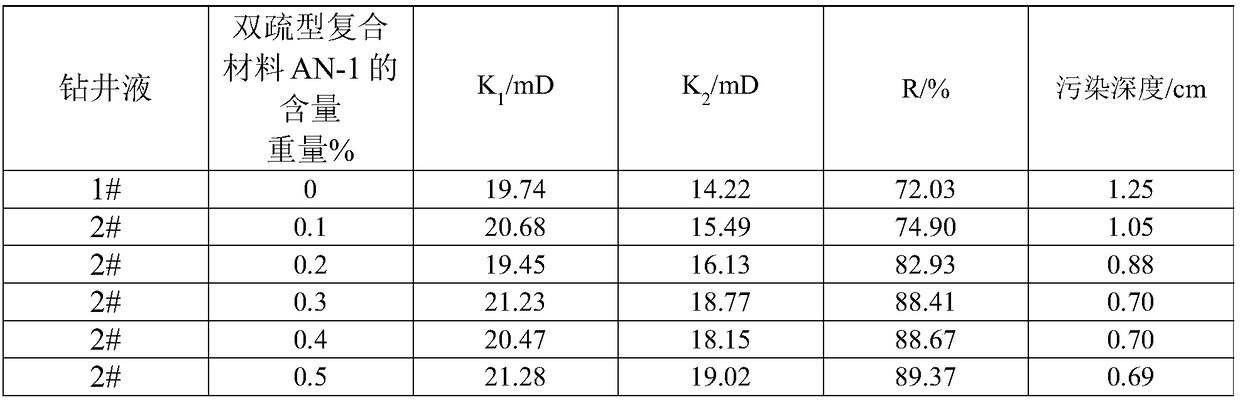

Superamphiphobic composites and their applications as inhibitors, lubricants and reservoir protectants in water-based drilling fluids

ActiveCN108165241BHydrophobic and oleophobicSuperamphiphobicDrilling compositionWater basedHorizontal wells

The invention relates to the field of oil and gas drilling, in particular to a super-hydrophobic composite material, and application of the super-hydrophobic composite material used as an inhibitor, alubricant and a hydrocarbon reservoir protective agent in water-based drilling fluid. A preparation method of an amphiphobic composite material comprises the steps of under an alkaline condition, inan ethanol-water mixture solvent, mixing nanometer TiO2 and nanometer SiO2 for the first time, and obtaining dispersion liquid of the nanometer TiO2 and the nanometer SiO2; then introducing a fluorine-containing silicon coupling agent into the dispersion liquid of the nanometer TiO2 and the nanometer SiO2, and mixing for the second time. The amphiphobic composite material provided by the inventioncan be used in the water-based drilling fluid, has the effect of strongly inhibiting hydrous disintegration, is low in toxicity and good in compatibility, can effectively solve the problems of wellbore instability, drill jamming, reservoir damage and the like, further promotes development and application of high-difficulty wells such as extra-deep wells, horizontal wells and large displacement wells in a clay shale-containing formation, and has long-term practical value and economic benefit.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Oil-based shaft stabilizing fluid for gas-liquid conversion and preparation method thereof

InactiveCN102851014AStability is not affectedDoes not affect rheologyDrilling compositionActive agentWell drilling

The invention discloses oil-based shaft stabilizing fluid for gas-liquid conversion and a preparation method thereof and relates to working solution for gas-liquid conversion in the petroleum and gas drilling process. The preparation method comprises the following steps of: uniformly dissolving 3 to 5 parts of tackifier into 50 to 75 parts of mineral oil at a temperature of 20 DEG C to 60 DEG C and sufficiently stirring for 1 to 2 hours; then adding 5 to 20 parts of surfactant and sufficiently stirring for 1 to 2 hours; and adding 5 to 20 parts of formation sealant and 3 to 20 parts of temporary plugging additive and sufficiently stirring for 2 to 3 hours to form fluid with stable performance, i.e. the oil-based shaft stabilizing fluid for gas-liquid conversion. According to the invention, a mode of combining chemical and physical means is adopted; and while a well wall is prevented from being collapsed, the loading capacity of an open formation is improved, the possibility of wellbore instability and lost circulation in the gas-liquid conversion process is reduced, the unproductive time is shortened, the drilling effectiveness is improved and the drilling cost is saved.

Owner:浙江仁智股份有限公司

Method and computer program product for drilling mud design optimization to maintain time-dependent stability of argillaceous formations

InactiveUS7660672B2Increase pressureElectric/magnetic detection for well-loggingSurveyInstabilityField based

Owner:SCHLUMBERGER TECH CORP

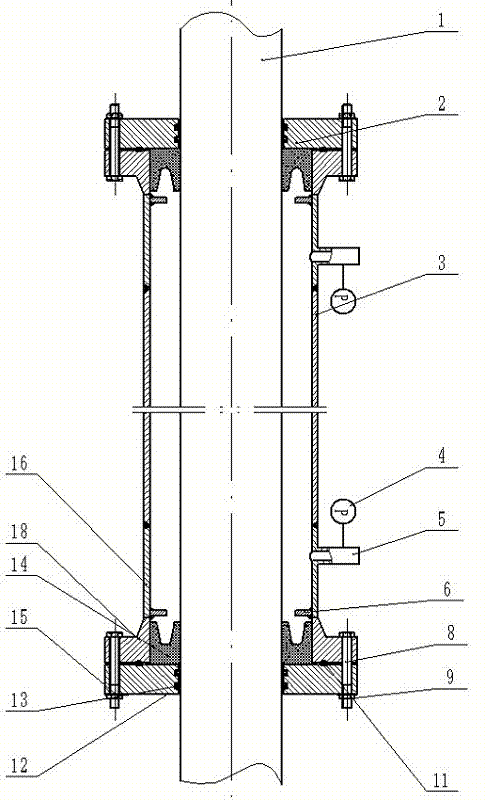

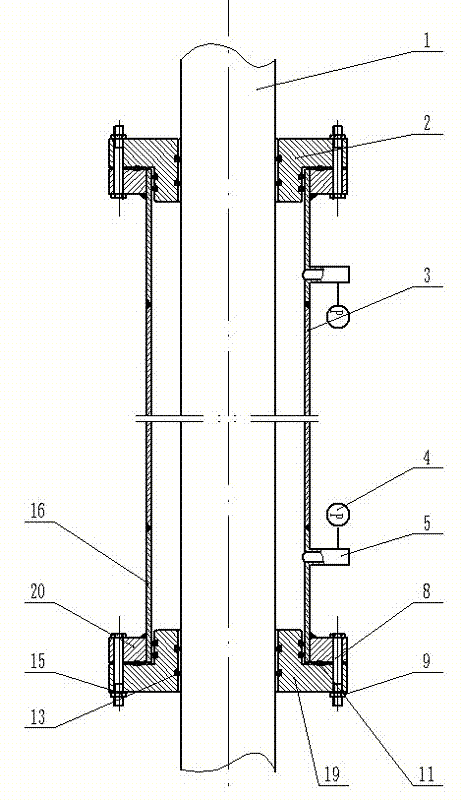

Protective device for directional penetrating pipeline

InactiveCN103672298AReliable sealing structureSimple sealing structurePipe supportsPipe protection against damage/wearLine tubingWellbore instability

The invention relates to a protective device for a directional penetrating pipeline. The problems that the penetrating pipeline is crushed, damaged and locally deformed are solved. According to the technical scheme, a protective pipeline is arranged outside the penetrating pipeline in a sleeved mode, the length of the protective pipeline is equal to that of the penetrating pipeline needing to be protected, a sealing ring and a slip are arranged at the two ends of a protective pipeline, fluid is filled into a circle between the protective pipeline and the penetrating pipeline, and the pressure of the fluid is smaller than that of internal media in the penetrating pipeline. The slip and the sealing ring seal the annular fluid and tightly hold the penetrating pipeline. The penetrating pipeline is effectively protected, the situation that pipeline is crushed, broken, injured by a crashing object and locally deformed due to wellbore instability is avoided, the penetrating pipeline is prevented from being repaired or replaced or penetrating a new pipeline again, and the protective device is especially suitable for protecting pipelines penetrating through rivers, gravel layers, soft and hard connecting strata, faults and easily-collapsing strata and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Method of minimizing wellbore instability

ActiveUS9719332B2Fluid removalAnalogue processes for specific applicationsInstabilityWellbore instability

Owner:MI

Wellbore treatment apparatus and method

A treatment apparatus and method for wellbore instability is described including a caliper with one or more radially extending arms which are capable of extending and retracting movement in a radial direction and a fluid supply facility to deliver treatment fluid from the ends of the arms to the wellbore wall, with a sensing and valve mechanism such that in use fluid is being delivered from the end of any extended arm to a breakout region of the wellbore where there is instability.

Owner:SCHLUMBERGER TECH CORP

A Method for Predicting the Equivalent Density Window of Collapse Pressure in Weak Face Formation

ActiveCN104806233BAvoid instabilityEasy to operateBorehole/well accessoriesStress distributionLower limit

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of strong inhibitory drilling fluid for drilling shale

The invention relates to a strong inhibitive drilling fluid for drilling shale for shale gas development and solves the problem of wellbore instability, and hydration collapse of the shale stratum is inhibited. The technical scheme of the strong inhibitive drilling fluid is that the the drilling fluid is prepared from the compositions of, by mass unit, 900-1,000 g of tap water, 30-60 g of bentonite for drilling fluid, 2-4 g of Na2CO3, 0.3-1 g of strong inhibitive filtrate reducer JT900 for drilling fluid, 0.5-1 g of potassium strong inhibitor FK-1, 2-5 g of coating agent FK-421 for drilling fluid, 1-1.5 g of shale inhibitor NF-923, 1-2 g of positive ion viscosity reducer XH-1, 2-3 g of shale stabilizer DLSAS, 4-6 g of reservoir shielding agent QCX-1, 2-4 g of blocking agent DE-1 and 0.5-1 g of lubricant RT-881 for drilling fluid; finally, the alkali liquor with the mass percentage concentration of 40% is prepared by adding water to NaOH, the system PH is adjusted to be 8.5, the drilling fluid weighting agent baryte is used for weighting the the system density to be 1.8-2.0 g / cm<3>, and the drilling liquid is prepared. The drilling fluid system has small environment pollution, and the drilling liquid has excellent rheological property and high sealing capacity and is used for drilling the shale.

Owner:SOUTHWEST PETROLEUM UNIV

A trenchless underground pipeline protection device

InactiveCN103672297BGuarantee long-term normal deliveryAvoid uneven forcePipe supportsPipe protection against damage/wearEngineeringWellbore instability

The invention relates to a non-excavation sunken pipe protecting device which can prevent the accidents that sunken pipes are squashed, crushed and partially deformed due to wellbore instability, and the process that the sunken pipes are repaired and replaced or a new pipe is rearranged is omitted. The protecting device is composed of a sunken pipe, blocking devices and a protecting pipe, wherein the sunken pipe penetrates into the protecting pipe, the length of the protecting pipe is equal to the length of the sunken pipe needing protection, the blocking devices are mounted at the two ends of the protecting pipe, the annular space between the protecting pipe and the sunken pipe is filled with fluid, and the pressure of the fluid is smaller than or equal to the pressure of media in the sunken pipe; each blocking device is composed of a slips structure or a flange structure, a Y-shaped sealing ring, a pressure gage, a fluid inlet pipe and an O-shaped sealing ring, so that the fluid in the annular space is sealed, and pressure detection and fluid supplement are achieved. The non-excavation sunken pipe protecting device is simple in structure, convenient to operate and suitable for protecting pipes which penetrate through railways, roads, buildings, soft soil sections and the like.

Owner:SOUTHWEST PETROLEUM UNIV

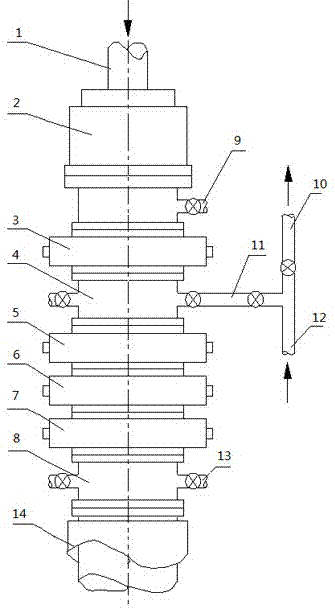

Continuous circulation drilling system and method

InactiveCN106996271AContinuous Cycle GuaranteeThe continuous cycle guarantees to keepFlushingDrilling machines and methodsWell drillingHigh pressure

The invention relates to a continuous circulation drilling system and method. The continuous circulation drilling system is formed by connecting of a rotating blowout preventer, a full-sealing blowout preventer, a semi-sealing blowout preventer, a four-way joint, an anti-rotation hanger, a circulation outlet, a high-pressure side circulation opening, a throttling flow path and the like. According to the system, in drilling of a complex stratum, drilling liquid circulation is still kept during the period of making a connection, accordingly stable equivalent circulating density and unintermittent rock debris discharging are achieved in the whole drilling period, downhole pressure is kept balance, the borehole condition is improved overall, the situations that downhole accidents such as pump suffocation, jamming of a drilling tool and overflow occur due to sand setting, wellbore instability and unbalance of the downhole pressure caused by making the connection in common drilling are avoided, and the success rate and safety of complex stratum drilling operation are improved.

Owner:中石化石油工程技术服务有限公司 +2

A kind of low-density water-based drilling fluid for drilling shale

The invention relates to low density water-based drilling fluid for drilling into shale. The fluid overcomes the problem of wellbore instability when the water-based drilling fluid is used. The drilling fluid adopts the technical scheme that the drilling fluid comprises the following raw materials: 30-50g bentonite for the drilling fluid, 1.5-2.5g sodium carbonate, 5-10g sodium hydroxide, 15-20g shear strength improving agent SZT, 2-5g zwitterionic polymer coating agent FA367, 10-15g fluid loss agent CG810S-T, 0.2-1g drilling fluid rheological regulator JHRM, 40-60g highlight calcium carbonate C-L501, 10-30g lubricant R-16, 25-35g emulsified paraffin, 40-60g solid polymerization alcohol JHGC for the drilling fluid and 1000g tap water. The tap water, the bentonite for the drilling fluid and soda are added for prehydration for 24h first, the shear strength improving agent SZT is added under the mixing condition at 8000r / min, then the treatment agents are sequentially added under the mixing condition at 500r / min, pH (potential of hydrogen) of a system is regulated to 8.5, and barite is added finally. The drilling fluid system has good rejection capability and blocking performance and is used for drilling of a long horizontal section of a shale bed.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of clay inhibitor for drilling fluid and preparation method thereof

ActiveCN110551488BEnhanced inhibitory effectReduce collapseDrilling compositionNitrohumic acidWater chlorination

Owner:北京宏勤石油助剂有限公司

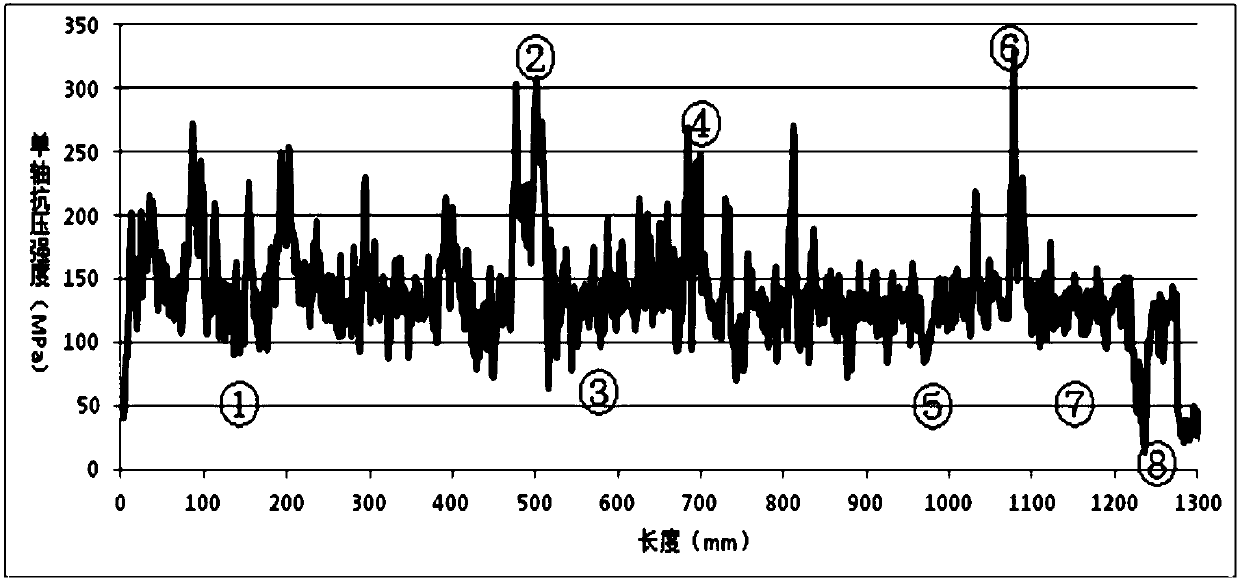

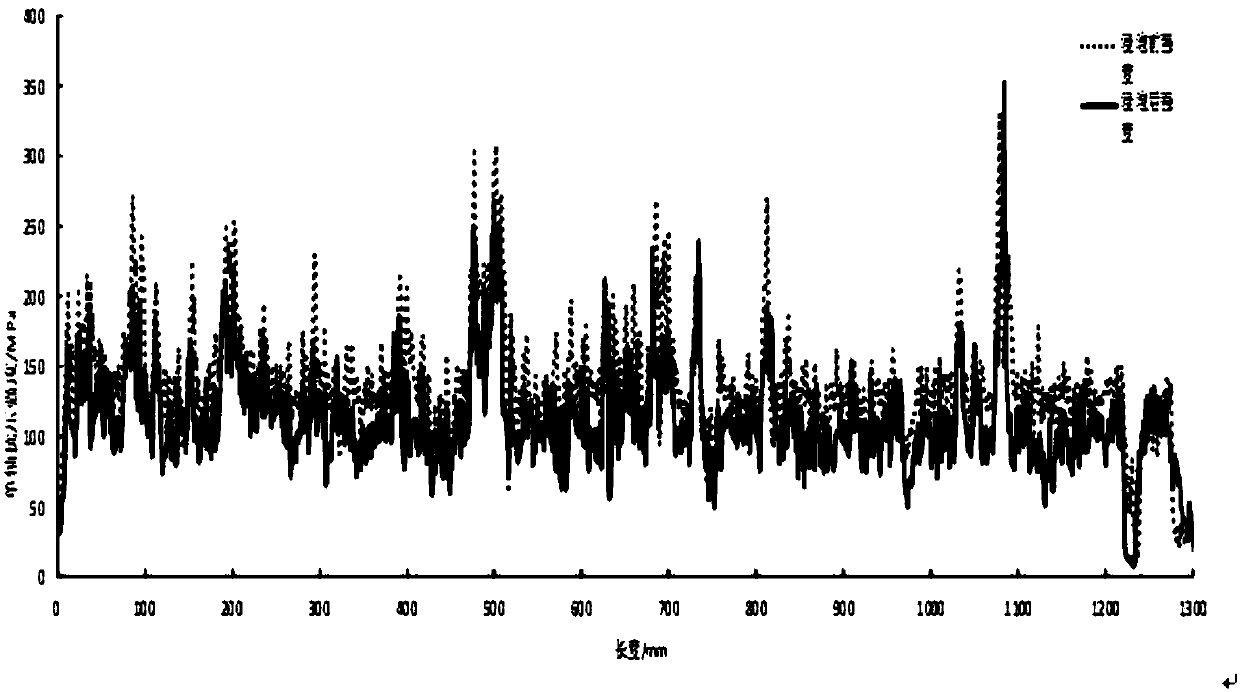

Evaluation method of degree of shale strength reduction in research on shale wellbore instability

InactiveCN109900568AReduce damageEffective response heterogeneityInvestigating material hardnessOutcropWorking fluid

The invention discloses an evaluation method of degree of shale strength reduction in research on shale wellbore instability. The evaluation method comprises the steps that (1) a shale core or outcropwith one flat surface is adopted, the shale sample is placed in a rock strength continuous marking test system to be marked, strength values in all marked positions are acquired; (2) the whole shalesample is immersed into a working fluid to be soaked; (3) in the same position, the shale sample is marked again in the same direction as the first marking, and strength values in all marking positions after soaking are acquired; and (4) difference of the strength values between the same position before soaking and after being soaked is the degree of shale strength reduction, degree of reduction is divided by the strength values before soaking, and thus strength reduction rate is obtained. According to the evaluation method of degree of shale strength reduction in the research on shale wellbore instability, errors due to core taking damage in a traditional pressure resistance method are avoided, the evaluation method has the characteristics that accuracy, fastness and convenience are achieved, and damage degree of the shale sample is small, the heterogeneous characteristic of the shale can be effectively reflected, and influence on the shale strength and strength reduction degree of mineral components and structures is finely evaluated.

Owner:CHINA PETROLEUM & CHEM CORP +1

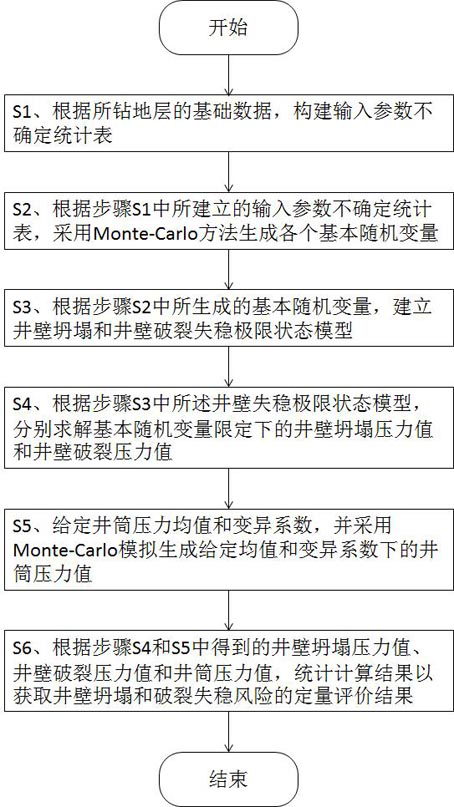

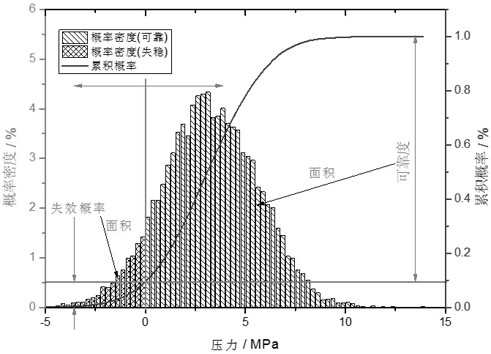

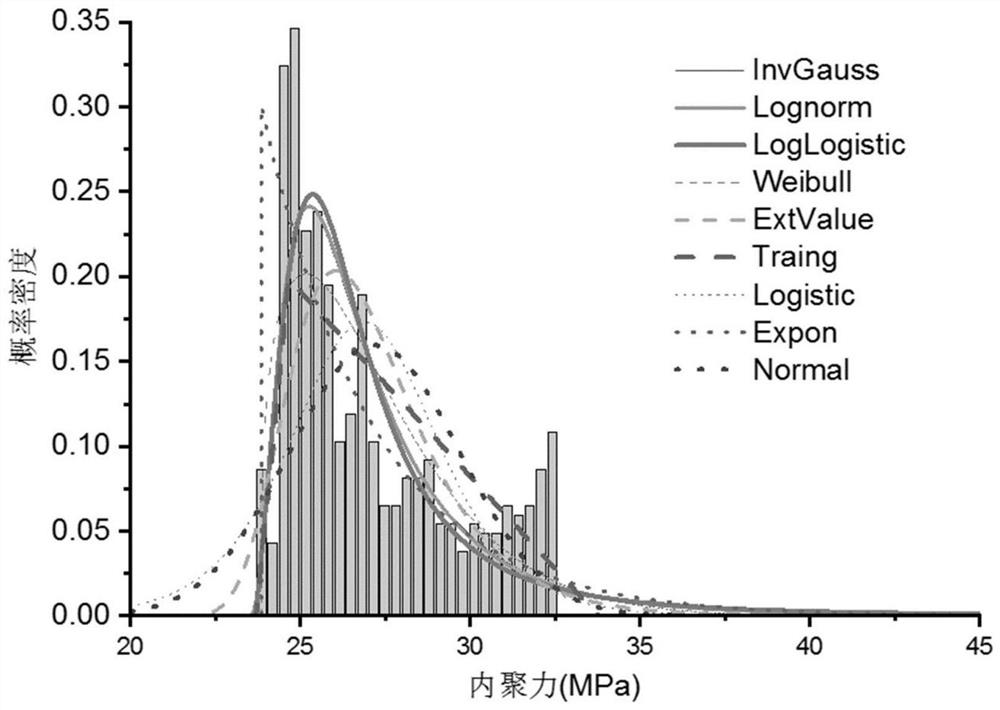

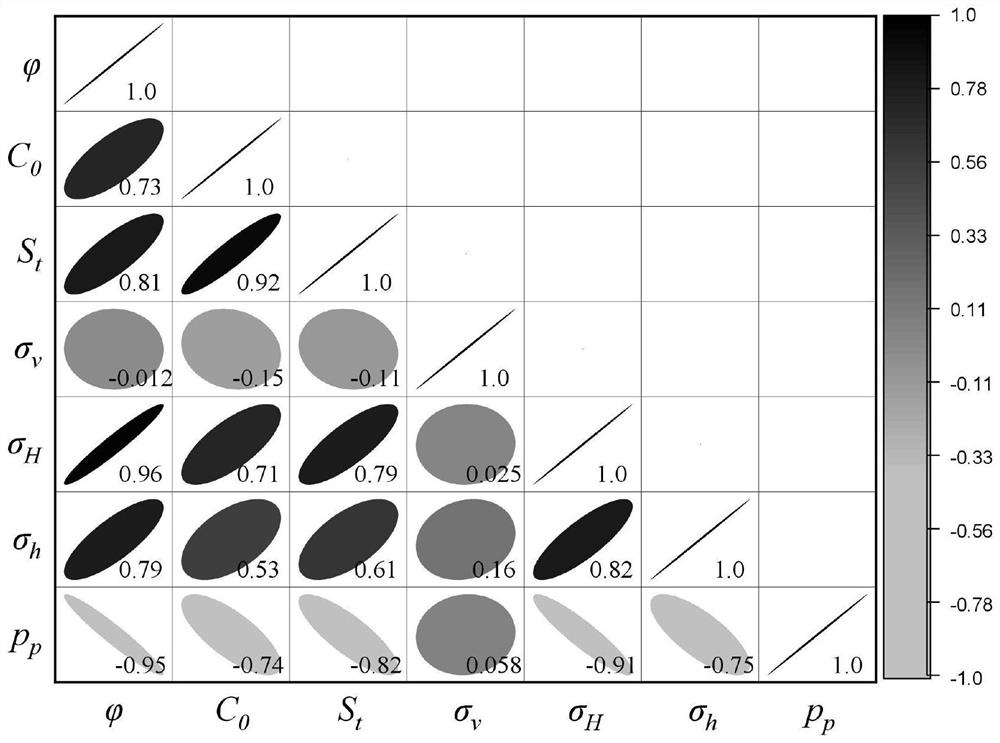

A quantitative evaluation method for wellbore instability risk based on reliability theory

ActiveCN109858147BOvercoming the inability to account for the effects of parameter uncertaintyAccurate decision basisDesign optimisation/simulationResourcesWell drillingClassical mechanics

The invention discloses a method for quantitative evaluation of wellbore instability risk based on reliability theory, which comprises the following steps: S1, according to the basic data of the drilled stratum; S2, according to the input parameter uncertainty statistical table established in step S1 S3, establish the limit state model of wellbore collapse and wellbore fracture instability; S4, according to the wellbore instability limit state model described in step S3, respectively solve the wellbore collapse pressure value and wellbore fracture limited by the basic random variables Pressure value; S5. Given the mean value and coefficient of variation of wellbore pressure, and use Monte Carlo simulation to generate the value of wellbore pressure under the given mean value and coefficient of variation; S6, Statistical calculation results to obtain the quantification of the risk of wellbore collapse and rupture instability Evaluation results. The beneficial effects of the invention are that the risk of wellbore instability under the influence of parameter uncertainty can be quantitatively evaluated, and more accurate and effective decision-making basis can be provided for drilling technicians and construction personnel.

Owner:SOUTHWEST PETROLEUM UNIV

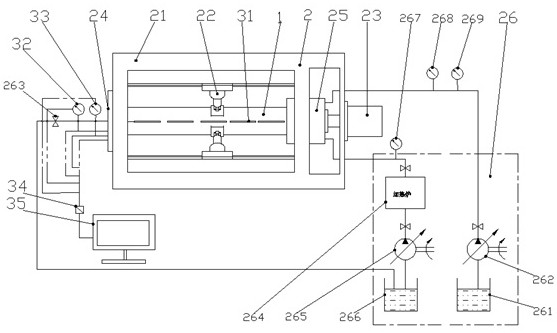

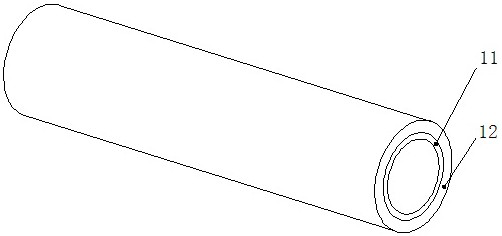

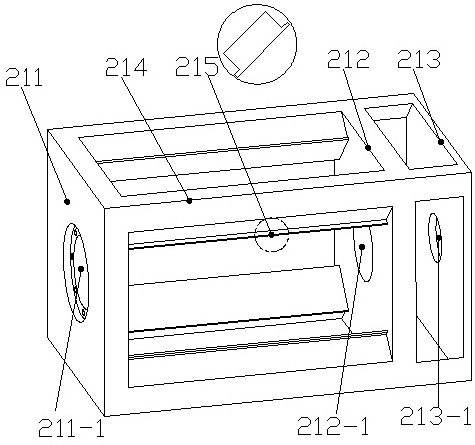

A Wellbore Instability Loading Experiment Platform and Its Loading Method

The invention relates to a wellbore instability loading test platform and a loading method thereof, wherein the wellbore instability loading test platform includes a test piece, a loading system, and a detection system; the test piece is a simulated wellbore, and is cemented by a cement sheath and a casing Formed together, the loading system includes a loading platform, a radial loading cylinder assembly, an axial loading cylinder assembly, and a hot and cold water circulation injection system. Each radial loading cylinder assembly provides a radial load for the test specimen, and the axial loading cylinder assembly provides The test piece provides axial load; the cold water injection system simulates the high and low temperature environment of the wellbore in the formation. The detection system includes multiple stress and strain sensors, temperature sensors, pressure sensors, signal transmitters, computers, and stress and strain sensors. At the outer wall of the casing and at the inner and outer walls of the cement sheath. The invention can truly simulate the actual wellbore instability and destruction process, and can accurately and real-time monitor and detect the deformation and failure data of the cement sheath and the casing.

Owner:NORTHEAST GASOLINEEUM UNIV

Protective device for directional penetrating pipeline

InactiveCN103672298BReliable sealing structureSimple sealing structurePipe supportsPipe protection against damage/wearLine tubingEngineering

The invention relates to a protective device for a directional penetrating pipeline. The problems that the penetrating pipeline is crushed, damaged and locally deformed are solved. According to the technical scheme, a protective pipeline is arranged outside the penetrating pipeline in a sleeved mode, the length of the protective pipeline is equal to that of the penetrating pipeline needing to be protected, a sealing ring and a slip are arranged at the two ends of a protective pipeline, fluid is filled into a circle between the protective pipeline and the penetrating pipeline, and the pressure of the fluid is smaller than that of internal media in the penetrating pipeline. The slip and the sealing ring seal the annular fluid and tightly hold the penetrating pipeline. The penetrating pipeline is effectively protected, the situation that pipeline is crushed, broken, injured by a crashing object and locally deformed due to wellbore instability is avoided, the penetrating pipeline is prevented from being repaired or replaced or penetrating a new pipeline again, and the protective device is especially suitable for protecting pipelines penetrating through rivers, gravel layers, soft and hard connecting strata, faults and easily-collapsing strata and the like.

Owner:SOUTHWEST PETROLEUM UNIV

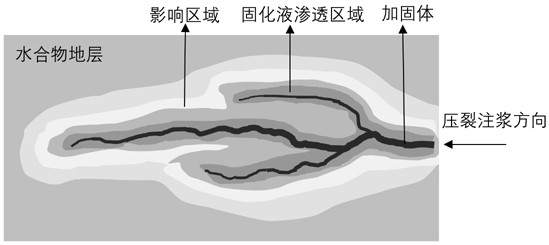

Theories and Realization Methods of Reinforcement and Anti-Slump and Sand Control in Natural Gas Hydrate Formation

ActiveCN113417596BImprove stabilityGood cementing propertiesFluid removalSealing/packingClassical mechanicsWell cementing

The invention belongs to the field of reservoir reconstruction in the natural gas hydrate development process, and in particular relates to the theory and realization method of reinforcement and anti-slump and sand prevention in the natural gas hydrate stratum. The present invention combines stratum reconstruction with fracturing and grouting reinforcement technology, through the fracturing and grouting process, cracks appear in the natural gas hydrate formation, and the solidified liquid enters the cracks and goes deep into the formation through the pressure difference, forming a "rib" structure And it is a reinforced body with certain strength and permeability, which supports and prevents the formation from collapsing and sand. In the present invention, through the analysis of the physical parameters of the target formation, the use of the curing agent system, the regulation of the fracturing construction process and the pumping of the solidification liquid into the formation during the fracturing process, the purpose of strengthening and preventing collapse and sand prevention in the natural gas hydrate formation is realized, forming The reinforced body can be well cemented with the surrounding formation, effectively avoiding sand production caused by hydrate decomposition, and well wall instability caused by formation collapse.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

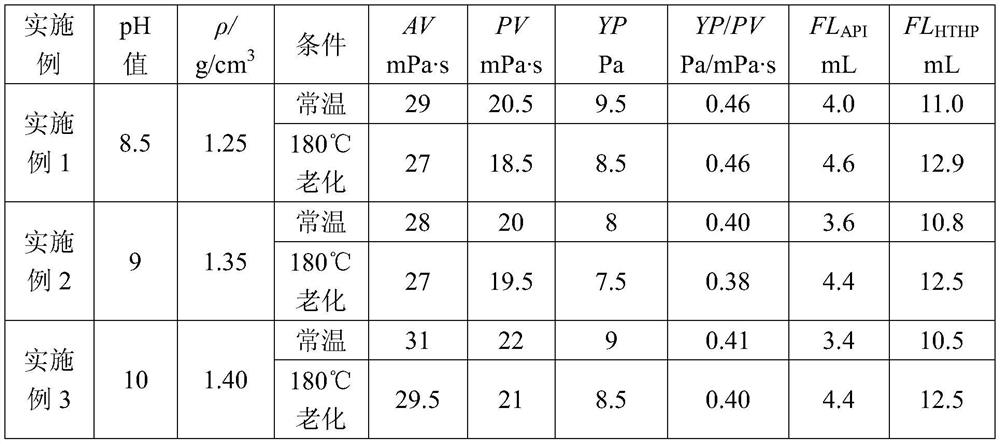

Polymer Clean Drilling Fluid System

A polymer cleaning drilling fluid system, which is made of the following raw materials: tap water, bentonite, sodium carbonate, sodium hydroxide, fluid loss reducer, wall solidifying agent, coating agent, polyanionic cellulose, high temperature resistant Salt fluid loss reducer, lubrication inhibitor, solid lubricant for drilling fluid, solid lubricant graphite, KCl, gel plugging agent, ultrafine calcium carbonate powder, weighting agent barite powder. The preparation method of the fluid loss reducer and the wall-fixing agent is also provided. FL after aging at 180°C in the present invention HTHP ≤13mL, 8h linear expansion reduction rate ≥80%, cuttings rolling recovery rate ≥92%, mud cake adhesion coefficient ≤0.1, it has good fluid loss control performance, inhibition performance and lubricating performance, suitable for sand-shale mixed layer Drilling of deviated or horizontal sections of formations. The invention has good comprehensive performance, low cost, environmental protection, effectively solves the problem of well wall instability easily caused by water-based drilling fluid in the drilling process, and is beneficial to wellbore cleaning, reservoir cleaning and environmental protection.

Owner:石家庄华莱鼎盛科技有限公司

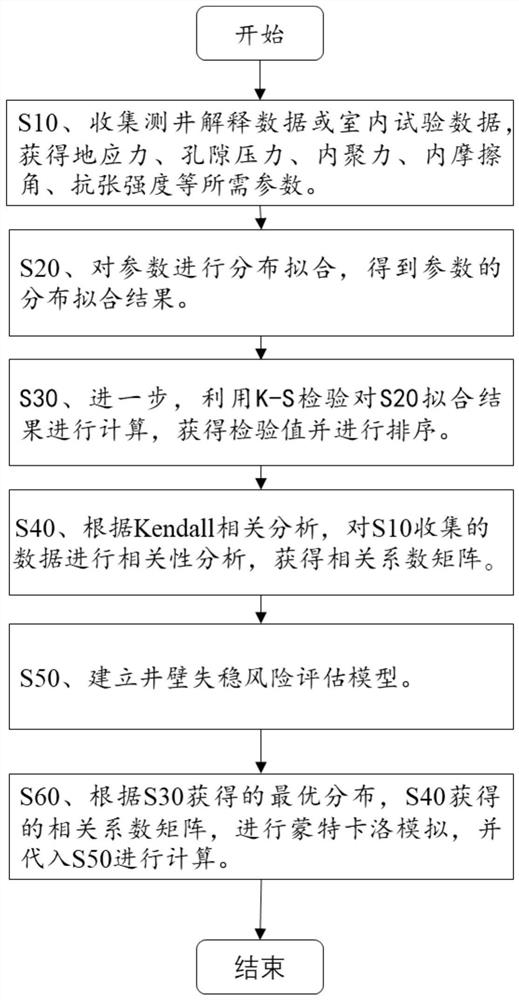

A Quantitative Evaluation Method for Borehole Instability Risk in Complex Formation Drilling

ActiveCN113239577BImprove accuracyDesign optimisation/simulationResourcesCorrelation coefficientWell logging

The invention discloses a method for quantitatively evaluating the risk of wellbore instability in complex formation drilling, including: determining geomechanical parameters and rock mechanical parameters; obtaining distribution fitting results of the geomechanical parameters and rock mechanical parameters; Calculate the distribution fitting results of parameters and rock mechanics parameters, obtain K-S test values and sort them; conduct correlation analysis on geomechanics parameters and rock mechanics parameters to obtain a correlation coefficient matrix; establish a reliability evaluation model for wellbore instability risk; According to the K-S test value and the correlation coefficient matrix, Monte Carlo simulation is carried out and brought into the wellbore instability risk reliability evaluation model to calculate the wellbore instability risk. The invention fully characterizes the uncertainty of parameters by using well logging data or indoor experiment results, especially considering the correlation between various parameters, so that the samples obtained by Monte Carlo sampling are more accurate, and the risk assessment of well wall instability is improved. accuracy.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com