Patents

Literature

50results about How to "Hydrophobic and oleophobic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-hydrophobic and oleophobic composite coating and preparation method thereof

InactiveCN104745045AImprove hydrophobicity and oleophobicityHydrophobic and oleophobicPretreated surfacesEpoxy resin coatingsGas phaseSolvent

The invention discloses a super-hydrophobic and oleophobic composite coating which comprises a super-hydrophobic and oleophobic primer coat layer and a super-hydrophobic and oleophobic finishing coat layer. The coating is characterized in that the super-hydrophobic and oleophobic finishing coat layer is located on the super-hydrophobic and oleophobic primer coat layer; the super-hydrophobic and oleophobic primer coat layer is coated by a super-hydrophobic and oleophobic primer coat which is a composition containing epoxy resin, an auxiliary A, extinction powder and a solvent; the super-hydrophobic and oleophobic finishing coat layer is coated by a super-hydrophobic and oleophobic finishing coat which is a composition containing fumed silica, an auxiliary B, an auxiliary C, a mixed solution A and a mixed solution B. Compared with the prior art, the super-hydrophobic and oleophobic composite coating disclosed by the invention not only has a super-hydrophobic performance, but also can resist greasy dirt and has a super-oleophobic performance as well as good wear resistance and stability; the preparation process is simple, and realization of industrialized production is facilitated.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

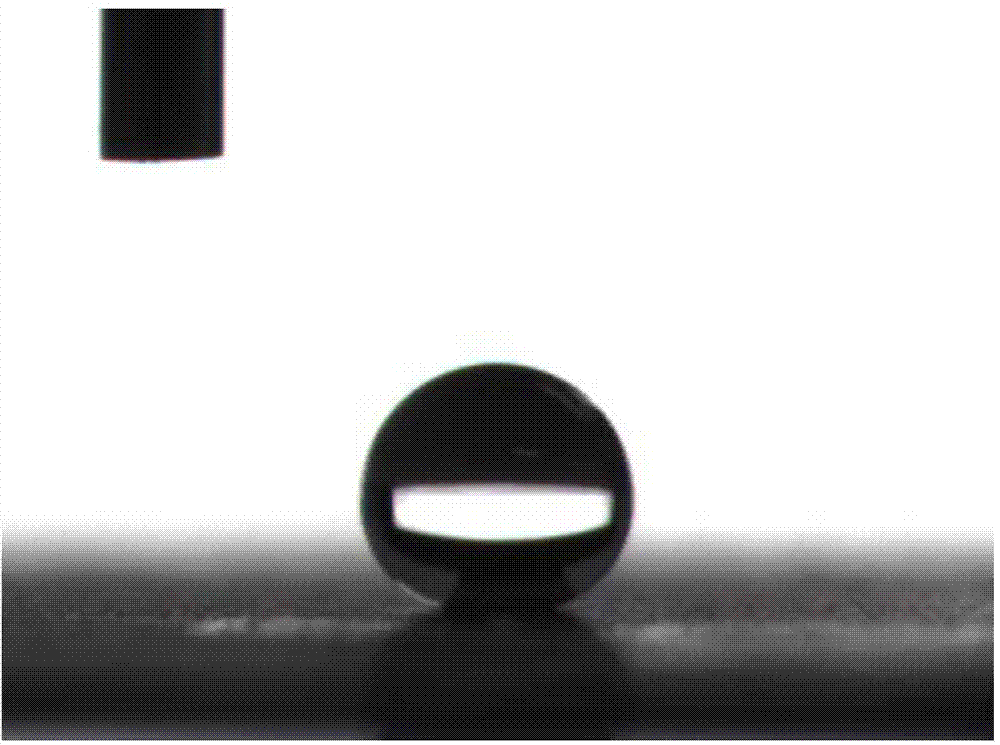

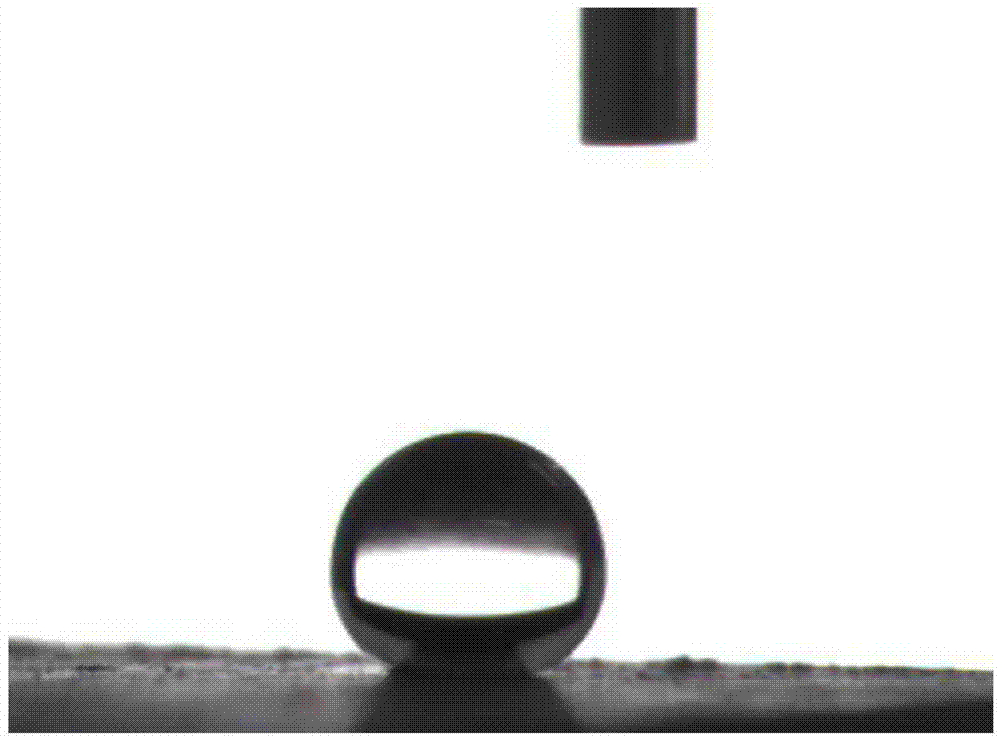

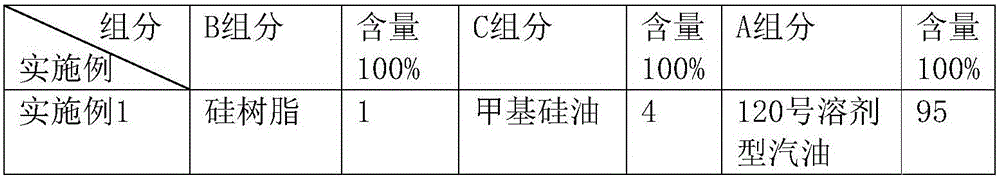

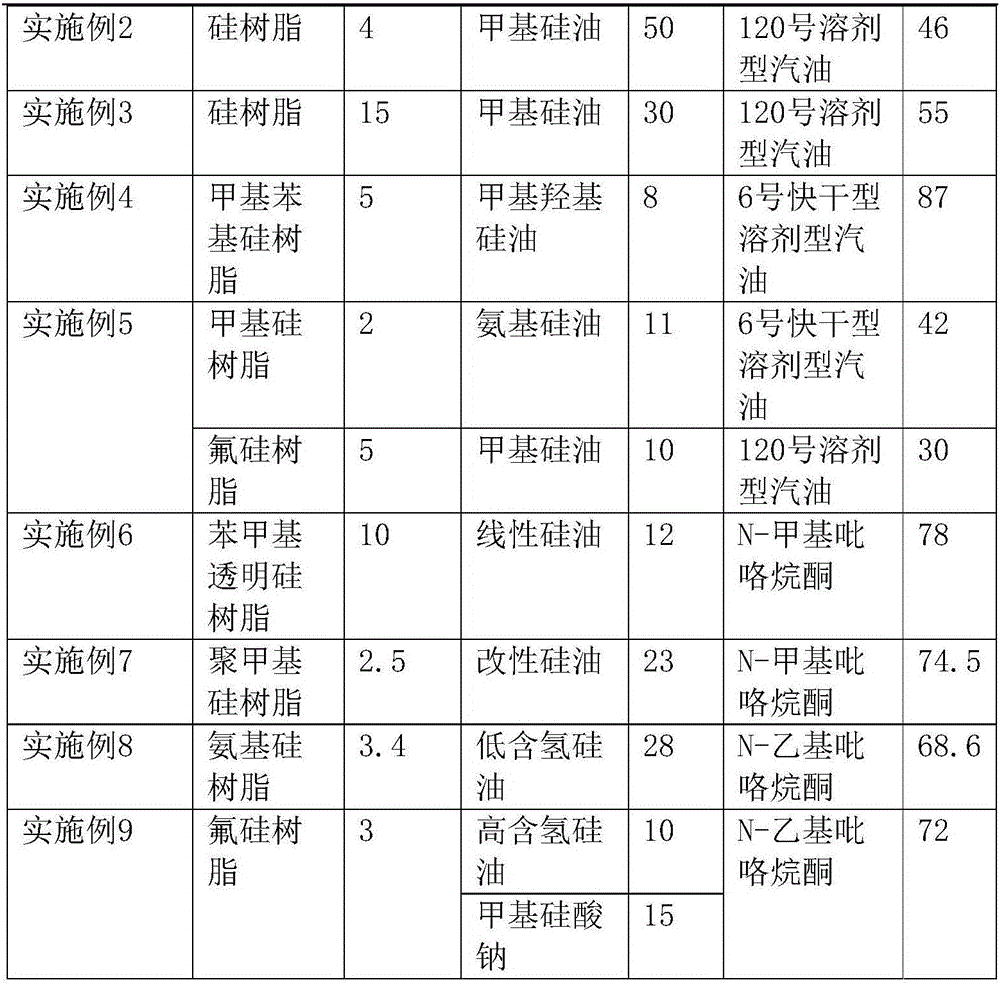

Matte brick stain-proofing agent and preparation method thereof

ActiveCN105860831AAntifoulingExtended service lifeAntifouling/underwater paintsPaints with biocidesOrganic solventBrick

The invention discloses a matte brick stain-proofing agent. The matte brick stain-proofing agent is prepared from a component A, a component B and a component C, wherein the component A is an organic solvent, the component B is silicon resin, and the component C is at least one of silicone oil and organosiloxane monomers. The invention further provides a preparation method of the matte brick stain-proofing agent. By compounding the components, the matte brick stain-proofing agent can achieve a good stain-proofing effect when used for performing stain-proofing treatment on the surfaces of matte bricks in follow-up application; besides, the matte brick stain-proofing agent has a very long shelf life and service life; moreover, the preparation technology is simple and easy to implement and can be conveniently applied to industrial production.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

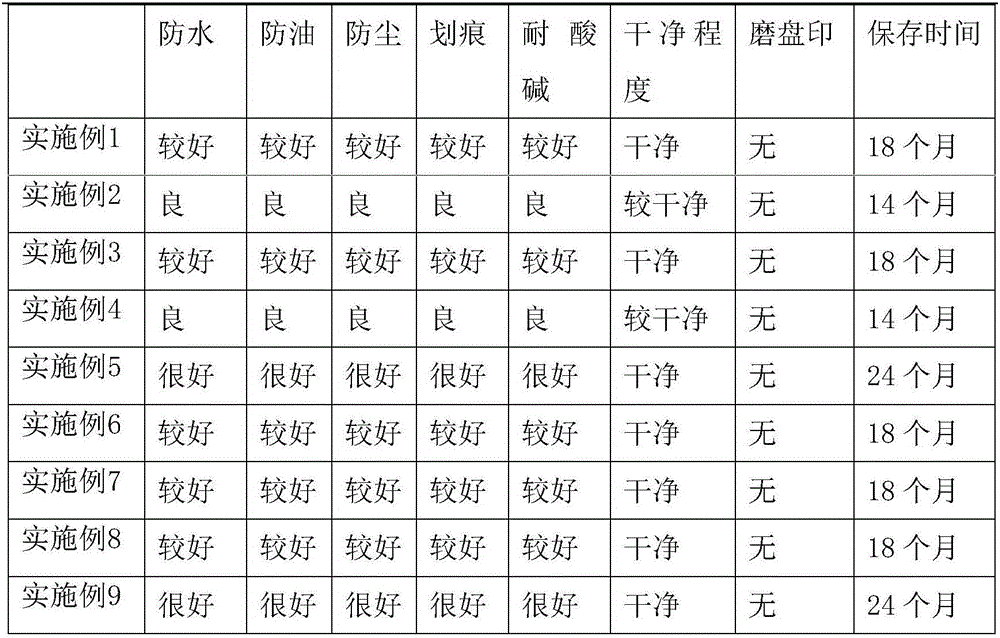

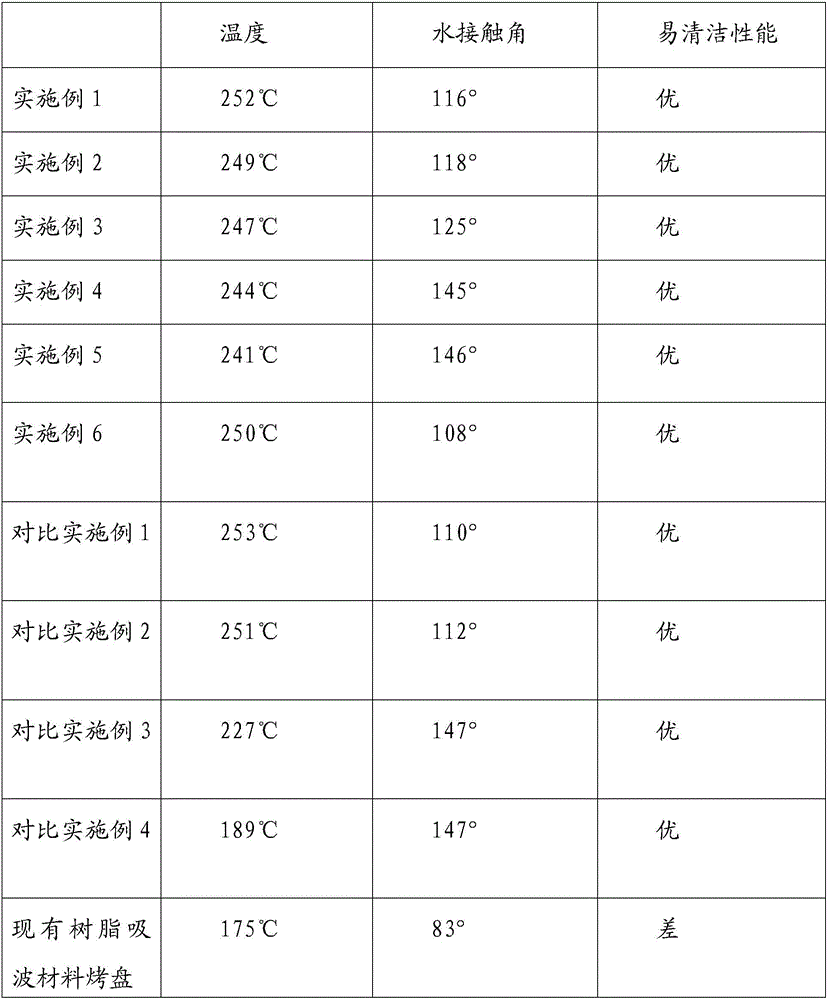

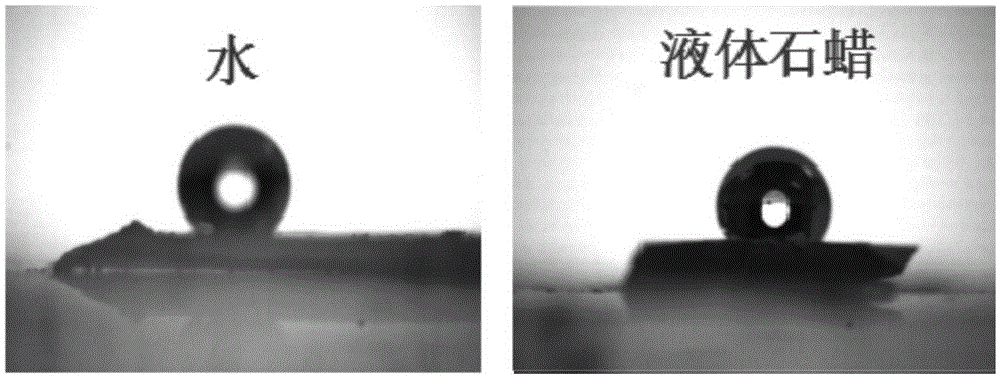

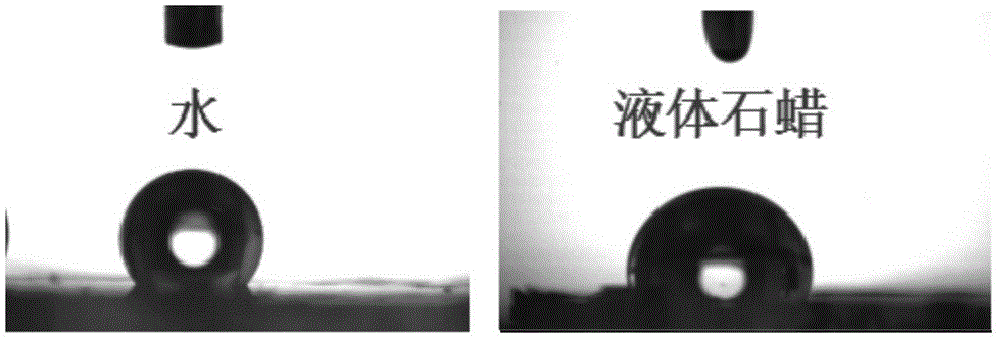

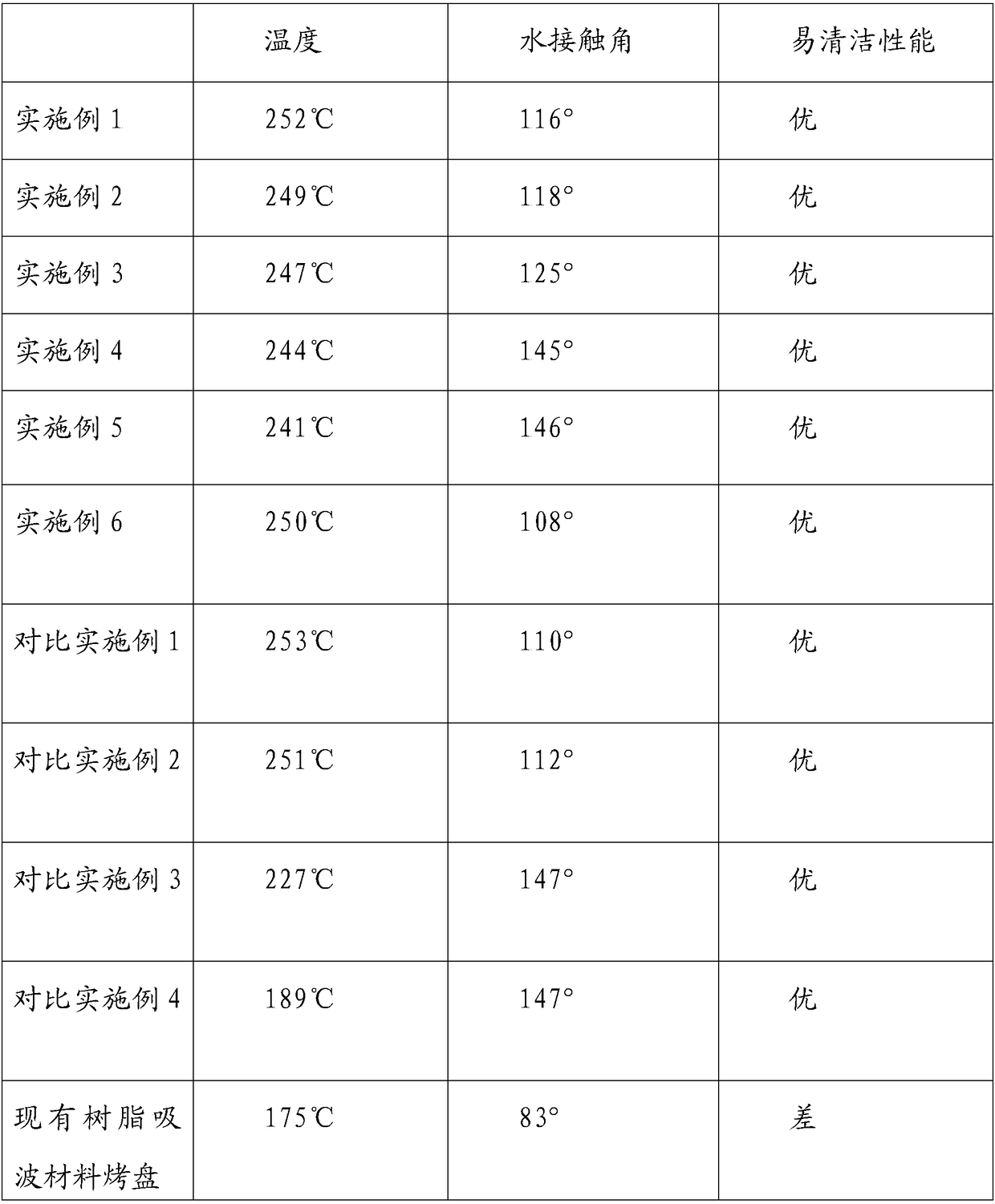

Lyophobic and oleophobic wave absorption material and preparation method thereof

ActiveCN105925023AHydrophobic and oleophobicNot easy to stickFireproof paintsRadiation-absorbing paintsMaterials scienceCoating

The invention relates to a lyophobic and oleophobic wave absorption material and a preparation method thereof. The lyophobic and oleophobic wave absorption material is prepared from the following ingredients in percentage by weight: 87 percent to 93 percent of wave absorption material bonding agents with lyophobic and oleophobic performance, 6 percent to 12 percent of wave absorption materials and 0.5 percent to 1 percent of auxiliary agents. During the preparation, all ingredients are uniformly mixed. The lyophobic and oleophobic wave absorption material can be used for coatings of kitchen electric products. The lyophobic and oleophobic wave absorption material has the advantages that the lyophobic performance is good; the cleaning is easy; high temperature resistance is realized; the health and environment protection are realized, and the like.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Preparing method for hydrophobic and oleophobic cosmetic pigment powder

ActiveCN105456048AHydrophobic and oleophobicSoft touchCosmetic preparationsMake-upNano siliconAlcohol

The invention discloses a preparing method for hydrophobic and oleophobic cosmetic pigment powder. The preparing method includes the following steps that 1, nano-silicon sol is sprayed to the surface of inorganic powder under the high-speed stirring condition; 2, first-time heat treatment is carried out; 3, fluorine containing silane is dispersed through ethyl alcohol or isopropanol, and then the fluorine containing silane is sprayed to the surface of the treated inorganic powder under the high-speed stirring condition; 4, second-time heat treatment is carried out; 5, airflow smashing is carried out. The powder prepared with the preparing method has the advantages that the hydrophobic performance and the oleophobic performance are achieved, soft and smooth hand feeling is achieved, and the skin fitting performance is good; as various kinds of toner are added into an emulsification system at the same time, the color floating problem can be solved, the color floating problem of the pigment powder treated through the fluorine containing silane in the cosmetic formula is fundamentally solved, and quite large convenience is provided for production and quality control of fluorated liquid foundation (cream) products.

Owner:SHANGHAI CO FUN BIOTECH

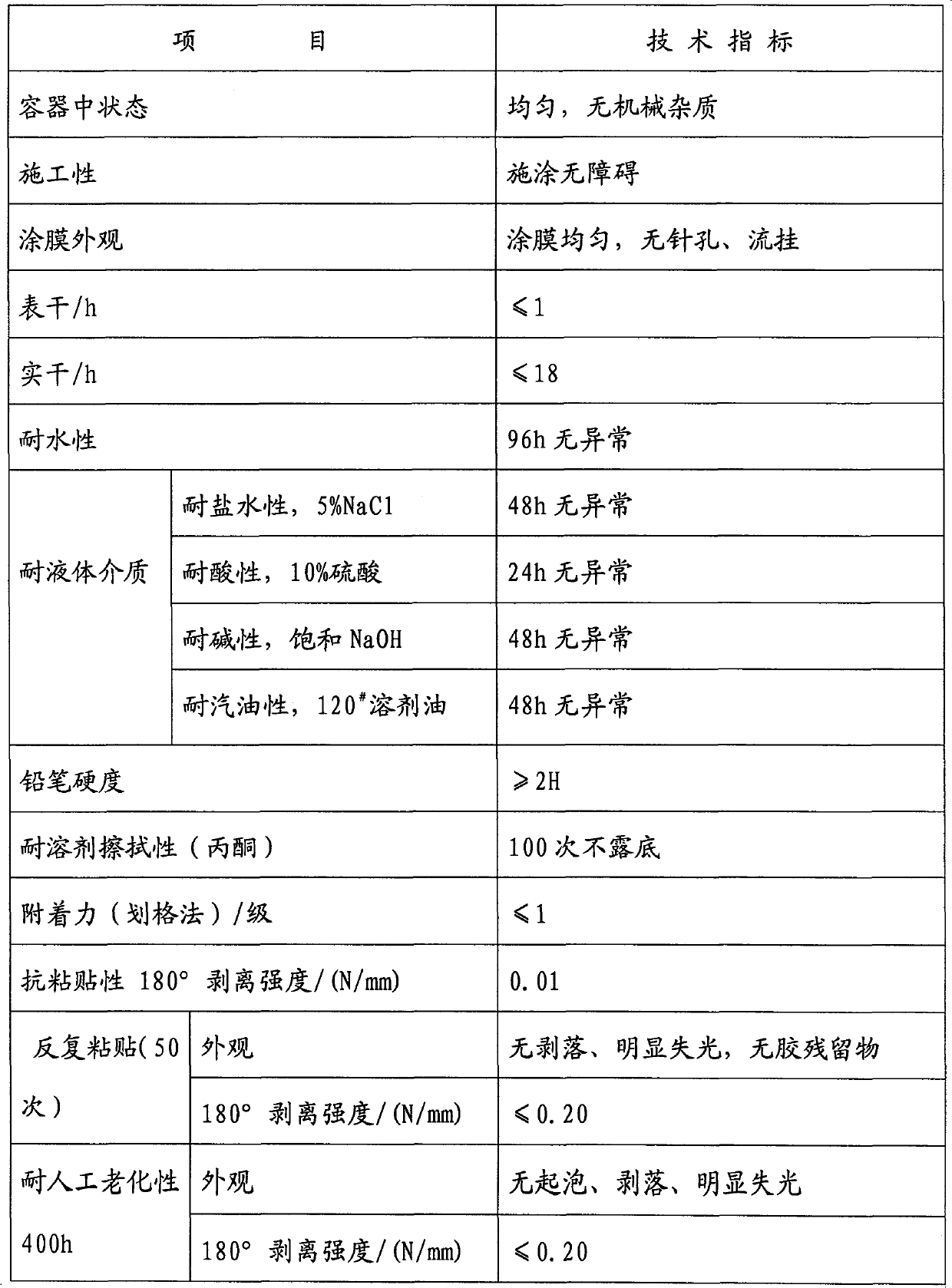

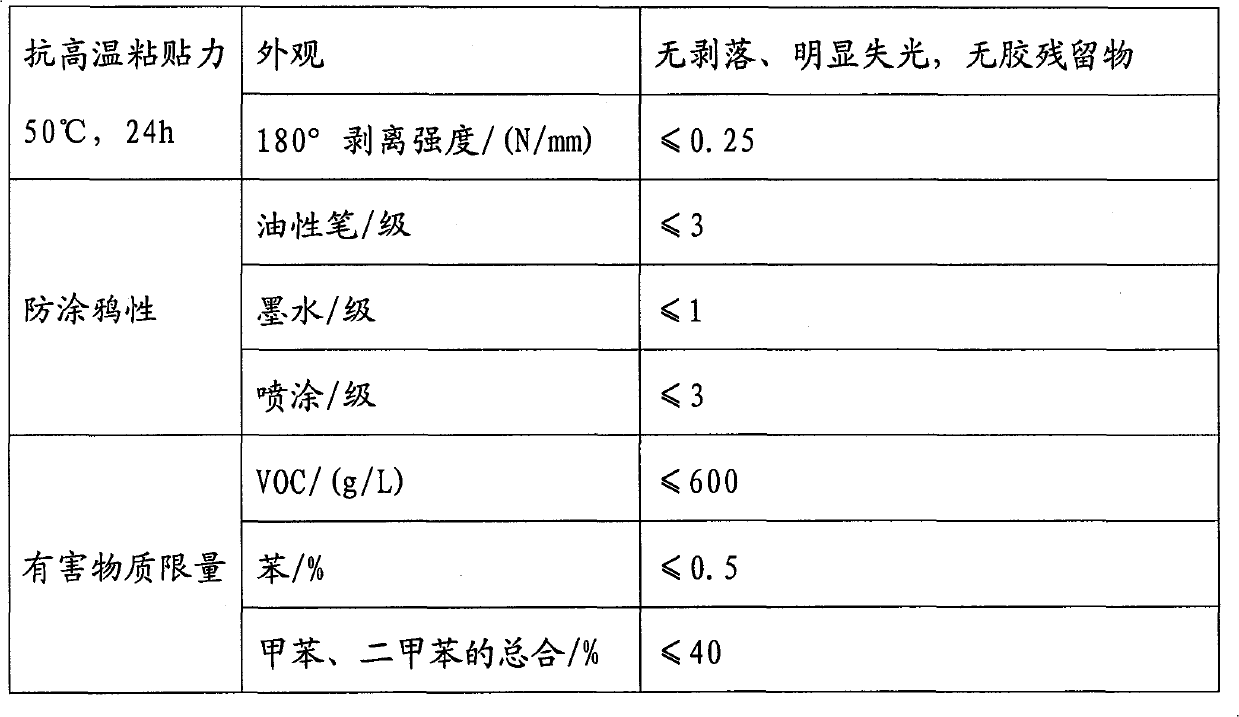

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

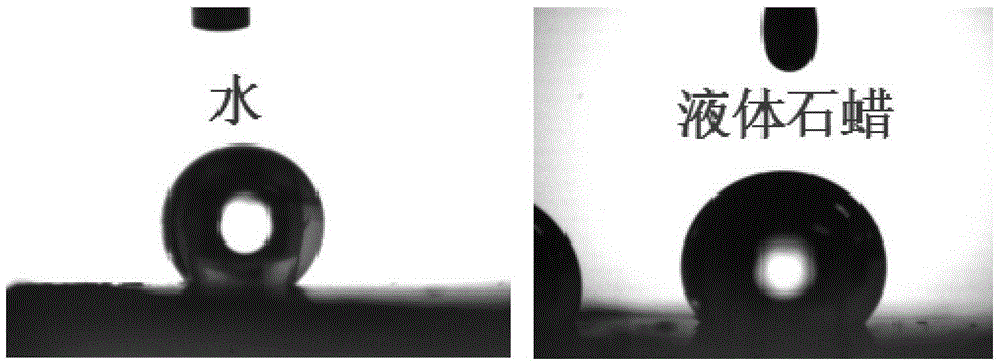

ActiveCN101585995BHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, polydimethyl siloxane resin containing hydroxyl functional group, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easycleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

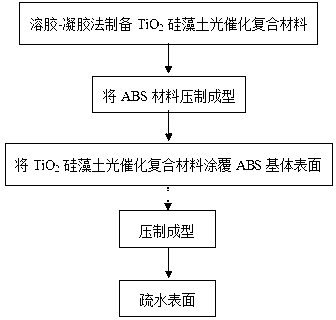

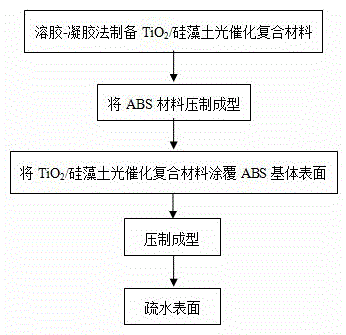

ABS hydrophobic and oleophobic material with surface loaded by TiO2/diatomite, and preparation method thereof

InactiveCN103275456AEasy to useOleophobicOrganic-compounds/hydrides/coordination-complexes catalystsFungicidesCompression moldingPollution

The invention provides an ABS hydrophobic and oleophobic material with surface loaded by TiO2 / diatomite, and a preparation method thereof. The ABS hydrophobic and oleophobic material is composed by the following raw materials by mass: 98-99.9% of an ABS resin and 0.1-2% of a TiO2 / diatomite composite photocatalytic material. The ABS hydrophobic and oleophobic material with the surface loaded by TiO2 / diatomite is obtained by the steps of A. firstly preparing the TiO2 / diatomite composite photocatalytic material, B. dispersing the TiO2 / diatomite composite photocatalytic material in ethanol to form a suspension liquid, and C. coating the suspension liquid on the surface of a mold, then keeping ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, and compression molding at the temperature of 150-180 DEG C; or keeping the ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, compression molding at the temperature of 150-180 DEG C, then coating the suspension liquid obtained by the step B on the surface of the compression molded ABS resin material, and then compression molding at the temperature of 150-180 DEG C. The ABS hydrophobic and oleophobic material has the characteristics of super-hydrophobic surface self-cleaning effect and self-cleaning capacity. The preparation method is simple in process, simple in operations, small in investment, low in operation cost and no pollution to environment.

Owner:KUNMING UNIV OF SCI & TECH

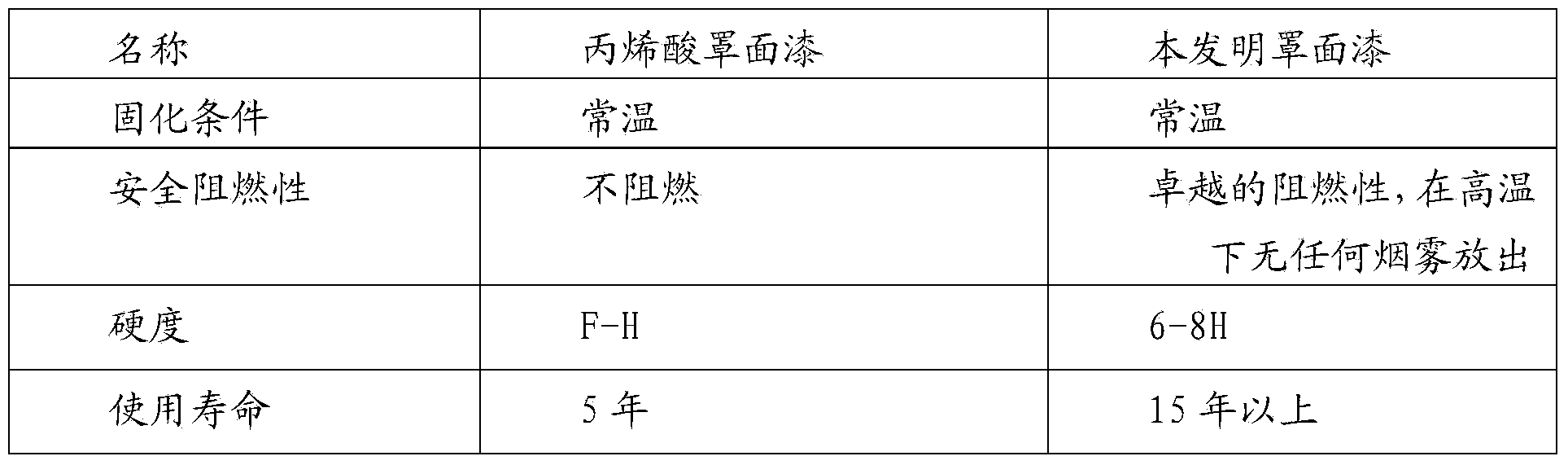

Inorganic overcoat resin and preparation method thereof

The invention discloses an inorganic overcoat resin which comprises an inorganic nano material having a solid content of 42-46%, wherein the inorganic nano material is synthesized through a sol-gel method process from the following components in parts by weight: 1-30 parts of ethyl orthosilicate, 1-10 parts of methyltrimethoxy silane, 1-50 parts of mixture of silicon dioxide, aluminum oxide, titanium dioxide and zirconium dioxide and 1-50 parts of water-alcohol mixture; the weight ratio of the silicon dioxide, aluminum oxide, titanium dioxide and zirconium dioxide in the mixture thereof is 50:20:20:10; and the water-alcohol weight ratio of the water-alcohol mixture is 65:35. According to the invention, the inorganic overcoat resin is prepared from the pure inorganic nano material, and the service life can be kept at 15 years or above; and the composition adopts a methyl introduction manner, so that the overcoat has hydrophobic / oleophobic properties, thus ensuring that self cleaning of a decorative layer can be realized by rainfall.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

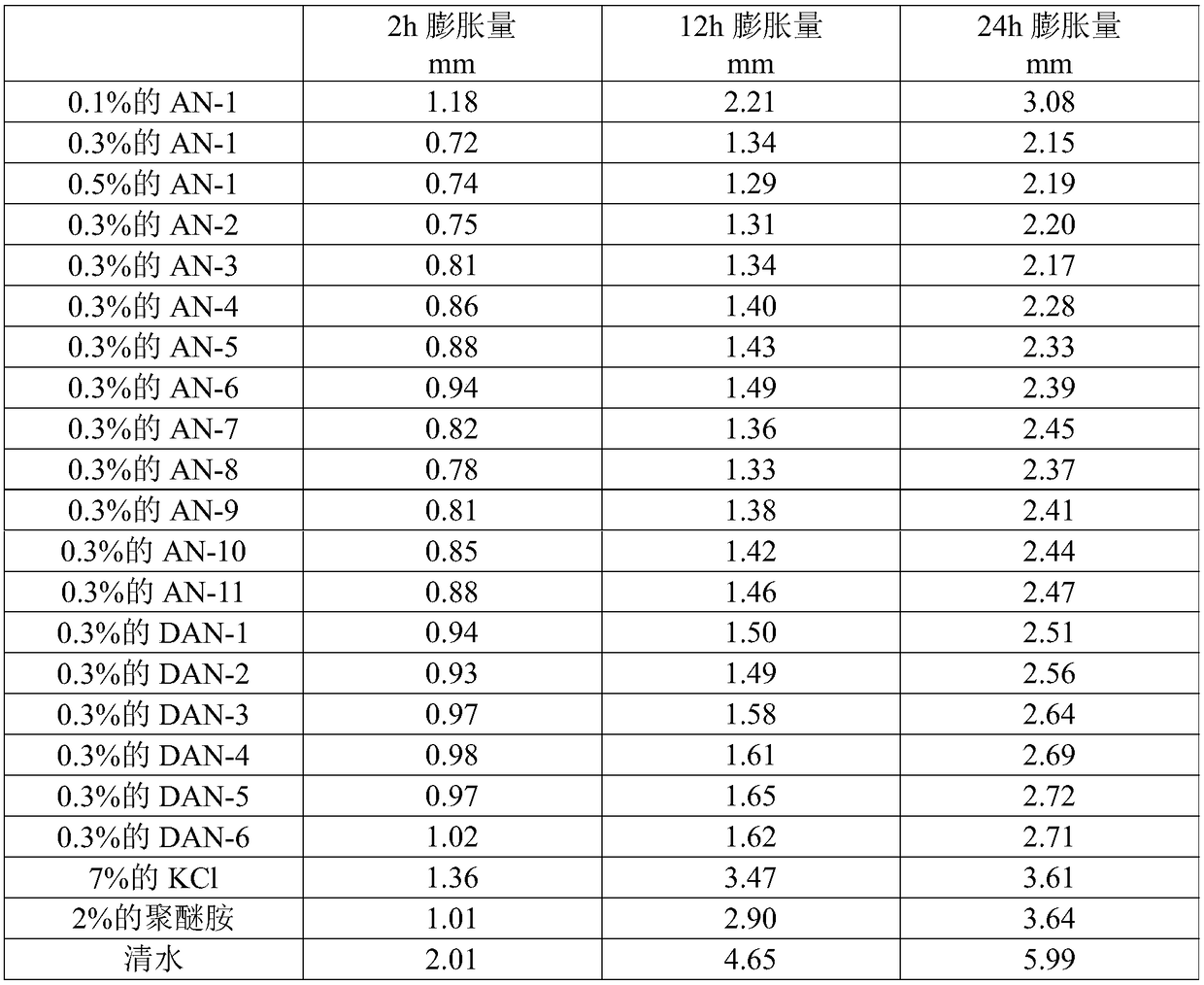

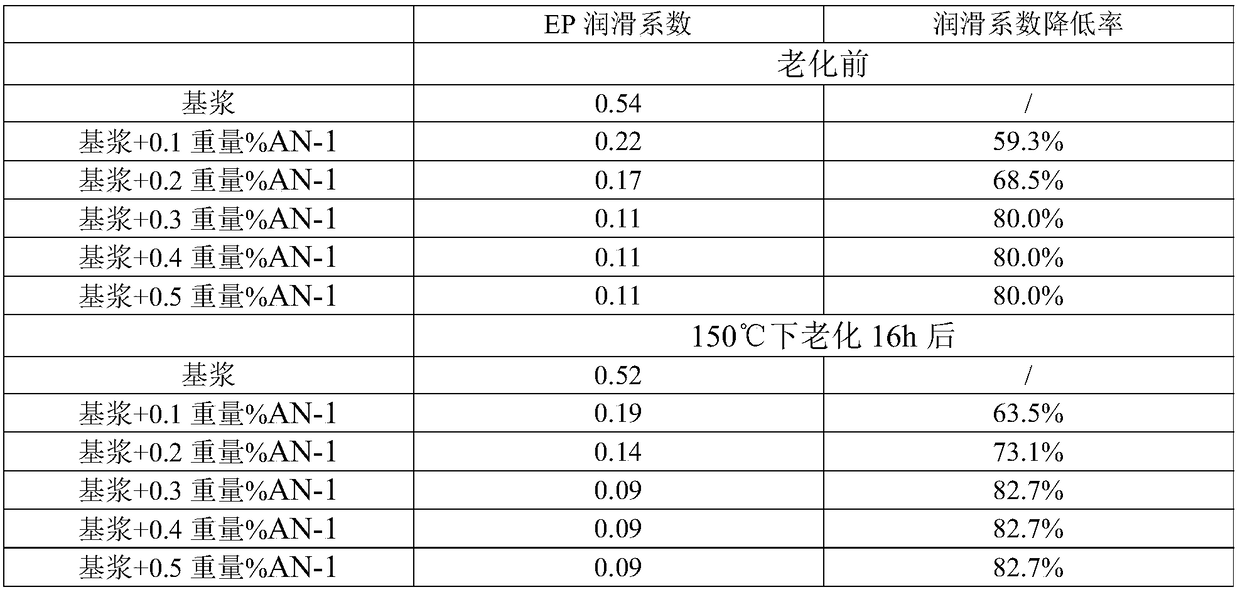

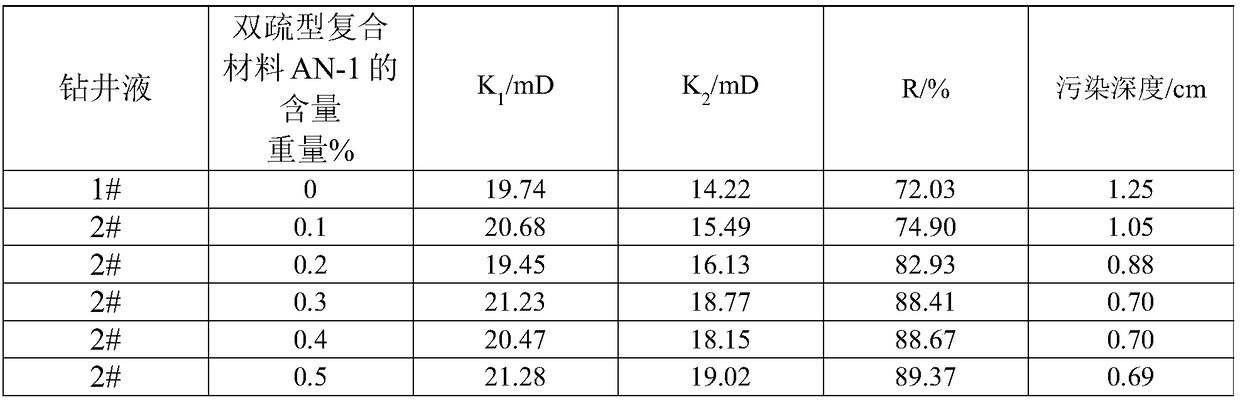

Superamphiphobic composites and their applications as inhibitors, lubricants and reservoir protectants in water-based drilling fluids

ActiveCN108165241BHydrophobic and oleophobicSuperamphiphobicDrilling compositionWater basedHorizontal wells

The invention relates to the field of oil and gas drilling, in particular to a super-hydrophobic composite material, and application of the super-hydrophobic composite material used as an inhibitor, alubricant and a hydrocarbon reservoir protective agent in water-based drilling fluid. A preparation method of an amphiphobic composite material comprises the steps of under an alkaline condition, inan ethanol-water mixture solvent, mixing nanometer TiO2 and nanometer SiO2 for the first time, and obtaining dispersion liquid of the nanometer TiO2 and the nanometer SiO2; then introducing a fluorine-containing silicon coupling agent into the dispersion liquid of the nanometer TiO2 and the nanometer SiO2, and mixing for the second time. The amphiphobic composite material provided by the inventioncan be used in the water-based drilling fluid, has the effect of strongly inhibiting hydrous disintegration, is low in toxicity and good in compatibility, can effectively solve the problems of wellbore instability, drill jamming, reservoir damage and the like, further promotes development and application of high-difficulty wells such as extra-deep wells, horizontal wells and large displacement wells in a clay shale-containing formation, and has long-term practical value and economic benefit.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

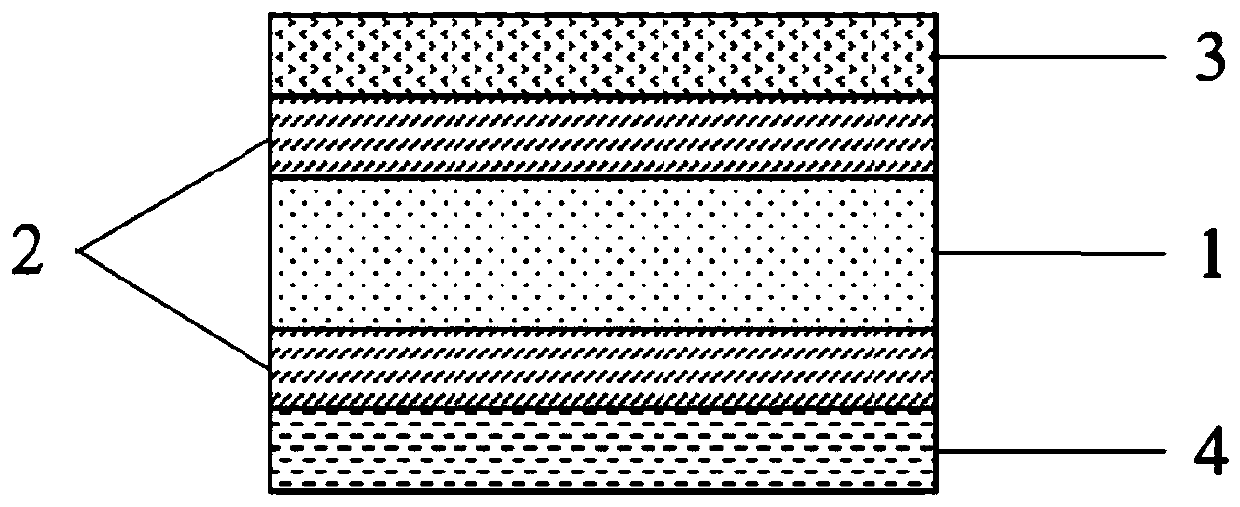

Fingerprint-proof veneer adhesive film paper, and preparation method and application thereof

ActiveCN109695180AHydrophobic and oleophobicAchieve "lotus leaf" effectPaper coatingCoatingsAdhesiveMelamine formaldehyde resin

The invention discloses fingerprint-proof veneer adhesive film paper, and a preparation method and an application thereof. The fingerprint-proof veneer adhesive film paper includes a base material; adhesive intermediate layers are arranged on both sides of the base material, a melamine formaldehyde resin surface coating layer is arranged on the adhesive intermediate layer at one side, and a melamine resin back coating layer is arranged on the adhesive intermediate layer at the other side; the melamine formaldehyde resin surface coating layer is made of melamine formaldehyde resin with a mattefunction. At the same time, the invention also discloses the preparation method of the fingerprint-proof veneer adhesive film paper, and an application of the fingerprint-proof veneer adhesive film paper in preparation of decorative panels. The melamine formaldehyde resin used for coating is specially treated to make the melamine formaldehyde resin film have hydrophobic and oleophobic properties,so a lotus leaf effect of the veneer adhesive film paper product is realized, and the fingerprint-proof effect is realized; moreover, the modified melamine formaldehyde resin also contains matte powder which can provide the interior matte effect.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

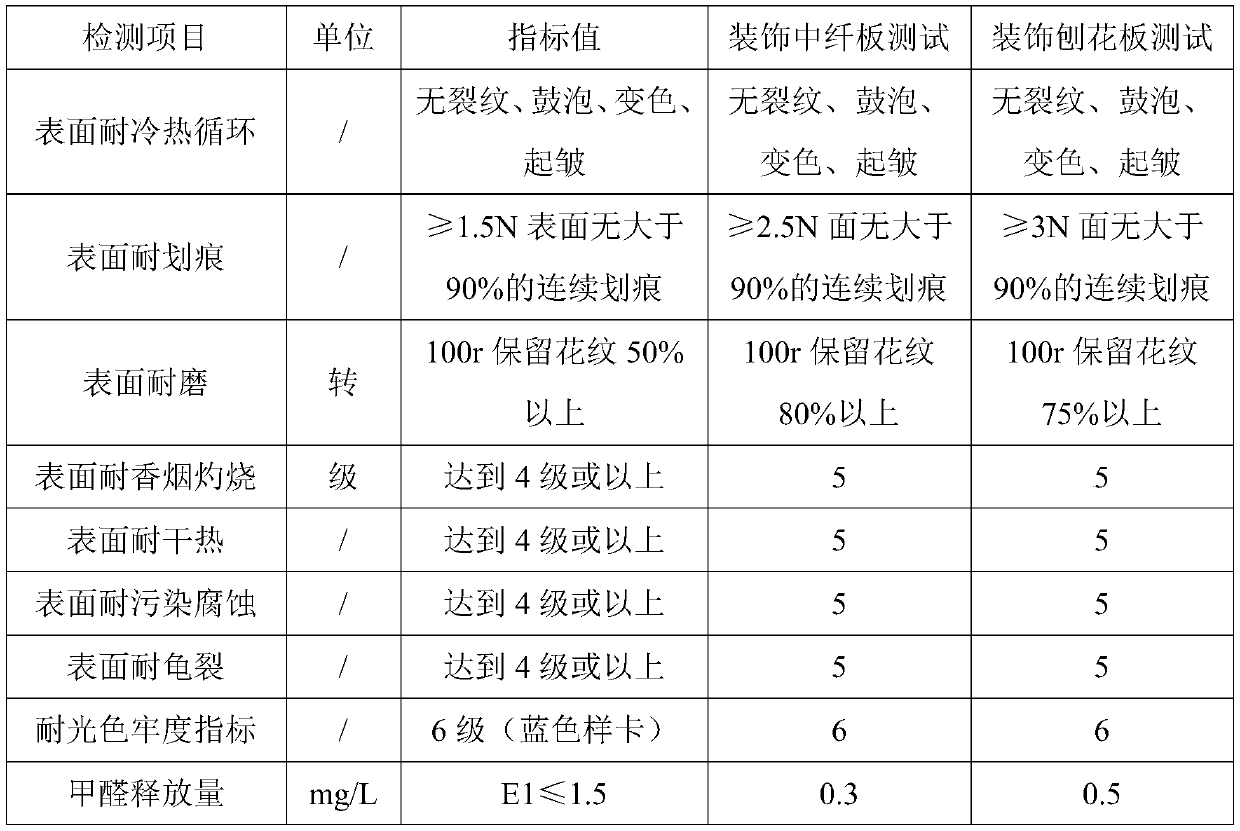

Hydrophobic and oleophobic wave-absorbing material and preparation method thereof

ActiveCN105925023BHydrophobic and oleophobicNot easy to stickFireproof paintsRadiation-absorbing paintsPolymer scienceHydrophobe

The invention relates to a lyophobic and oleophobic wave absorption material and a preparation method thereof. The lyophobic and oleophobic wave absorption material is prepared from the following ingredients in percentage by weight: 87 percent to 93 percent of wave absorption material bonding agents with lyophobic and oleophobic performance, 6 percent to 12 percent of wave absorption materials and 0.5 percent to 1 percent of auxiliary agents. During the preparation, all ingredients are uniformly mixed. The lyophobic and oleophobic wave absorption material can be used for coatings of kitchen electric products. The lyophobic and oleophobic wave absorption material has the advantages that the lyophobic performance is good; the cleaning is easy; high temperature resistance is realized; the health and environment protection are realized, and the like.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Coating for replacing electronic product screen protection film and preparation method

InactiveCN113122127AIncrease elasticityImprove rigidityPolyurea/polyurethane coatingsPolyester coatingsTetrafluoroethylenePolysilazane

The invention relates to the technical field of functional coatings, and provides a coating for replacing an electronic product screen protection film and a preparation method thereof.The coating is prepared by uniformly stirring surface-treated composite powder, polytetrafluoroethylene powder, urethane acrylate and a flatting agent at a high speed, then adding a reactive diluent and a photoinitiator, and uniformly dispersing; and the surface-treated composite powder is prepared by the following steps: mixing PET and SBS, extruding and granulating, crushing to obtain composite powder, stirring at a high speed at a constant temperature, and sequentially spraying ammonia water and perhydropolysilazane for stirring. The coating provided by the invention has the excellent characteristics of high hardness, good flexibility, no cracking, wear resistance, drop resistance and the like, has a release effect, can be integrally peeled off for re-coating, is convenient to replace, is hydrophobic and oleophobic, is clean and stain-resistant, and can well replace a current electronic product screen protection film.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

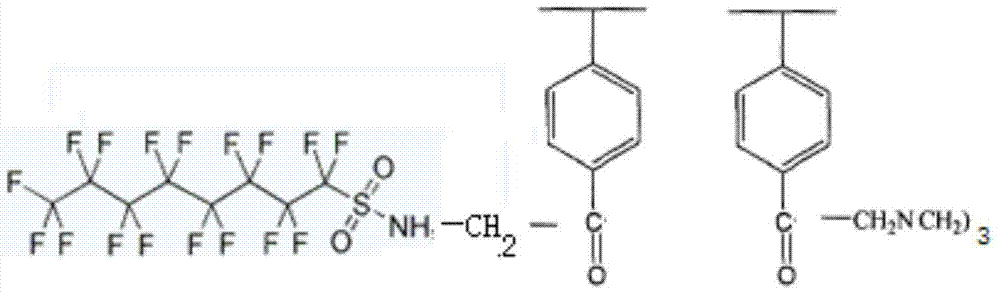

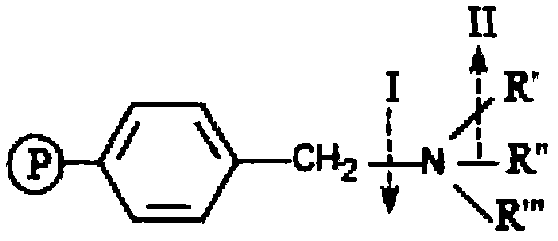

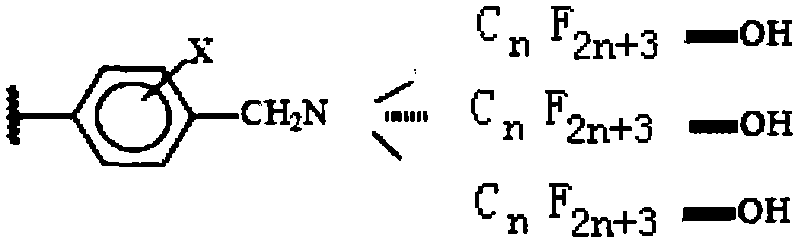

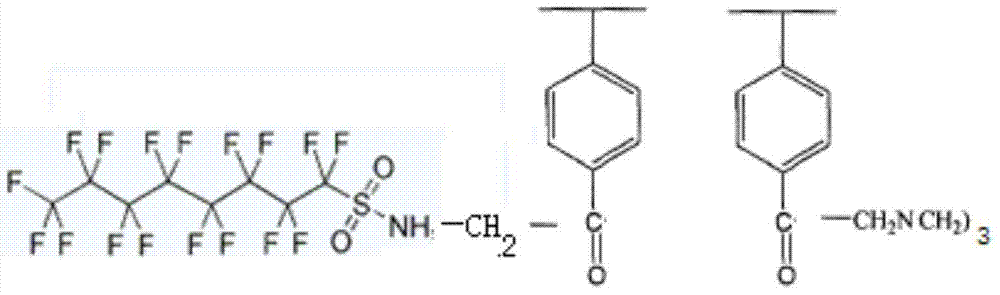

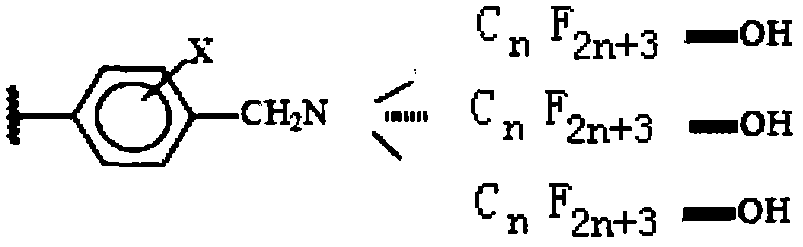

Preparation method of resin catalyst for synthesis of difluoromethyl ether

InactiveCN103611570AHydrophobic and oleophobicGood compatibilityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by ester reactionsQuaternary ammonium cationPolystyrene

The invention provides a preparation method of a resin catalyst for synthesis of difluoromethyl ether. Strong basic anion-exchange resin is prepared by reacting chloromethylated polystyrene with perfluorinated octyl sulfonamide and trimethylamine simultaneously. The resin catalyst comprises a mixture of the quaternary ammonium salt of perfluorinated octyl sulfonamide and the quaternary ammonium salt of the trimethylamine. A fluorine element and a sulfonamide group are introduced, so the compatibility of the catalyst and a fluorine-containing raw material can be improved, an amino group is unlikely to drop off, and the yield of the difluoromethyl ether is increased.

Owner:HUAIHUA JINXIN NEW MATERIAL CO LTD

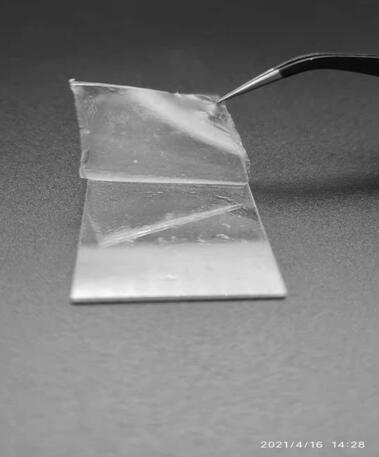

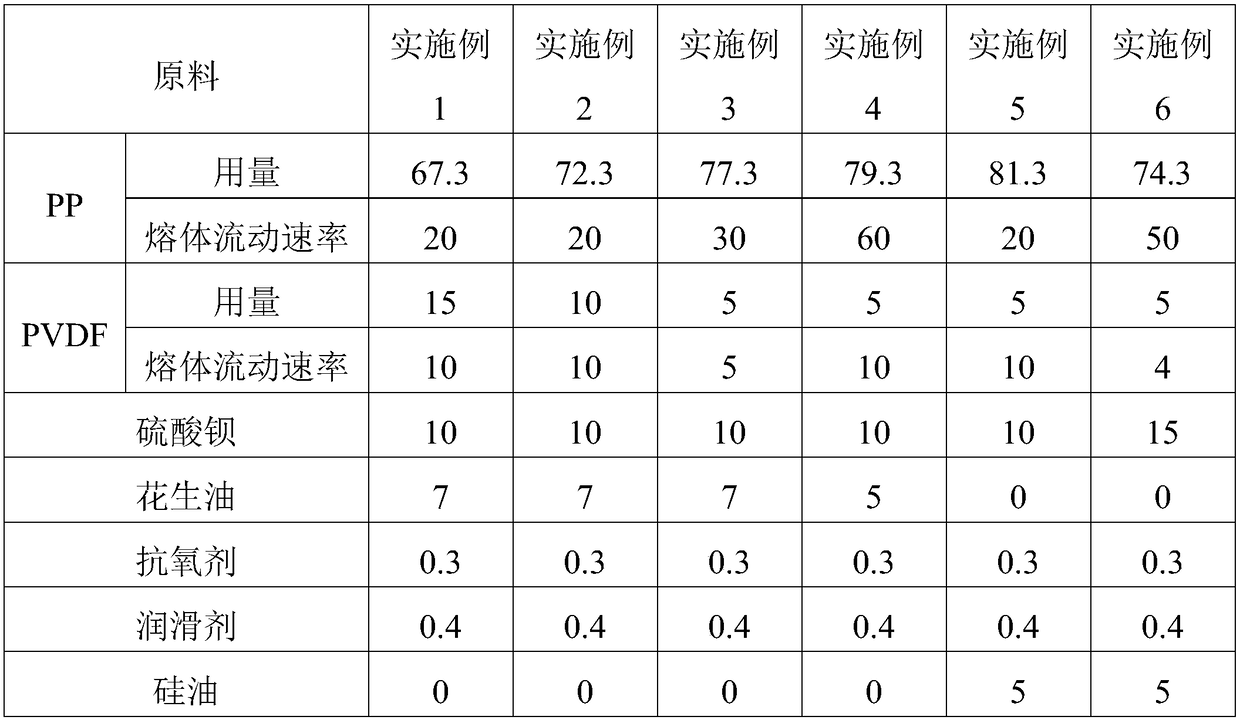

PP/PVDF alloy material and preparation method thereof

The invention provides a PP / PVDF alloy material. The PP / PVDF alloy material is prepared from the following raw materials in mass percent: 67-95% of polypropylene resin, 3-20% of polyvinylidene fluoride resin, 8-17% of barium sulfate, 2-10% of oil additives, 0.1-0.6% of antioxidant and 0.3-0.7% of lubricating agent. By virtue of synergetic cooperation of the components, on the premise of ensuring the mechanical properties of the material, the material simultaneously has a high oil and water contact angle and a very low oil and water roll angle, so that the material has the characteristics of being capable of preventing oil stains, easy to clean and hydrophobic and oleophobic; and water and oil stains on the surface of the material easily slip off from the surface of the material, so that the part prepared from the material is capable of preventing oil stains and keeping cleanness in the kitchen environment and is easy to clean.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Anti-sticking coating and manufacturing method

The invention discloses an anti-sticking coating and a manufacturing method and relates to the technical field of coating production. The anti-sticking coating is prepared from the following raw materials in parts by weight: 7 parts to 10 parts of superfine calcined kaolin, 5 parts to 10 parts of titanium dioxide, 10 parts to 12 parts of amino methyl silane, 30 parts to 40 parts of ethyl orthosilicate, 15 parts of 20 parts of butyl alcohol, 0.5 part of flatting agent, 0.2 part of defoaming agent, 0.1 part of preservative, 0.3 part of thickener and 10 parts to 15 parts of deionized water. Compared with the prior art, the anti-sticking coating disclosed by the invention can solve the problem that existing adlet and scrawl on building outer walls are difficult to clean.

Owner:赖禄波

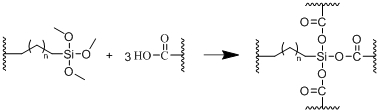

Solvent-free UV curing hardening liquid, preparation method thereof and hardened film

ActiveCN114149706AHigh hardnessImprove scratch resistancePolyurea/polyurethane coatingsPhotovoltaic energy generationPolymer scienceUV curing

The invention provides a solvent-free UV curing hardening liquid, a preparation method thereof and a hardening film. The solvent-free UV curing hardening liquid is prepared by mixing a polyurethane prepolymer or an acrylate prepolymer, a diluting monomer, a photoinitiator and special silicon modified resin, the preparation method of the special silicon modified resin comprises the following steps: S01, stirring and mixing an acrylic acid soft monomer, an acrylic acid hard monomer, an acrylic acid monomer containing a carboxyl group and a photoinitiator, and carrying out UV illumination reaction; and S02, dropwise adding a monomer containing a siloxane group, and carrying out a UV illumination reaction to obtain the special silicon modified resin with the molecular weight of 5000-15000. The special silicon modified resin is introduced into the hardening liquid, so that compared with other similar hardening liquids in the market, the hardness and scratch resistance of a hardened film can be remarkably enhanced; in addition, along with the introduction of silicon, the hardened film also has good hydrophobicity.

Owner:SHENZHEN TONGTAIYING ELECTRONICS TECH CO LTD

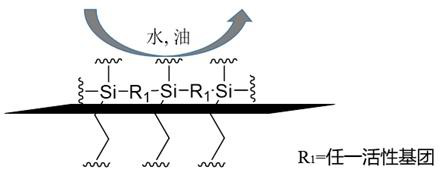

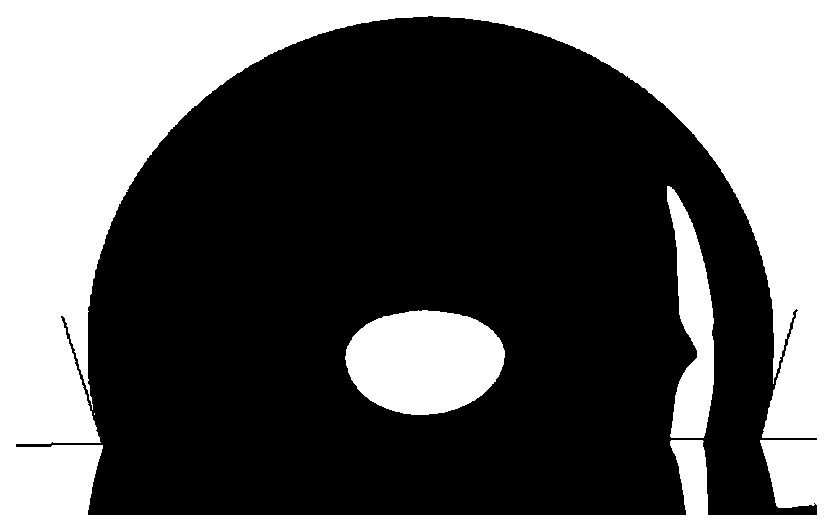

Hydrophobic treatment agent and preparation method and application thereof, and wear-resistant self-cleaning glass and preparation method thereof

InactiveCN110724256AExcellent hydrophobic and oleophobicImprove featuresAntifouling/underwater paintsPaints with biocidesOrganic solventSilanes

The invention belongs to the technical field of hydrophobic materials, and particularly relates to a hydrophobic treatment agent and a preparation method and application thereof, and wear-resistant self-cleaning glass and a preparation method thereof. The hydrophobic treatment agent provided by the invention has a perfluoropolyether compound containing a triethoxy silane group which can be bondedwith a silicon hydroxyl group, so formation of an organic-inorganic hybrid structure in the application process is facilitated, then the perfluoropolyether compound is anchored to the surface of glass, and the wear resistance of the hydrophobic surface of the glass is greatly improved; meanwhile, the glass surface is endowed with the characteristic of low surface energy, so the glass surface has the characteristics of excellent full lyophobicity and pollution resistance. Test results show that the wear-resistant self-cleaning glass obtained by coating of the hydrophobic treatment agent provided by the invention can be effectively isolated from various organic solvents; and after friction 200,000 times under a pressure of 100 kPa, a contact angle between the surface and water can still be kept at 105 degrees or above, and excellent wear resistance is achieved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

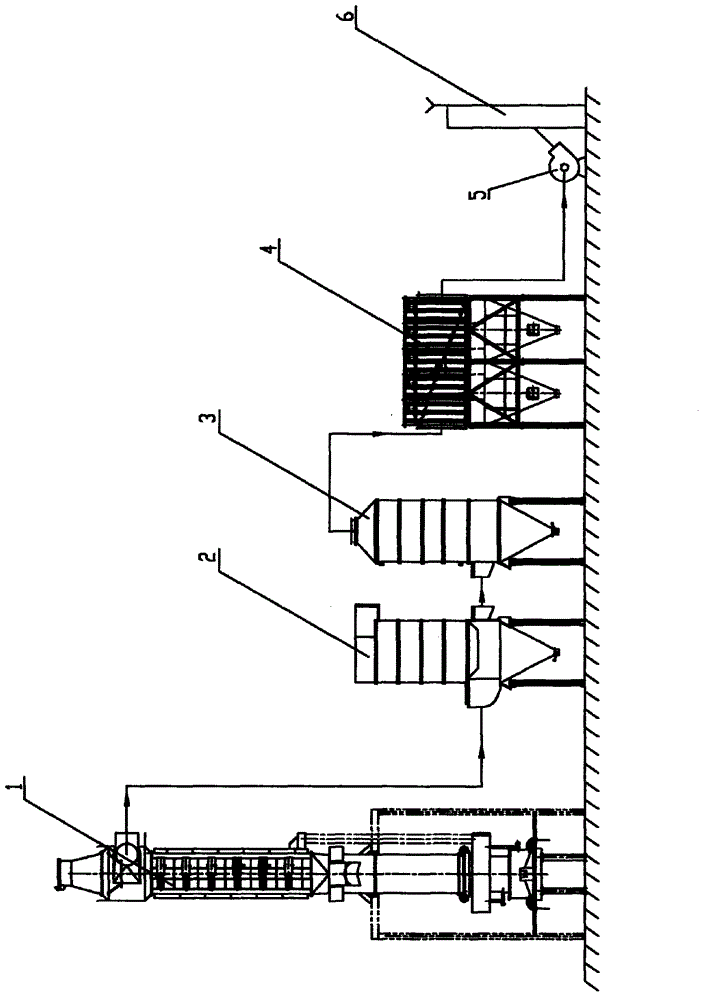

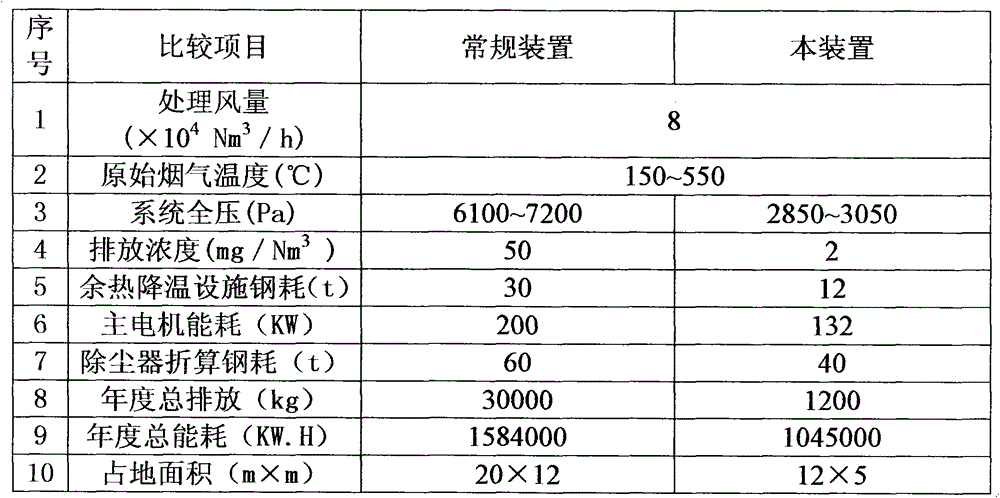

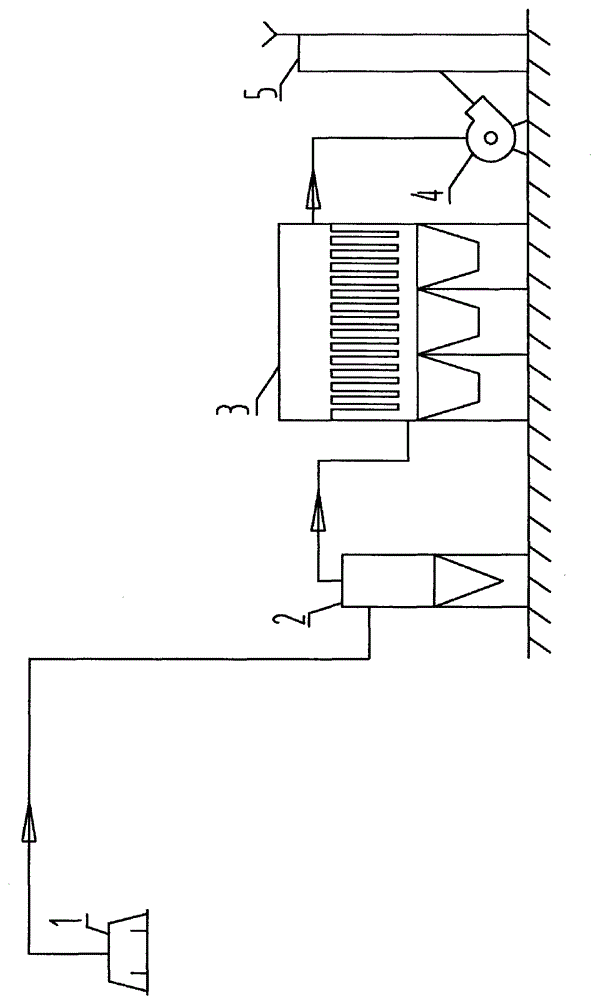

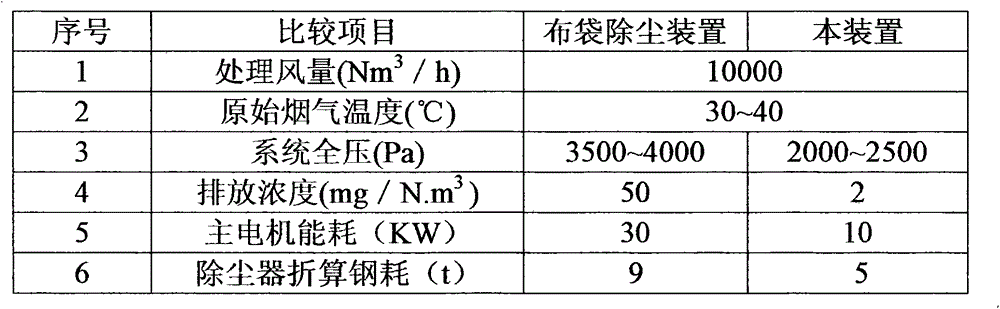

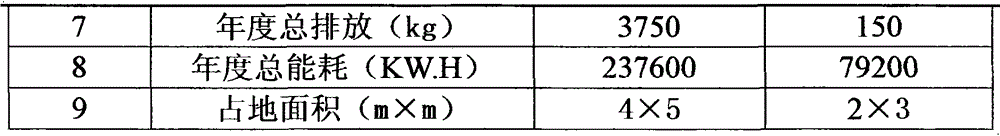

Micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust of cupola furnace

InactiveCN104101205ASmall temperature fluctuationsLow powerVertical furnacesParticulatesAtmospheric air

The invention discloses a micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust of a cupola furnace. The method is characterized in that high-temperature dusty flue gas is exhausted from the cupola furnace and enters a turbulent flow type water cooler, so that large-particle dust carried in the flue gas is settled, the flue gas temperature is reduced to 210 DEG C, the fluctuation amplitude of the flue gas temperature can be greatly reduced, and the peak value of the flue gas temperature is decreased; the flue gas enters a multi-tube water cooler, and the multi-tube water cooler exchanges heat, so that the flue gas temperature is reduced to 100 DEG C, and the allowed working temperature of a plastic sintering plate dust collector is met; the cooled flue gas enters the plastic sintering plate dust collector, the dust concentration is 2mg / Nm<3> after dust collection, and the flue gas is pressed into a gas exhaust cylinder through a main fan and is exhausted into the atmosphere. A micro-pore plastic sintering plate filter core molded by sintering carbon and polyvinyl chloride is arranged in the plastic sintering plate dust collector. According to the method, fine dust is collected by using the plastic sintering plate dust collector, the dust collection efficiency is high, the low-concentration emission is guaranteed, and a device is low in operating resistance, low in investment cost, low in maintenance cost and small in occupied space.

Owner:WUXI XIZHANG ENVIRONMENTAL PROTECTION EQUIP

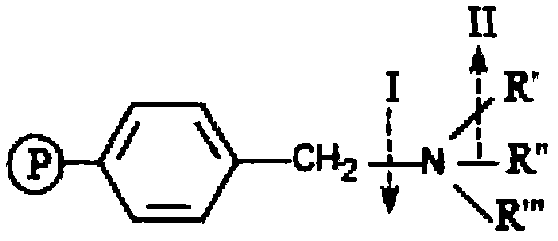

Preparation method of perfluorinated quaternary ammonium type strong base anion exchange resin

ActiveCN104744615AHydrophobic and oleophobicGood compatibilityAnion exchangersPolystyreneIon-exchange resin

The invention provides a preparation method of perfluorinated quaternary ammonium type strong base anion exchange resin. The preparation method is characterized by preparing the strong base anion exchange resin by adopting chloromethyl polystyrene to react with perfluorinated tertiary amine and trimethylamine simultaneously. The preparation method has the beneficial effects that the compatibility between aminating agents and chloromethylated beads is improved, the efficiency of aminating reaction is improved, the binding force of bonds between alkylbenzylamine and alkyl N-C is reinforced, amino is not easy to fall of, and the resin can be used at a higher temperature; by introducing fluorine-containing groups, the corrosion resistance of a resin insert is reinforced and the surface of the sphere is protected, thus prolonging the service life and expanding the application range of the resin.

Owner:上海邢东化工科技有限公司

Micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust formed by cleaning and polishing of casting

InactiveCN104097149AHigh precision of dust removalLarge filter areaCombination devicesGrinding/polishing safety devicesParticulatesOperating energy

The invention discloses a micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust formed by cleaning and polishing of a casting. The method is characterized in that the casting of a valve is cleaned and polished to generate mixed dust of metal iron scraps, grinding wheel scraps and the like; the mixed dust enters a trapping cover and is conveyed to a cyclone dust collector through a pipeline; the cyclone dust collector filters large-particle dust, the dust collection efficiency is 95 percent, and the aim of dust pre-collection is achieved; after the dust is purified by a plastic sintering plate dust collector, the dust concentration is 2mg / Nm<3>, and the dust is pressed into a gas exhaust cylinder through a main fan and is exhausted into the atmosphere. According to the method, the large-particle dust is filtered by using the cyclone dust collector, so that the dust collection efficiency is high, and the aim of dust pre-collection is achieved; fine dust is collected by using the plastic sintering plate dust collector in the later stage, so that the dust collection efficiency is high, the smoke dust emission concentration is low, and a device is low in investment and low in operating energy consumption and has a good purification effect.

Owner:WUXI XIZHANG ENVIRONMENTAL PROTECTION EQUIP

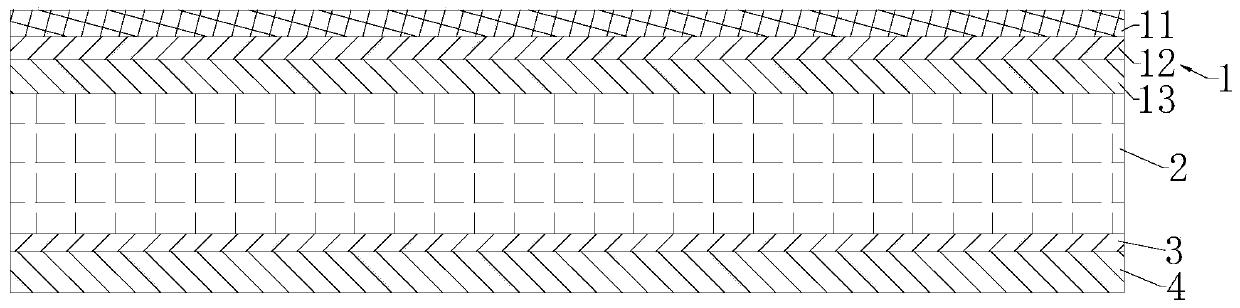

Environmentally-friendly pre-coating film and production method thereof

InactiveCN110669454AFlat surfaceImprove the finishFilm/foil adhesive primer layersWax adhesivesEpoxyOXALIC ACID DIHYDRATE

The invention discloses an environmentally-friendly pre-coating film and a production method thereof. The environmentally-friendly pre-coating film comprises a hydrophobic and oleophobic layer, a baselayer, a base coating agent layer and a hot melt adhesive layer which are sequentially arranged from outside to inside, the hydrophobic and oleophobic layer is of a three-layer structure and comprises a nano-silica layer, a fluorosilane layer and a protective layer which are sequentially arranged from outside to inside, and the protective layer is composed of an acrylic resin, nano-silica, distilled water, an oxalic acid solution, a methylated hexamethylol melamine resin, an epoxy resin and ethanol; the base layer comprises polypropylene, ethoxylated alkylamine and ethoxylauric acid amine; the base coating agent layer is composed of an aqueous polyethyleneimine solution and alcohol; and the hot melt adhesive layer is composed of an ethylene-vinyl acetate copolymer, rosin, paraffin and anantioxidant. The bonding strength of the base layer and the hot melt adhesive layer is high, and the pre-coating film has diversified functions and a good protection effect.

Owner:宁波盈瑞聚合科技有限公司

Easy-to-clean powder coating and production process thereof

InactiveCN112391110AHigh surface hardnessSoft lusterAnti-corrosive paintsPolyurea/polyurethane coatingsMixed materialsSilicon dioxide

The invention discloses an easy-to-clean powder coating and a production process thereof. The easy-to-clean powder coating is prepared from the following raw materials in parts by weight: 400-600 parts of hydroxyl-terminated polyurethane resin, 150-400 parts of fluorocarbon resin, 10-40 parts of modified nano silicon dioxide, 2-10 parts of graphene, 120-150 parts of titanium dioxide, 60-70 parts of barium sulfate, 8-10 parts of leveling agent, 8-10 parts of wetting accelerator, 3-5 parts of benzoin, 1 part of pigment carbon black, 0.5 part of phthalocyanine blue and 2 parts of iron oxide yellow. The production process comprises the following specific steps: S1, premixing all the components of the polyurethane powder coating according to the proportion to obtain a mixed material; and S2, the mixed material obtained in the step S1 is subjected to melt extrusion, tabletting crushing and crushing and passes through a 180-mesh sieve, the self-cleaning powder coating with excellent weather resistance is formed, the coating has good weather resistance and pollution resistance, the raw materials are cheap and easy to obtain, special manufacturing is not needed, and the preparation processis simple.

Owner:安徽博泰装饰材料有限公司

A controllable method for preparing nanofibers with core-shell structure

ActiveCN104264248BEasy to form core-shell structureAnti-foulingElectro-spinningConjugated synthetic polymer artificial filamentsEpoxyFiber

The invention discloses a preparation method for controllable core-shell structure nanofiber and belongs to the field of functional nanofiber preparation. According to the preparation method for the controllable core-shell structure nanofiber, polymer is blended with micro-molecular cationic photoinitiator and fluorine-containing epoxy monomer, electro-spinning is performed under UV light irradiation by means of the characteristics that the macro molecule has high mobility, and the surface with a little of fluorine-containing compound is capable of migrating to the fiber surface, the functional fluorine-containing core-shell structure nanofiber with controllable thickness is prepared through controlling the dosage of the fluorine-containing monomer, wherein the core layer of the functional fluorine-containing core-shell structure nanofiber is polymer fiber while the surface is a fluorine-containing photo-polymerization cross-linked shell layer. The preparation method for the controllable core-shell structure nanofiber effectively prepares material through electro-spinning and photo-polymerization, the novel nanofiber has the excellent performances of the polymer fiber and fluorine-containing material, the performance is improved, and the application field is widened. The fiber has hydrophobic property, lipophobic property, pollution resistance, wearing resistance and the like, and the bio-compatibility is good; the nanofiber can be used for the fields of tissue engineering, wound repairing and the like, and the controllable core-shell thickness has high latent medical value in the drug sustained-release aspect.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of resin catalyst for synthesis of difluoromethyl ether

InactiveCN103611570BHydrophobic and oleophobicGood compatibilityOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

Owner:HUAIHUA JINXIN NEW MATERIAL CO LTD

A kind of preparation method of perfluorinated quaternary ammonium type strongly basic anion exchange resin

ActiveCN104744615BHydrophobic and oleophobicGood compatibilityAnion exchangersPolystyreneIon-exchange resin

The invention provides a preparation method of perfluorinated quaternary ammonium type strong base anion exchange resin. The preparation method is characterized by preparing the strong base anion exchange resin by adopting chloromethyl polystyrene to react with perfluorinated tertiary amine and trimethylamine simultaneously. The preparation method has the beneficial effects that the compatibility between aminating agents and chloromethylated beads is improved, the efficiency of aminating reaction is improved, the binding force of bonds between alkylbenzylamine and alkyl N-C is reinforced, amino is not easy to fall of, and the resin can be used at a higher temperature; by introducing fluorine-containing groups, the corrosion resistance of a resin insert is reinforced and the surface of the sphere is protected, thus prolonging the service life and expanding the application range of the resin.

Owner:上海邢东化工科技有限公司

A kind of surface-loaded tio2/diatomite abs amphiphobic material and preparation method thereof

InactiveCN103275456BEasy to useOleophobicOrganic-compounds/hydrides/coordination-complexes catalystsFungicidesCompression moldingPollution

The invention provides an ABS hydrophobic and oleophobic material with surface loaded by TiO2 / diatomite, and a preparation method thereof. The ABS hydrophobic and oleophobic material is composed by the following raw materials by mass: 98-99.9% of an ABS resin and 0.1-2% of a TiO2 / diatomite composite photocatalytic material. The ABS hydrophobic and oleophobic material with the surface loaded by TiO2 / diatomite is obtained by the steps of A. firstly preparing the TiO2 / diatomite composite photocatalytic material, B. dispersing the TiO2 / diatomite composite photocatalytic material in ethanol to form a suspension liquid, and C. coating the suspension liquid on the surface of a mold, then keeping ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, and compression molding at the temperature of 150-180 DEG C; or keeping the ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, compression molding at the temperature of 150-180 DEG C, then coating the suspension liquid obtained by the step B on the surface of the compression molded ABS resin material, and then compression molding at the temperature of 150-180 DEG C. The ABS hydrophobic and oleophobic material has the characteristics of super-hydrophobic surface self-cleaning effect and self-cleaning capacity. The preparation method is simple in process, simple in operations, small in investment, low in operation cost and no pollution to environment.

Owner:KUNMING UNIV OF SCI & TECH

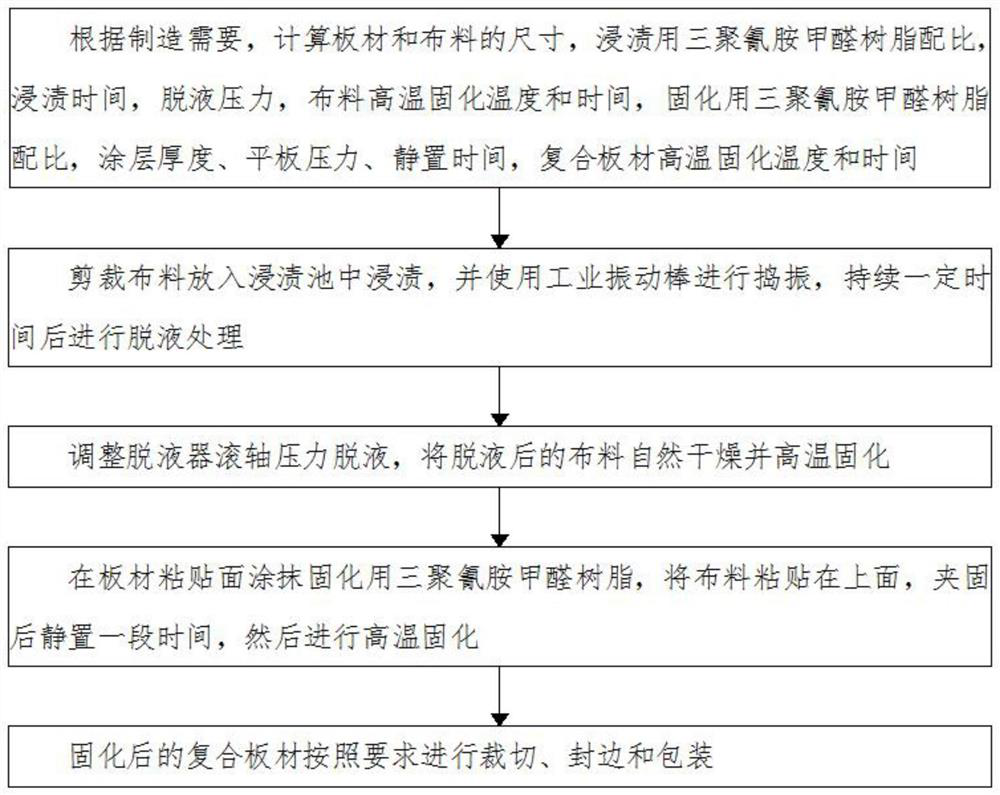

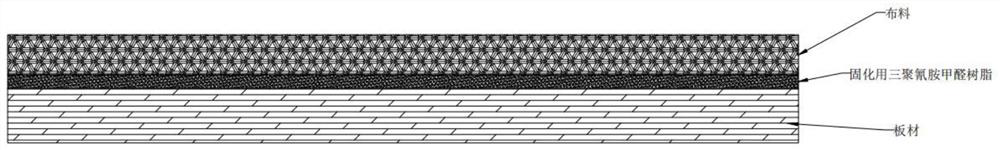

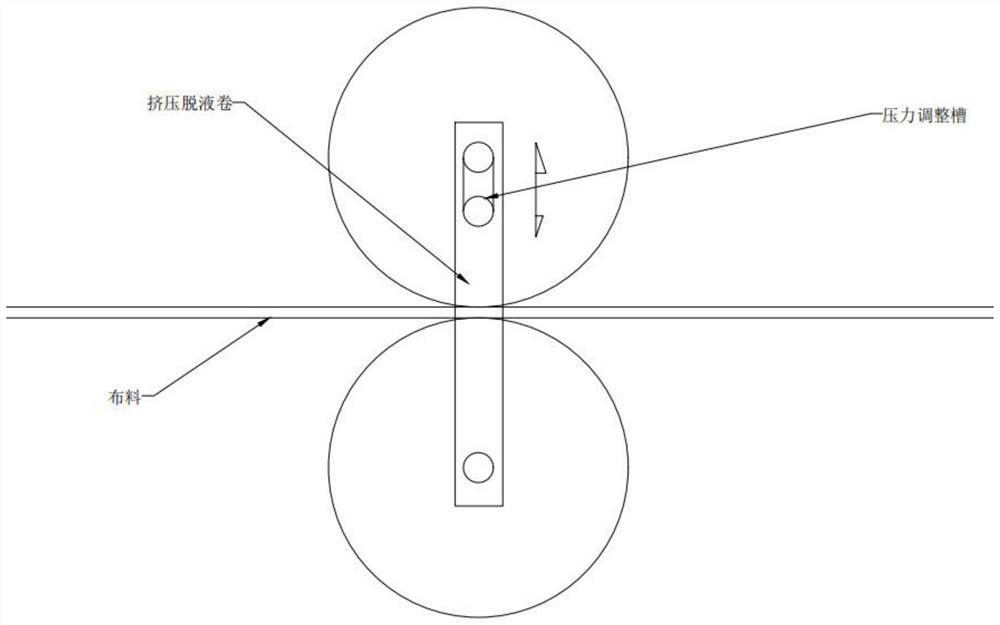

Preparation method of textile fabric composite board

InactiveCN113547821AHydrophobic and oleophobicHigh strengthLamination ancillary operationsSynthetic resin layered productsTextile fiberPolymer science

The invention discloses a preparation method of a textile fabric composite board, which comprises the following steps of calculating the sizes of the board and cloth and the proportion of melamine formaldehyde resin for impregnation according to the manufacturing requirements, putting the cut cloth into a dipping pool to be dipped, using an industrial vibrating bar for ramming and vibrating, and conducting liquid removal treatment after the ramming and vibrating lasts for a certain period of time, adjusting the pressure of a roller of a liquid exhauster for liquid exhaustion, naturally drying the cloth subjected to liquid exhaustion, and curing at high temperature, smearing melamine formaldehyde resin for curing on the pasting face of the board, pasting cloth on the melamine formaldehyde resin, standing for a period of time after clamping and fixing, and then conducting high-temperature curing, and conducting cutting, edge sealing and packaging on the cured composite board according to requirements. The fabric is soaked in the melamine formaldehyde resin and then subjected to thermocuring, textile fibers obtained after soaking and thermocuring treatment have the characteristics of hydrophobicity and oleophobicity, enhanced strength and mutual adhesion of textile threads, and meanwhile, the melamine formaldehyde resin is flame-retardant, so that the fabric is flame-retardant.

Owner:刘大卫

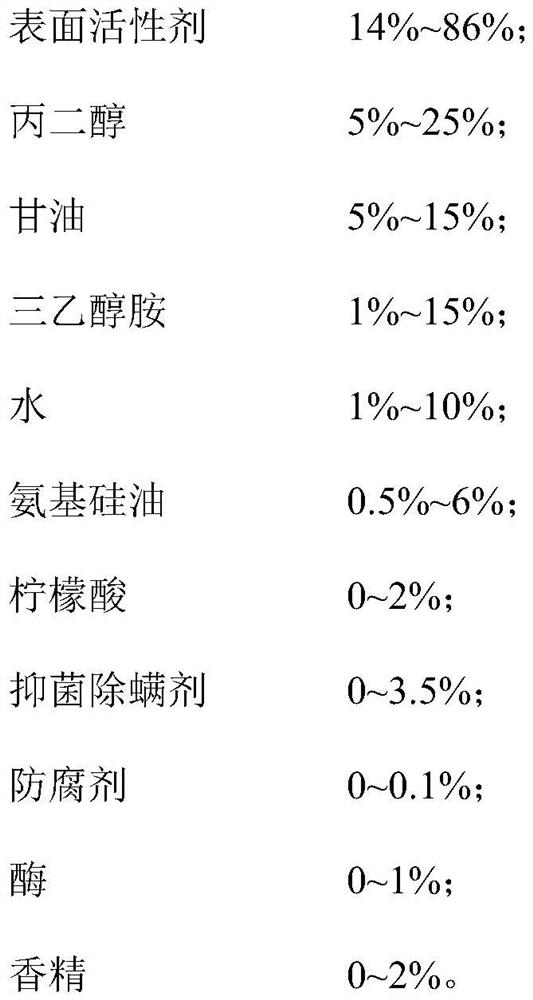

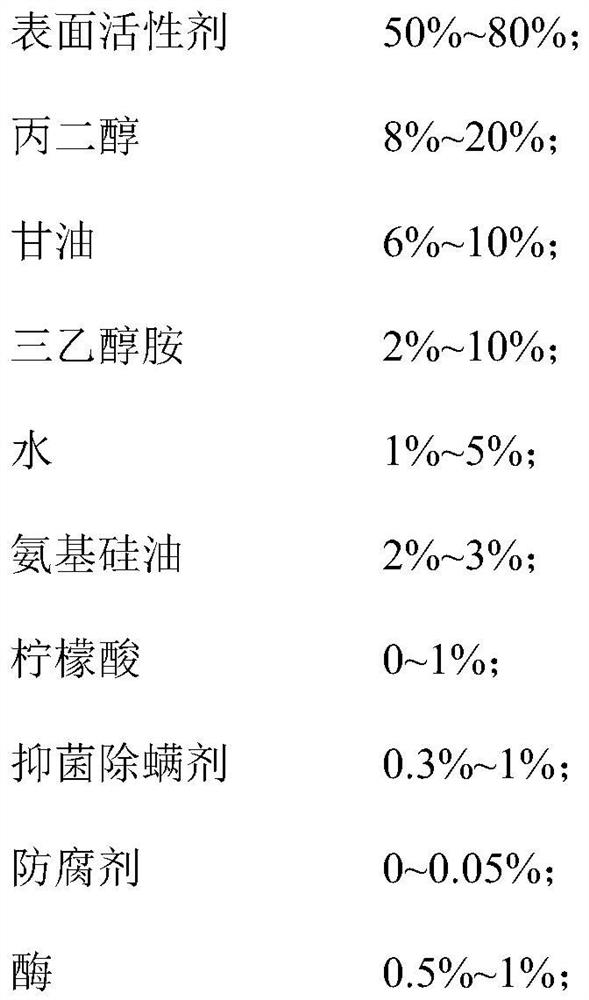

Super-strong decontamination anti-cross-color laundry gel beads and preparation method thereof

InactiveCN113337350ATo achieve the coating effectPrevent elutionNon-ionic surface-active compoundsOrganic detergent compounding agentsActive agentGlycerol

The invention belongs to the technical field of daily chemical products, and discloses super-strong decontamination anti-cross-color laundry gel beads and a preparation method thereof. The cleaning liquid in the laundry gel beads comprises the following components in percentage by mass: 14%-86% of a surfactant; 5%-25% of propylene glycol; 5%-15% of glycerin; 1%-15% of triethanolamine; 1%-10% of water; 0.5%-6% of amino silicone oil; 0-2% of citric acid; 0-3.5% of a bacteriostatic acaricide; 0-0.1% of a preservative; 0-1% of enzyme; and 0-2% of essence. According to the invention, the amino silicone oil is added as an anti-cross-color agent, and the specific nonionic surfactant and the anionic surfactant are compounded, so that the obtained laundry gel beads have a good anti-cross-color effect and extremely high detergency.

Owner:佛山菁亮日化用品有限公司

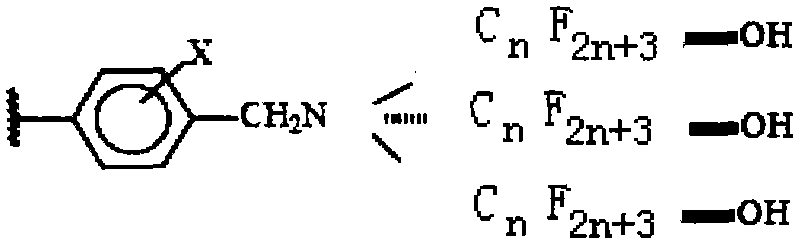

Method for raising anti-pollution of paper products

ActiveCN1304692CImprove stabilityImprove surface propertiesNon-fibrous pulp additionPulp and paper industryPolymer

The present invention relates to method of making paper product posses waterproof and oilproof effect. Fluorous acrylic acid polymer of the molecular expression [C8F17SOR(CH2)2CRO-CH2]n, where R is C1-C5 alkyl group and n is 2-5, is used as the waterproof and oilproof agent for paper, and is applied into paper pulp or on the surface of paper sheet to obtain antifouling paper. The present invention is suitable especially for various bills, such as banknote.

Owner:CHINA BANKNOTE PRINTING & MINTING

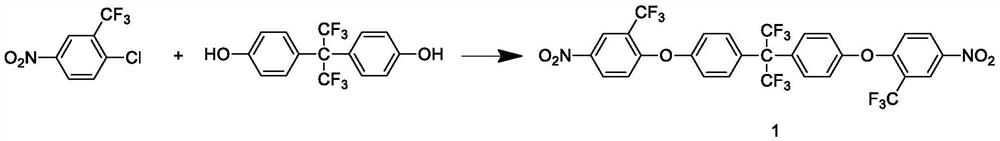

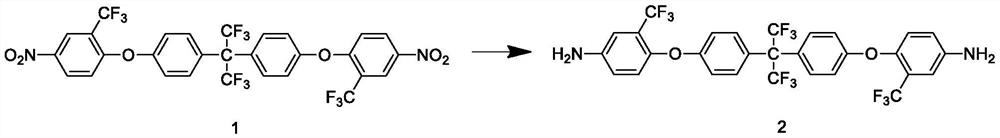

A kind of corrosion-resistant polyarylate composite material and preparation method thereof

The invention discloses a corrosion-resistant polyarylate composite material, which belongs to the technical field of polymer materials and aims to solve the problem that polyarylate is not resistant to concentrated acids and alkalis such as ammonia water and concentrated sulfuric acid. The polyarylate composite material includes the following raw materials in parts by weight: 22-34 parts of modified polyarylate monomers, 15-20 parts of modified epoxy resins, and 1-3 parts of antioxidants; the invention also discloses the polyarylate The preparation method of the arylate composite material includes raising the temperature of the modified epoxy resin to 150°C, adding the modified polyarylate monomer and antioxidant, pouring it into a preheated mold, and placing it in an oven after the air bubbles are eliminated. Cured in the middle to obtain a polyarylate composite material. The introduction of the trifluoromethyl group in the present invention reduces the regularity and orderliness of the main chain arrangement of the polymer molecules, which is conducive to the co-curing reaction between the modified polyarylate monomer and other polymers, and improves its processing performance. In addition, it can Improve the hydrophobic performance of the substrate and reduce its moisture absorption performance, endow the substrate with excellent corrosion resistance.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

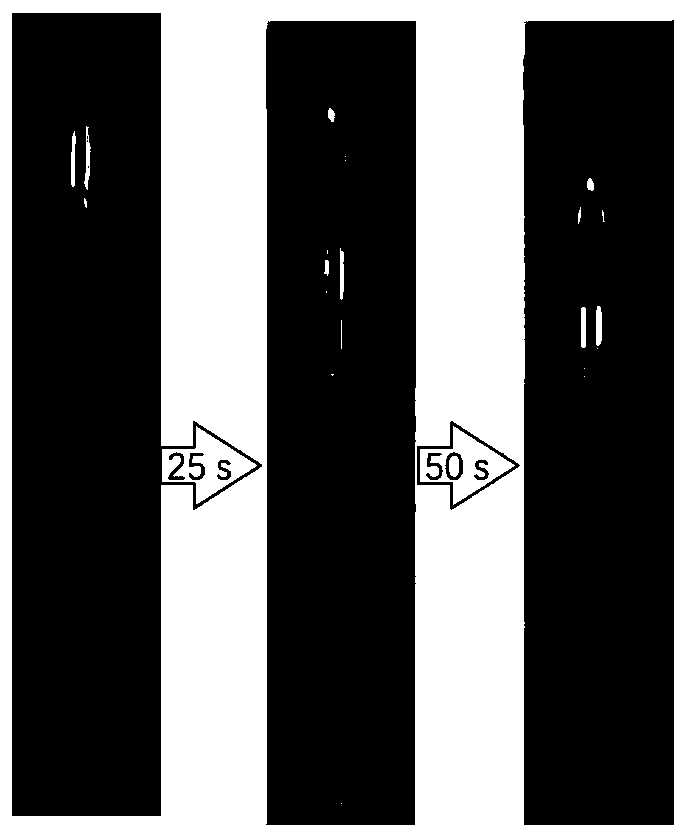

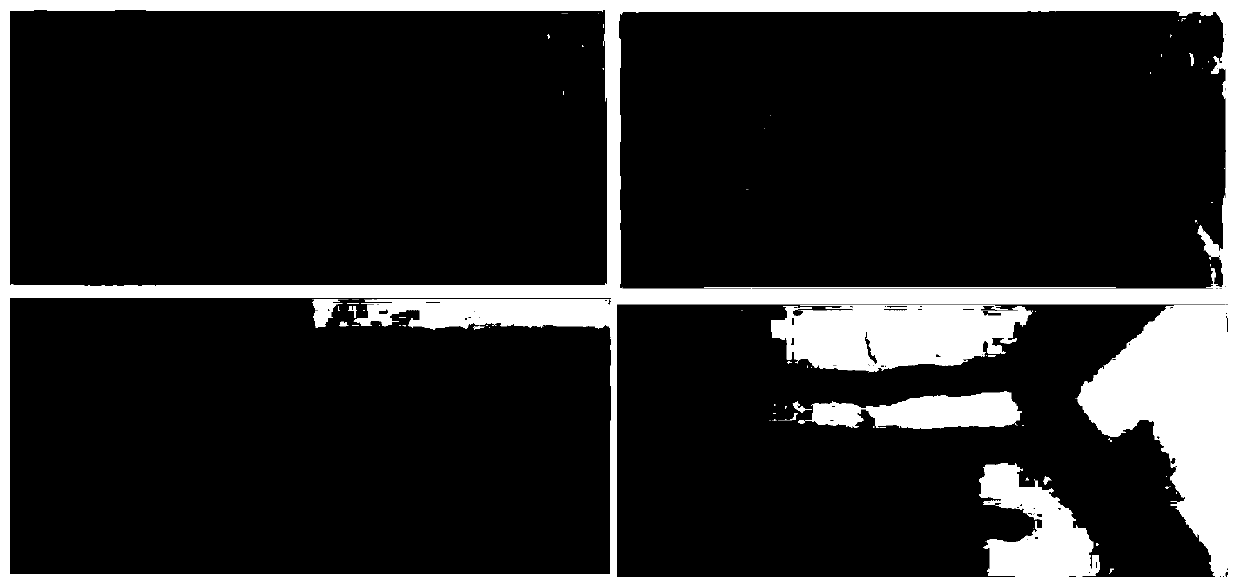

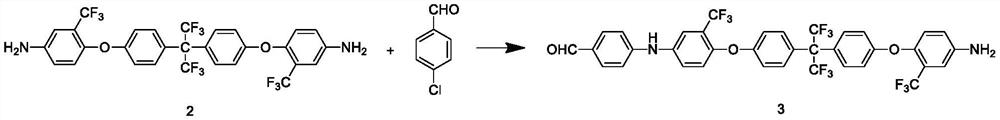

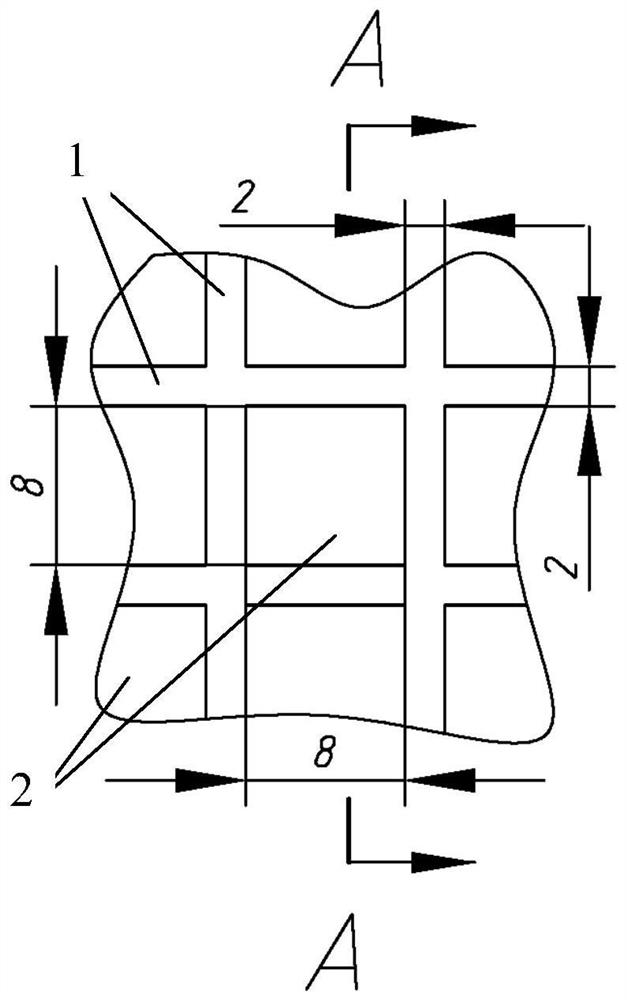

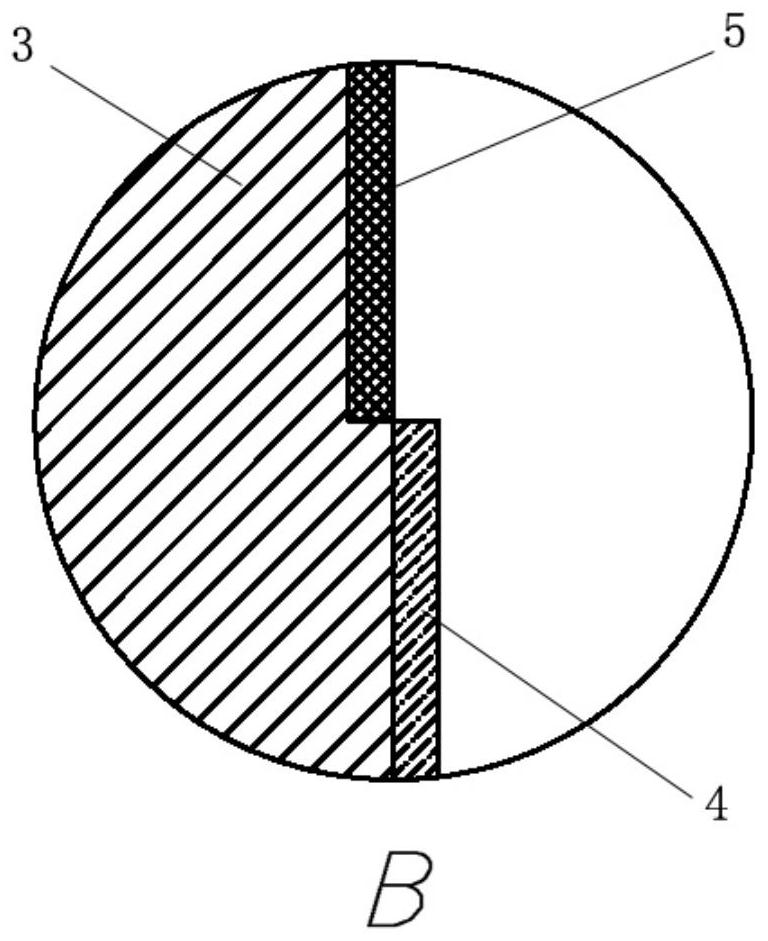

Preparation method of hydrophobic and oleophobic titanium alloy plate with laser processing skeleton strengthening structure

ActiveCN114535932AImprove wear and scratch resistanceImprove hydrophobicity and oleophobicityGeneral water supply conservationIncreasing energy efficiencyLaser processingNano structuring

The invention provides a preparation method of a hydrophobic and oleophobic titanium alloy plate with a laser processing skeleton strengthening structure, which is characterized by comprising the following steps of: coarsening the surface of a titanium alloy plate by adopting laser, processing a skeleton structure with a grid-shaped space on the surface of the titanium alloy plate subjected to laser coarsening by adopting laser, and arranging a cladding layer with a micro-nano structure in the grid-shaped space, the hydrophobic and oleophobic performance of the titanium alloy surface is achieved through fluorosilane modification; and the framework structure and the grid-shaped space form a step, and a wear-resistant cladding layer is arranged on the framework structure, so that wear allowance is reserved, the hardness of the surface of the titanium alloy plate is enhanced, and the mechanical performance of the surface of the titanium alloy is achieved. According to the preparation method of the hydrophobic and oleophobic titanium alloy plate with the laser processing skeleton strengthening structure, the hydrophobic and oleophobic performance and the mechanical performance of the titanium alloy surface can be considered, and the defects that the mechanical performance of the titanium alloy surface treated through an existing method is poor and scraping resistance is not achieved are overcome.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com