Preparation method of hydrophobic and oleophobic titanium alloy plate with laser processing skeleton strengthening structure

A titanium alloy plate, laser processing technology, applied in the direction of general water supply saving, metal material coating process, coating, etc., can solve the problems of non-scratch resistance, poor mechanical properties of titanium alloy surface, etc., to achieve enhanced wear resistance and scratch resistance Scratchability, improve hydrophobic and oleophobic properties, and solve the effect of not being scratch resistant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

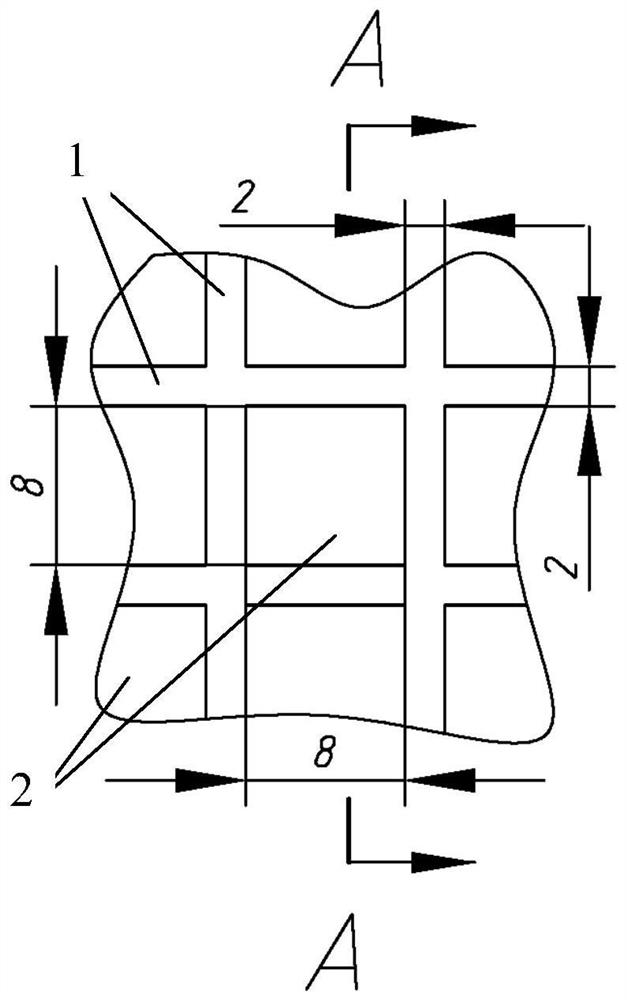

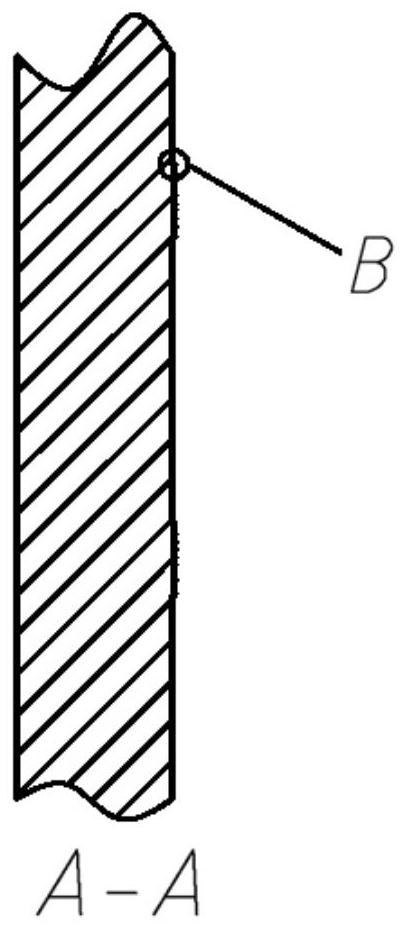

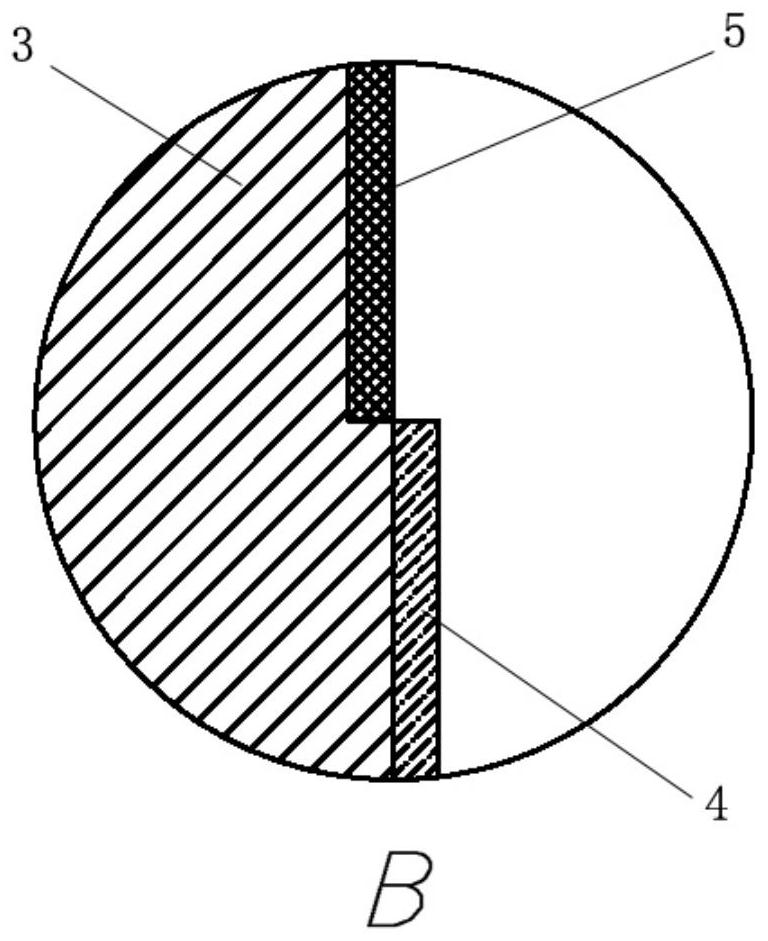

[0029] The preparation method of the hydrophobic titanium alloy plate of the skeleton strengthening structure of the laser processing skeleton is as follows: the surface of the laser coarsened titanium alloy plate, the surface of the titanium alloy plate after laser roughing is laser processed with a grid-like space of the skeleton structure, and the cladding layer having a micro-nano structure is provided in the grid-like space, and the hydrophobic performance of the titanium alloy surface is achieved by fluorosilane modification; the skeleton structure and the grid-like space form a step, and the wear-resistant cladding layer is provided on the skeleton structure, In order to leave a wear margin and enhance the hardness of the titanium alloy plate surface, the mechanical properties of the titanium alloy surface are realized. This includes the following steps:

[0030] Step 1, set powder one and powder two; wherein powder one is tungsten powder; powder two is to dry nickel powder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com