Environmentally-friendly pre-coating film and production method thereof

A kind of pre-coating film and environmental protection technology, applied in the direction of epoxy resin coating, coating, heat-activated film/sheet, etc., can solve the problems of low bonding strength, single function, poor protection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

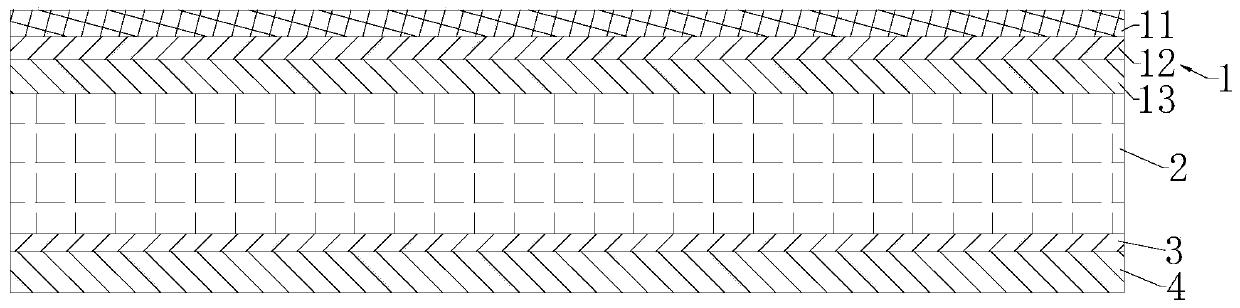

[0024] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0025] Such as figure 1 As shown, the environmentally friendly precoating film includes a hydrophobic and oil-repellent layer 1, a base layer 2, a primer layer 3 and a hot-melt adhesive layer 4 arranged in sequence from the outside to the inside, and the hydrophobic and oil-repellent layer 1 is a three-layer structure, which includes from the outside to the inside The nano silicon dioxide layer 11, the fluorosilane layer 12 and the protective layer 13 arranged in sequence, the protective layer 13 is made of acrylic resin, nano silicon dioxide, distilled water, oxalic acid solution, methylated hexamethylol melamine resin, epoxy resin , Ethanol composition;

[0026] Base layer 2 is composed of polypropylene, ethoxylated alkylamine and ethoxylated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com