PP/PVDF alloy material and preparation method thereof

A technology of alloy materials and raw materials, which is applied in the field of PP/PVDF alloy materials and its preparation, can solve problems such as improvement of surface properties, and achieve the effect of simple and easy-to-operate preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6、 comparative example 1-3

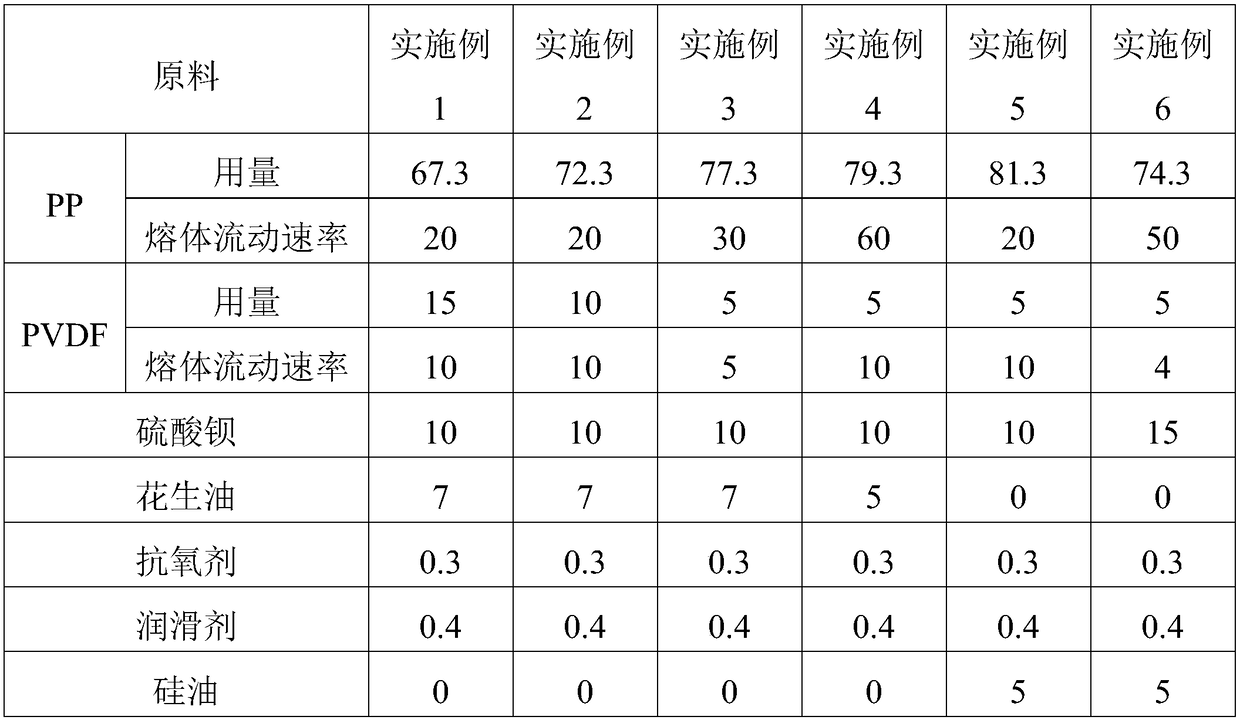

[0036] The embodiment of the present invention, comparative example provides a kind of PP / PVDF alloy material, and its raw material composition, by mass fraction, specifically as shown in table 1, table 2:

[0037] Table 1

[0038]

[0039] Table 2

[0040]

[0041]

[0042] The antioxidant described in the above table is a compound composed of a hindered phenolic antioxidant and a phosphite antioxidant in a mass ratio of 1:1; in the embodiments of the present invention, the hindered phenolic antioxidant is further preferably As the antioxidant 1010, the phosphite antioxidant is more preferably the antioxidant 168. The lubricant is at least one of EBS, PETS and TAF. The barium sulfate is preferably nanoscale precipitated barium sulfate. The polypropylene resin (PP) is a composite of homopolypropylene and copolymerized polypropylene, preferably mixed with polyvinylidene fluoride resin at a mass ratio of (3-5):1.

[0043]Among them, the melt flow rate of polypropyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com