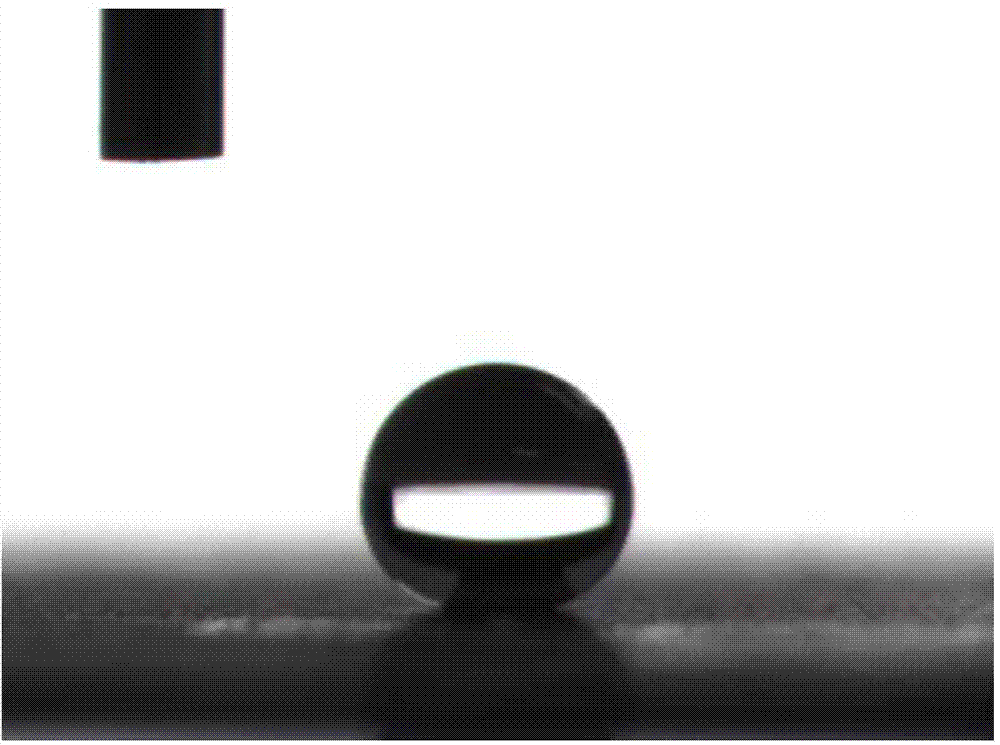

Super-hydrophobic and oleophobic composite coating and preparation method thereof

A super-hydrophobic and oleophobic composite coating technology, which is applied in coatings, epoxy resin coatings, and devices for coating liquids on the surface, can solve problems such as oil resistance, wear resistance, and poor stability, and reduce Effect of surface energy, improved hydrophobicity and oleophobicity, good wear resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step (1) Preparation of superhydrophobic and oleophobic primer: at room temperature, 10g epoxy resin, 1g 3-glycidyl etheroxypropyl trimethoxysilane and 2g particle diameter are 3 μm matting powder added to 100g butanone In the process, use 1500r / min to stir for 30min on a high-speed mixer, and after mixing evenly, a superhydrophobic and oleophobic primer is obtained;

[0033] Step (2) Preparation of superhydrophobic and oleophobic topcoat: After mixing 90g of ethanol and 10g of water evenly, add 1g of fumed silica with a particle size of 16nm, 1g of heptadecafluorodecyltrimethoxysilane, 1g of γ-aminopropyl Triethoxysilane, stirred on a high-speed mixer at 1500r / min for 30min, added dropwise 2g of 10wt% acetic acid aqueous solution, mixed evenly, moved to a 500ml four-necked flask, and placed in a water bath at 65°C for 8 hours of heating. , to obtain a superhydrophobic and oleophobic topcoat;

[0034] Step (3) Use spraying process, spray superhydrophobic and oleophobic...

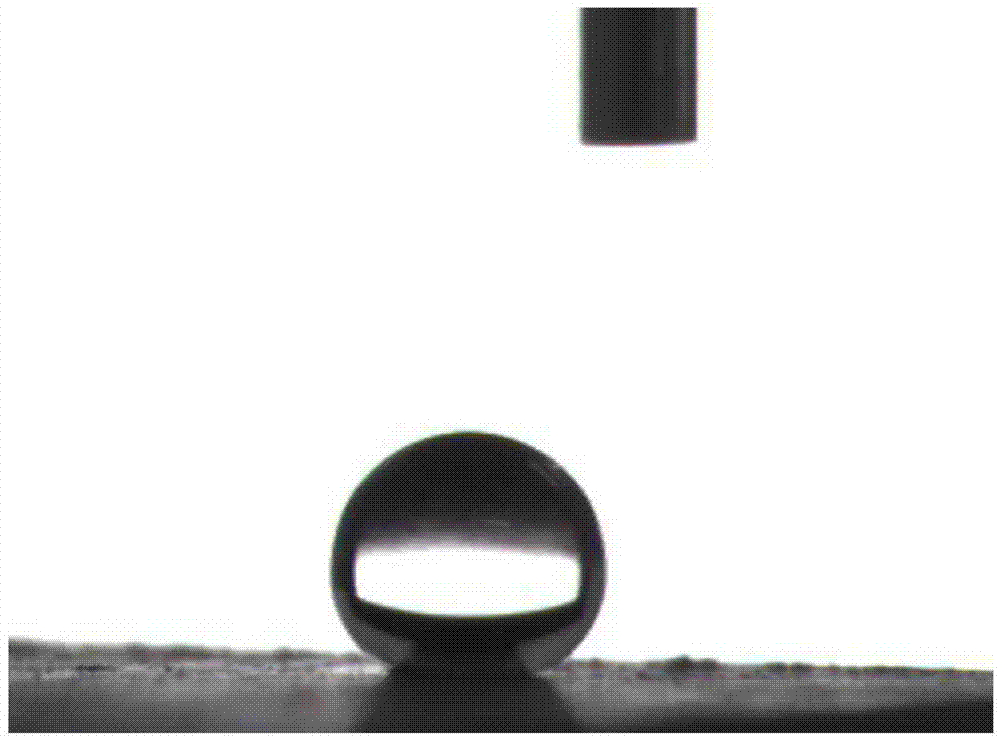

Embodiment 2

[0037] Step (1) Preparation of superhydrophobic and oleophobic primer: at room temperature, 10g epoxy resin, 1g 3-glycidyloxypropyltrimethoxysilane and 4g particle diameter are 3 μm matting powder added to 100g butanone In the process, use 1500r / min to stir for 30min on a high-speed mixer, and after mixing evenly, a superhydrophobic and oleophobic primer is obtained;

[0038] Step (2) Preparation of superhydrophobic and oleophobic topcoat: After mixing 90g of ethanol and 10g of water evenly, add 2g of fumed silica with a particle size of 16nm, 2g of heptadecafluorodecyltrimethoxysilane, 1g of γ-aminopropyl Triethoxysilane, stirred on a high-speed mixer at 1500r / min for 30min, added dropwise 2g of 10wt% acetic acid aqueous solution, mixed evenly, moved to a 500ml four-necked flask, and placed in a water bath at 65°C for 8 hours of heating. , to obtain a superhydrophobic and oleophobic topcoat;

[0039] Step (3) is the same as in Example 1.

[0040] The superhydrophobic and ol...

Embodiment 3

[0042]Step (1) Preparation of superhydrophobic and oleophobic primer: at room temperature, 10g epoxy resin, 1g2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane and 2g particle size are 6 μm Add the powder into 100g methyl ethyl ketone, stir on a high-speed mixer at 1500r / min for 30min, and mix evenly to obtain a superhydrophobic and oleophobic primer;

[0043] Step (2) Preparation of superhydrophobic and oleophobic topcoat: After mixing 90g of ethanol with 10g of water, add 1g of fumed silica with a particle size of 20nm, 1g of tridecafluorooctyltriethoxysilane, 1g of diethylene Triaminopropyltrimethoxysilane, stirred on a high-speed mixer at 1500r / min for 30min, added dropwise 2g of 10wt% acetic acid aqueous solution, mixed evenly, moved to a 500ml four-necked flask, and placed in a water bath at a temperature of 65°C Heating and reacting for 8 hours to obtain a superhydrophobic and oleophobic topcoat;

[0044] Step (3) is the same as in Example 1.

[0045] The contact angle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com