Hydrophobic and oleophobic antibacterial wave-absorbing material and preparation method thereof

A wave-absorbing material, hydrophobic and oleophobic technology, applied in the field of coatings, can solve problems that affect the application, easy to produce bacteria, complex production process of wave-absorbing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

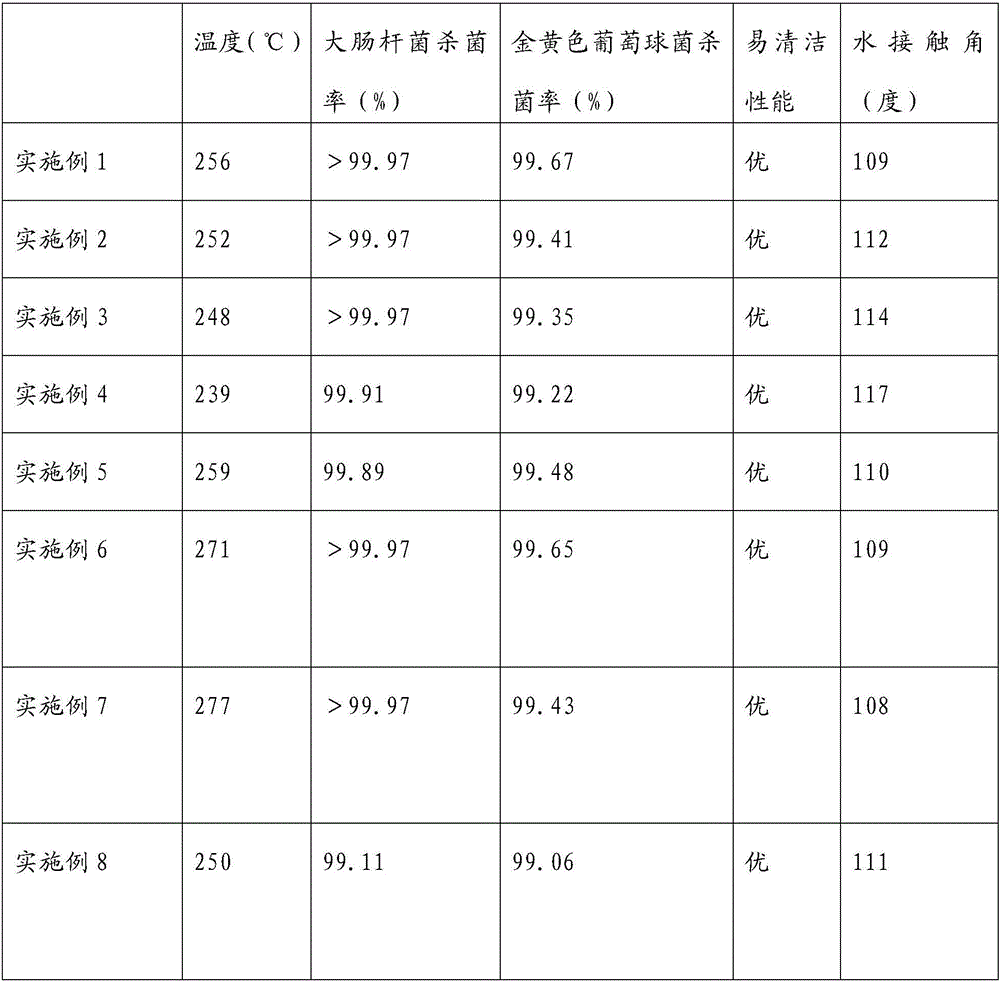

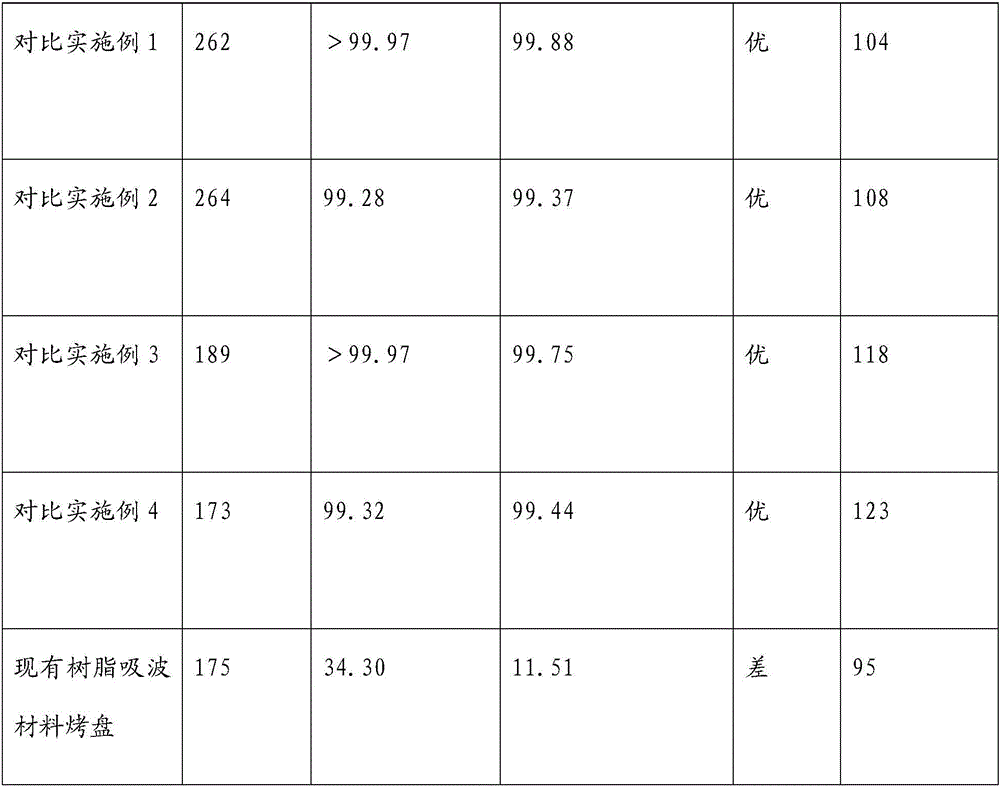

Examples

Embodiment 1

[0071] A hydrophobic and oleophobic antimicrobial wave-absorbing material and its preparation method, the components of the coating are calculated by mass percentage, the wave-absorbing material binder is 87%, the wave-absorbing material is 11%, the antibacterial material is 1%, and the auxiliary agent is 1%. The particle size of the absorbing material is 5nm.

[0072] The preparation method is as follows:

[0073] 1) Preparation of mixed system:

[0074] Mix 87 kg of hydrophobic and oleophobic ceramic materials with 0.5 kg of adhesion-enhancing and leveling agent J-50, mechanically stir at a speed of 500 r / min for 5 minutes, add 0.1 kg of silver-phosphate, 0.3 kg of chitosan and 0.6 kg of nano-titanium dioxide, Continue to stir until evenly mixed to obtain a mixed system;

[0075] 2) Preparation of hydrophobic and oleophobic antibacterial absorbing materials:

[0076] Add 4 kg of β-SiC, 4 kg of ZnO, 2.95 kg of nanographite, and 0.05 kg of Ce to the mixed system prepared i...

Embodiment 2

[0078] A hydrophobic and oleophobic antimicrobial wave-absorbing material and its preparation method, each component of the coating is calculated by mass percentage, the wave-absorbing material binder is 89%, the wave-absorbing material is 9.4%, the antibacterial material is 0.8%, and the auxiliary agent is 0.8%. The particle size of the absorbing material is 15nm.

[0079] The preparation method is as follows:

[0080] 1) Preparation of mixed system:

[0081] Mix 89 kg of hydrophobic and oleophobic ceramic materials with 0.4 kg of adhesion-enhancing and leveling agent J-50, mechanically stir at a speed of 500 r / min for 5 minutes, add 0.1 kg of silver-phosphate, 0.3 kg of chitosan and 0.4 kg of nano-titanium dioxide, Continue to stir until evenly mixed to obtain a mixed system;

[0082] 2) Preparation of hydrophobic and oleophobic antibacterial absorbing materials:

[0083] Add 3.4 kg of β-SiC, 3 kg of ZnO, 2.93 kg of nano-graphite, and 0.07 kg of Ce to the mixed system pr...

Embodiment 3

[0085] A hydrophobic and oleophobic antimicrobial wave-absorbing material and its preparation method, each component of the coating is calculated by mass percentage, the wave-absorbing material binder is 91%, the wave-absorbing material is 7.8%, the antibacterial material is 0.6%, and the auxiliary agent is 0.6%. The particle size of the absorbing material is 30nm.

[0086] The preparation method is as follows:

[0087] 1) Preparation of mixed system:

[0088] Mix 91 kg of hydrophobic and oleophobic ceramic materials with 0.3 kg of adhesion and leveling agent J-50, mechanically stir at 500r / min for 5 minutes, add 0.1 kg of silver-phosphate, 0.2 kg of chitosan and 0.3 kg of nano-titanium dioxide, Continue to stir until evenly mixed to obtain a mixed system;

[0089] 2) Preparation of hydrophobic and oleophobic antibacterial absorbing materials:

[0090] Add 1.4 kg of β-SiC, 3.4 kg of ZnO, 2.92 kg of nano-graphite, and 0.08 kg of Ce to the mixed system prepared in step 1). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com