Preparation method of resin catalyst for synthesis of difluoromethyl ether

A difluoromethyl ether and catalyst technology, which is applied in the field of resin catalyst preparation, can solve problems such as the impact of catalyst service life and application times, the impact on the use effect of industrial devices, and the difficulty of catalyst separation, achieving enhanced binding force and compatibility Improvement, corrosion resistance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Chloromethylated polystyrene spheres can use commercially available products, such as chlorine spheres produced by Anhui Sanxing Resin Technology Co., Ltd.

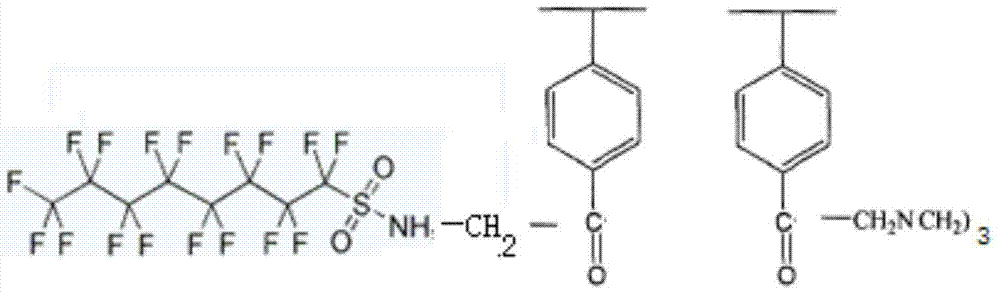

[0019] FC-99: perfluorooctane sulfonamide, such as the product of Guangzhou Liyuan Industrial Materials Co., Ltd.

[0020] Amination reaction:

[0021] Chloromethylated polystyrene spheres are swollen in 3 times (weight ratio) trimethylamine aqueous solution (mass percentage concentration is 40%), add the perfluorooctane sulfonamide of chloromethylated polystyrene spheres 10wt%; At 45 The reaction was stirred at ℃ for 18 hours, and the product was obtained after the reaction was completed, and the obtained product number was M-1.

[0022] Known by the infrared spectrum of reaction product: at 1371cm -1 Asymmetric vibrational absorption peak of sulfonamide appears at 1153cm -1 A sulfonamide symmetrical vibration absorption peak appears, indicating that a sulfonamide group has been introduced into the skeleton of ...

Embodiment 2

[0024] Add 5wt% perfluorooctane sulfonamide to chloromethylated polystyrene spheres; others are the same as in Example 1. The resulting product number was M-2. The infrared spectrum of the reaction product is substantially the same as in Example 1.

Embodiment 3

[0026] Add chloromethylated polystyrene spheres of 20 wt% perfluorooctane sulfonamide; others are the same as in Example 1. The resulting product number was M-3. The infrared spectrum of the reaction product is substantially the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com