Preparation method of textile fabric composite board

A technology for composite sheets and textile fabrics, applied in textiles and papermaking, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as high production costs, inability to obtain a tighter fit with adhesives, and easy falling off. achieve strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

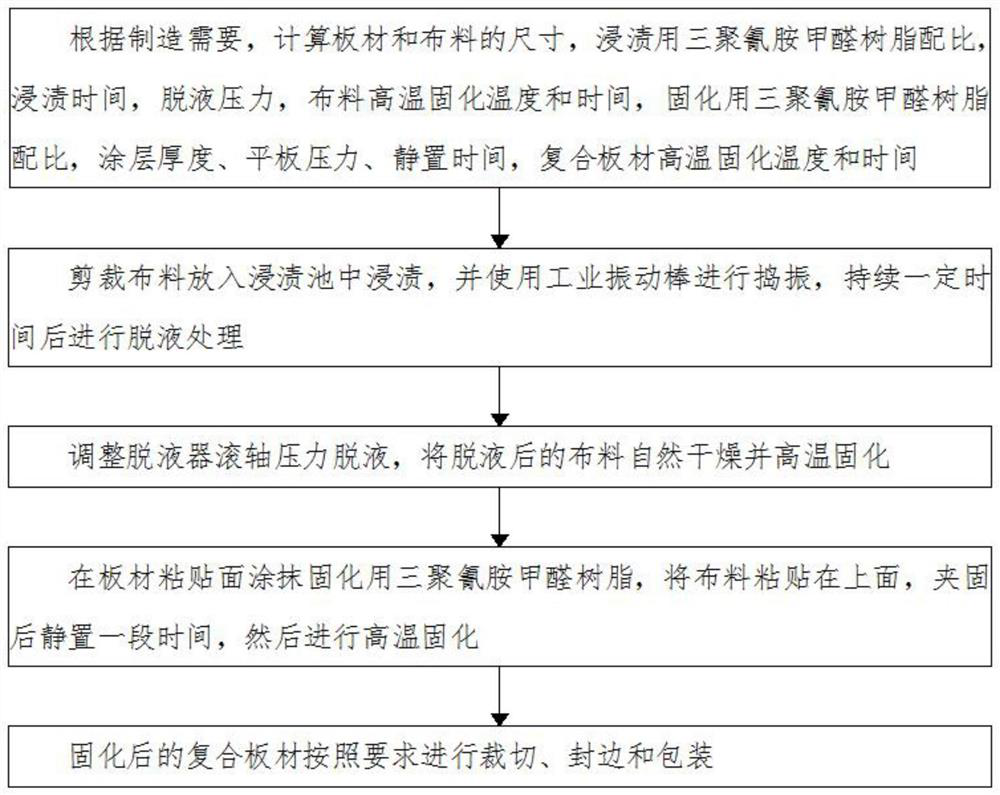

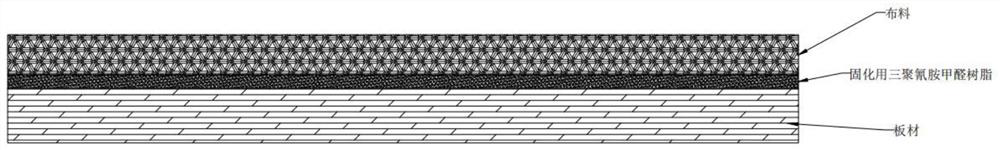

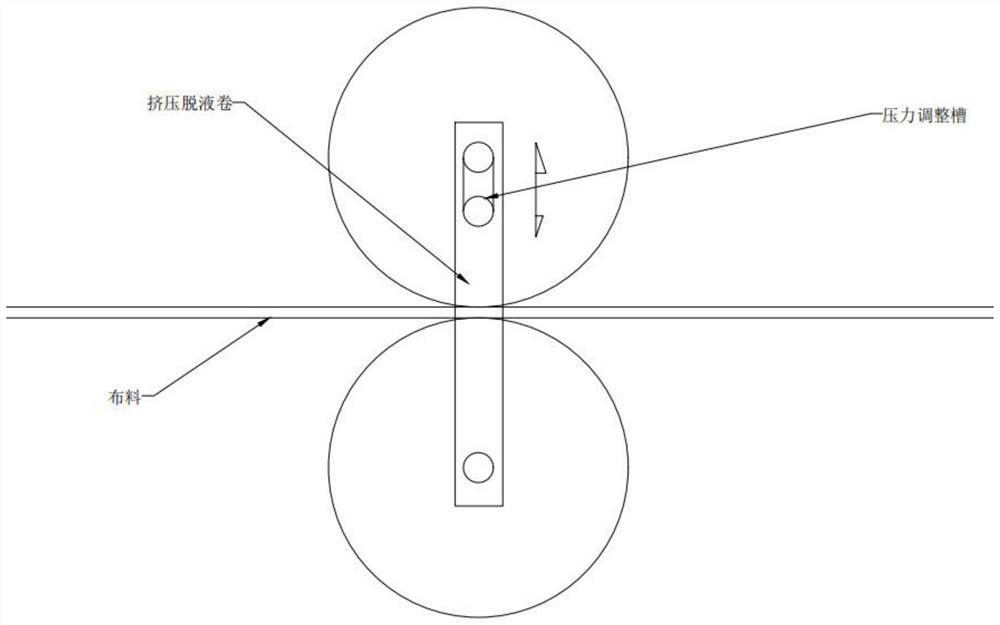

[0024] see Figure 1-3 , the invention provides a technical solution for the preparation method of a textile fabric composite board: comprising the following steps:

[0025] S1, according to manufacturing needs, calculate the size of the board and cloth, the ratio of melamine-formaldehyde resin for impregnation, impregnation time, dehydration pressure, high-temperature curing temperature and time of cloth, the ratio of melamine-formaldehyde resin for curing, coating thickness, plate pressure, Standing time, composite plate high temperature curing temperature and time;

[0026] S2, the cut cloth is dipped in the dipping tank, and an industrial vibrating rod is used for tamping to ensure that the air bubbles in the cloth are fully released, so that the resin can fully cover each fiber, and dehydration treatment is carried out after a certain period of time;

[0027] S3, adjusting the roller pressure of the dehydrator to remove the liquid, and drying the dehydrated fabric natura...

specific Embodiment

[0034] Specific examples are as follows:

[0035] It is necessary to produce a batch of 30cm×150cm colored flower fabric decorative panels, which need to be continuous in design and color. According to the production process and process, we cannot guarantee that all fabrics can be cut well. Therefore, fabrics with a width of 160cm and solid wood multi-layer composites with a width of 150cm×200cm are selected. sheet.

[0036] The first step, fabric treatment: firstly select a melamine formaldehyde resin with a certain viscosity for impregnation according to the thickness of the fabric and the diameter of the weaving thread, pour the resin into the impregnation tank, and cut the fabric according to the length of 210cm according to the shrinkage rate calculation After that, put it into the dipping tank for impregnation. The impregnation time is 20 minutes. During this period, an industrial vibrating rod is used to vibrate, so that the air bubbles in the cloth wire diameter can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com