A kind of corrosion-resistant polyarylate composite material and preparation method thereof

A composite material and polyarylate technology, applied in the field of corrosion-resistant polyarylate composite material and its preparation, can solve the problems of fracture, influence on service life, damage of molecular main chain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Modified polyarylate monomer is prepared by the following steps:

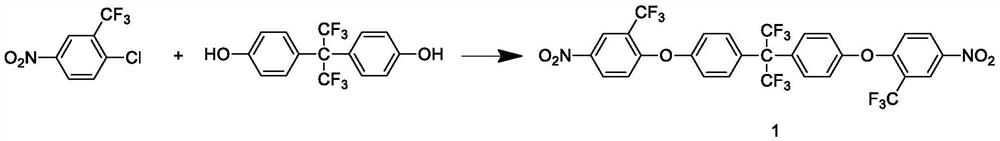

[0043] Step S1, add 0.02mol 2,2-bis-(4-hydroxyphenyl)hexafluoropropane, 0.04mol 2-chloro-5-nitrobenzotrifluoride and 25mL DMF to the three-necked flask, stir to dissolve, then add 0.035mol Potassium carbonate was heated up to 110°C for 5 hours, suction filtered while it was hot, the filtrate was poured into a methanol solution with a mass fraction of 70% to precipitate, filtered, the filter cake was washed with methanol, and then dried at 60°C for 3 hours to obtain intermediate 1;

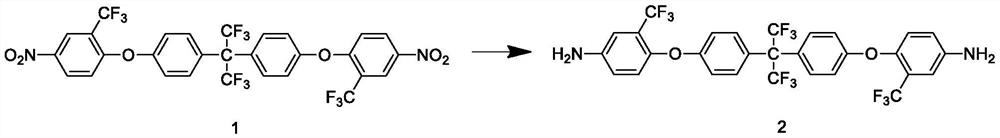

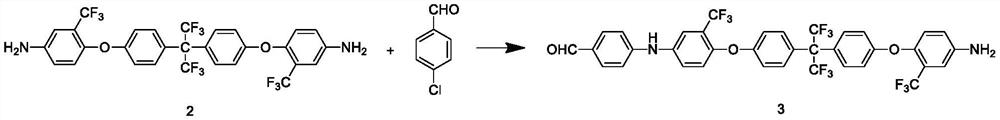

[0044] Step S2, add 0.010 mol of intermediate 1, 40 mL of absolute ethanol, and 0.10 g of Pd / C catalyst to the three-necked flask, ultrasonically disperse at a frequency of 30 kHz for 20 min, raise the temperature to 105 ° C, add 2.2 mL of hydrazine hydrate to it, and control the dropwise within 30 min After the addition was completed, the reflux reaction was continued for 3 h, suction filtered while hot, the filtrate was pour...

Embodiment 2

[0050] Modified polyarylate monomer is prepared by the following steps:

[0051] Step S1, add 0.025mol 2,2-bis-(4-hydroxyphenyl)hexafluoropropane, 0.042mol 2-chloro-5-nitrobenzotrifluoride and 26mL DMF to the three-necked flask, stir and dissolve, then add 0.036mol Potassium carbonate was heated to 115°C for 5 hours, suction filtered while it was hot, the filtrate was poured into a methanol solution with a mass fraction of 70% to precipitate, filtered, the filter cake was washed with methanol, and dried at 65°C for 3 hours to obtain intermediate 1;

[0052] Step S2, add 0.011mol of intermediate 1, 43mL of absolute ethanol, and 0.12g of Pd / C catalyst to the three-necked flask, ultrasonically disperse at a frequency of 35kHz for 25min, raise the temperature to 108°C, add 2.4mL of hydrazine hydrate to it, and control the dropwise within 30min After the addition was completed, the reflux reaction was continued for 3 h, suction filtered while hot, the filtrate was poured into deion...

Embodiment 3

[0058] Modified polyarylate monomer is prepared by the following steps:

[0059] Step S1, add 0.03mol 2,2-bis-(4-hydroxyphenyl)hexafluoropropane, 0.045mol 2-chloro-5-nitrobenzotrifluoride and 28mL DMF to the three-necked flask, stir and dissolve, then add 0.037mol Potassium carbonate was heated up to 120°C for 6 hours, suction filtered while it was hot, the filtrate was poured into a methanol solution with a mass fraction of 70% to precipitate, filtered, the filter cake was washed with methanol, and dried at 70°C for 4 hours to obtain intermediate 1;

[0060] Step S2, add 0.012mol of intermediate 1, 45mL of absolute ethanol, and 0.14g of Pd / C catalyst to the three-necked flask, ultrasonically disperse at a frequency of 40kHz for 30min, raise the temperature to 110°C, add 2.5mL of hydrazine hydrate to it, and control the dripping within 30min After the addition was completed, the reflux reaction was continued for 4 hours, suction filtered while it was hot, the filtrate was pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com