Super-strong decontamination anti-cross-color laundry gel beads and preparation method thereof

A technology for laundry condensation and anti-staining, which is applied in the field of daily chemical products to achieve the effects of high detergency, good color protection and color fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

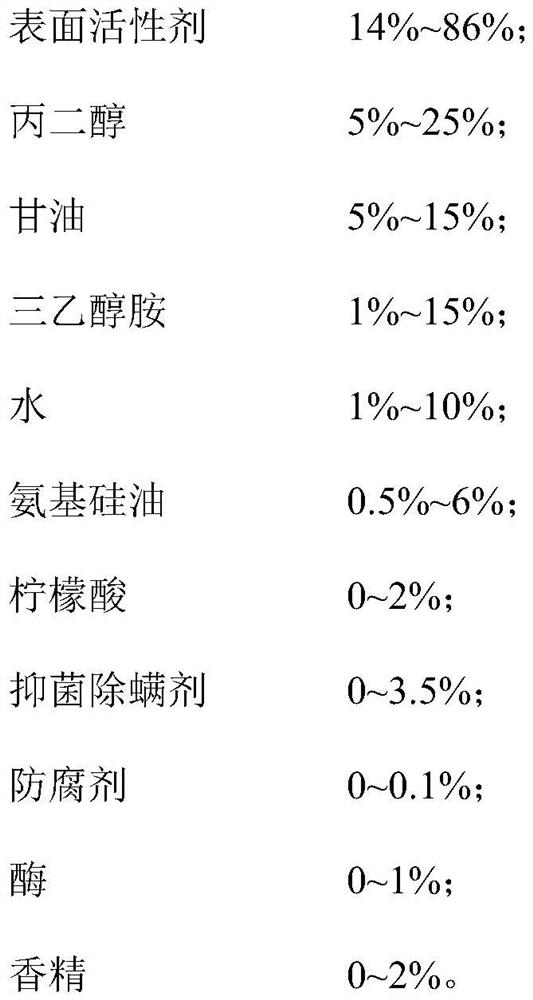

[0034] A kind of super strong decontamination anti-cross-color laundry pod of this embodiment, its internal cleaning solution comprises the following components in mass percentage:

[0035]

[0036]

[0037] The super strong decontamination and anti-cross-color laundry pods are prepared by the following method:

[0038] (1) Mix isomeric alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, fatty acid methyl ester ethoxylate, fatty alcohol polyoxyethylene ether sodium sulfate, dodecylbenzenesulfonic acid, propylene glycol, glycerin and water After heating to 65-70°C, stir and dissolve evenly, then add triethanolamine, citric acid and amino silicone oil (average molecular weight 9600, ammonia value 0.5) successively, stir and dissolve evenly.

[0039] (2) Cool the mixed solution in step (1) to room temperature, then add in sequence antibacterial and mite-removing plant extract, preservative Cathone, protease, lipase and essence, stir and mix evenly to obtain ...

Embodiment 2

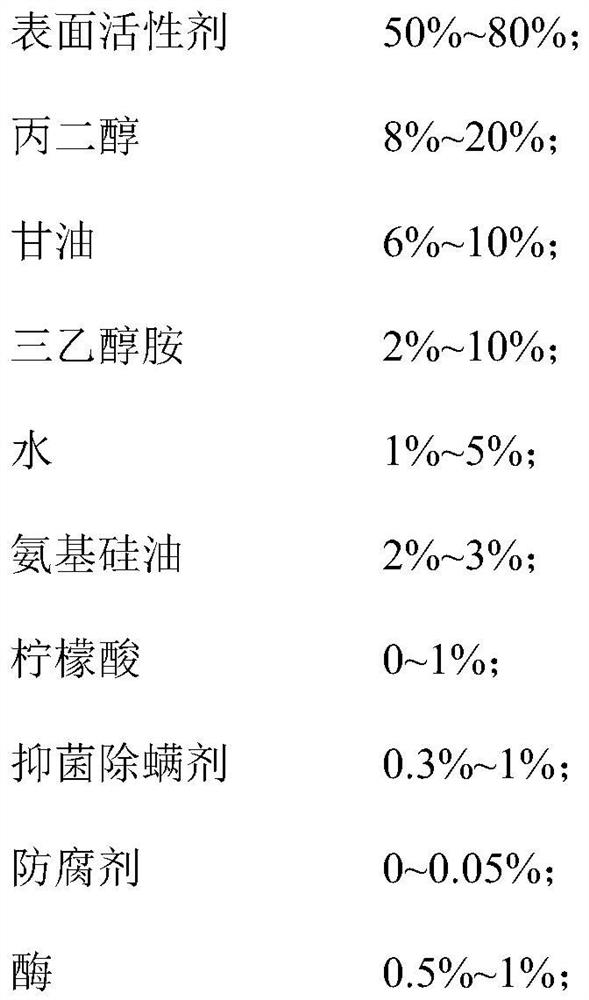

[0042] A kind of super strong decontamination anti-cross-color laundry pod of this embodiment, its internal cleaning solution comprises the following components in mass percentage:

[0043]

[0044]

[0045] The super strong decontamination and anti-cross-color laundry pods are prepared by the following method:

[0046] (1) Mix isomeric alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, fatty acid methyl ester ethoxylate, fatty alcohol polyoxyethylene ether sodium sulfate, dodecylbenzenesulfonic acid, propylene glycol, glycerin and water After heating to 65-70°C, stir and dissolve evenly, then add triethanolamine and amino silicone oil (average molecular weight 24000, ammonia value 0.3) in turn, stir and mix evenly.

[0047] (2) Cool the mixed solution in step (1) to room temperature, then add silver ion antibacterial and acaricide agent, protease, lipase and essence in sequence, stir and mix evenly to obtain a cleaning solution.

[0048] (3) Wrapping t...

Embodiment 3

[0050] Compared with Example 2, this example adopts amino silicone oil with an average molecular weight of 5000 and an ammonia value of 1.0, and the rest are identical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com