A kind of moisturizing capsule and its preparation and application in cigarette

A technology for moisturizing capsules and capsules, applied in the field of the tobacco industry, can solve the problems of insufficient strength of the outer layer wax, complicated processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Weigh 12g of polyvinyl alcohol, was dissolved in 400mL of deionized water at 80 deg.] C to give a polyvinyl alcohol solution.

[0065] 3g polylactic acid particles were weighed, dissolved in 30mL of dichloromethane, to obtain a polylactic acid solution.

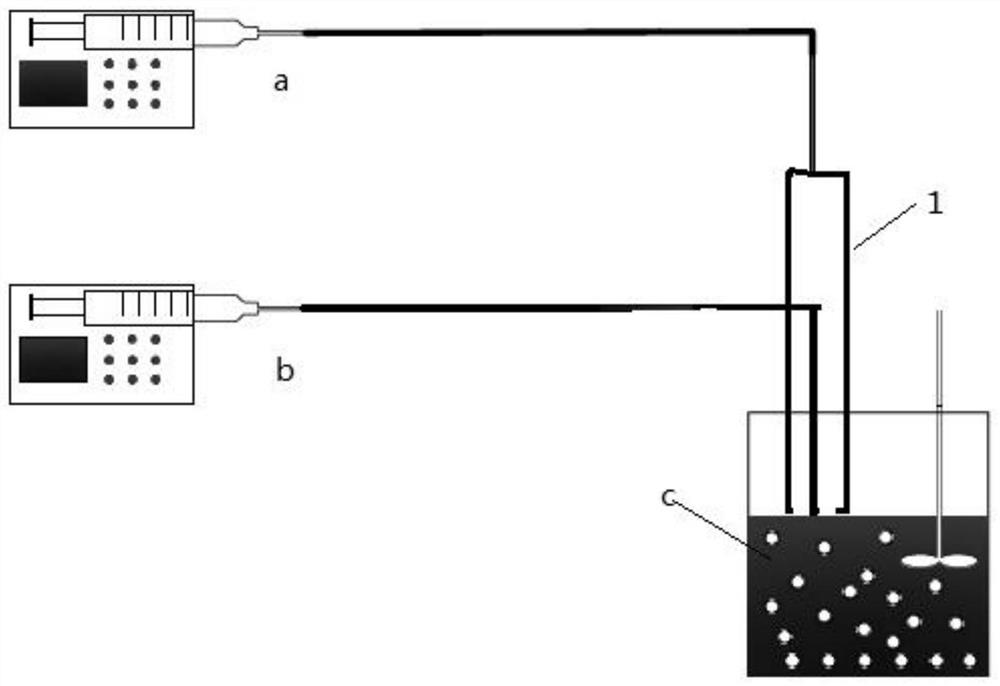

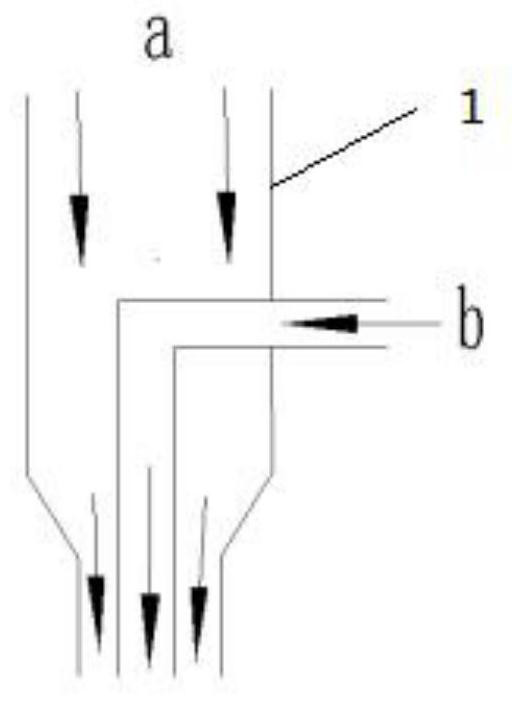

[0066] The propylene glycol solution of polylactic acid were charged in a syringe, the syringe pump is placed on two, coaxial needle connected to the reactor, the flow rate of two syringe pumps were 5mL / h (flow rate propylene glycol), 6mL / h (poly the flow rate of lactic acid solution), was added dropwise a solution of polyvinyl alcohol, mechanically stirred 6h, stirring speed of 250r / min, the product was vacuum filtration, washed with deionized water, then collected, i.e., to obtain a polylactic acid-Run capsule. Particle size was measured capsules 3.3mm.

Embodiment 2

[0068] Weigh 12g of polyvinyl alcohol, was dissolved in 400mL of deionized water at 80 deg.] C to give a polyvinyl alcohol solution.

[0069] Weigh 3.6g of polylactic acid particles, was dissolved in 30mL of dichloromethane, to obtain a polylactic acid solution.

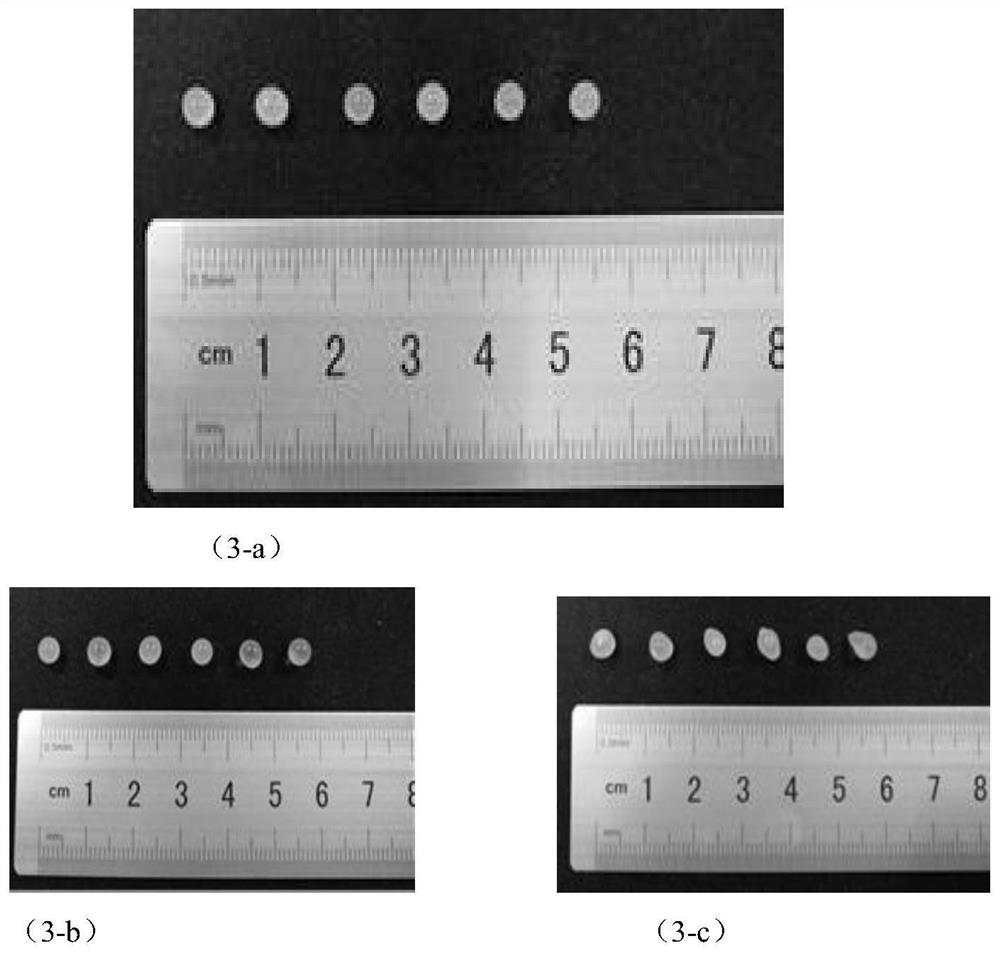

[0070] The solution of polylactic acid and deionized water were charged in a syringe, the syringe pump is placed on two, coaxial needle connected to the reactor, the flow rate of two syringe pumps were 5mL / h (water flow), 6mL / h (flow rate of polylactic acid solution), was added dropwise a solution of polyvinyl alcohol, mechanically stirred 6h, stirring speed of 250r / min, the product was vacuum filtration, washed with deionized water, then collected, i.e., to obtain a polylactic acid water capsule. Water was measured to 3.5mm capsule diameter (see image 3 -a).

Embodiment 3

[0072] Example 2 and compared, the main difference is that the wall material solution PLA solubility of 0.15g / mL; as follows:

[0073] Weigh 12g of polyvinyl alcohol, was dissolved in 400mL of deionized water at 80 deg.] C to give a polyvinyl alcohol solution.

[0074] Weigh 4.5g of polylactic acid particles, was dissolved in 30mL of dichloromethane, to obtain a polylactic acid solution.

[0075] The solution of polylactic acid and deionized water were charged in a syringe, the syringe pump is placed on two, coaxial needle connected to the reactor, the flow rate of two syringe pumps were 5mL / h (water flow), 6mL / h (flow rate of polylactic acid solution), was added dropwise a solution of polyvinyl alcohol, mechanically stirred 6h, stirring speed of 250r / min, the product was vacuum filtration, washed with deionized water, then collected, i.e., to obtain a polylactic acid water capsule. Water capsule package diameter is about 4mm (see image 3 -b),

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com