A heat-not-burn cigarette and its preparation method

A technology for heating non-combustion and cigarettes, which is applied in the tobacco industry and can solve the problems of easy moisture absorption and limited addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Weigh 12g of polyvinyl alcohol and dissolve it in 400mL of deionized water at 80°C to obtain a polyvinyl alcohol solution.

[0082] Weigh 3g of polylactic acid particles and dissolve in 30mL of dichloromethane to obtain a polylactic acid solution.

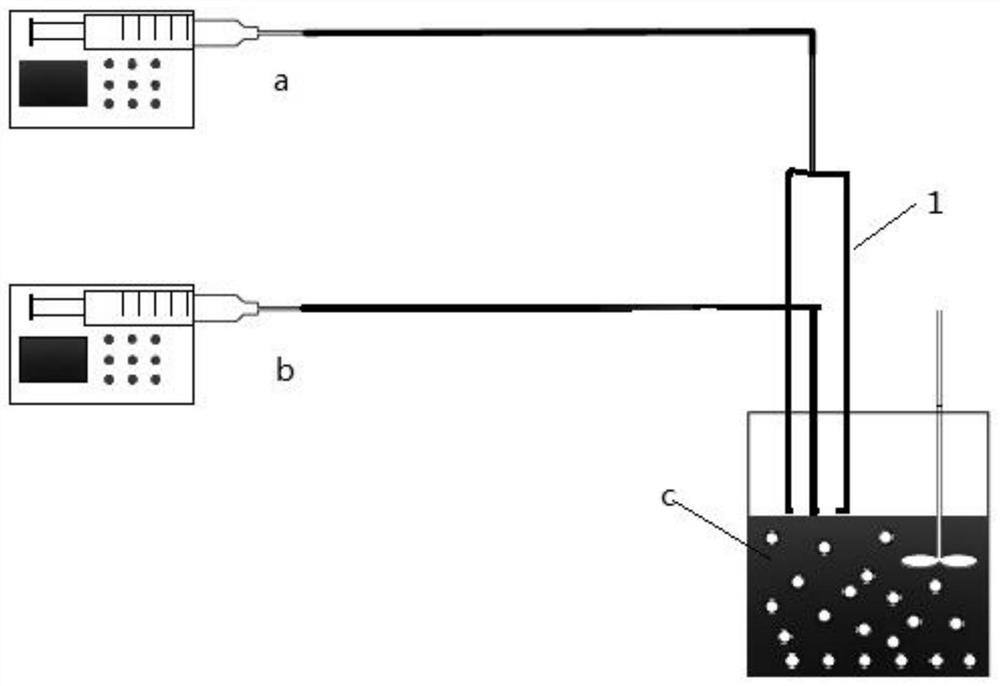

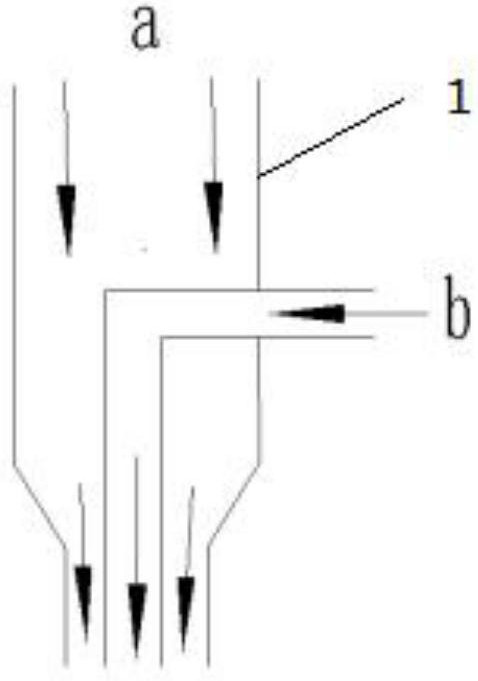

[0083] The polylactic acid solution and propylene glycol were put into syringes respectively, placed on two syringe pumps, connected to the coaxial double-needle reactor, and the flow rates of the two syringe pumps were 5mL / h (the flow rate of propylene glycol), 6mL / h (poly Lactic acid solution), drop into polyvinyl alcohol solution, mechanically stir for 6h, stirring speed is 250r / min, filter the product under reduced pressure, wash with deionized water, and then collect to obtain polylactic acid functional capsules. The particle size of the capsules was measured to be 3.3 mm.

Embodiment 2

[0085] Weigh 12g of polyvinyl alcohol and dissolve it in 400mL of deionized water at 80°C to obtain a polyvinyl alcohol solution.

[0086] Weigh 3.6g of polylactic acid particles and dissolve in 30mL of dichloromethane to obtain a polylactic acid solution.

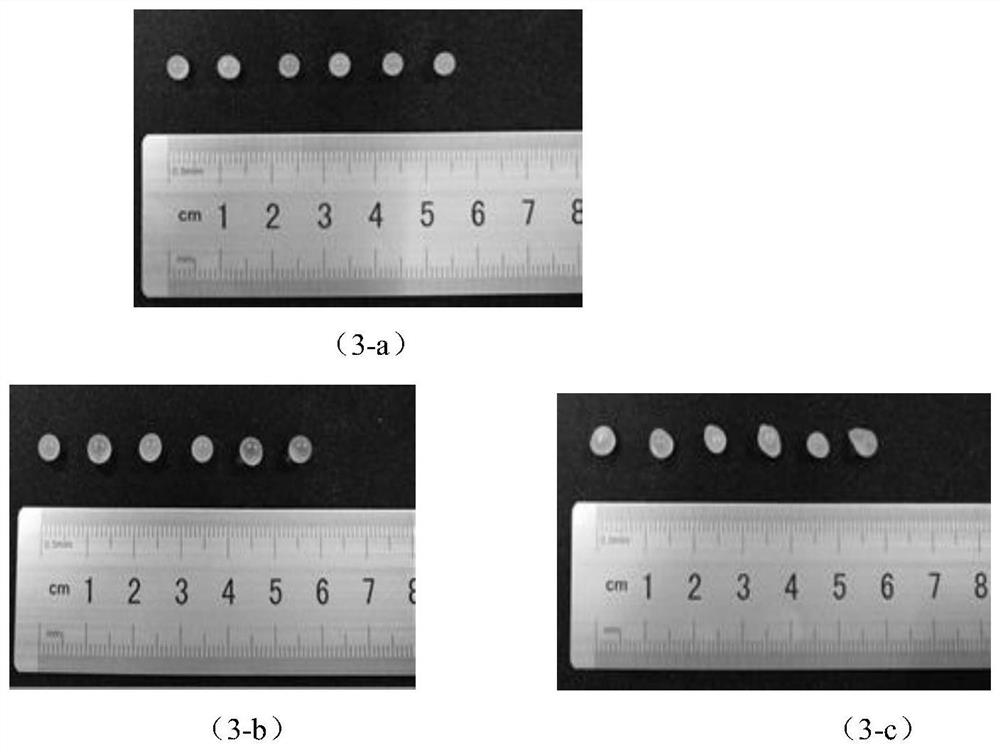

[0087] Put the polylactic acid solution and deionized water into syringes respectively, place them on two syringe pumps, connect the coaxial double-needle reactor, and the flow rates of the two syringe pumps are 5mL / h (water flow rate) and 6mL / h respectively. h (the flow rate of the polylactic acid solution), drip into the polyvinyl alcohol solution, mechanically stir for 6h, and the stirring speed is 250r / min, the product is vacuum filtered, washed with deionized water, and then collected to obtain polylactic acid-in-water capsules . The particle diameter that measures water-packed capsule is 3.5mm (see image 3 -a).

Embodiment 3

[0089] Compared with Example 2, the main difference is that the PLA solubility of the wall material solution is 0.15g / mL; details are as follows:

[0090] Weigh 12g of polyvinyl alcohol and dissolve it in 400mL of deionized water at 80°C to obtain a polyvinyl alcohol solution.

[0091] Weigh 4.5g of polylactic acid particles and dissolve in 30mL of dichloromethane to obtain a polylactic acid solution.

[0092] Put the polylactic acid solution and deionized water into syringes respectively, place them on two syringe pumps, connect the coaxial double-needle reactor, and the flow rates of the two syringe pumps are 5mL / h (water flow rate) and 6mL / h respectively. (the flow rate of the polylactic acid solution); drip into the polyvinyl alcohol solution, mechanically stir for 6 hours, the stirring speed is 250r / min, the product is filtered under reduced pressure, washed with deionized water, and then collected to obtain polylactic acid water-in-capsules. The particle size of the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com