Micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust formed by cleaning and polishing of casting

A PM2.5, casting cleaning technology, applied in separation methods, chemical instruments and methods, grinding/polishing equipment, etc., can solve the problems of dust collectors that cannot operate normally, high operating resistance of dust collectors, and unsatisfactory dust removal effects. Achieve complete cleaning effect, low maintenance cost and strong self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

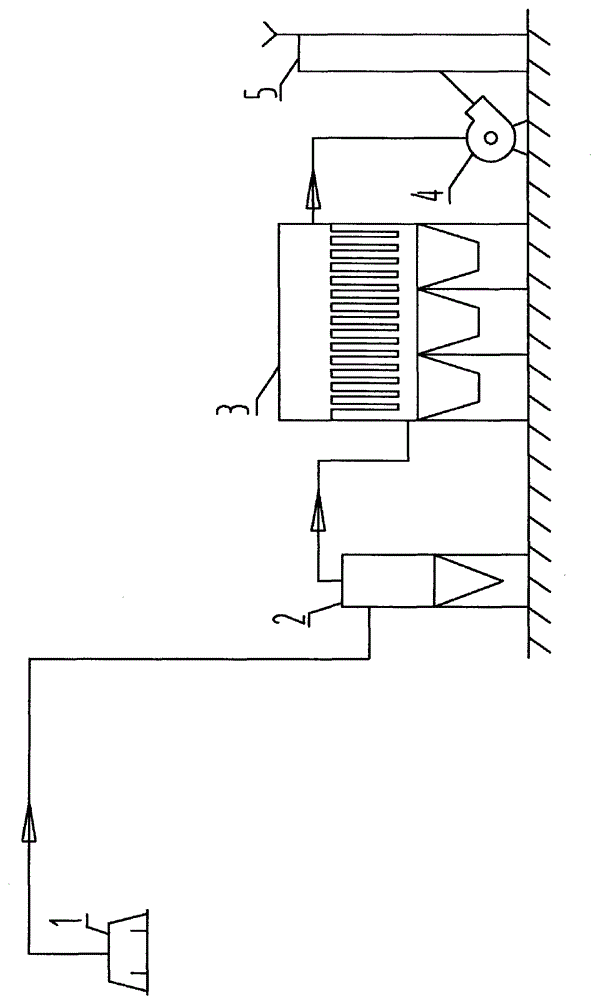

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] Such as figure 1 Shown: a kind of microfiltration filtration method step of cleaning and polishing PM2.5 microdust of the present invention is as follows:

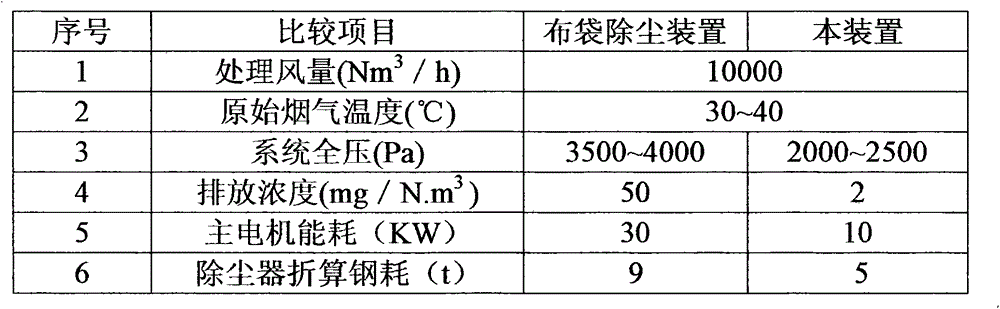

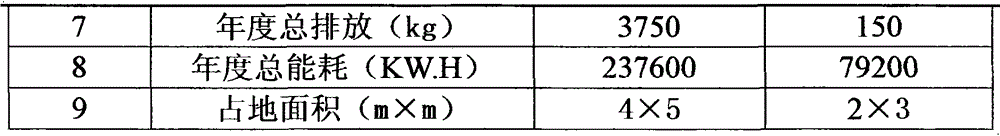

[0020] Take the production of ¢1500mm valve casting cleaning, grinding and dust removal process as an example, when the flow rate is 10000Nm 3 / h, temperature 40℃, dust concentration 7g / Nm 3 The mixed dust such as metal iron filings and grinding wheel chips enters the collection cover 1, and is transported to the cyclone dust collector 2 through a pipeline. The cyclone dust collector 2 filters large particles of dust, and the dust removal efficiency is 95%, which achieves the purpose of pre-dust removal. Plate dust collector 3, the dust concentration is 2mg / Nm after being purified by plastic fired plate dust collector 3 3 , is pressed into the exhaust cylinder 5 by the main fan 4 through the pipeline and disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com