A kind of ultra-high polymer microporous filter material, processing equipment and processing method

An ultra-high polymer and ultra-high molecular weight technology, which is applied to ultra-high polymer microporous filter materials and processing equipment and processing fields, can solve the problems of inability to realize automatic continuous production, simple dispersion of production equipment units, and backward production technology of filter materials. Achieve the effect of improving the ability to protect the environment and health of residents, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

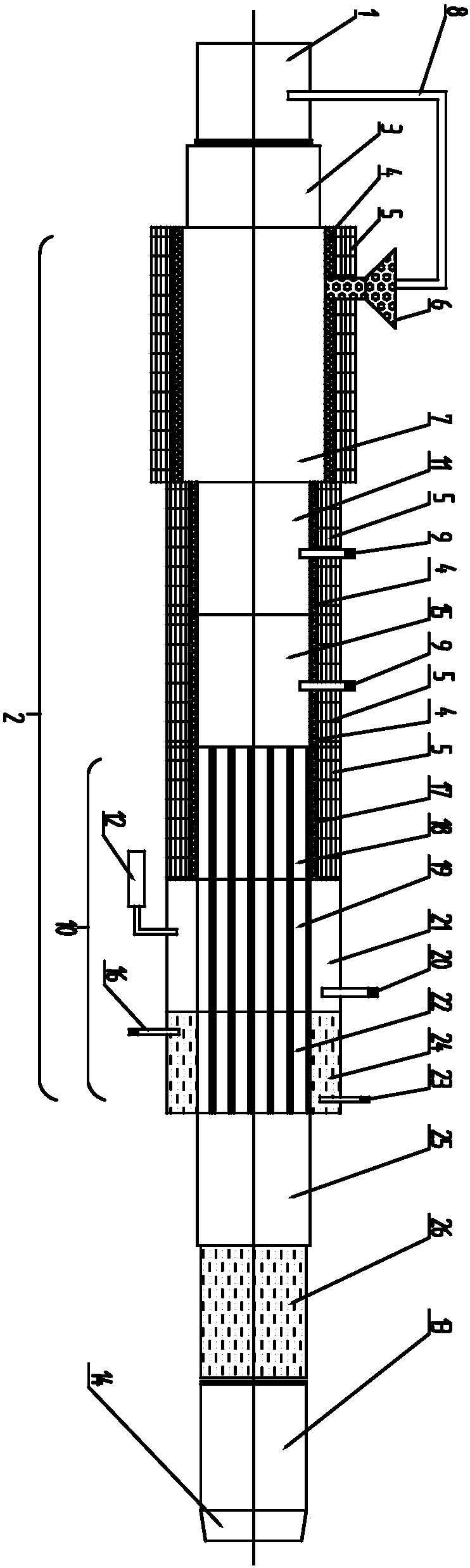

[0049] Such as figure 1 As shown, the feeding machine 1 is an automatic powder feeding machine, which automatically adds powder raw materials into the feeding hopper.

[0050] The reducer 3 adopts a high-strength hard-toothed helical gear reducer to drive the single-screw plunger integrated machine to work.

[0051] The upper part of the high-temperature stretching working chamber 15 is respectively provided with compressed nitrogen gas introduction pipes 9, and the compressed nitrogen gas is introduced into the high-temperature stretching working chamber to make the raw material form an air-floating semi-molten state.

[0052] The reciprocating traction device 25 adopts the frequency conversion speed regulating cylinder linkage mechanism, and reciprocates, so that the profile is only drawn forward and displaced.

[0053] The cutting machine 13 performs chip-free fixed-length cutting to the profiles with stable dimensions.

[0054] The mold head 18 allows the uniform air-flo...

Embodiment 2

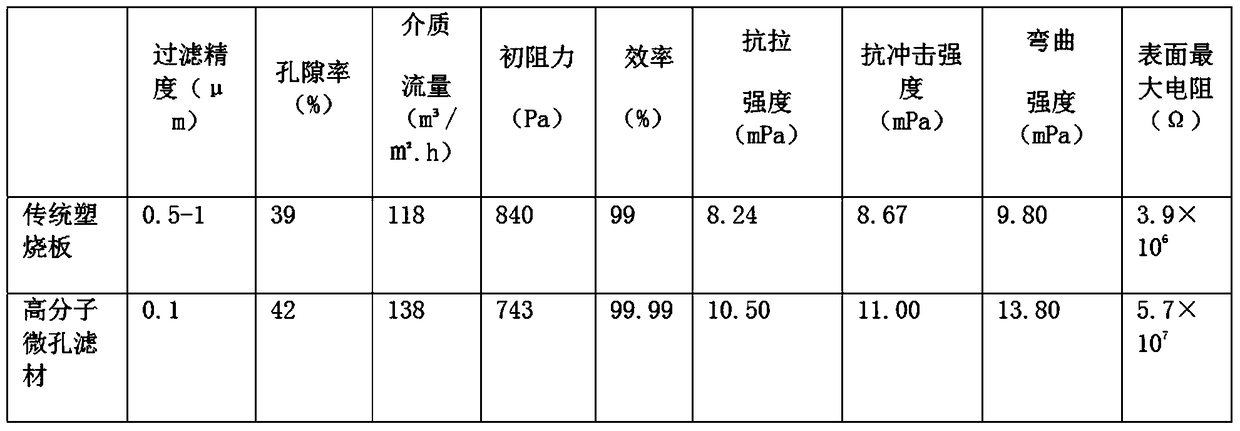

[0058] According to the principle that when the polymer melt is pulled, the molecular chain will be oriented and relaxed, the melt extrusion stretching process is designed to produce micropores by low-temperature stretching, and expand the micropores by high-temperature stretching, so that the pore size can be adjusted according to the mixture. The particle size of the raw material and the temperature and pressure parameters of the extrusion machine can be adjusted flexibly.

[0059]The technological parameters of manufacturing characteristic ultra-high molecular microporous gas-liquid filter material by extrusion fluorine leaching process raw material ratio are as follows:

[0060] 1) The running speed of the extruder is 35 rpm / min

[0061] 2) The running speed of the traction device is 0.13m / min

[0062] 3) Produce Φ340mm, wall thickness 2.3mm filter cartridges, and the finished product forming speed of the production line is 6.5m / h.

[0063] 4) Low-temperature stretching ...

Embodiment 3

[0072] After weighing various raw materials according to the following proportions, fully stir them in a three-dimensional high-speed powder mixer, mix them for 15 minutes, and take them out for later use.

[0073] Ultra-high molecular weight polyethylene powder with a particle size of 63-108 μm: 81-77%;

[0074] High-density polyethylene powder with a particle size of 43-69 μm: 8.8-8.4%;

[0075] Hollow glass microspheres with a particle size of 63-89μm: 8.3-7.1%;

[0076] Conductive carbon black with a particle size of 42-53 μm: 4.9-4.5%.

[0077] Add the mixed powder into the hopper of the extruder.

[0078] Start the heating and heating operation system of each part of the extruder through the touch screen.

[0079] Input the following parameters through the touch screen: 151℃±2℃; pressure 0.26MPa; 169℃±2℃; pressure 0.35MPa; 164 ℃±2℃, pressure 0.32MPa.

[0080] After 15-20 minutes, the temperature control digital display of each part of the extruder reaches the set pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com