Microfiltration method for treating PM2.5 particulates in hot rolling mill

A technology of PM2.5 and filtration method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. Thorough ash effect, low maintenance cost, strong self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

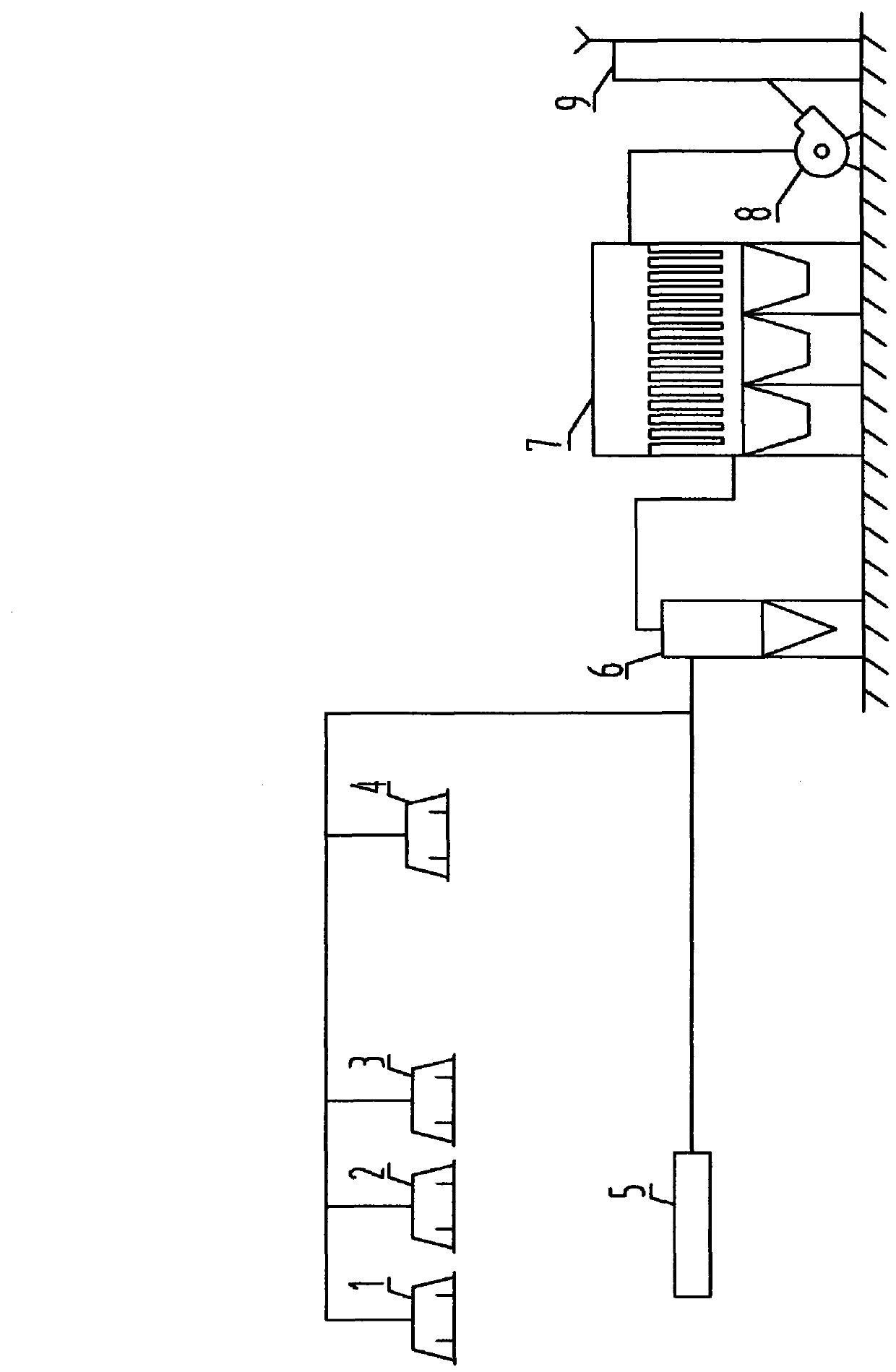

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] Such as figure 1 Shown: a kind of microfiltration method step of controlling hot rolling mill PM2.5 fine dust of the present invention is as follows:

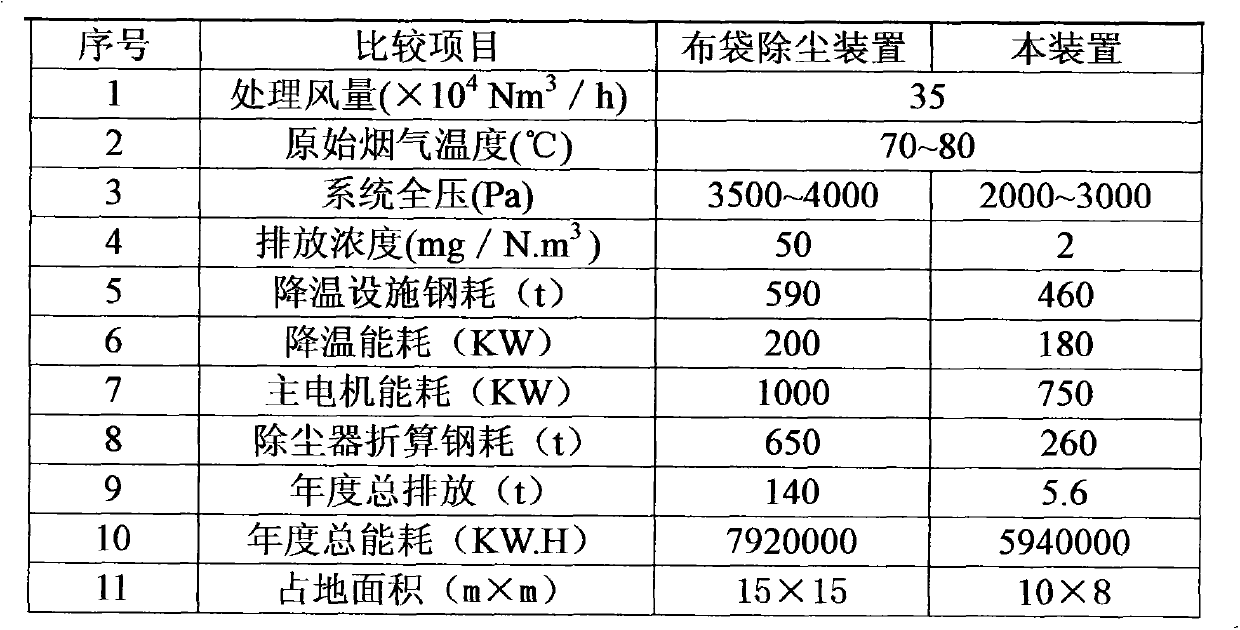

[0020] Taking the production of ¢178mm petroleum steel pipe hot rolling mill dust removal process as an example, when the flow rate is 35×10 4 N m 3 / h, temperature 80℃, dust concentration 15g / Nm 3 Highly dusty and saturated water vapor is captured by the hot rolling mill entrance collecting hood 1, the hot rolling mill upper collecting hood 2, the hot rolling mill exit collecting hood 3, the pipe stripping machine collecting hood 4, and the sandblasting collecting hood 5 Collected, transported to the cyclone dust collector 6 through pipelines, the cyclone dust collector 6 filters large particle dust, and the dust removal efficiency is 95%, which achieves the purpose of pre-dust removal, and then passes through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com