Desulfurization, denitration and dust removal equipment for flue gas of chemical plant

A technology for desulfurization, denitrification, and dust removal equipment, which is applied in gas treatment, chemical instruments and methods, and dispersed particle filtration. It can solve problems such as imperfect functions, poor environmental protection performance, and dust doping, and achieves simple structure and strong mechanical linkage. , The effect of high dust removal accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the examples.

[0040] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

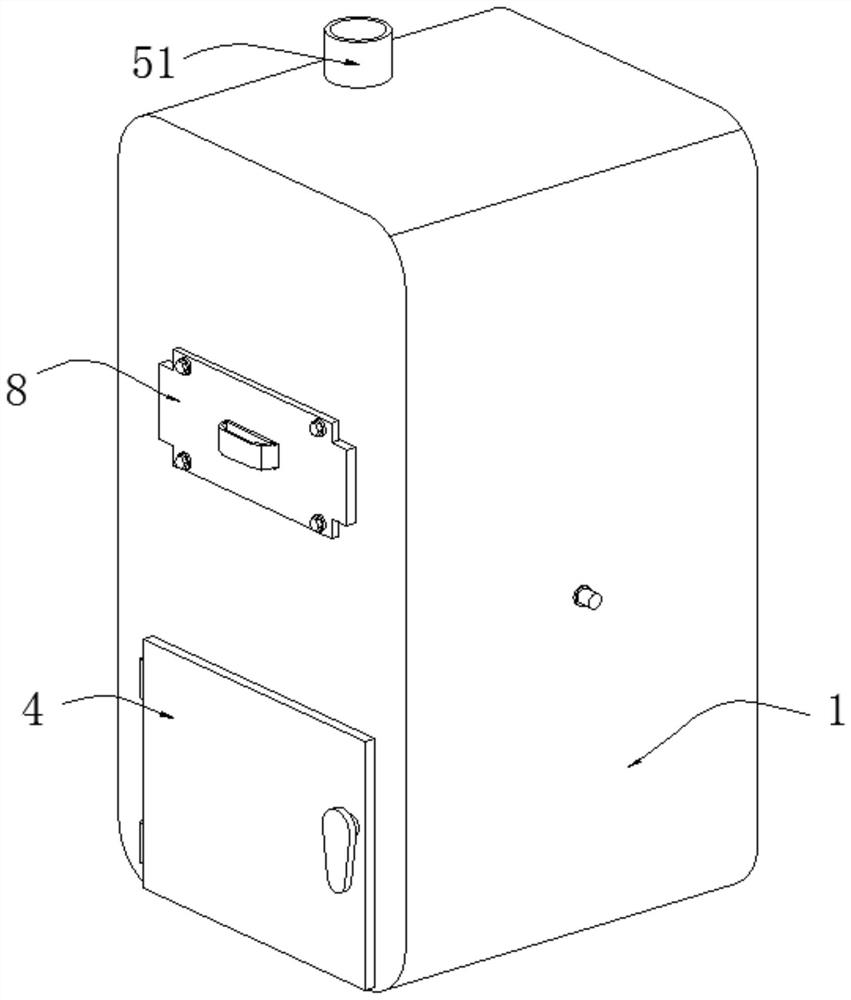

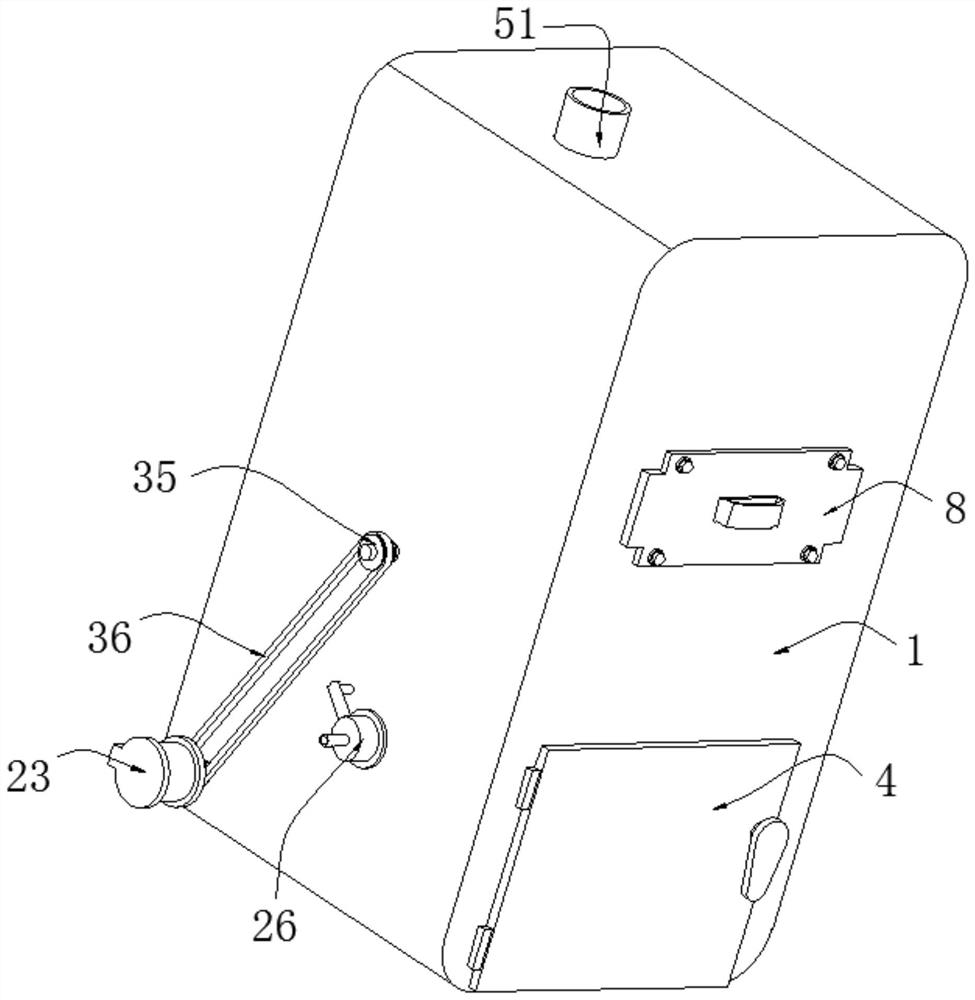

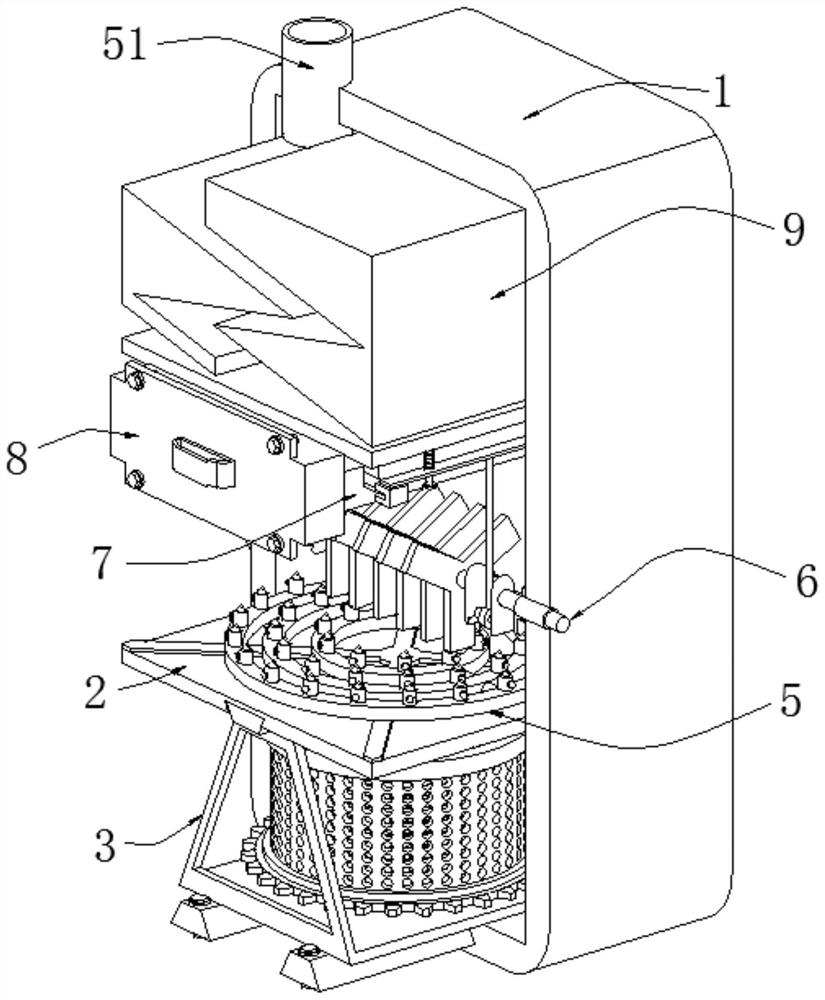

[0041] see Figure 1-10 , the present invention provides a flue gas desulfurization, denitrification and dust removal equipment in a chemical plant, which includes a housing 1 .

[0042] Two partitions 2 are installed inside the casing 1 one above the other and divide the casing 1 into three cavities from bottom to top, and the three cavities are respectively the first-level dust removal chamber and the second-level In the dust removal chamber and the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com