Spinning air conditioning unit for water curtain dust-removing and humidifying

A technology for water curtain dust removal and air conditioning units, which is applied to air conditioning systems, heating methods, lighting and heating equipment, etc. Guaranteed clean operation and guaranteed blowing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

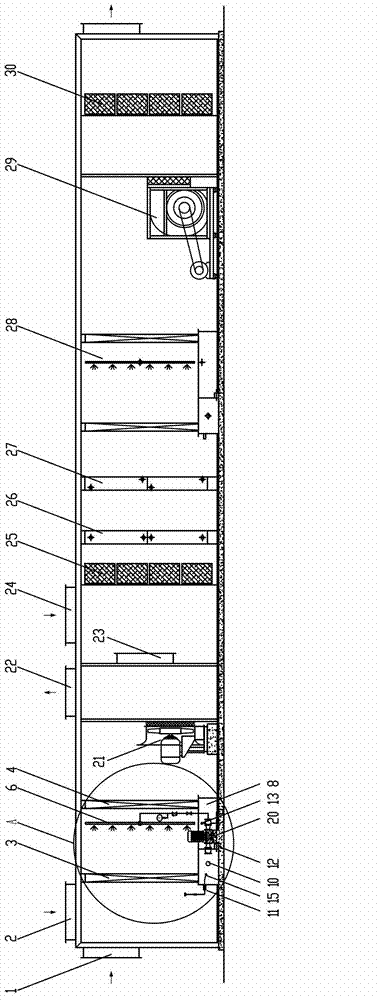

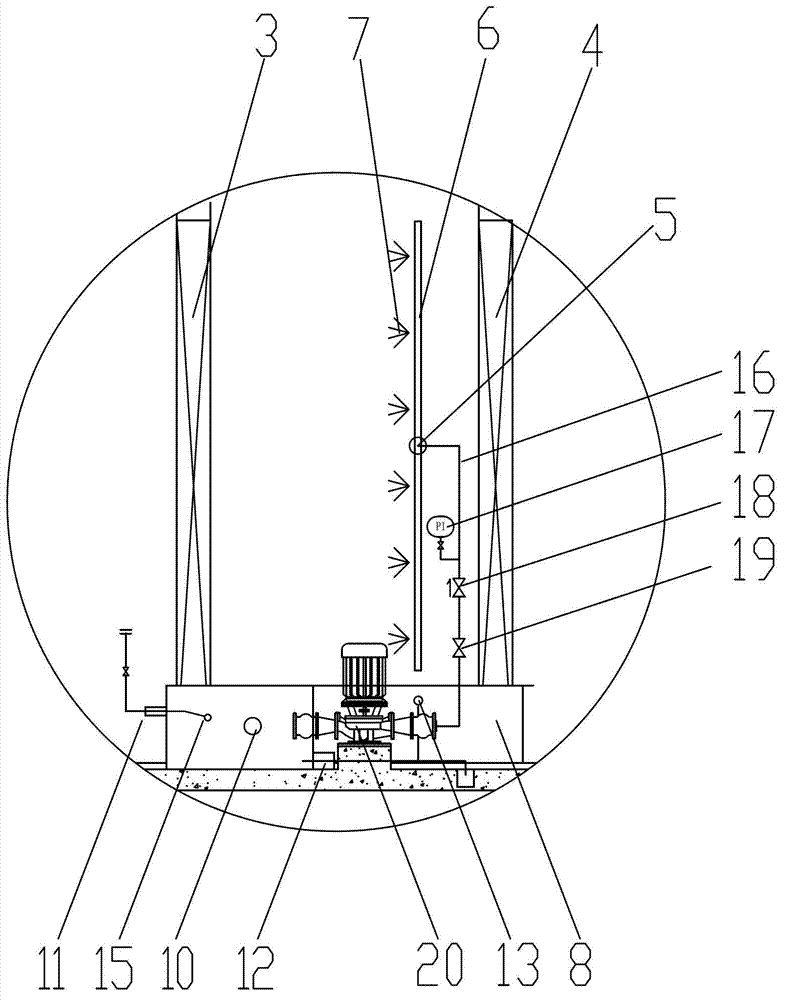

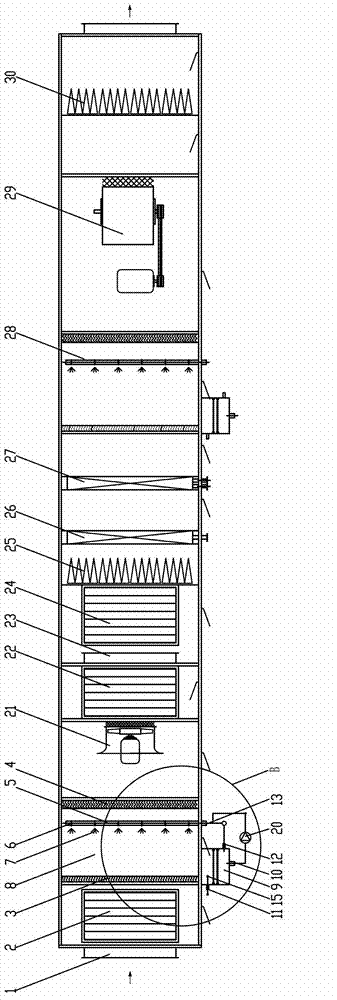

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as Figure 1-4 , a water curtain dedusting and humidifying spinning air conditioning unit, comprising a return air device, a water curtain washing dedusting and humidifying device, a return fan 21, an air inlet device, a coarse filter 25, a heater 26, a surface cooler 27, Spray section 28, air blower 29, high-efficiency filter device 30, the water curtain washing dust removal and humidifying device includes an external water tank 9, a spray water tank 8, the external water tank 9 and the spray water tank 8 are integrated, and the external water tank 9 passes through the circulation The water pipe 16 is connected with the spray main pipe 5, the spray main pipe 5 is connected with the spray branch pipe 6, the spray branch pipe 6 is provided with the nozzle 7, and the external water tank 9 is connected with the water supply device 11. The circulating water pipe 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com