Micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust of cupola furnace

A filtration method and technology of a cupola, applied in the field of flue gas dust removal, can solve the problems that the precipitator cannot operate normally, cannot complete the filtration work, and the operating resistance of the precipitator is high. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

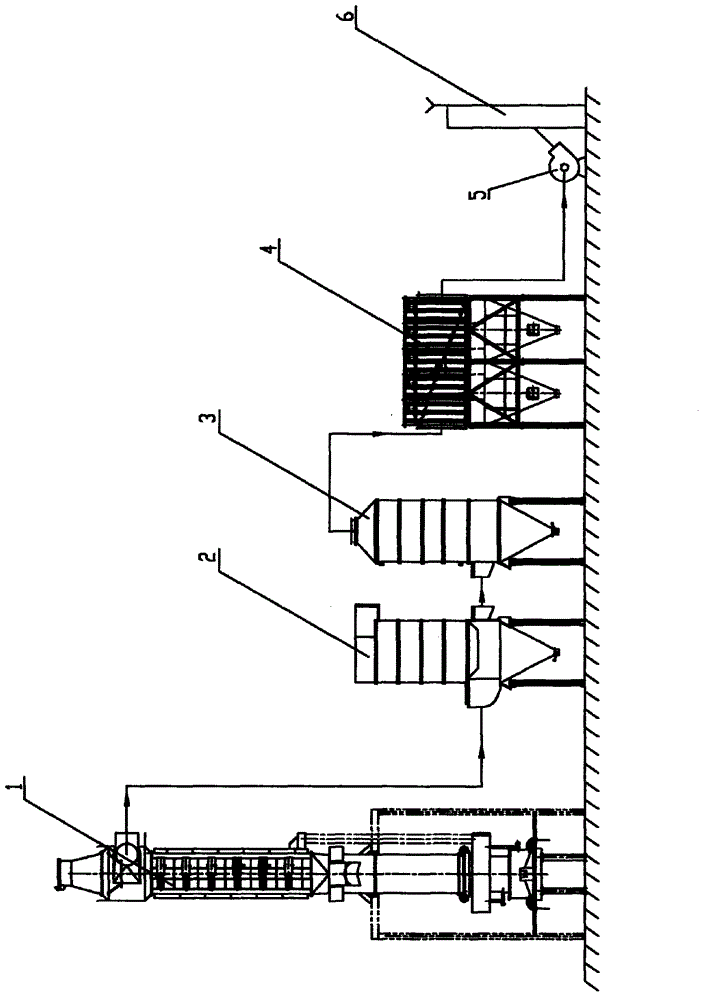

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] Such as figure 1 Shown: a kind of microfiltration method step of controlling cupola PM2.5 fine dust of the present invention is as follows:

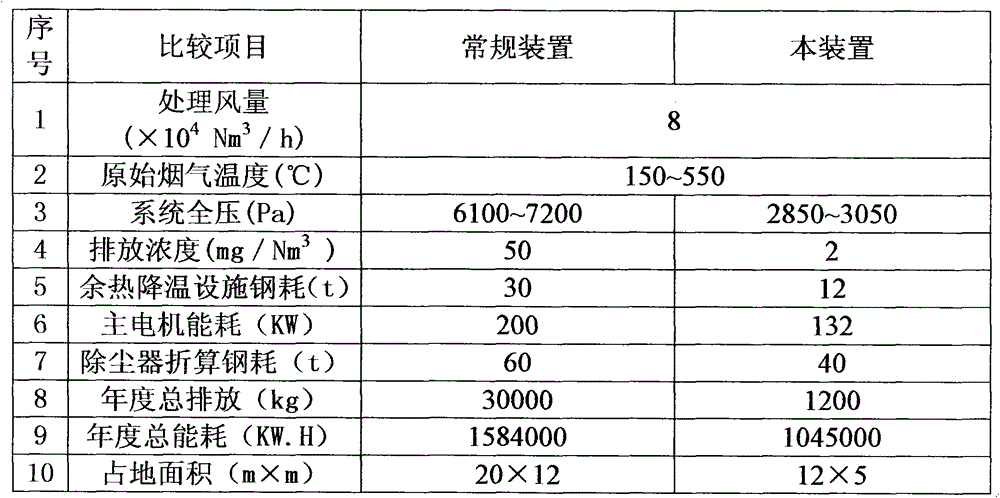

[0022] 15t / h cupola 1 flue gas flow rate 8×10 4 N m 3 / h, temperature 550℃, dust concentration 25g / Nm 3 Exhausted from the furnace, the high-temperature flue gas enters the turbulent flow water cooler 2, which makes the large particles of dust carried in the flue gas settle, and the flue gas temperature drops to 210°C, so that the flue gas temperature fluctuation range can be greatly reduced, and at the same time After reaching the peak value of the flue gas temperature, it enters the multi-tube water cooler 3. After exchanging heat through the multi-tube water cooler 3, the flue gas temperature drops to 100°C, which meets the allowable working temperature of the plastic fired plate dust collector 4. After cooling The flue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com