Preparing method for hydrophobic and oleophobic cosmetic pigment powder

A hydrophobic, oleophobic, and cosmetics technology, which is applied in the direction of cosmetic preparations, cosmetics, cosmetics, etc., can solve problems such as color drift, and achieve the effect of good skin adhesion, smooth hand feeling, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

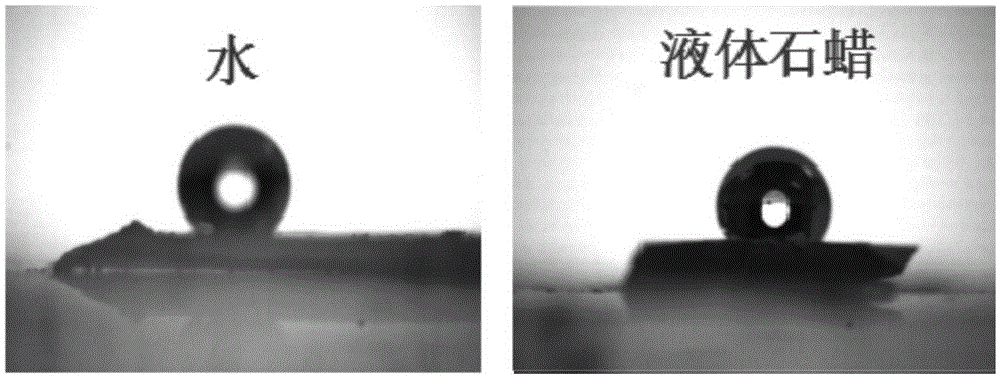

Embodiment 1

[0043] 1Kg titanium dioxide, under high-speed stirring, 100g nano-silica sol (SiO 2 content of 30%) into a mixer, heated at 80°C, and stirred at a high speed to fully mix the nano-silica sol and titanium dioxide, then discharged, and heat-treated at 120°C. 30 g of perfluorooctyltriethoxysilane (Dynasylan F8261, Evonik Degussa) was dissolved in 70 g of ethanol to prepare a treatment solution. Under high-speed stirring, spray the treatment liquid into the titanium dioxide treated with nano-silica sol, heat at 80°C, and stir at high speed to fully mix the treatment liquid and powder, discharge, and heat-treat at 120°C. After the material is discharged, it is jet-milled to obtain titanium dioxide treated with 3% nano-silica sol + 3% perfluorooctyltriethoxysilane.

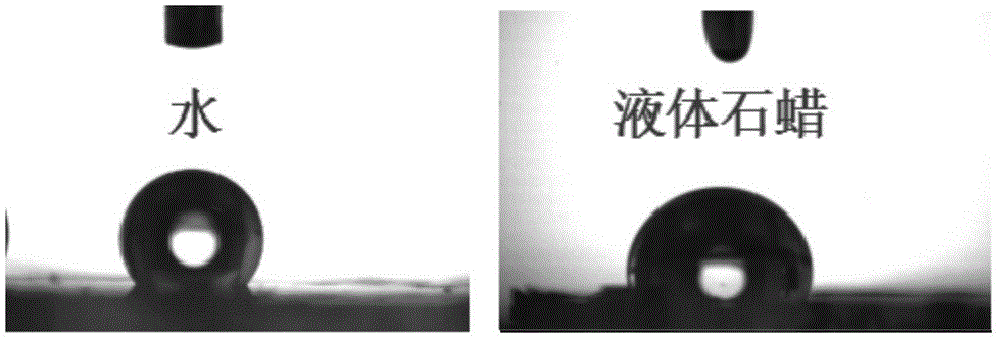

Embodiment 2

[0045] 1Kg iron oxide yellow powder, under high-speed stirring, 100g nano-silica sol (SiO 2 content of 30%) into a mixer, heated at 80°C, and stirred at a high speed to fully mix the nano-silica sol and yellow iron oxide powder, then discharged, and heat-treated at 105°C. 30 g of perfluorooctyltriethoxysilane (Dynasylan F8261, Evonik Degussa) was dissolved in 70 g of ethanol to prepare a treatment solution. Under high-speed stirring, spray the treatment liquid into the aforementioned iron oxide yellow powder treated with nano-silica sol, heat at 80°C, and stir at high speed to fully mix the treatment liquid and powder, discharge, and heat-treat at 105°C. After the material is discharged, it is jet-milled to obtain iron oxide yellow powder treated with 3% nano-silica sol + 3% perfluorooctyltriethoxysilane.

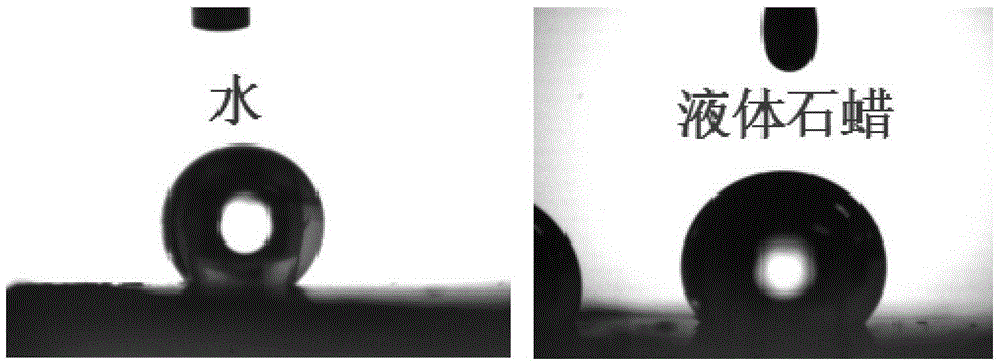

Embodiment 3

[0047] 1Kg iron oxide red powder, under high-speed stirring, 100g nano-silica sol (SiO 2 content of 30%) into a mixer, heated at 80°C, and stirred at a high speed to fully mix the nano-silica sol and red iron oxide powder, then discharged, and heat-treated at 105°C. 30 g of perfluorooctyltriethoxysilane (Dynasylan F8261, Evonik Degussa) was dissolved in 70 g of ethanol to prepare a treatment solution. Under high-speed stirring, spray the treatment liquid into the aforementioned iron oxide red powder treated with nano-silica sol, heat at 80°C, and stir at high speed to fully mix the treatment liquid and powder, discharge, and heat-treat at 105°C. After the material is discharged, it is jet-milled to obtain red iron oxide powder treated with 3% nano-silica sol + 3% perfluorooctyltriethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com