Hydrophobic treatment agent and preparation method and application thereof, and wear-resistant self-cleaning glass and preparation method thereof

A hydrophobic treatment, self-cleaning technology, applied in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problem of unstable hydrophobic performance, poor wear resistance, and insufficient bonding between hydrophobic coatings and glass and other problems, to achieve the effect of stable hydrophobic and oleophobic performance, improved binding ability, and excellent self-cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

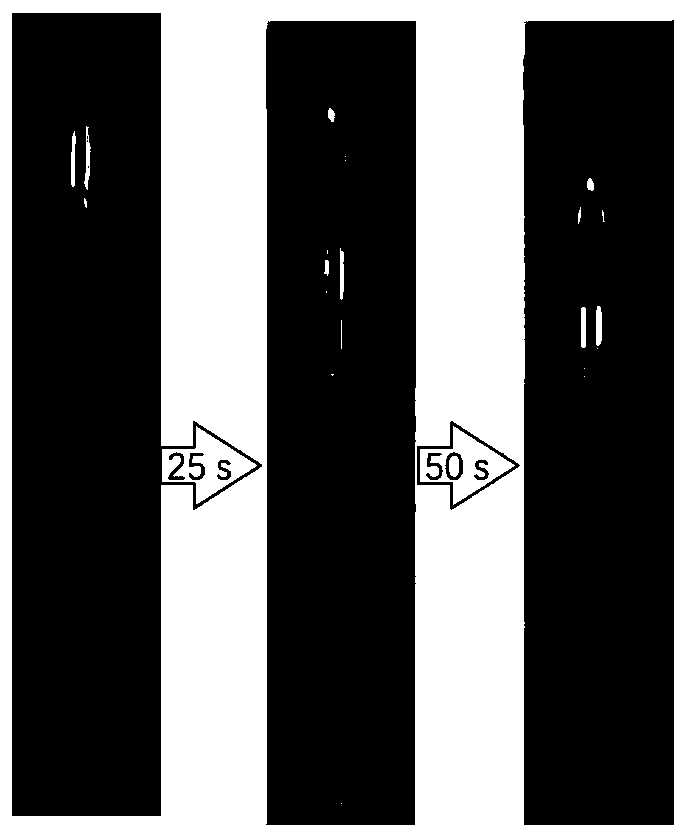

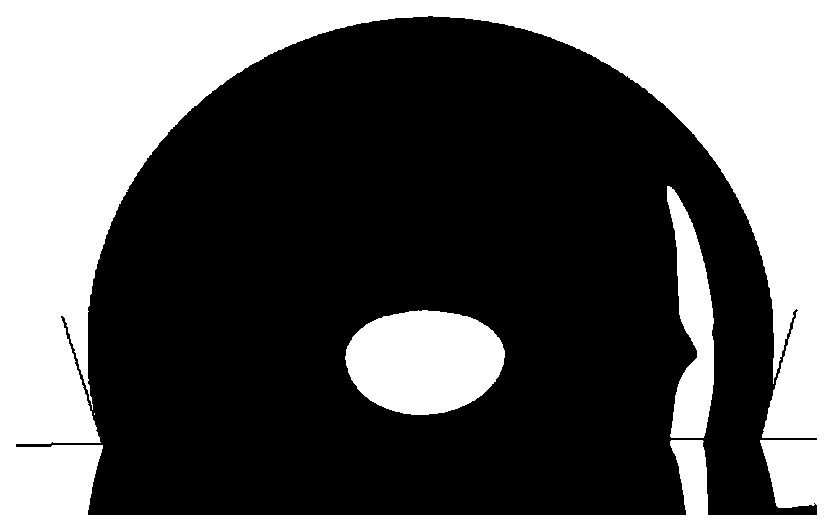

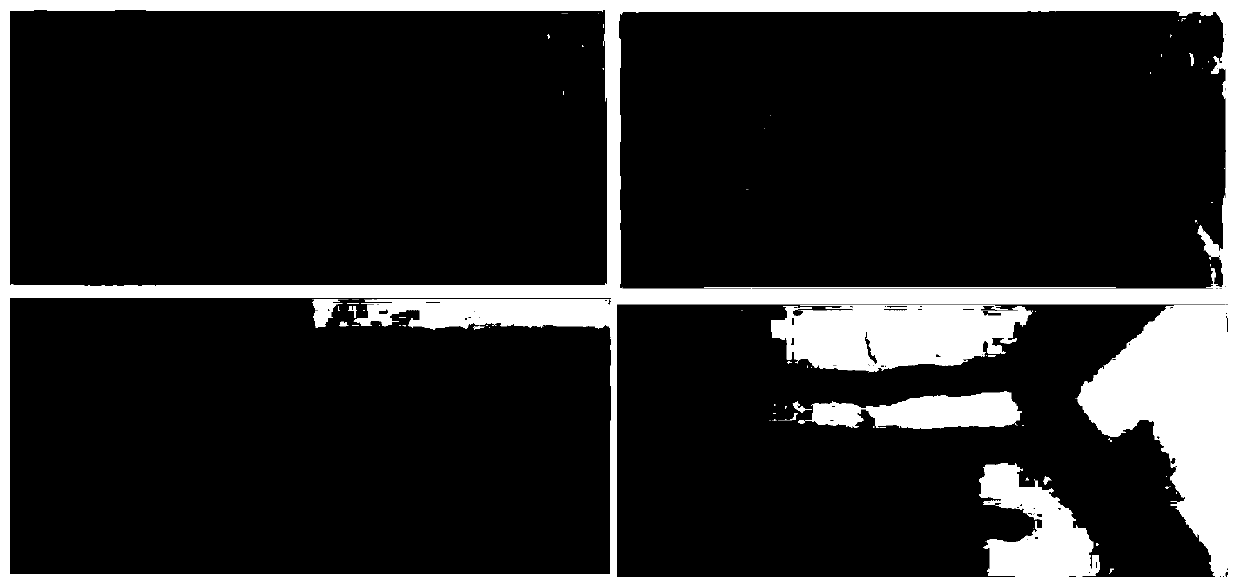

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the hydrophobic treatment agent described in the above technical scheme, comprising the following steps:

[0037] Addition reaction of single-end hydroxyl perfluoropolyether and propyltriethoxysilane isocyanate in the presence of a catalyst to obtain the hydrophobic treatment agent;

[0038] The single-end hydroxyl perfluoropolyether has a structure shown in formula II:

[0039]

[0040] In the present invention, unless otherwise specified, the preparation raw materials are commercially available products well known to those skilled in the art.

[0041] In the present invention, the average molecular mass of the single-terminated hydroxyl perfluoropolyether is preferably 2000-4000.

[0042] In the present invention, the molar ratio of the single-terminated hydroxyl perfluoropolyether to propyltriethoxysilane isocyanate is preferably (0.8-1):1, more preferably (0.85-0.95):1. In the present invention, there ...

Embodiment 1

[0063] Mix 20g of single-terminated hydroxyl perfluoropolyether (molecular weight: 2000) with 2.47g of propyltriethoxysilane isocyanate, add 0.06g of dibutyltin dilaurate, and react at 20°C for 6 hours to obtain a hydrophobic treatment agent.

Embodiment 2~6

[0065] Embodiments 2-6 have the same process steps as Embodiment 1, and the reagents and preparation conditions used are shown in Table 1.

[0066] Table 1 embodiment 2~6 reagent and preparation condition

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com