Anti-fouling auxiliary agent for photocurable coating and application thereof

A light-curing coating, a light-curing technology, applied in the application of ultraviolet light-curing coatings, in the field of anti-fouling additives for light-curing coatings, can solve the problems of long synthesis time, low surface energy, long reaction time, etc., and achieve excellent hydrophobicity Oleophobic and anti-fouling effect, good compatibility, long-lasting anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

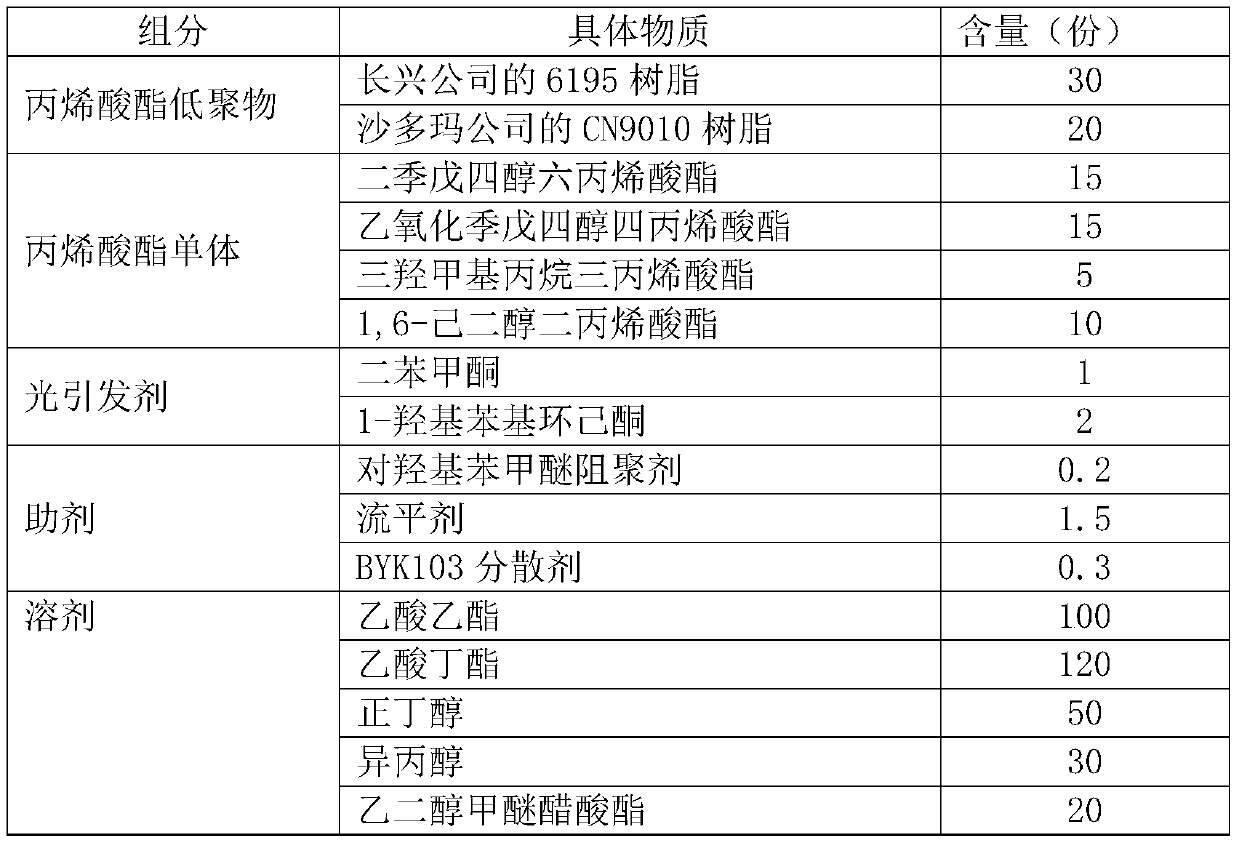

Examples

Embodiment 1

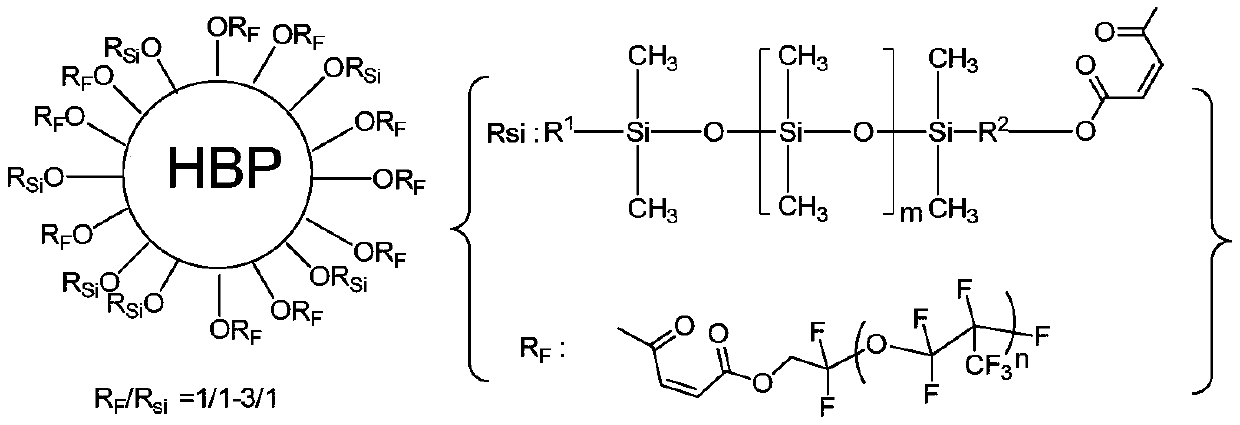

[0037] In a 100 ml four-neck flask equipped with a magnetic stirrer, a serpentine condenser, a thermometer and a water separator, under nitrogen protection, first add 20 grams of toluene, and then add 11.0 grams of single-end monocarboxysilane oil (molecular weight 2000, 0.0055 mol), 16.5 grams of perfluoropolyether methanol (molecular weight 1000, 0.0165mol), 2.16 grams of maleic anhydride (0.022mol), 0.01 grams of p-hydroxyanisole and 0.03 grams of 4-dimethylaminopyridine were reacted at 90°C for 8 Hour. Then add 1.97 grams of hyperbranched polyester / polyether polyol Boltorn P500 (hydroxyl value 565.9 mgKOH / g, 0.020 mol-OH), 0.10 grams of methanesulfonic acid, and 30 toluene, and heat up to 110 ° C for 8 hours under reflux . After the reaction is finished, filter while hot to remove a small amount of insoluble matter, add an appropriate amount of ethyl acetate to dilute to 20% solid content.

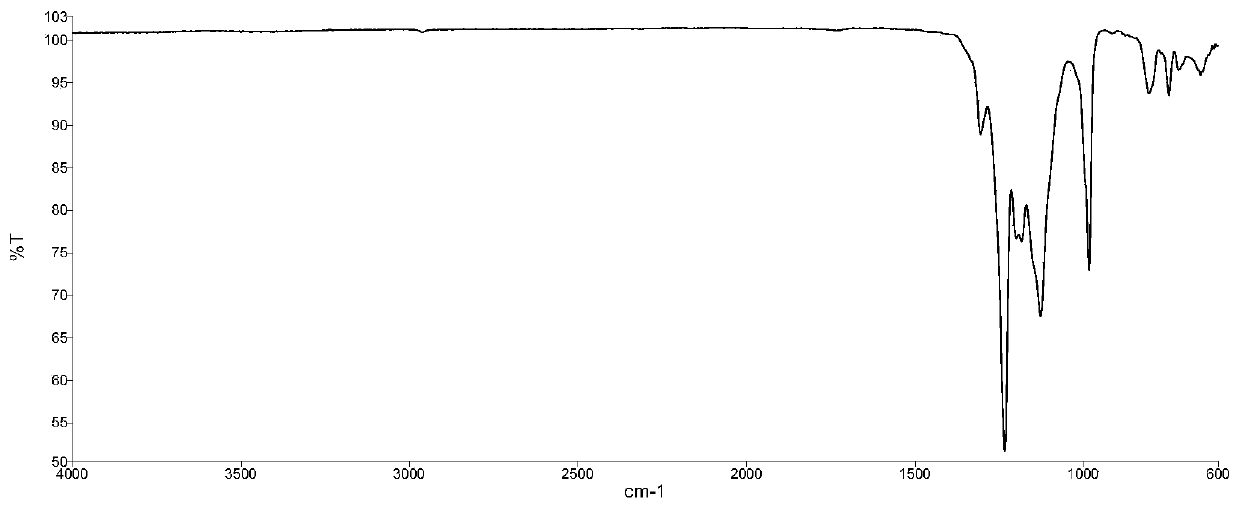

[0038] To gained product, after removing solvent, through 50 degree of vacuum dr...

Embodiment 2

[0040] To a 100 ml four-neck flask equipped with a magnetic stirrer, a serpentine condenser, a thermometer and a water separator, under nitrogen protection, first add 20 grams of toluene, then add 13.2 grams of single-end monocarboxysilane oil (molecular weight 3000, 0.0044 mol), 17.60 grams of perfluoropolyether methanol (molecular weight 2000; 0.0088mol), 1.29 grams of maleic anhydride (0.0132mol), 0.01 grams of p-hydroxyanisole and 0.03 grams of 4-dimethylaminopyridine were reacted at 90°C for 8 Hour. Then add 1.18 grams of hyperbranched polyester / polyether polyol Boltorn P500 (hydroxyl value 565.9mgKOH / g, 0.012mol-OH), 0.058 grams of methanesulfonic acid, and 30 grams of toluene, and heat up to 110°C for reflux reaction 8 Hour. After the reaction is finished, filter while hot to remove a small amount of insoluble matter, add an appropriate amount of ethyl acetate to dilute to 20% solid content.

Embodiment 3

[0042] In a 100 ml four-neck flask equipped with a magnetic stirrer, a serpentine condenser, a thermometer and a water separator, under nitrogen protection, first add 20 grams of toluene, and then add 24.2 grams of single-end monocarboxysilane oil (molecular weight 4000, 0.0061 mol), 6.05 grams of perfluoropolyether methanol (molecular weight 1000; 0.0061mol), 1.19 grams of maleic anhydride (0.0121mol), 0.01 grams of p-hydroxyanisole and 0.03 grams of 4-dimethylaminopyridine at 90 ° C for 8 Hour. Then add 1.08 grams of hyperbranched polyester / polyether polyol Boltorn P500 (hydroxyl value 565.9 mgKOH / g, 0.011 mol-OH), 0.053 grams of methanesulfonic acid, and 30 grams of toluene, and heat up to 110 ° C for reflux reaction 8 Hour. After the reaction is finished, filter while hot to remove a small amount of insoluble matter, add an appropriate amount of ethyl acetate to dilute to 20% solid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com