Antifouling aid and application thereof in ultraviolet photocureable coatings

A light-curing coating and light-curing technology, used in antifouling/underwater coatings, biocide-containing paints, polyurea/polyurethane coatings, etc. It can achieve excellent hydrophobic and oleophobic and anti-fouling effects, improve hydrophobic and oleophobic performance, and lasting anti-fouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

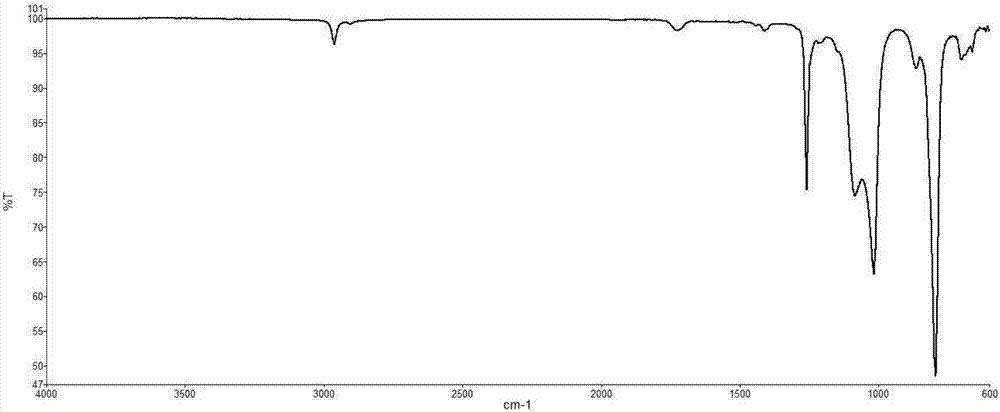

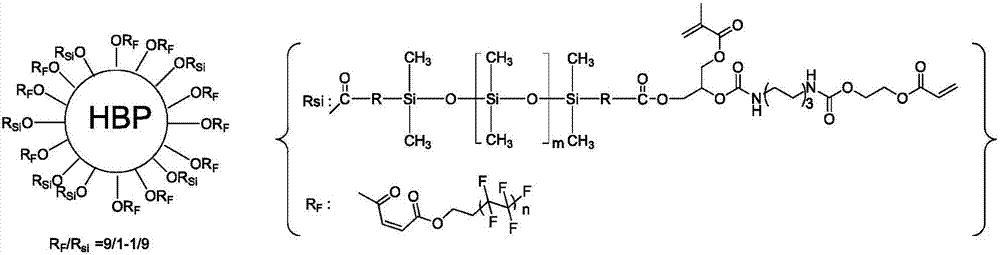

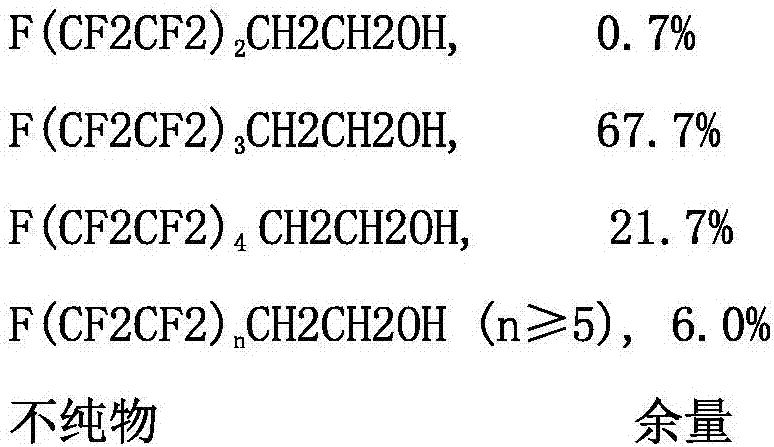

[0037] Into a 250ml four-necked flask equipped with magnetic stirring, serpentine condenser, thermometer and water separator, under the protection of nitrogen, add 30 grams of toluene and 68 grams of two-terminal carboxyl modified silicone oil (molecular weight 4000, 0.017mol) , 2.42 g glycidyl methacrylate (0.017 mol), 0.07 g benzyl triethylammonium bromide, 0.14 g p-hydroxyanisole, and react for 3 hours at 100 degrees. Then, 2.86 g of hexamethylene diisocyanate (0.017 mol) and 0.01 g of dibutyltin dilaurate were added and reacted at 80 degrees for 2 hours. Then add 20 g of toluene, 1.97 g of hydroxyethyl acrylate (0.017 mol), and 0.14 g of p-hydroxyanisole, and react at 80 degrees for 2 hours. Add 20 grams of toluene, 23.45 grams of maleic acid half ester of perfluoroalkyl ethanol (acid value 94.9mgKOH / g, 0.040mol), 5.40 grams of hyperbranched polyester polyol (hydroxyl value 592.2mgKOH / g, 0.057mol-OH) ), 0.28 g of p-hydroxyanisole, 0.27 g of methanesulfonic acid, reflux for...

Embodiment 2

[0040] Into a 250ml four-necked flask equipped with magnetic stirring, snake condenser, thermometer and water separator, under the protection of nitrogen, add 30 grams of toluene and 75 grams of two-terminal carboxyl modified silicone oil (molecular weight 5000, 0.015mol) , 2.13 g glycidyl methacrylate (0.015 mol), 0.077 g benzyl triethylammonium bromide, 0.15 g p-hydroxyanisole, and react for 3 hours at 100 degrees. Then 2.52 g of hexamethylene diisocyanate (0.015 mol) and 0.01 g of dibutyltin dilaurate were added, and the reaction was carried out at 80 degrees for 2 hours. Then add 20 g of toluene, 1.74 g of hydroxyethyl acrylate (0.015 mol), and 0.15 g of p-hydroxyanisole, and react at 80 degrees for 2 hours. Add 20 grams of toluene, 20.69 grams of maleic acid half ester of perfluoroalkyl ethanol (acid value 94.9mgKOH / g, 0.035mol), 4.74 grams of hyperbranched polyester polyol (hydroxyl value 592.2mgKOH / g, 0.05mol-OH) ), 0.31 g of p-hydroxyanisole, 0.24 g of methanesulfonic ...

Embodiment 3

[0042] Into a 250ml four-necked flask equipped with magnetic stirring, snake condenser, thermometer and water separator, under the protection of nitrogen, add 30 grams of toluene and 78 grams of two-terminal carboxyl modified silicone oil (molecular weight 6000, 0.013mol) , 1.85 g of glycidyl methacrylate (0.013 mol), 0.080 g of benzyl triethylammonium bromide, 0.16 g of p-hydroxyanisole, and react for 3 hours at 100 degrees. Then, 2.19 g of hexamethylene diisocyanate (0.013 mol) and 0.01 g of dibutyltin dilaurate were added and reacted at 80 degrees for 2 hours. Then add 20 g of toluene, 1.51 g of hydroxyethyl acrylate (0.013 mol), and 0.16 g of p-hydroxyanisole, and react at 80 degrees for 2 hours. Add 20 grams of toluene, 17.93 grams of maleic acid half ester of perfluoroalkyl ethanol (acid value 94.9mgKOH / g, 0.030mol), 4.11 grams of hyperbranched polyester polyol (hydroxyl value 592.2mgKOH / g, 0.043mol-OH) ), 0.32 g of p-hydroxyanisole, 0.21 g of methanesulfonic acid, reflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com