Preparation method of perfluorinated quaternary ammonium type strong base anion exchange resin

A technology for exchanging resin and anion, applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of affecting the use effect of industrial equipment, reducing resin strength, long process flow, etc., to achieve enhanced binding force and compatibility. Improve and expand the effect of application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

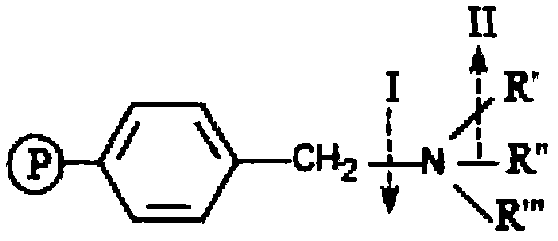

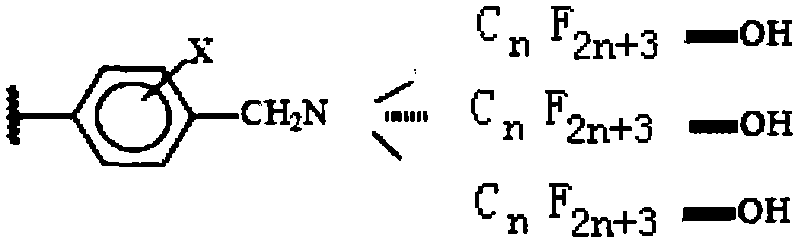

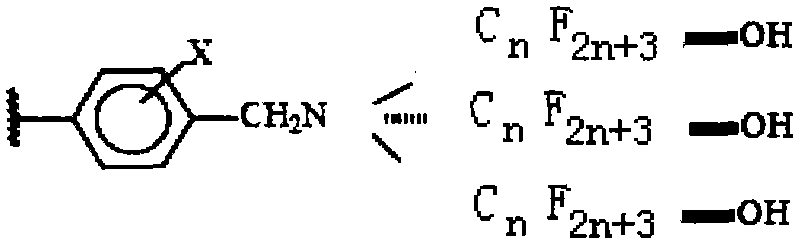

Method used

Image

Examples

Embodiment 2

[0025] Add 100Kg of chloromethylated polystyrene spheres into a 500L reactor, swell in 200Kg of trimethylamine aqueous solution, add 10Kg of perfluorotriethylamine, stir and react at 40°C for 20h, and the reaction is completed to obtain perfluoroquaternary ammonium Strongly basic anion exchange resin. The resulting product number is SX-2.

Embodiment 3

[0027] Add 100Kg chloromethylated polystyrene spheres into a 500L reactor, swell in 500Kg trimethylamine aqueous solution, add 50Kg perfluorotriethylamine, stir and react at 70°C for 10 hours, and the reaction is completed to obtain perfluoroquaternary ammonium Strongly basic anion exchange resin. The resulting product number is SX-3.

Embodiment 4

[0029] The perfluorotertiary amine is perfluorotripropylamine, and the others are the same as in Example 1. The resulting product number is SX-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com