A controllable method for preparing nanofibers with core-shell structure

A nanofiber, core-shell structure technology, applied in the field of preparation of functionalized nanofibers, can solve the problems of nanofiber membrane cross-linking polymerization, inflexibility, cumbersome experimental steps, etc., and achieve good biocompatibility and high medical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

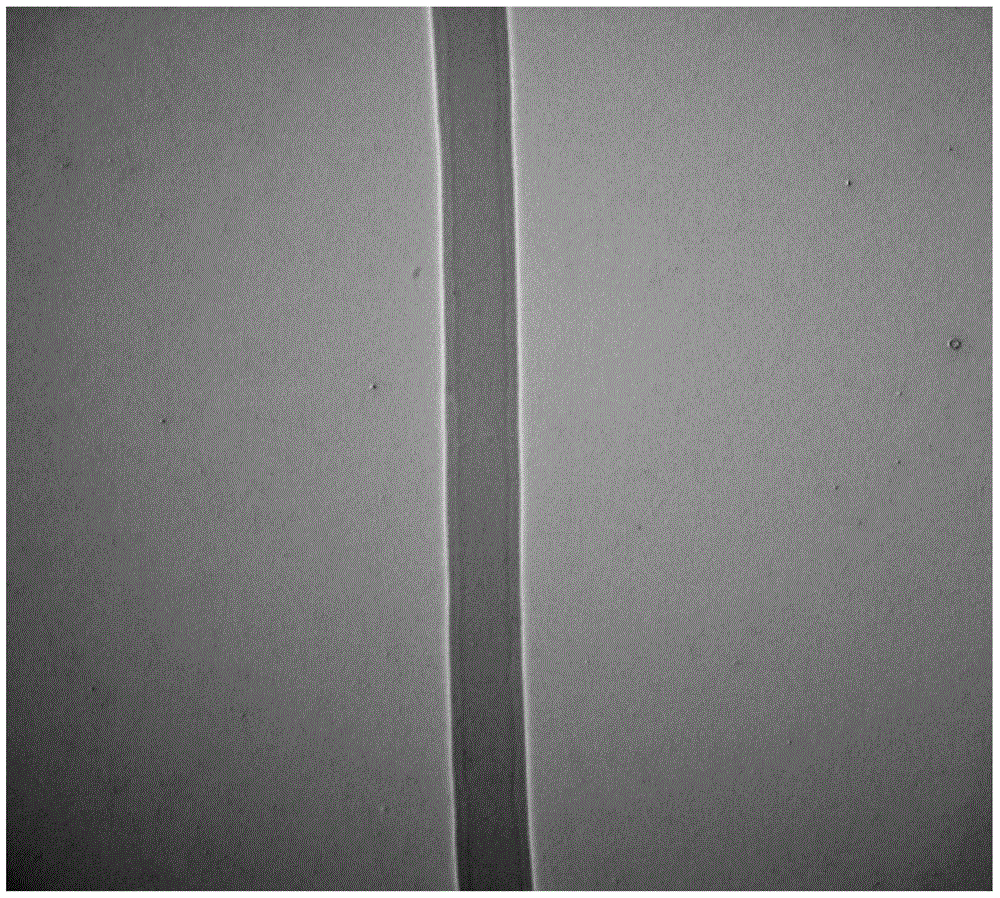

Image

Examples

Embodiment 1

[0021] 1) Preparation of electrospinning solution: prepare DMF / C with a molecular weight of 20,000 g / mol polyvinylpyrrolidone at a concentration of 30 wt % 3 h 6 The volume ratio of O is 1:1 composite solvent solution, after it is completely dissolved, 5wt% fluorine-containing epoxy monomer 3-(perfluoro-n-hexyl) propylene oxide and 1wt% mixed type adding triarylsulfonium hexafluorophosphate into the polymer solution, fully stirring, and obtaining an electrospinning solution after it is completely dissolved;

[0022] 2) Preparation of nanofibers with core-shell structure: electrospinning the electrospinning solution prepared in step 1) under UV light irradiation. The spinning voltage was set to 20kV, the distance from the spinning port to the receiver was 25cm, the diameter of the spinning port was 1.0mm, and the flow rate was controlled at 0.2mL / h. The light intensity at the center of the spinneret spindle is 400mw / cm 2 . Fluorine-containing core-shell nanofibers were prep...

Embodiment 2

[0024] 1) Preparation of electrospinning solution: prepare DMF / C with a molecular weight of 20,000 g / mol polyvinylpyrrolidone at a concentration of 25 wt % 3 h 6 The volume ratio of O is 1:1 composite solvent solution, after it is completely dissolved, 10wt% fluorine-containing epoxy monomer 3-(perfluoro-n-hexyl) propylene oxide and 2wt% mixed type adding triarylsulfonium hexafluorophosphate into the polymer solution, fully stirring, and obtaining an electrospinning solution after it is completely dissolved;

[0025] 2) Preparation of nanofibers with core-shell structure: electrospinning the electrospinning solution prepared in step 1) under UV light irradiation. The spinning voltage was set to 15kV, the distance from the spinning port to the receiver was 20cm, the diameter of the spinning port was 1.0mm, and the flow rate was controlled at 0.4mL / h. The light intensity at the center of the spinneret spindle is 350mw / cm 2 . Fluorine-containing core-shell nanofibers were pre...

Embodiment 3

[0027] 1) Preparation of electrospinning solution: prepare DMF / C with a molecular weight of 20,000 g / mol polyvinylpyrrolidone at a concentration of 20 wt % 3 h 6 The volume ratio of O is 1:1 composite solvent solution, after it is completely dissolved, in the dark room, with respect to polymer content 8wt% fluorine-containing epoxy monomer 3-(perfluoro-n-hexyl) propylene oxide and 2wt% mixed type adding triarylsulfonium hexafluorophosphate into the polymer solution, fully stirring, and obtaining an electrospinning solution after it is completely dissolved;

[0028] 2) Preparation of nanofibers with core-shell structure: electrospinning the electrospinning solution prepared in step 1) under UV light irradiation. The spinning voltage was set to 10kV, the distance from the spinning port to the receiver was 17cm, the diameter of the spinning port was 1.0mm, and the flow rate was controlled at 0.6mL / h. The light intensity at the center of the spinneret spindle is 300mw / cm 2 . F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com